Din Rails Manufacturer

VIOX Electric, a leading manufacturer and supplier, produces high-quality DIN Rails. With extensive industry experience, we ensure our products meet stringent safety and performance standards. Our DIN Rails provide reliable support in various electrical systems. As a factory known for excellent customer service and innovation, VIOX Electric is your trusted source for superior DIN Rails.

Certified By

VIOX Din Rails Products

A Brief Self-Nomination: Why Choose VIOX Electric?

VIOX Electric is dedicated to providing the best DIN Rails. Our mission is to offer tailored solutions that meet your specific needs. Over the years, we have collaborated with industry professionals to develop innovative designs for electrical solutions. By choosing us, you will receive the perfect combination of quality, functionality, and reliability.

Custom Solutions: We focus on providing solutions that solve your unique electrical challenges. Whether you need specific configurations, sizes, or capabilities for your DIN Rails, we can create a custom solution just for you.

Expert Guidance: Our customer support team comprises industry experts. They will work closely with you to understand your requirements and provide informed, practical solutions to meet your needs.

Advanced Production Techniques: To ensure you receive superior DIN Rails, we employ state-of-the-art equipment, materials, and production processes. This guarantees that our solutions are both efficient and durable.

VIOX FULL RANGE DIN RAILS

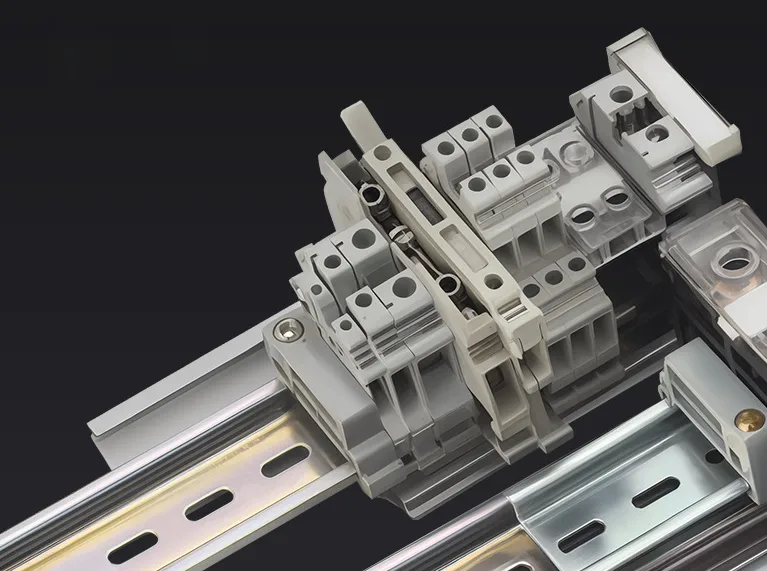

Manufactured with precision and reliability in mind, our DIN Rails are designed to provide exceptional performance across various applications, including electrical enclosures, distribution cabinets, and control panels. VIOX’s commitment to excellence ensures that each product meets high standards of durability, corrosion resistance, and ease of installation. Reach out to us for more information on how our DIN Rails can meet your specific requirements.

- Aluminum DIN Rail

- Steel DIN Rail

- Stainless Steel DIN Rail

- Top Hat DIN Rail

- G Type DIN Rail

- Mini DIN Rail

- 35×7.5mm DIN Rail

- 35x15mm DIN Rail

- 32x15mm DIN Rail

- 15×5.5mm DIN Rail

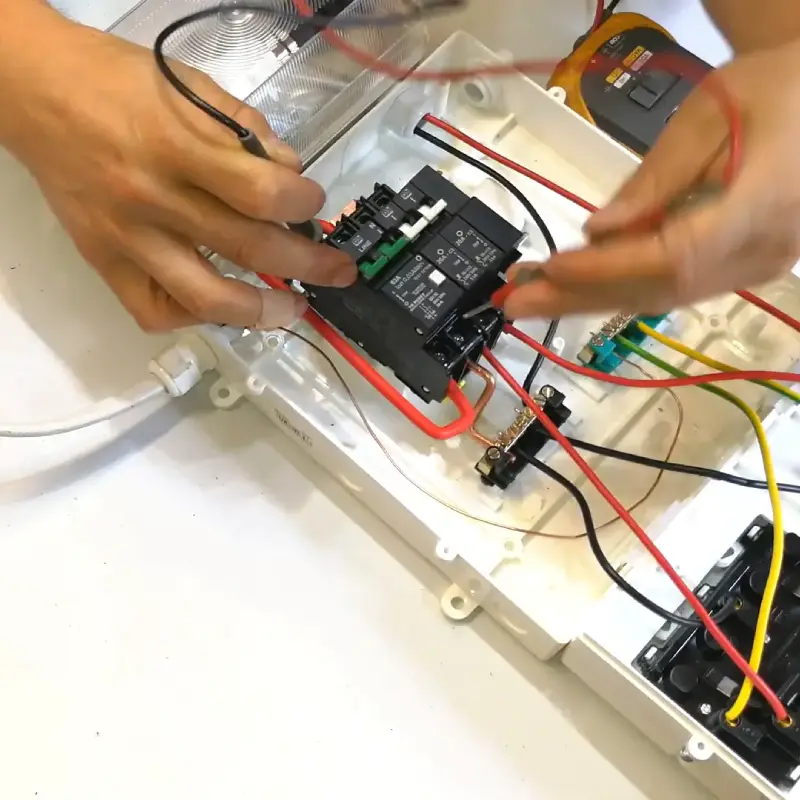

How to install DIN Rails

01

02

03

04

05

06

VIOX High-Quality Cable Solutions

At VIOX, we pride ourselves on offering a comprehensive range of high-quality cable solutions designed to meet diverse needs across various industries. Our products are engineered for durability, reliability, and performance, ensuring that you have the right tools for every application. Discover our range of products below:

Get Your Free Sample!

We provide samples for free, you just need to tell us what you need

More Than Just a Din Rail Manufacturer

At VIOX, we pride ourselves on providing timely support, adhering to high standards, and offering tailor-made solutions that meet our customers’ needs, forming the foundation of our growing reputation with Din Rails.

Service Consultation

If your Din Rail requirements are straightforward and you don’t need an external consultation, our team can offer expert advice and guidance for a reasonable fee.

DIN RAIL Recommendations

Unsure which Din Rail to choose for your project? We provide personalized recommendations based on your specific needs, free of charge for all our customers.

Logistics Support

If you lack a suitable freight forwarder, we can help arrange the transportation of your Din Rails from our factory to your project site without any extra service fees.

Installation Support

If you have questions about installing Din Rail, feel free to reach out to us. We offer installation assistance and can even send an engineer to your project site for hands-on support.

KNOWLEDGE

What are DIN rails?

DIN rails are standardized metal strips that serve as a foundation for mounting various electrical and industrial components in equipment racks and control cabinets. These versatile mounting systems originated in Germany in 1928, developed by Rheinisch-Westfälisches Elektrizitätswerk to address the lack of standardization in electrical panel development. By the 1950s, DIN rails had gained widespread international adoption, revolutionizing the installation and compatibility of electrical equipment across different manufacturers. Today, they play a crucial role in industrial settings, providing a simple yet effective solution for organizing and securing a wide range of devices, from circuit breakers to programmable logic controllers.

Common DIN Rail Materials (Steel, Aluminum, Stainless Steel)

DIN rails are manufactured from various materials, each offering distinct properties suited for different applications. The most common materials include:

Galvanized Steel: This is the most widely used material due to its durability, corrosion resistance, and cost-effectiveness. It’s suitable for standard indoor environments and can support heavy components.

Aluminum: Lightweight and naturally resistant to oxidation, aluminum DIN rails are ideal for weight-sensitive applications and moderately corrosive environments. They weigh about 2.5 times less than steel rails but have lower strength, typically supporting lighter components.

Stainless Steel: Offering superior corrosion resistance, stainless steel DIN rails are suitable for harsh environments, particularly in food processing, chemical, and marine industries.

Copper: While less common, copper DIN rails are available for specialized applications, particularly where electrical conductivity is required.

The choice of material depends on factors such as load-bearing requirements, environmental conditions, and specific industry standards. For instance, steel DIN rails can typically support 15-20 kg per meter, making them ideal for heavy equipment, while aluminum rails are better suited for lighter components

Types of DIN Rails

DIN rails come in three major variants, each designed for specific applications:

- Top Hat (TH) Section: The most common type, measuring 35mm in width and available in 7.5mm and 15mm depths. It’s primarily used for mounting circuit breakers and control equipment.

- C Section: Available in C20, C30, C40, and C50 variants, with the number indicating the vertical height. This type offers versatility for different component sizes.

- G Section: Designed for heavier components, featuring a deeper bottom side for enhanced support and stability in industrial settings.

These standardized rail types ensure compatibility across manufacturers, allowing for efficient installation and organization of electrical and industrial components in equipment racks and control cabinets.

Din Rails Evolution and Outlook

The history of DIN rails traces back to 1928 when Rheinisch-Westfälisches Elektrizitätswerk (RWE) in Germany developed the first standardized mounting system for electrical components. Initially made from porcelain with a metal bus bar, these rails evolved to all-metal construction for improved durability. The German Institute for Standardization (DIN) further refined and standardized the design in the 1950s, leading to widespread adoption across industries.

Looking to the future, DIN rail technology is poised for significant advancements. The integration of Internet of Things (IoT) capabilities is enabling remote monitoring, diagnostics, and control of connected devices4. Ongoing innovations in materials and design are enhancing the durability and efficiency of DIN rail components, extending their lifespan and improving system performance4. As industries continue to embrace automation and smart technologies, DIN rails are expected to play a crucial role in supporting the evolving needs of electrical and industrial applications, particularly in areas such as smart grids and renewable energy systems.

Physical Characteristics of DIN Rails

DIN rails are typically manufactured from cold-rolled carbon steel, featuring a zinc-plated or chromated bright surface finish for durability and corrosion resistance. These metal strips serve as mechanical support structures rather than electrical conductors, although they may provide chassis grounding connections. The most common variant, known as the Top Hat (TH) section, measures 35mm in width and is available in 7.5mm and 15mm depths. While primarily designed for mounting purposes, DIN rails do not conduct electricity themselves, ensuring safety and versatility in various industrial and electrical applications.

Choosing the Right Din Rail

When selecting the right DIN rail for your application, consider the following key factors:

Material: Choose from steel, aluminum, copper, or other metals based on durability requirements and environmental conditions1. Steel rails are ideal for heavy components due to their strength.

Profile type: Select from Top Hat (TS35), C-Rail, G-Rail, or Miniature DIN Rail profiles depending on your specific needs and space constraints.

Dimensions: Ensure compatibility with your components, typically opting for the standard 35mm width for most industrial applications.

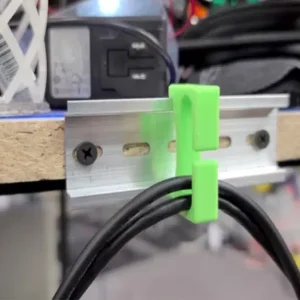

Mounting options: Consider rails with pre-manufactured mounting slots for easier installation and reduced setup time.

Load capacity: Evaluate the weight of the components to be mounted and choose a rail that can support the total load.

Additionally, factor in the specific requirements of your application, such as corrosion resistance, electrical grounding needs, and compatibility with existing equipment. For specialized applications, consult with manufacturers or suppliers to ensure the selected DIN rail meets all necessary standards and specifications.

DIN Rail Production Process

The manufacturing process for DIN rails involves several key steps to transform raw materials into precise, standardized mounting components:

Material Preparation: Cold-rolled carbon steel sheets are typically used as the base material, though aluminum and stainless steel are also common for specific applications.

Roll Forming: The metal strip passes through a series of roller dies that progressively bend and shape it into the desired DIN rail profile.

Surface Treatment: Rails undergo zinc-plating or chromate bright surface finishing to enhance durability and corrosion resistance.

Cutting and Punching: Formed rails are cut to specified lengths, and mounting holes are punched as needed.

Quality Control: Inspection units check the rails against quality standards to ensure dimensional accuracy and surface finish.

Modern DIN rail production lines often incorporate automated features for high-efficiency manufacturing, including inline processes for cleaning, straightening, and degreasing. This standardized manufacturing process ensures compatibility across different manufacturers, facilitating efficient installation and maintenance of electrical systems worldwide

Din Rail Applications

DIN rails find extensive use in various industrial and commercial applications, providing a standardized mounting solution for electrical components. Here are some key applications of DIN rail systems:

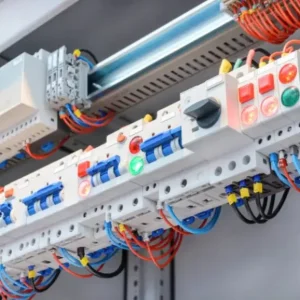

Industrial Control Systems: DIN rails are widely used in manufacturing and process control environments for mounting PLCs, relays, and other control devices.

Building Automation: They play a crucial role in organizing components for lighting, heating, and cooling control systems in smart buildings.

Power Distribution: DIN rails are essential in electrical panels for mounting circuit breakers, surge arresters, and terminal blocks.

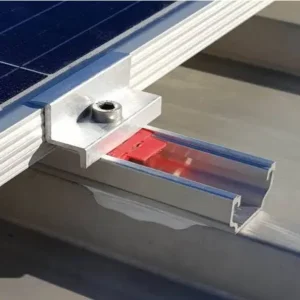

Renewable Energy Systems: Solar and wind energy installations utilize DIN rail-mounted components for power management and control.

Telecommunications: Network equipment and data monitoring systems are often housed in DIN rail enclosures for efficient organization.

Transportation: Railway signaling systems and automotive manufacturing processes incorporate DIN rail-mounted devices.

Industrial Automation: DIN rails support the integration of sensors, actuators, and control devices in automated production lines.

The versatility and standardization of DIN rail systems make them indispensable in organizing and securing electrical components across these diverse applications, promoting efficiency and ease of maintenance.

Advantages of Using DIN Rails in Industrial Systems

DIN rails offer significant advantages in industrial systems, making them a preferred choice for mounting electrical components. Their modular and standardized design allows for flexible configurations, easy expansion, and simplified maintenance, reducing installation time and complexity. This approach leads to cost savings and improved space efficiency, enabling high-density installations in compact control cabinets.

Key benefits of DIN rail systems include:

- Enhanced organization and accessibility of components

- Improved safety through standardized mounting

- Flexibility to mix and match components from various manufacturers

- Efficient heat dissipation in electrical enclosures

- Reduced downtime during repairs or upgrades

- Easy troubleshooting due to clear labeling and organized layout

These advantages contribute to increased productivity, lower maintenance costs, and improved overall system reliability in industrial applications.

Common Installation Mistakes

When installing DIN rails, several common mistakes can compromise the system’s integrity and safety. One frequent error is improper alignment, which can lead to instability and potential damage to mounted components. Overloading the rail beyond its weight capacity is another critical mistake that can result in structural failure.Installers should also be cautious of:

- Inadequate ventilation, causing overheating of components

- Incorrect wiring connections, potentially leading to short circuits or electrical fires

- Insufficient grounding, increasing the risk of electrical shocks

- Using incompatible components or incorrect rail sizes

- Failing to secure loose components after vibrations or poor installation

To avoid these issues, it’s crucial to follow manufacturer guidelines, use appropriate tools, and conduct regular maintenance checks. Proper installation not only ensures safety but also enhances the longevity and efficiency of the electrical system.

Identifying Quality DIN Rails

To distinguish high-quality DIN rails, consider the following key factors:

Material quality: Premium DIN rails use high-grade steel or aluminum with superior corrosion resistance. Look for rails made from galvanized steel with a thick passivated layer for optimal durability.

Precision manufacturing: High-quality rails have consistent dimensions and smooth edges. Check for uniform thickness and straightness along the entire length.

Certification compliance: Reputable manufacturers ensure their DIN rails meet international standards like IEC 60715. Look for products with MID certification for guaranteed accuracy and reliability.

Load capacity: Superior DIN rails offer higher load-bearing capabilities. Steel rails typically support 15-20 kg per meter, while high-grade variants can handle even greater loads.

Surface finish: Quality rails feature a smooth, even surface coating that resists wear and corrosion. Inspect for uniform coloration and absence of imperfections.

By evaluating these aspects, you can identify DIN rails that offer better performance, longevity, and reliability for your specific application needs.

Chinese DIN Rail Manufacturers

China has emerged as a leading hub for DIN rail manufacturing, offering a wide range of high-quality products at competitive prices. Among the prominent manufacturers is VIOX Electric, a global supplier of low-voltage electrical equipment, including DIN rails, with ISO-certified manufacturing facilities. Leveraging advanced production techniques and modern machinery, VIOX ensures compliance with international standards such as DIN, IEC, and RoHS.

The combination of quality, affordability, and innovation has positioned Chinese manufacturers like VIOX as key players in the global DIN rail market, catering to diverse industrial and electrical applications.

Request an OEM DIN Rails Quote

VIOX Electric is ready to assist you with your OEM DIN Rails needs. We offer high-quality and cost-effective solutions.