Leading MCB Manufacturer | VIOX Electric - 20+ Years Excellence

VIOX Electric is a professional MCB manufacturer with over 20 years of experience in designing, producing, and exporting miniature circuit breakers. Located in Yueqing – China’s “Electric Device Metropolis” – we serve distributors, contractors, and electrical engineers across 60+ countries with high-quality, IEC/CE/UL certified circuit protection solutions.

Certified By

VIOX MCB Product Lineup - Complete Technical Specifications

- Poles: 1P, 2P, 3P, 4P

- Rated Current: 1A-63A (18 ratings)

- Breaking Capacity: 6000A (In ≤ 6A to 40A), 4500A (In 50A, 63A) Rated Voltage: 1P: 240/415V~, 2P/3P/4P: 415V~

- Rated Voltage: 1P: 240/415V~, 2P/3P/4P: 415V~

- Curve Code: B, C, D

- Mechanical Durability: 10,000 cycles

- Electrical Durability: 4,000 cycles

- Protection Degree: IP20/IP40

- Poles: 1P, 2P, 3P, 4P

- Rated Current: 1A-63A (18 ratings)

- Breaking Capacity: 6000A or 10000A

- Rated Voltage: 1P: 240/415V~, 2P/3P/4P: 415V~, AC 500V~

- Curve Code: B, C, D

- Mechanical Durability: 10,000 cycles

- Electrical Durability: 4,000 cycles

- Protection Degree: IP20/IP40

- Trip Unit: Thermal-magnetic

- Poles: 1P, 2P, 3P, 4P

- Rated Current: 80A, 100A, 125A

- Breaking Capacity: 6000A

- Rated Voltage: 230V/400V~, 240V/415V~

- Curve Code: C, D

- Mechanical Durability: 10,000 cycles

- Electrical Durability: 6,000 cycles

- Endurance: ≥20,000 operations

- Standards: IEC 60898-1

- Poles: 1P, 2P, 3P, 4P

- Rated Current: 80A, 100A, 125A

- Breaking Capacity: 6000A

- Rated Voltage: 240V/415V~

- Curve Code: C, D

- Mechanical Durability: 10,000 cycles

- Electrical Durability: 6,000 cycles

- Endurance: ≥20,000 operations

- Standards: IEC 60898-1 AND IEC 60947-2 (Dual Certified)

A Brief Self-Nomination: Why Choose VIOX Electric?

At VIOX Electric, we pride ourselves on being a leading manufacturer of Miniature Circuit Breakers (MCBs) with over 20 years of industry experience. Our commitment to excellence has established us as a trusted partner for electrical contractors, engineers, and distributors worldwide.

- Industry-Leading Quality: Every MCB undergoes rigorous testing to ensure consistent performance and safety

- Innovative Design: Our R&D team continuously improves our products to meet evolving industry standards

- Comprehensive Support: From selection guidance to after-sales service, we're with you at every step

- Global Compliance: All VIOX MCBs meet international safety standards, including IEC, UL, CE, and more

- Competitive Pricing: Premium quality without the premium price tag

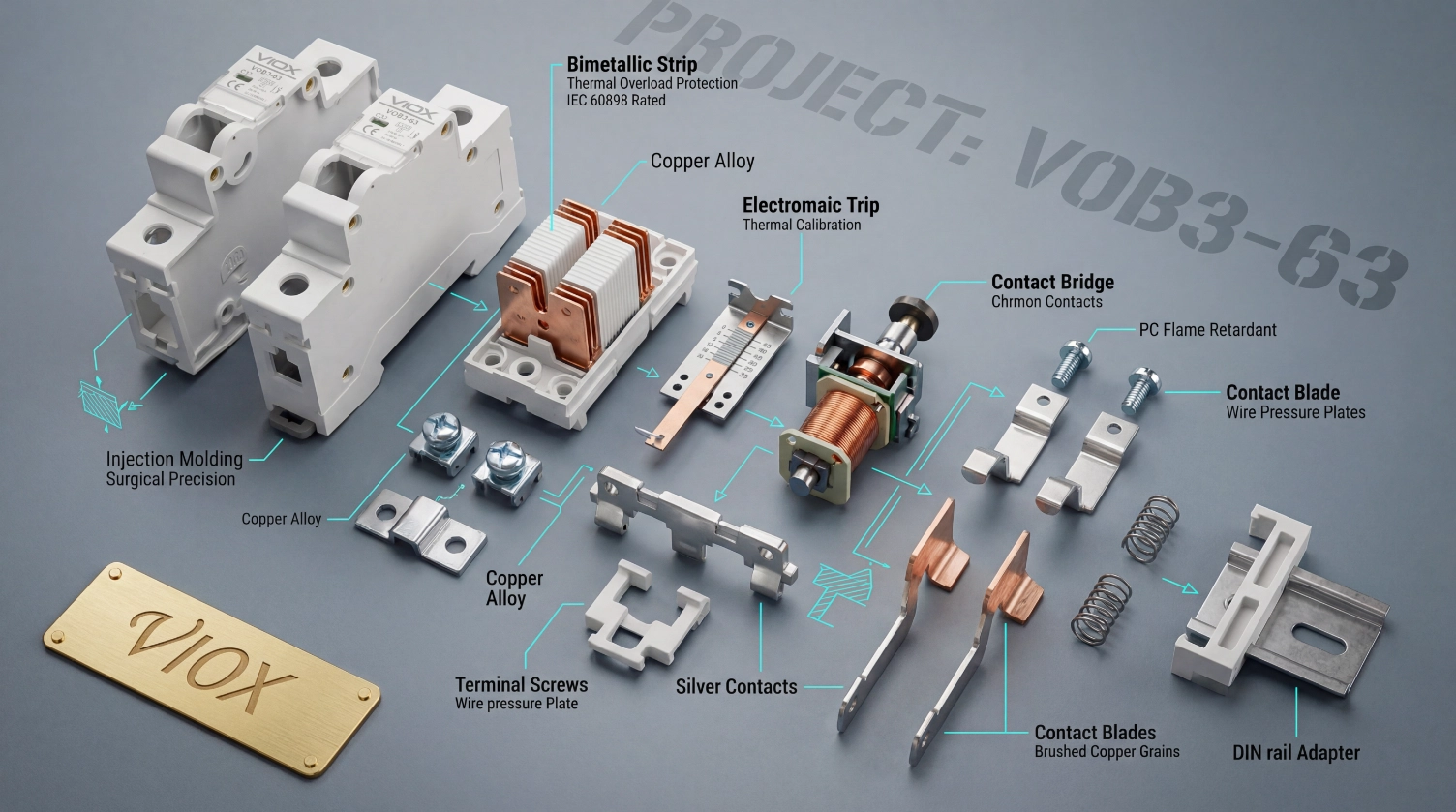

Precision Engineering - Inside VIOX MCB Technology

At VIOX Electric, we believe that true quality is revealed in the details. Our MCB manufacturing philosophy centers on “Sublime Micro-Engineering Narratives” – where every component, from the smallest spring to the largest contact assembly, represents surgical precision and artistic interpretation of technical excellence.

- Fire-Retardant Casing: The shell is made of PA66 nylon material, offering V0-grade flame retardancy and high impact resistance.

- Silver Alloy Contacts: We use premium silver-graphite contacts to ensure low contact resistance and prevent welding during short circuits.

- Arc Extinguishing Chamber: An optimized 13-plate grid design rapidly cools and extinguishes arcs, extending the electrical life of the breaker.

- Visual Indicator: Clear Red/Green window indicates contact position for safe maintenance.

Get Your Free Sample!

We provide samples for free, you just need to tell us what you need

How to Select the Right MCB for Your Application

Proper MCB selection requires considering multiple factors. Use this comprehensive guide to specify the correct circuit breaker for your installation.

| Selection Factor | Consideration | VIOX Recommendation |

|---|---|---|

| Current Rating (In) | Must exceed normal load current with 20% headroom | VOB3/VOB4: 1-63A, VOB4-125/VOB5-125: 80-125A |

| Breaking Capacity (Icn) | Must exceed maximum prospective fault current at installation point | 6kA (residential), 10kA (commercial/industrial) |

| Trip Curve Type | B: Lighting, C: General use, D: Motors/transformers | Type C recommended for 90% of applications |

| Number of Poles | 1P: L-N, 2P: L-L or L-N, 3P: 3-phase, 4P: 3-phase+N | All configurations available in each series |

| Voltage Rating | Must meet or exceed system voltage | Up to 500V AC available (VOB4 series) |

| Ambient Temperature | Derate by 10% for each 10°C above 30°C | Operating range: -25°C to +55°C |

| Standards Compliance | Match local electrical codes and regulations | Match local electrical codes and regulations |

| Installation Environment | Consider IP rating for dust/moisture protection | IP20/IP40 standard, higher ratings available |

MCB Trip Curve Comparison: B vs C vs D Explained

Understanding trip curve characteristics is essential for proper MCB selection. The curve type determines when the magnetic element provides instantaneous protection against short circuits.

| Curve Type | Magnetic Trip Range | Typical Applications | Inrush Tolerance | VIOX Availability |

|---|---|---|---|---|

| Type B | 3-5 × In | Resistive loads: Lighting, heating elements, general outlets | Low - triggers on modest overcurrent | All VOB series |

| Type C | 5-10 × In | Mixed loads: General distribution, small motors, fluorescent lighting | Medium - standard for 90% of applications | All VOB series (recommended default) |

| Type D | 10-20 × In | Inductive loads: Motors, transformers, welding equipment | High - tolerates high starting currents | All VOB series (specify when ordering) |

| Type K | 8-14 × In | Specialized: Compressors, X-ray equipment, heavy-duty motors | Very high - custom applications | Available on request (MOQ applies) |

MCB Manufacturing Process - From Raw Materials to Certified Products

Our Production Workflow As a vertically integrated MCB manufacturer, we control every stage:

1. Raw Material Inspection

- Imported silver alloy contacts

- High-purity electrolytic copper terminals

- PA66 flame-retardant housing (UL94 V0)

- Bimetallic strips from certified suppliers

2.Automated Assembly

- Robotic contact assembly (±0.01mm precision)

- Arc chamber installation & testing

- Thermal & magnetic element calibration

- Final assembly in Class 10,000 cleanroom

3.100% Quality Testing

- Automatic electrical testing station

- Temperature rise measurement

- Dielectric strength testing

- Mechanical operation testing (20+ cycles)

4. Certification & Packaging

- Batch traceability labeling

- IEC/CE compliance documentation

- Anti-static packaging

- Custom branding (OEM orders)

Applications

Electrical Solutions for Every Need

As a trusted electrical equipment manufacturer, VIOX delivers high-performance electrical solutions designed for residential, commercial, industrial, and renewable energy applications—providing cost savings, operational efficiency, and reliability across diverse industries worldwide.

Solar & Renewable Energy Systems

The solar sector relies on specialized DC components for safe high-voltage management and surge protection in photovoltaic systems.

Industrial Manufacturing & Automation

Industrial manufacturing requires robust electrical controls for heavy machinery and automation systems.

Commercial & Residential Buildings

Buildings need electrical solutions prioritizing safety and efficiency while meeting codes.

Marine & Offshore Industries

Marine applications require components withstanding saltwater, humidity, and vibration.

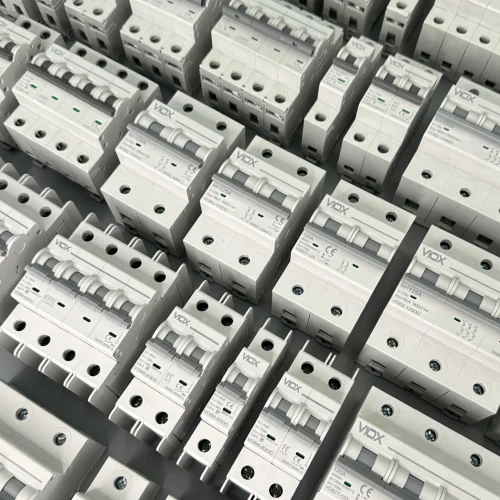

MCB Factory Image

Discover Our Best-Selling Electrical Equipment – High Efficiency, Reliable Performance, and Trusted by Electrical Equipment Suppliers Worldwide.

More Than Just a MCB Manufacturer

At VIOX, we go beyond manufacturing MCBby offering a suite of value-added services tailored to meet your project needs. Our commitment to excellence ensures that every customer receives personalized attention, expert guidance, and seamless support throughout their journey with us.

Service Consultation

Whether your MCB requirements are straightforward or complex, our team provides expert advice and technical consultation. For more intricate projects, we offer in-depth engineering support to ensure optimal product selection and application, guaranteeing safety and efficiency in your electrical systems.

Product Recommendations

Unsure which MCB suits your system? Our specialists provide free, customized recommendations based on your specific operational and environmental requirements, ensuring you get the perfect fit for your electrical protection needs.

Logistics Support

If you lack a reliable freight forwarder, we can arrange transportation from our factory to your project site at no extra cost. Our logistics team ensures timely and secure delivery to keep your project on schedule, minimizing downtime and delays.

Installation Support

Need help with installation? Our technical team is available to answer your questions or provide hands-on support. For larger projects, we can even dispatch an engineer to your site for on-the-ground assistance, ensuring your MCBs are installed correctly and function seamlessly within your electrical network.

KNOWLEDGE About RCCB

What is an MCB?

A miniature circuit breaker (MCB) is an automatically operated electrical switch designed to protect circuits from overcurrent damage caused by overloads or short circuits. Unlike fuses that must be replaced after operating, MCBs can be reset and reused indefinitely. They work through two protection mechanisms: a thermal element (bimetallic strip) that provides time-delayed protection against overloads, and a magnetic element (solenoid) that provides instantaneous protection against short circuits, typically operating in 0.01-0.1 seconds.

How Does an MCB Work?

Modern MCBs from our manufacturing facility employ two protection mechanisms:

1. Thermal Protection (Overload)

- Bimetallic strip heats and bends under prolonged overcurrent

- Provides time-delayed tripping for overload conditions

- Allows temporary harmless overcurrents (motor starting)

- Typically trips at 1.13-1.45x rated current within 1 hour

2. Magnetic Protection (Short Circuit)

- Electromagnetic solenoid activates under sudden high current

- Provides instantaneous tripping for fault conditions

- Operates in milliseconds (0.01-0.1 seconds)

- Prevents arc flash and equipment damage

Key Components of an MCB

- Operating Mechanism: The handle and latching mechanism

- Contacts: The conducting parts that connect and disconnect the circuit

- Arc Extinguishing Chamber: Quenches the arc formed during contact separation

- Thermal Element: Bimetallic strip for overload protection

- Magnetic Element: Solenoid for short-circuit protection

- Terminals: Connection points for incoming and outgoing cables

What is the difference between B, C, and D trip curves?

B-curve MCBs trip at 3-5 times the rated current and are ideal for resistive loads like lighting and heating. C-curve MCBs trip at 5-10 times the rated current, making them suitable for general-purpose applications including slightly inductive loads like small motors—this is the most commonly used curve representing about 90% of installations. D-curve MCBs trip at 10-20 times the rated current and are designed for highly inductive loads with high inrush currents such as large motors, transformers, and welding equipment.

How do I determine the correct MCB size for my application?

Calculate the maximum current draw of your circuit, then select an MCB with a rating slightly higher than this value. Consider factors like cable size, load type, and potential future expansion. For specific guidance, consult our selection guide or contact our technical team.

Are VIOX MCBs compatible with other brands’ distribution boards?

Yes, all VIOX MCBs conform to standard DIN rail mounting specifications (35mm) according to IEC 60715, making them compatible with most distribution boards on the market from any manufacturer. The standard mounting clip design ensures secure installation and easy replacement. However, always verify physical dimensions and busbar compatibility when retrofitting, especially in very old or non-standard enclosures. VIOX provides detailed dimensional drawings for all products to assist with compatibility verification.

How often should MCBs be replaced?

MCBs typically have a mechanical lifetime of 10,000+ operations. Under normal conditions, they can last 15-20 years. However, we recommend inspection every 5 years and replacement if you notice:

- Discoloration or burning marks

- Difficulty in switching operation

- Frequent nuisance tripping

- After a major short circuit event

What is breaking capacity (Icn) and why does it matter?

Breaking capacity (also called short-circuit capacity or Icn) is the maximum fault current that an MCB can safely interrupt without being damaged or causing hazards. It’s expressed in kiloamperes (kA). For example, a 6kA MCB can interrupt fault currents up to 6,000 amperes. This is critical because the prospective fault current depends on the transformer size, distance from the source, and cable impedance. Residential installations typically require 6kA, while commercial and industrial sites near transformers may need 10kA or higher to safely clear faults without MCB failure.

What’s the difference between an MCB and an RCCB?

An MCB (Miniature Circuit Breaker) protects against overcurrent conditions—specifically overloads and short circuits caused by excessive current flow through the circuit. An RCCB (Residual Current Circuit Breaker) protects against earth leakage currents by detecting imbalances between live and neutral conductors, providing protection against electric shock hazards and earth faults. For comprehensive protection, both devices are often used together in electrical installations, or you can use an RCBO (Residual Current Circuit Breaker with Overcurrent Protection) which combines both functions in a single device.

MCB Selection Factors

When choosing an MCB, consider:

- Current Rating: The normal current the MCB can carry continuously

- Breaking Capacity: Maximum fault current the MCB can safely interrupt

- Tripping Curve: Defines the time-current characteristic (B, C, D, etc.)

- Voltage Rating: Maximum voltage the MCB can safely handle

- Number of Poles: Single pole for single-phase, three poles for three-phase, etc.

- Standards Compliance: Ensuring the MCB meets relevant certification standards

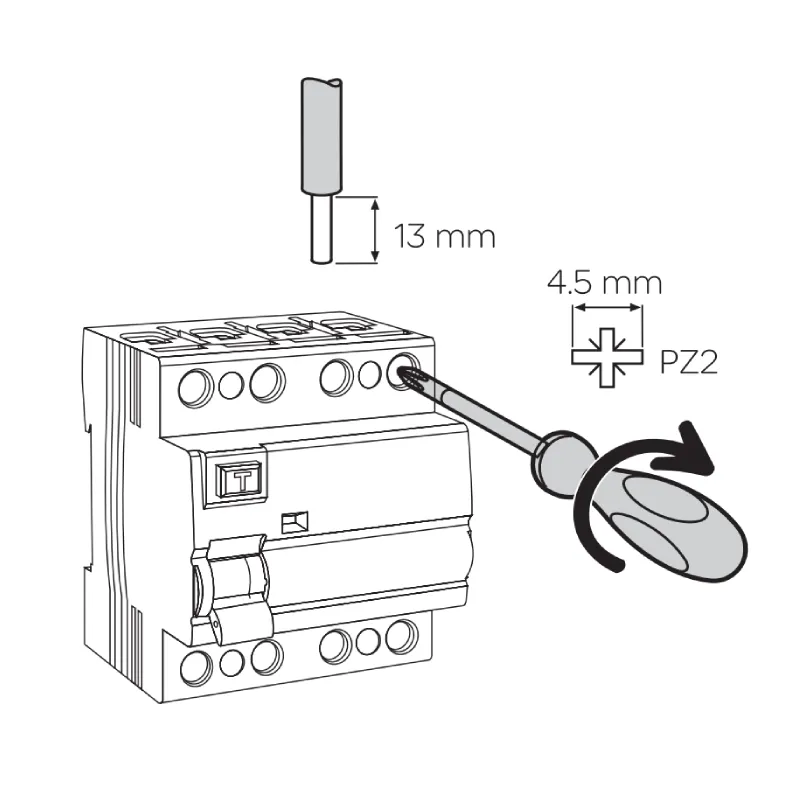

Common MCB Installation and Safety Guidelines

Proper MCB installation is crucial for electrical safety:

- Always disconnect power before installing or replacing MCBs

- Ensure firm connections to avoid loose contacts that can cause heating

- Install MCBs in well-ventilated areas to prevent overheating

- Label circuits clearly for easy identification during emergencies

- Periodically test MCB operation by pressing the test button (if available)

- Never bypass an MCB or increase its rating to avoid tripping

Why do MCBs trip and how do I reset them?

MCBs trip due to: overloading (too many devices on one circuit), short circuits (direct contact between conductors), earth faults (current leaking through damaged insulation), faulty appliances drawing excessive current, or MCB aging/mechanical issues. To reset: (1) Move the MCB switch to the fully “off” position, (2) Identify and resolve the cause of tripping, (3) Wait 30 seconds to allow thermal elements to cool, (4) Firmly switch back to “on”. If the MCB immediately trips again, there’s an unresolved fault requiring professional inspection—never bypass an MCB or increase its rating to avoid tripping.

How to Reset a Tripped MCB

After identifying and resolving the cause of tripping:

- Move the MCB switch to the fully “off” position

- Wait approximately 30 seconds

- Firmly switch it back to the “on” position

If the MCB immediately trips again, there’s still an unresolved fault that requires professional attention.

What is the difference between an MCB and a fuse?

While both protect against overcurrent, MCBs can be reset after tripping, whereas fuses must be replaced. MCBs also offer more precise trip characteristics and faster operation during short circuits.

How long do MCBs typically last?

With proper installation and normal operating conditions, MCBs typically last 15-20 years. However, they should be tested periodically and replaced if they show any signs of malfunction.

Can I replace a fuse with an MCB?

Yes, upgrading from fuses to MCBs is common in older installations. However, this often requires modifying the distribution board and should be performed by a qualified electrician.

What does the amperage rating on an MCB mean?

The amperage rating indicates the maximum continuous current the MCB can carry without tripping. For example, a 16A MCB will typically allow currents up to 16A to flow continuously but will trip if the current exceeds this value for an extended period.

How do I determine the correct MCB size for my application?

To select the correct MCB size: (1) Calculate the maximum current draw of your circuit under normal operation, (2) Select an MCB rated current (In) that exceeds this value by at least 20% to allow for headroom, (3) Verify the cable size can safely carry the MCB rating, (4) Ensure the breaking capacity meets or exceeds the prospective fault current at the installation point, and (5) Choose the appropriate trip curve based on the load type (B for resistive, C for general purpose, D for motors). For complex installations, consult our engineering team for load calculations and selection assistance.

Yueqing: MCB Manufacturing Hub

Yueqing, in Zhejiang province, China, is known as the “Electric Device Metropolis of China” and a global leader in electrical equipment, particularly miniature circuit breakers (MCBs) and other low-voltage devices. VIOX ELECTRIC, a key manufacturer in the city, has bolstered this reputation by prioritizing innovation, securing certifications like ISO9001 and CE, and exporting extensively to international markets.

The city’s success is rooted in its strong industrial ecosystem, featuring specialized manufacturers and decades of expertise in refining production processes. VIOX ELECTRIC exemplifies this by delivering high-quality products to regions like Europe and North America, reinforcing Yueqing’s status as a global leader in the MCB market.

Get Your MCB Quote Today

Factory-direct pricing on IEC/CE/UL certified miniature circuit breakers. Free samples available for project evaluation. Expert technical support included with every order.