Leading Busbar Manufacturer & Supplier: VIOX Electric

VIOX Electric is a leading China-based manufacturer and supplier specializing in high-quality copper comb busbars, phase distribution busbars, and circuit breaker busbars. With years of industry expertise, we deliver reliable, safe, and high-performance busbar solutions tailored to diverse electrical systems. As an ISO, UL, CE, RoHS, and CSA certified factory, we are committed to innovation and exceptional customer service, making VIOX Electric your ideal partner for standard and custom busbar needs. Explore our range of pin-type and fork-type busbars or contact us for a custom quote today.

Certified By

Our Busbar Product Range

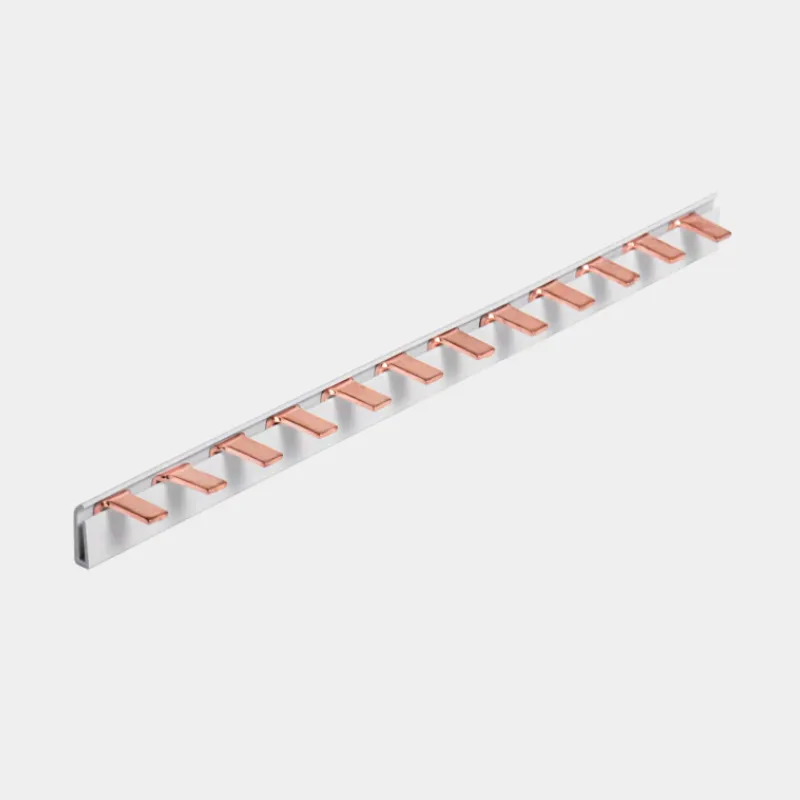

Pin-Type Circuit Breaker Busbars

Ideal for direct insertion into MCB terminals, offering easy installation and secure connections.

Fork-Type Circuit Breaker Busbars

Featuring a U-shaped design for easy connection and disconnection, suitable for various terminal configurations.

Busbar Connectors & Accessories

Complement your installation with our range of high-quality connectors and accessories.

Why Partner with VIOX Electric for Your Busbar Needs?

VIOX Electric is dedicated to providing superior circuit breaker busbars and tailored solutions backed by industry expertise and a commitment to quality.

Custom Solutions: We focus on providing solutions that solve your unique electrical challenges. Whether you need specific configurations, sizes, or capabilities for your circuit breaker busbars, we can create a custom solution just for you.

Expert Guidance: Our customer support team comprises industry experts. They will work closely with you to understand your requirements and provide informed, practical solutions to meet your needs.

Advanced Production Techniques: To ensure you receive superior busbars, we employ state-of-the-art equipment, materials, and production processes. This guarantees that our solutions are both efficient and durable.

VIOX Full Range Mcb Busbars

VIOX Electric provides a comprehensive range of accessories to complement our MCB busbars, including busbar end caps, connectors, 5 pole protective cover & wing bridges, pan assembly busbars, copper bars, brass terminal blocks, brass bars, terminal block boxes, and steel & aluminum DIN rails. Choose VIOX Electric for reliable and efficient electrical solutions.

- Busbar End Caps

- Connectors

- 5 Pole Protective Cover & Wing Bridges

- Pan Assembly Busbar

- Copper Bar

- Brass Terminal Block

- Brass Bar

- Terminal Block Box

- Steel & Aluminum DIN Rails

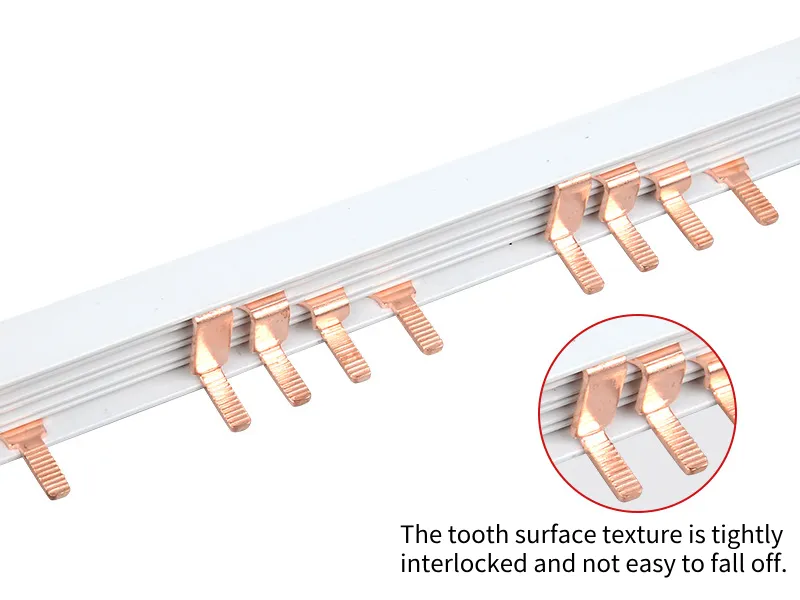

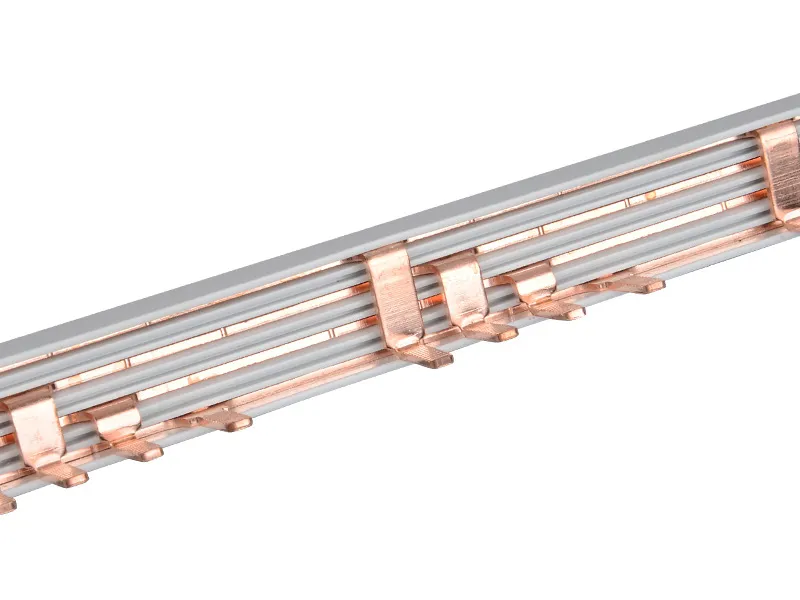

Precision Craftsmanship & Superior Materials

Premium High-Conductivity Copper

We utilize high-strength, roll-formed copper (or specified aluminum) ensuring optimal conductivity and mechanical integrity.

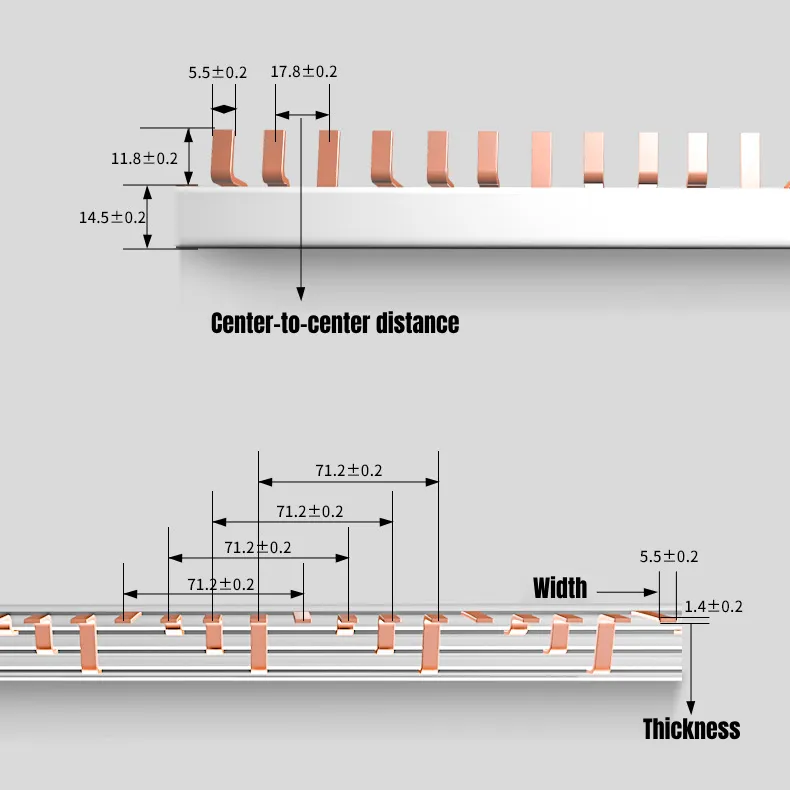

Flawless Finish & Dimensional Accuracy

Our busbars feature a smooth finish, free from burrs or imperfections. Strict process control guarantees high stability in width and flatness, adhering precisely to standard dimensions.

Consistent Quality

Meticulous workmanship results in a uniform texture and consistently high-quality busbars you can depend on.

MCB BUSBAR DIMENSIONS AND SIZE CHART

| Model Series | Phases | Cross Sections | Length Options (mm) | Max Current |

|---|---|---|---|---|

| S-1L | 1-phase | 8-16mm² | 210, 1000, 1016 | 50-80A |

| S-2L | 2-phase | 8-16mm² | 210, 1000, 1016 | 50-80A |

| S-3L | 3-phase | 8-16mm² | 210, 1000, 1016 | 50-80A |

| S-4L | 4-phase | 8-16mm² | 210, 1016 | 50-80A |

| S-3L+N | 3P+N | 8-16mm² | 210, 1000 | 50-80A |

| P-1L | 1-phase | 8-16mm² | 210, 1000, 1016 | 50-80A |

| P-2L | 2-phase | 8-16mm² | 210, 1000, 1016 | 50-80A |

| P-3L | 3-phase | 8-16mm² | 210, 1000, 1016 | 50-80A |

| P-4L | 4-phase | 8-16mm² | 210, 1016 | 50-80A |

| P-1+N | 1P+N | 8-16mm² | 210, 1000 | 50-80A |

| P-1+N-LE | 1P+N-LE | 8-16mm² | 210, 1000 | 50-80A |

| C-1L | 1-phase | 8-16mm² | 210, 1000, 1016 | 50-80A |

| C-2L | 2-phase | 8-16mm² | 210, 1000, 1016 | 50-80A |

| C-3L | 3-phase | 8-16mm² | 210, 1000, 1016 | 50-80A |

| C-4L | 4-phase | 8-16mm² | 210, 1016 | 50-80A |

| Model Series | Phases | Connector Type | Cross Sections | Length Options (mm) | Max Current |

|---|---|---|---|---|---|

| F-1L | 1-phase | Fork (M6) | 8-16mm² | 210, 1000, 1016 | 50-80A |

| F-2L | 2-phase | Fork (M6) | 8-16mm² | 210, 1000, 1016 | 50-80A |

| F-3L | 3-phase | Fork (M6) | 8-16mm² | 210, 1000, 1016 | 50-80A |

| F-3L (M5) | 3-phase | Fork (M5) | 8-16mm² | 210, 1000, 1016 | 50-80A |

| F-4L | 4-phase | Fork (M6) | 8-16mm² | 210, 1016 | 50-80A |

| G-1L | 1-phase | Fork (M6) | 8-16mm² | 210, 1000, 1016 | 50-80A |

| G-2L | 2-phase | Fork (M6) | 8-16mm² | 210, 1000, 1016 | 50-80A |

| G-3L | 3-phase | Fork (M6) | 8-16mm² | 210, 1000, 1016 | 50-80A |

| G-4L | 4-phase | Fork (M6) | 8-16mm² | 210, 1016 | 50-80A |

| G-3L+N | 3P+N | Fork (M6) | 8-16mm² | 210, 1000 | 50-80A |

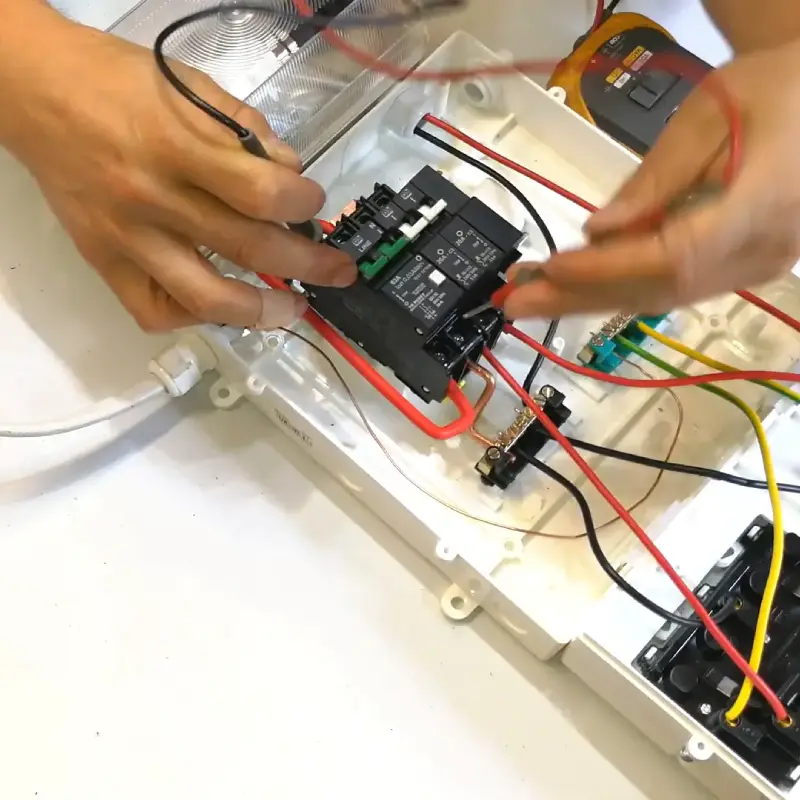

VIOX Busbar Step-by-Step Installation

The installation process for MCB busbars requires careful preparation and attention to detail. Begin by ensuring all terminal screws are fully opened and positioning the highest-rated MCBs or RCBOs nearest to the main incoming device12. Follow these steps for proper installation

01

02

03

04

05

06

Get Your Free Busbars Sample!

We provide samples for free, you just need to tell us what you need

More Than Just a Busbar Manufacturer

At VIOX, we pride ourselves on providing timely support, adhering to high standards, and offering tailor-made solutions that meet our customers’ needs, forming the foundation of our growing reputation with Busbar.

Service Consultation

If your Busbar requirements are straightforward and you don’t need an external consultation, our team can offer expert advice and guidance for a reasonable fee.

Busbar Recommendations

Unsure which Busbar to choose for your project? We provide personalized recommendations based on your specific needs, free of charge for all our customers.

Logistics Support

If you lack a suitable freight forwarder, we can help arrange the transportation of your Switch Position Indicators from our factory to your project site without any extra service fees.

Installation Support

If you have questions about installing Busbar, feel free to reach out to us. We offer installation assistance and can even send an engineer to your project site for hands-on support.

VIOX Busbar Technical Workshop

Frequently Asked Questions

We have compiled some common questions from our clients. If your question isn’t included here, our customer service is always available to help. We’d love to talk with you.

How Can I Get a Quote for the Circuit Breaker Busbars?

To get a quote for our circuit breaker busbars, contact our customer service team. We are available 24/7. Just provide the specifics of your order like the type, size, and quantity. We’ll guide you through the entire ordering process.

What is Your MOQ for the Order?

We have a low MOQ or minimum order quantity. You can order as little as one unit, and we will deliver according to your specifications.

What Is the Turnaround Time for My Order?

The standard turnaround time for our circuit breaker busbars is 7 to 10 business days. Delivery time may extend by up to 15 business days due to transit. For custom or bulk orders, we can discuss the turnaround time before finalizing your order.

Can I Get a Sample Before Placing the Order?

Yes, we provide samples for evaluation and approval. Creating samples typically takes 3 to 7 business days.

Can You Make Customized Circuit Breaker Busbars?

Yes, we offer customized circuit breaker busbars. Let us know your requirements, and our expert customer service team will work with you through the design process.

What is Your Warranty for the Circuit Breaker Busbars?

We offer a 5-year warranty on all circuit breaker busbars we produce. This ensures we deliver high-quality products. Every product is thoroughly tested before delivery.

Expert Circuit Breaker Busbar Knowledge Resources

What is a circuit breaker BUSBAR?

A circuit breaker busbar is a specialized electrical component designed to efficiently distribute power and connect multiple circuit breakers in electrical systems. These busbars are typically made of highly conductive materials like copper or aluminum and serve as central connection points for incoming and outgoing electrical currents.

MCB Busbar Components

Composed of metallic conductors typically made from copper or aluminum, MCB busbars serve as the backbone for power distribution in switchboards and electrical apparatus. These essential components come in various cross-sections, with common sizes including 10mm² (rated for 63A) and 16mm² (rated for 80A). The system incorporates critical elements such as:

- Straight sections for energy transport and distribution

- Additional accessories for system completion

- Isolators and circuit breakers for protection

- Cage-type terminals for secure connections

- Shunt trips for remote tripping capabilities

Busbar Operating Principles

Circuit breaker busbars function as efficient power distribution systems, collecting electricity from incoming feeders and distributing it to outgoing feeders. They act as centralized electrical junctions where incoming and outgoing currents converge. The busbar system incorporates isolators and circuit breakers for safety. In the event of a fault, the circuit breaker trips, disconnecting the faulty section from the circuit.

Key aspects of busbar operation include:

Conduction: Busbars serve as pathways for transmitting electrical current from power supplies to various components.

Distribution: They evenly distribute power across different parts of the electrical system.

Connection: Busbars link multiple electrical devices, such as transformers and generators, to the main power supply.

Heat dissipation: The design of busbars helps dissipate heat generated by electric currents, preventing overheating and ensuring safe system operation.

By centralizing power distribution, busbars simplify wiring complexities, enhance safety, and ensure reliable power delivery in various applications, from industrial settings to renewable energy systems.

How do busbars differ from other electrical conductors?

Busbars and other electrical conductors differ significantly in their design, application, and performance characteristics. Busbars are typically larger, flat or bar-shaped structures designed for high-current applications, often used in industrial settings for power distribution within electrical panels or switchgear. They are usually non-insulated and can handle larger amounts of current more efficiently due to their larger surface area. In contrast, traditional electrical conductors like wires and cables are generally cylindrical, insulated, and more versatile in application, including residential wiring.

The key advantages of busbars include their ability to carry higher currents, better heat dissipation, and improved efficiency in power distribution systems due to lower resistance. They also offer easier access for power tapping and simpler installation in certain contexts. However, cables provide greater flexibility and are more suitable for environments where adaptability and insulation are crucial. The choice between busbars and other conductors depends on the specific requirements of the electrical system, including current capacity, installation environment, and application needs.

Types of MCB Busbars

MCB busbars come in various types to accommodate different electrical system requirements and configurations. Here’s an overview of the main types:

Single-phase (1P): Designed for single-phase circuits, typically used in residential and small commercial applications.

Two-phase (2P): Suitable for connecting two-pole MCBs or single-phase devices with neutral connections.

Three-phase (3P): Used in three-phase systems, common in industrial and larger commercial installations.

Four-phase (4P): Accommodates three-phase systems with neutral, providing comprehensive protection for all conductors.

Pin-type: Features copper pins that insert directly into MCB terminals, offering easy installation and removal.

Comb-type: Resembles a comb structure, allowing for flexible connection of multiple devices along its length.

Fixed-length: Come in predetermined sizes for specific panel configurations.

Cut-to-length: Can be customized on-site to fit exact panel dimensions, offering greater flexibility.

These various types ensure that MCB busbars can be tailored to meet diverse electrical system needs across residential, commercial, and industrial applications.

Busbar Application Areas

Circuit breaker busbars find widespread use in various electrical systems, offering efficient power distribution and protection. Key applications include:

Power distribution boards in buildings, where busbars split incoming power into separate circuits

Data centers, ensuring reliable power distribution to servers and equipment

Hospitals, providing critical power needs to operating rooms and intensive care units

Industrial machinery, facilitating internal power distribution from main feeders to components

Renewable energy systems, such as solar and wind installations, where busbars offer efficient power transfer

Electric vehicles and battery storage systems, utilizing insulated aluminum busbars for weight reduction

These applications leverage the compact design, flexibility, and safety features of busbar systems, making them essential components in modern electrical infrastructure across residential, commercial, and industrial sectors.

Comparison of Pin-Type and Fork-Type MCB Busbars

Pin-type and fork-type MCB busbars offer distinct advantages for different electrical applications. Pin-type busbars feature copper pins that insert directly into MCB terminals, providing easy installation and removal. They offer wider contact areas, resulting in lower power consumption and reduced temperature rise. Fork-type busbars, also known as spade terminals, have a U-shaped design that allows for easy connection and disconnection without removing the terminal point completely.

Key differences include:

Installation: Pin-type busbars are generally faster and easier to install, while fork-type offer more flexibility for removal and replacement.

Conductivity: Both types provide good conductivity, but pin-type busbars often have lower contact resistance.

Applications: Fork-type busbars are particularly useful when there are two input terminals for voltage, while pin-type are more universal for MCBs.

Customization: Fork-type busbars can be more easily personalized by reducing their length, offering greater adaptability in some installations.

When choosing between pin-type and fork-type busbars, consider factors such as the specific MCB configuration, ease of maintenance, and the potential need for future modifications to the electrical system.

Safety Features and Ratings

Safety features in MCB busbar systems include built-in circuit breakers that automatically trip during faults, isolating faulty sections to prevent further damage. These systems are designed to operate at voltages up to 415V and can handle currents ranging from 63A to 225A, depending on their size. The rated impulse withstand voltage is 4kV, ensuring protection against voltage spikes. When using the maximum busbar size of 36mm², it’s important to note that the largest compatible cable is 6 AWG (16mm²).

Busbar Selection Criteria

When selecting circuit breaker busbars, consider the following key factors:

Current capacity: Choose busbars rated for the maximum expected current load, accounting for factors like ambient temperature and altitude.

Voltage rating: Ensure the busbar can handle the system’s operational voltage, including potential surges.

Short-circuit current: Select busbars capable of withstanding the maximum fault current in the system.

Number of poles: Match the busbar configuration (1P, 2P, 3P, 4P) to your circuit requirements.

Compatibility: Verify the busbar is compatible with your specific circuit breaker models and mounting arrangements.

Environmental conditions: Consider factors like humidity, temperature, and potential exposure to corrosive elements when selecting materials and insulation.

Always consult manufacturer specifications and local electrical codes to ensure proper selection and installation of circuit breaker busbars for your specific application.

Advantages of Copper vs. Aluminum Busbars

Copper and aluminum busbars each offer distinct advantages in electrical systems. Copper busbars excel in conductivity, with approximately 60% higher electrical conductivity than aluminum. This superior conductivity allows copper busbars to carry more current in a smaller cross-section, making them ideal for space-constrained applications. Copper also demonstrates excellent corrosion resistance and thermal management, dissipating heat efficiently and reducing the risk of system failure.

On the other hand, aluminum busbars shine in terms of cost-effectiveness and weight. Aluminum is generally more affordable than copper, making it an attractive option for large-scale projects or budget-sensitive applications. Additionally, aluminum’s lower density results in lighter busbars, which can be advantageous in industries like aerospace and automotive where weight reduction is crucial. While aluminum requires additional surface treatments to enhance corrosion resistance, its natural oxide layer provides some inherent protection. Ultimately, the choice between copper and aluminum busbars depends on specific project requirements, balancing factors such as conductivity, cost, weight, and environmental conditions.

Quality MCB Busbar Criteria

A high-quality MCB busbar can be defined by several key characteristics:

- Material composition: Superior busbars are typically made of high-conductivity copper or aluminum, with copper being preferred for its excellent electrical properties and corrosion resistance.

- Insulation: Quality busbars feature robust insulation, often using materials like PET film or heat-resistant plastics such as Cycoloy 3600, ensuring safety and preventing electrical leakage.

- Current capacity: Good busbars should have appropriate current ratings for their intended application, with common ratings ranging from 63A to 225A.

- Certification compliance: High-quality busbars meet or exceed industry standards, such as UL489, CSA C22.2 No.5, and RoHS requirements.

- Durability: Superior busbars demonstrate high mechanical strength, with impact resistance ratings like IK10, and can withstand harsh environmental conditions.

A good quality MCB busbar should also offer flexibility in installation, such as the ability to be cut to size, and provide accessories like end caps and protective covers for enhanced safety and functionality. Additionally, it should exhibit low electromagnetic emissions and efficient heat dissipation to ensure reliable performance in various electrical systems.

Busbar Testing Methods

To check if a circuit breaker busbar is working properly, follow these steps:

Perform a visual inspection for signs of damage, corrosion, or loose connections.

Use a multimeter to test voltage:

Set the multimeter to measure AC voltage

Place one probe on the busbar terminal and the other on the neutral bus

A reading close to the rated voltage (e.g., 120V or 240V) indicates the busbar is energized

Check continuity:

Set the multimeter to continuity or resistance mode

Test between the busbar terminal and breaker output terminal

A near-zero resistance reading indicates proper connection

Conduct an insulation resistance test:

Use a megger to measure insulation resistance between phases and between each phase and ground

Readings should meet manufacturer specifications

Perform a contact resistance test using a Digital Low Resistance Ohmmeter (DLRO) to ensure low resistance at connection points

If any issues are detected during these tests, consult a qualified electrician for further inspection and potential repairs.

Chinese MCB Busbar Producers

China has emerged as a leading global manufacturer of MCB (Miniature Circuit Breaker) busbars, with several companies specializing in this essential electrical component. Among them, VIOX Electric stands out for its advanced manufacturing techniques and commitment to quality, catering to diverse industrial needs with precision-engineered products.As a reliable supplier in the global market, VIOX Electric offers an extensive range of busbar solutions tailored to various specifications. Its emphasis on innovation and rigorous quality control highlights China’s leadership in the MCB busbar industry.

Custom OEM Circuit Breaker Busbars

VIOX Electric is ready to assist you with your OEM circuit breaker busbar needs. We offer high-quality and cost-effective solutions.