As electric vehicle adoption accelerates worldwide, the electrical infrastructure supporting EV charging faces unprecedented safety challenges. A critical but often misunderstood component in this ecosystem is the Residual Current Circuit Breaker (RCCB)—the frontline defense against electric shock and fire hazards at charging points.

Unlike conventional electrical loads, EV charging systems introduce smooth DC fault currents that can “blind” standard Type A RCCBs, rendering them unable to detect dangerous leakage currents. This phenomenon has led to serious safety incidents and prompted international standards bodies to mandate specialized protection for EV charging installations.

This guide examines three RCCB variants designed for EV charging applications: Type B, Type F, and Type EV (IEC 62955 compliant). We’ll clarify the technical differences, decode relevant standards including IEC 62423 and OVE E8601, and provide practical selection criteria to help electrical engineers, contractors, and facility managers specify the right protection for their projects.

Whether you’re installing a single Level 2 charger or deploying a multi-station DC fast charging network, understanding these differences ensures reliable, safe operation—and keeps you compliant.

Understanding RCCB Requirements for EV Charging

The DC Fault Current Problem

Electric vehicles rely on sophisticated power electronics to convert AC grid power into DC current for battery charging. Within the vehicle’s onboard charger and the charging station itself, components such as inverters, rectifiers, and converters perform this transformation. Under normal operation, current flows cleanly through the intended circuit. However, insulation faults, component failures, or moisture ingress can create leakage paths where current escapes to ground.

When this leakage includes smooth DC components—a byproduct of the rectification process—it creates a safety hazard that standard RCCBs cannot address. A Type A RCCB, commonly specified for residential and commercial installations, detects AC and pulsating DC residual currents. But when exposed to smooth DC fault current exceeding approximately 6mA, the magnetic core inside the RCCB can become saturated—a condition known as “blinding.”

A blinded RCCB remains closed even when dangerous AC fault currents occur, leaving users exposed to potentially fatal electric shock. Field investigations of EV charging incidents have documented cases where Type A RCCBs failed to trip due to DC saturation, resulting in equipment damage and safety breaches.

Regulatory Framework: IEC 60364-7-722 and Global Standards

The International Electrotechnical Commission (IEC) established specific requirements for EV charging protection in IEC 60364-7-722, which governs electrical installations for EV charging. Each charging point must be individually protected by an RCD with a rated residual operating current not exceeding 30mA for personal protection.

The standard specifies two compliant approaches:

- Type B RCCB: Capable of detecting AC, pulsating DC, and smooth DC residual currents

- Type A or Type F RCCB + Residual Direct Current Detecting Device (RDC-DD): A combination where the RDC-DD detects smooth DC currents ≥6mA and triggers circuit disconnection

Regional variations exist—Austria’s OVE E8601 standard, Germany’s DIN VDE 0100-722, and similar national codes all reference these fundamental protection requirements while adding local installation specifications.

Why 6mA Matters

The 6mA threshold for DC fault detection isn’t arbitrary. Research has shown that DC currents above this level can begin to saturate Type A RCCB cores, compromising their ability to detect subsequent AC faults. By ensuring disconnection at or below 6mA DC leakage, the protection system maintains its integrity even under fault conditions.

For personnel protection, the 30mA sensitivity requirement aligns with established safety thresholds. The human body can typically withstand currents below 30mA for brief periods without ventricular fibrillation, while higher currents pose lethal risks. Combined with the rapid tripping times mandated by standards (typically under 30 milliseconds at rated current), this sensitivity provides robust protection against direct and indirect contact hazards.

Type B vs Type F vs Type EV: Technical Comparison

Type B RCCB: Universal Protection

Governed by IEC 62423 (supplementing IEC 61008-1), Type B RCCBs represent the most comprehensive residual current protection available. These devices are engineered to detect:

- Sinusoidal AC residual currents (50/60Hz)

- Pulsating DC residual currents

- Smooth DC residual currents

- AC residual currents up to 1,000Hz

The smooth DC detection capability is the defining characteristic. IEC 62423 specifies that Type B RCCBs must trip at residual pulsating DC currents superimposed on smooth DC up to 0.4 times the rated residual current (IΔn) or 10mA, whichever is higher. For reference, a 30mA Type B RCCB will reliably trip at 12mA of smooth DC fault current.

This universal sensitivity makes Type B RCCBs inherently suitable for EV charging without additional protective devices. They provide robust protection regardless of the charger’s internal architecture, power electronics configuration, or fault current waveform. The tradeoff is cost—Type B units typically command 3-5x the price of Type A equivalents, reflecting their sophisticated magnetic core design and detection circuitry.

Typical Applications:

- EV charging stations (all power levels)

- Photovoltaic systems with transformerless inverters

- Industrial installations with variable frequency drives (VFDs)

- Medical equipment requiring maximum protection

Type F RCCB: Enhanced Frequency Response

Type F RCCBs, also defined under IEC 62423, build upon Type A capabilities by adding composite frequency detection. They reliably detect:

- AC residual currents (50/60Hz)

- Pulsating DC residual currents

- Composite residual currents with mixed frequencies up to 1,000Hz

The critical distinction from Type B: Type F cannot detect smooth DC residual currents on its own. However, when modern EV chargers include integrated RDC-DD (Residual Direct Current Detecting Device) compliant with IEC 62955, a Type F RCCB becomes a viable and cost-effective solution.

Type F’s frequency handling capability addresses a modern electrical environment where appliances with frequency converters—heat pumps, LED drivers, induction cooktops, and yes, EV chargers—generate harmonic-rich fault currents. Standard Type A RCCBs may experience nuisance tripping or reduced sensitivity with these complex waveforms, while Type F maintains reliable operation.

For EV charging applications, Type F RCCBs marked as “EV Charging Ready” (like VIOX’s VKL11F Series with OVE E8601 compliance) are specifically tested and certified for use with charging stations that include built-in DC fault protection.

Typical Applications:

- EV charging stations with integrated DC fault detection

- Residential installations with modern electronic loads

- Commercial buildings with LED lighting and HVAC systems

- Cost-sensitive projects requiring better-than-Type-A protection

Type EV (IEC 62955): Purpose-Built for Charging

IEC 62955 defines a specialized category: Residual Direct Current Detecting Devices (RDC-DDs) designed specifically for permanently connected AC EV charging stations (Mode 3 charging). These come in two configurations:

RDC-MD (Monitoring Device): Detects DC residual currents but relies on an external switching device (contactor) to interrupt the circuit. Used in larger charging stations with centralized control systems.

RDC-PD (Protective Device): Integrates DC detection with mechanical switching capability, functioning as a complete protective unit. This is what’s commonly marketed as “Type EV RCCB.”

- Must trip at smooth DC residual current ≥6mA

- Must not trip on pure AC residual currents up to 30mA

- Rated for voltages up to 440V AC

- Rated currents up to 125A

- Compatible with upstream Type A or Type F RCCBs

The 6mA DC tripping threshold is lower than Type B RCCBs’ 10mA minimum, providing an extra margin of safety specifically tuned to prevent upstream RCD blinding. Type EV devices are typically more economical than Type B RCCBs while still providing adequate protection for Mode 3 and Mode 4 charging scenarios.

Typical Applications:

- Dedicated EV charging installations (Mode 3)

- Multi-station charging networks

- Parking garage charging infrastructure

- Fleet charging facilities

Comparative Summary Table

| Feature | Type B | Type F | Type EV (IEC 62955) |

|---|---|---|---|

| AC Detection (50/60Hz) | ✓ | ✓ | Via upstream RCD |

| Pulsating DC Detection | ✓ | ✓ | Via upstream RCD |

| Smooth DC Detection | ✓ (10-60mA) | ✗ | ✓ (≥6mA) |

| Frequency Range | Up to 1kHz | Up to 1kHz | N/A (DC only) |

| Standalone EV Protection | Yes | No (needs RDC-DD) | No (needs Type A/F) |

| Cost (Relative) | High (3-5x) | Medium (1.5-2x) | Medium (2-3x) |

| Primary Standard | IEC 62423 | IEC 62423 | IEC 62955 |

| Best Use Case | Universal protection | Chargers with DC fault detection | Dedicated EV installations |

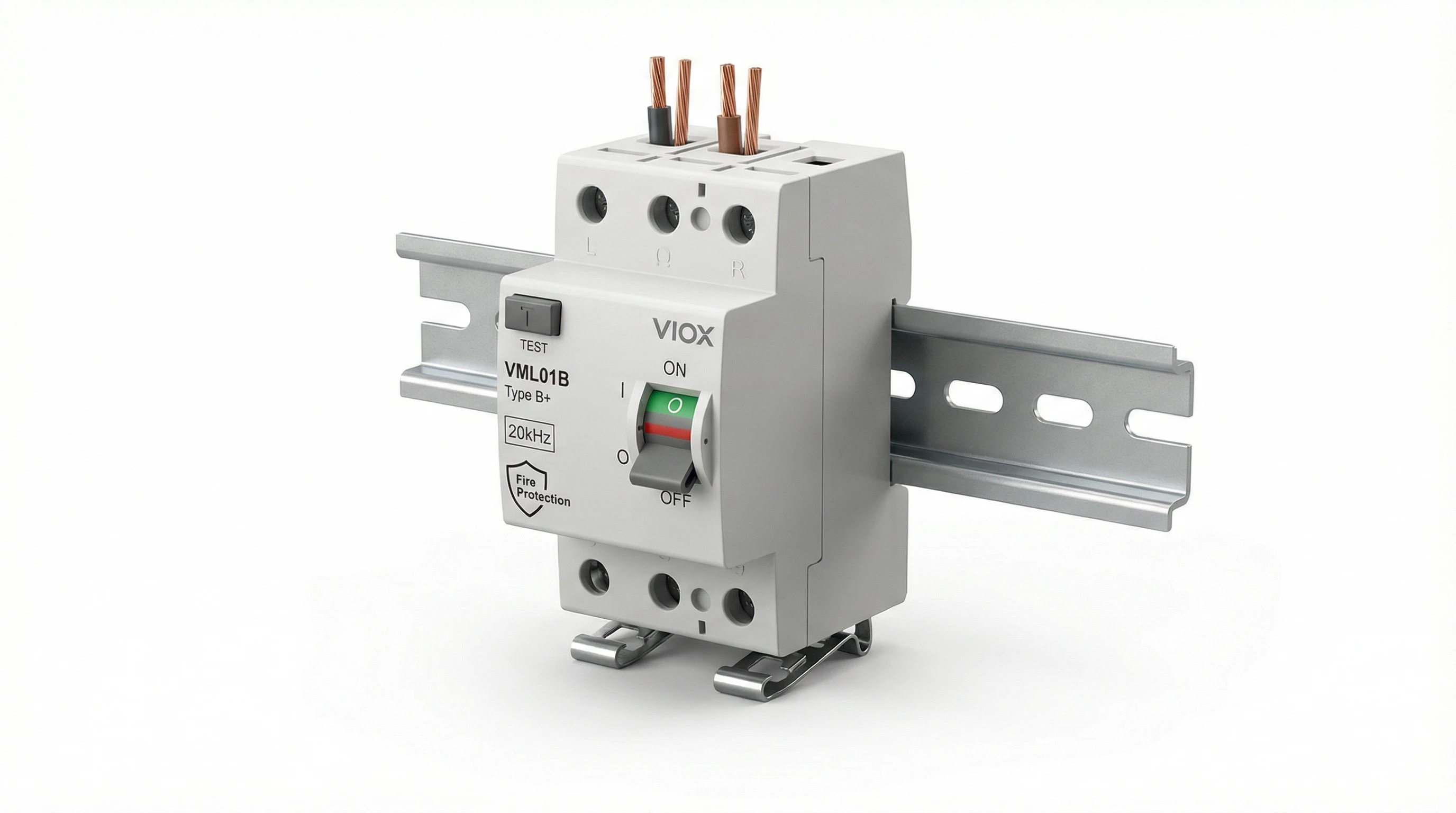

Type B+ RCCB: Extended Frequency Protection

While not a separate IEC classification, Type B+ RCCBs (specified in DIN VDE 0664-110) extend Type B capabilities to higher frequencies—up to 20kHz. This enhanced protection addresses fire hazards from high-frequency leakage currents in systems with advanced power electronics, including modern EV chargers with high-frequency switching.

VIOX’s VML01B Series exemplifies this specification, offering comprehensive protection for installations where both shock and fire hazards must be addressed across a broader frequency spectrum.

How to Select the Right RCCB for Your EV Charging Station

Selecting the optimal RCCB for an EV charging installation requires evaluating several interconnected factors. Here’s a systematic approach:

Step 1: Verify Charger DC Fault Protection

The first and most critical question: Does the charging station have integrated DC fault current detection?

Consult the charger’s technical documentation or datasheet. Look for statements like:

- “IEC 62955 compliant RDC-DD integrated”

- “Built-in DC fault current detection (6mA)”

- “Type A/F RCD compatible”

If YES → Type F or Type A RCCB is permissible (Type F recommended for better frequency handling)

If NO or UNCERTAIN → Type B RCCB is mandatory

Most modern Level 2 charging stations manufactured after 2020 include integrated DC fault protection. However, older units, basic EVSE (Electric Vehicle Supply Equipment), and some budget models may not. When in doubt, specify Type B for guaranteed protection.

Step 2: Determine Configuration (2-Pole vs 4-Pole)

Single-Phase Installations (120/240V): Use 2-pole (2P) RCCBs

- Residential Level 1 chargers (120V, up to 16A)

- Level 2 home chargers (240V, 16-32A)

- Small commercial installations

Three-Phase Installations (208/400/480V): Use 4-pole (4P) RCCBs

- Commercial Level 2 chargers (>7kW)

- DC fast charging station AC input

- Multi-station installations with three-phase distribution

Always match the RCCB pole configuration to your supply system. Installing a 2P device on a three-phase circuit leaves one phase unprotected.

Step 3: Select Rated Current (In)

The RCCB’s rated current must equal or exceed the circuit’s overcurrent protection device (MCB/MCCB) rating, which in turn should be sized for the charger’s maximum continuous current.

Example calculation for a 7.4kW Level 2 charger:

- Power: 7,400W

- Voltage: 240V single-phase

- Current: 7,400 ÷ 240 = 30.8A

- Circuit breaker: 40A (125% of continuous load per NEC)

- RCCB selection: 40A or 63A rated current

Common RCCB ratings for EV charging:

- 16A: Low-power Level 1 chargers

- 25A: Standard residential Level 2 (up to 6kW)

- 40A: Higher-power residential Level 2 (7-9kW)

- 63A: Commercial Level 2 (11-22kW three-phase)

- 80-100A: High-power commercial installations

Step 4: Choose Sensitivity (IΔn)

For EV charging applications:

30mA (standard): Mandatory for personnel protection in most jurisdictions. Provides direct contact protection and should be used for all user-accessible charging points.

100mA or 300mA: May be used for upstream protection in selective coordination schemes or fire protection, but a downstream 30mA device must still protect the charging point itself.

Recommendation: Always specify 30mA sensitivity for EV charging points unless you’re designing a selective coordination system with multiple protection levels.

Step 5: Consider Selective Coordination

In multi-station installations or facilities with critical loads, selective coordination prevents nuisance tripping of upstream devices. Two approaches:

Time-Delayed (Type S/G): Upstream RCCBs with short-time delay (e.g., VIOX VML01F with G tripping) allow downstream devices to clear faults first, maintaining power to unaffected circuits.

Current Discrimination: Use higher sensitivity downstream (30mA) and lower sensitivity upstream (100mA or 300mA) to achieve discrimination by magnitude.

Step 6: Verify Compliance Markings

Ensure the RCCB carries appropriate certifications:

- IEC 62423: For Type B or Type F devices

- OVE E8601: Austrian standard for EV charging (widely recognized in Europe)

- CE marking: Mandatory for European market

- UL/CSA: For North American installations

- Local authority approvals: Check jurisdiction-specific requirements

Decision Tree Summary

Does charger have integrated DC fault detection?

├─ YES → Does it meet IEC 62955?

│ ├─ YES → Type F RCCB (cost-effective, future-proof)

│ └─ NO/UNSURE → Type B RCCB (guaranteed protection)

└─ NO → Type B RCCB (mandatory)

What's your power supply?

├─ Single-phase → 2-pole RCCB

└─ Three-phase → 4-pole RCCB

Charger maximum current?

└─ Select RCCB rated current ≥ circuit breaker rating

Sensitivity: 30mA (standard for personnel protection)Installation and Configuration Best Practices

Proper installation is critical for RCCB performance and longevity. Follow these guidelines to ensure reliable operation:

Mounting and Positioning

DIN Rail Installation: All VIOX RCCBs mount on standard 35mm DIN rail. Ensure the rail is clean, straight, and securely fastened to the enclosure backplate. Click the RCCB firmly onto the rail until you hear the retention clip engage.

Orientation: Install RCCBs in the upright position as marked on the device. Horizontal or inverted mounting may affect mechanical operation and void warranties.

Environmental Considerations: Standard RCCBs are rated IP20 (finger-safe but not dust/moisture proof). For outdoor or harsh environment installations, mount inside an appropriately rated enclosure (minimum IP54 for outdoor, IP65 for wash-down areas).

Wiring Requirements

Terminal Torque: Tighten terminal screws to the manufacturer-specified torque (typically 2.5-3.0 Nm for VIOX units). Under-tightening causes resistance heating and potential connection failure; over-tightening can crack terminal blocks.

Conductor Sizing: Use conductors rated for the circuit current. For a 40A RCCB protecting a 32A charger, minimum 8 AWG (10mm²) copper conductors are typical, but always verify against local code requirements.

Line/Load Connections:

- LINE terminals (typically top): Connect to upstream power supply

- LOAD terminals (typically bottom): Connect to EV charger

Reversing line and load may prevent proper operation or cause immediate tripping.

Neutral Connection: Type B and Type F RCCBs monitor current balance including the neutral conductor. The neutral must pass through the RCCB. Do not connect to a separate neutral bar unless specifically designing a three-wire system without neutral monitoring (rare in EV applications).

Testing and Commissioning

Initial Test: After installation, press the TEST button. The RCCB should trip immediately, disconnecting the load. If it doesn’t trip, the device is faulty or incorrectly wired.

Functional Test Under Load: With the charger connected but not actively charging, reset the RCCB and verify normal operation. Then initiate a charging session and observe for nuisance tripping.

Monthly Testing: IEC 61008-1 recommends monthly testing using the built-in test button. This verifies the mechanical trip mechanism remains functional.

Common Installation Mistakes to Avoid

- Mixing neutral conductors: Each RCCB must have its dedicated neutral. Sharing neutrals between RCCBs or connecting to a common neutral bar causes false tripping.

- Ground-neutral bonding downstream: The ground-neutral bond should only exist at the service entrance. Downstream bonding creates parallel return paths that prevent proper residual current detection.

- Inadequate short-circuit protection: RCCBs protect against residual currents but don’t limit fault currents. Always install MCBs or MCCBs upstream or use combined RCBOs.

- Ignoring ambient temperature: RCCBs have specified operating ranges (typically -25°C to +60°C). Installations in extreme climates may require temperature-controlled enclosures.

VIOX RCCB Solutions for EV Charging Applications

VIOX Electric manufactures a comprehensive range of RCCBs specifically engineered for EV charging applications. With ISO 9001:2015-certified production facilities and over a decade of experience in electrical protection devices, VIOX offers reliable solutions backed by rigorous testing and international certifications.

VKL11B Series – Type B RCCB

Universal Protection for All EV Chargers

- Configuration: 2-pole and 4-pole

- Rated Current: 16A, 25A, 32A, 40A, 50A, 63A, 80A, 100A

- Sensitivity: 30mA, 100mA, 300mA, 500mA

- Frequency Response: Up to 1kHz

- Standards: IEC 62423, IEC 61008-1

- Key Feature: Full smooth DC detection (10-60mA)

Ideal for installations where charger DC fault protection is unknown, unverified, or absent. Provides comprehensive protection without dependency on charging station internal protection.

VML01B Series – Type B+ RCCB

Enhanced Fire Protection to 20kHz

- Configuration: 2-pole and 4-pole

- Rated Current: 16A to 100A

- Sensitivity: 30mA, 100mA, 300mA

- Frequency Response: Up to 20kHz

- Standards: IEC 62423, IEC 61008-1, DIN VDE 0664-110

- Key Feature: Extended frequency protection for high-switching-frequency inverters

Recommended for premium installations, solar-integrated EV chargers, and facilities requiring maximum protection against both shock and fire hazards.

VKL11F Series – Type F RCCB (EV Charging Ready)

Cost-Effective Solution for Modern Chargers

- Configuration: 2-pole and 4-pole

- Rated Current: 16A to 100A

- Sensitivity: 30mA, 100mA, 300mA

- EV Charging Compliance: OVE E8601 certified

- Standards: IEC 62423, IEC 61008-1

- Key Feature: Composite frequency detection, certified for chargers with integrated DC fault protection

Our most popular choice for new EV charging installations. Balances comprehensive protection with economical pricing when paired with IEC 62955-compliant charging stations.

VML01F Series – Type F RCCB with Selective Coordination

Intelligent Protection for Multi-Station Installations

- Configuration: 2-pole and 4-pole

- Rated Current: 16A to 100A

- Sensitivity: 30mA, 100mA, 300mA

- Special Feature: Short-time delayed (Type G) tripping

- Standards: IEC 62423, IEC 61008-1

Designed for parking facilities and commercial installations where selective coordination prevents total system shutdown when a single charger faults.

Why VIOX for EV Charging Protection?

Rigorous Testing: Every RCCB undergoes 17-stage quality validation including high-voltage arc testing and mechanical endurance beyond 20,000 operations—exceeding IEC requirements by 200%.

Global Certifications: CE, KEMA, VDE, and regional approvals ensure compliance across international markets.

Technical Support: Our engineering team provides selection guidance, custom configurations, and post-installation support for integrators and contractors.

Competitive Lead Times: Standard models ship within 7-10 business days; custom configurations in 15-20 days.

Frequently Asked Questions

Can I use a standard Type A RCCB for EV charging?

No, standard Type A RCCBs are not suitable for EV charging applications. While Type A devices detect AC and pulsating DC residual currents, they cannot detect the smooth DC fault currents generated by EV charger power electronics. Smooth DC currents above 6mA can saturate the RCCB’s magnetic core, rendering it “blind” to subsequent AC faults and leaving users unprotected. International standards including IEC 60364-7-722 explicitly require either Type B RCCBs or Type F/A RCCBs combined with a DC fault detection device (RDC-DD compliant with IEC 62955).

What’s the difference between Type B and Type B+ RCCBs?

Type B RCCBs detect residual currents up to 1,000Hz, covering AC, pulsating DC, and smooth DC fault currents as specified in IEC 62423. Type B+ RCCBs extend this protection to 20kHz, addressing high-frequency leakage currents from advanced power electronics with rapid switching (as defined in DIN VDE 0664-110). For most EV charging installations, standard Type B provides adequate protection. Type B+ offers enhanced fire protection in installations with high-frequency inverters, solar integration, or where maximum safety margins are required.

Do I need a 2-pole or 4-pole RCCB for my EV charger?

The pole configuration must match your electrical supply system. Use 2-pole RCCBs for single-phase installations (120V or 240V systems common in residential and small commercial applications). Use 4-pole RCCBs for three-phase installations (208V, 400V, or 480V systems typical in commercial and industrial settings). Installing a 2-pole device on a three-phase system leaves one phase unmonitored, creating a dangerous protection gap. Always verify your supply voltage and phase configuration before selecting an RCCB.

My EV charger already has built-in protection. Do I still need an RCCB?

Yes, but you have options. Even if your charger has internal protection, electrical codes require dedicated residual current protection at the charging point with 30mA sensitivity for personnel safety. If your charger includes IEC 62955-compliant DC fault current detection (check the technical datasheet), you can use a more economical Type F or Type A RCCB. If the charger lacks this certification or you’re uncertain, specify a Type B RCCB for guaranteed comprehensive protection. The redundancy between charger internal protection and the dedicated RCCB provides defense-in-depth safety.

What does OVE E8601 compliance mean?

OVE E8601 is an Austrian standard that has gained recognition throughout Europe as a benchmark for EV charging protection devices. An RCCB marked with OVE E8601 compliance has been specifically tested and certified for use with electric vehicle charging stations that include integrated DC fault current detection. While originally an Austrian standard, many European electrical contractors and authorities recognize OVE E8601 as evidence of EV charging suitability. VIOX’s VKL11F Series carries this certification, indicating verified performance in EV charging applications.

How often should I test my RCCB?

IEC 61008-1 recommends monthly testing using the built-in TEST button. Press the button—the RCCB should trip immediately, disconnecting power. If it doesn’t trip, the device is faulty and must be replaced immediately. This test verifies the mechanical trip mechanism remains functional. Additionally, qualified electricians should perform comprehensive testing during annual electrical inspections, including earth fault loop impedance testing to verify the complete protection system operates within specification. Regular testing is essential; mechanical components can degrade over time, and monthly verification ensures your protection remains functional.

Can multiple EV chargers share one RCCB?

While technically possible, individual protection for each charging point is strongly recommended and required by most electrical codes (including IEC 60364-7-722). Sharing one RCCB across multiple chargers means a fault on any charger disconnects all chargers, causing service disruption. Additionally, cumulative leakage currents from multiple chargers can approach the RCCB’s sensitivity threshold, causing nuisance tripping. For multi-station installations, specify individual 30mA RCCBs for each charging point, optionally with upstream selective coordination (time-delayed or higher-sensitivity devices) to maintain service continuity.

Will a Type F RCCB work if my charger’s DC protection fails?

No. Type F RCCBs cannot detect smooth DC residual currents independently. They rely entirely on the charger’s integrated DC fault detection device. If that internal protection fails, malfunctions, or was incorrectly specified, the Type F RCCB will not provide DC fault protection, potentially creating a dangerous situation. This is why Type B RCCBs—which provide inherent smooth DC detection—are considered the safest choice when charger internal protection is unknown, unverified, or in mission-critical installations where redundancy justifies the additional cost.

What sensitivity should I choose: 30mA, 100mA, or 300mA?

For EV charging points accessible to users, always specify 30mA sensitivity. This is mandated by IEC 60364-7-722 and most national electrical codes for personnel protection. The 30mA threshold provides protection against electric shock while minimizing nuisance tripping. Higher sensitivities (100mA or 300mA) are only appropriate for upstream devices in selective coordination schemes or for fire protection where a downstream 30mA device protects the actual charging point. Never use sensitivities higher than 30mA for the final protective device at a user-accessible EV charger.

Conclusion

As electric vehicle adoption transforms transportation infrastructure, proper residual current protection becomes non-negotiable. The unique electrical characteristics of EV charging—specifically smooth DC fault currents from power conversion electronics—demand specialized protection that standard Type A RCCBs cannot provide.

Type B RCCBs offer universal protection, detecting all fault current types without dependency on charger internal components. Type F RCCBs paired with IEC 62955-compliant charging stations provide cost-effective protection for modern installations. Type EV devices (IEC 62955 RDC-DDs) deliver purpose-built protection optimized for dedicated charging applications.

The decision isn’t just technical—it’s about liability, safety compliance, and long-term reliability. Incorrectly specified protection exposes facility owners to regulatory penalties, insurance complications, and most importantly, preventable safety incidents. Conversely, properly engineered residual current protection provides peace of mind, regulatory compliance, and protection that scales with evolving EV technology.

For electrical contractors and engineers specifying EV charging infrastructure, the investment in appropriate RCCB protection represents a small fraction of total installation cost while delivering critical safety performance. VIOX’s comprehensive RCCB portfolio—from universal Type B to cost-optimized Type F EV-ready units—ensures you can match protection precisely to your application requirements without compromise.

As the EV charging network expands, the foundation of that infrastructure must be electrical protection systems engineered for the unique demands of this technology. Choose wisely, install correctly, and test regularly. The safety of EV users depends on it.

For technical consultation on RCCB selection for your EV charging project or to request product samples, visit VIOX.com or contact our engineering support team.