Direct Answer: What is an Electrical Fuse and Why Does It Matter?

An electrical fuse is a sacrificial overcurrent protection device containing a metal element that melts when excessive current flows through it, automatically breaking the circuit to prevent equipment damage, fire hazards, and electrical system failures. Unlike resettable circuit breakers, fuses provide faster response times (0.002-0.004 seconds) and are non-reusable, making them ideal for protecting sensitive electronics, industrial machinery, and high-voltage systems where rapid fault isolation is critical.

For engineers specifying protection devices, fuses offer three key advantages: ultra-fast interruption during short circuits, precise current-limiting characteristics for semiconductor protection, and cost-effective reliability in applications ranging from 32V automotive systems to 33kV power distribution networks. This guide provides the technical framework for selecting, sizing, and applying fuses according to IEC 60269, UL 248, and industry best practices.

Section 1: How Electrical Fuses Work—The Physics of Protection

The Fundamental Operating Principle

Electrical fuses operate on the heating effect of electric current (Joule heating), expressed by the formula:

Q = I²Rt

Where:

- Q = Heat generated (Joules)

- I = Current flowing through fuse element (Amperes)

- R = Resistance of fuse element (Ohms)

- t = Time duration (seconds)

When current exceeds the fuse’s rated value, the I²t energy causes the fuse element to reach its melting point, creating an open circuit that interrupts current flow within milliseconds.

Three-Stage Fuse Operation Sequence

| Stage | Process | Duration | Physical Change |

|---|---|---|---|

| 1. Normal Operation | Current flows through fuse element | Continuous | Element temperature < melting point |

| 2. Pre-Arcing | Overcurrent heats element to melting point | 0.001-0.1 seconds | Element begins to melt, resistance increases |

| 3. Arcing & Clearing | Molten metal vaporizes, arc forms and extinguishes | 0.001-0.003 seconds | Arc quenched by filler material, circuit opens |

Critical insight: The I²t value (ampere-squared seconds) determines fuse selectivity and coordination. Fast-acting fuses have I²t values of 10-100 A²s, while time-delay fuses range from 100-10,000 A²s to tolerate motor starting currents.

Fuse Element Materials and Characteristics

| Material | Melting Point | Typical Application | Advantages |

|---|---|---|---|

| Tin | 232°C | Low-voltage, general purpose | Low cost, predictable melting |

| Copper | 1,085°C | Medium-voltage applications | Good conductivity, moderate speed |

| Silver | 962°C | High-performance, semiconductor protection | Excellent conductivity, fast response |

| Zinc | 420°C | Automotive, low-voltage circuits | Corrosion resistant, stable characteristics |

| Aluminum | 660°C | High-current applications | Lightweight, cost-effective |

Engineering note: Silver fuses provide the fastest interruption for sensitive semiconductor devices like IGBTs and SCRs, while copper-zinc alloys offer cost-effective protection for industrial motor circuits.

Section 2: Comprehensive Fuse Classification and Types

AC vs. DC Fuses: Critical Differences

| Parameter | AC Fuses | DC Fuses |

|---|---|---|

| Arc Extinction | Natural zero-crossing every 8.33ms (60Hz) | Continuous arc, requires forced extinction |

| Voltage Rating | 120V, 240V, 415V, 11kV | 12V, 24V, 48V, 110V, 600V, 1500V |

| Physical Size | Smaller for same current rating | Larger due to arc-quenching requirements |

| Breaking Capacity | Lower (arc self-extinguishes) | Higher (continuous DC arc) |

| Typical Applications | Building wiring, motor protection | Solar PV, EV charging, battery systems |

Why DC fuses are larger: DC current lacks the natural zero-crossing of AC, creating a sustained arc that requires longer fuse bodies filled with arc-quenching materials. A 32A DC fuse may be 50% larger than an equivalent AC fuse. Reference Reference

Major Fuse Categories by Construction

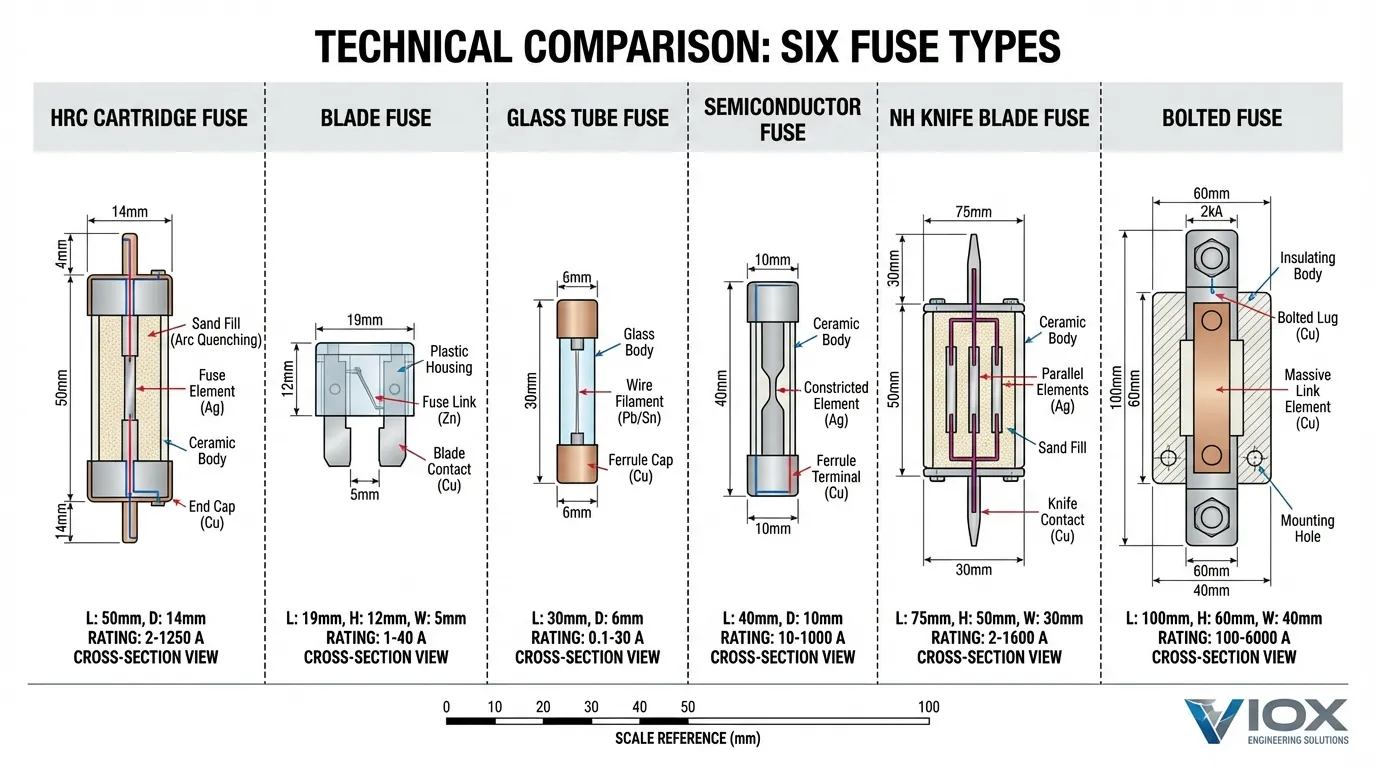

1. Cartridge Fuses

The most common industrial fuse type, featuring a cylindrical body with metal end caps:

- Ferrule Type: Cylindrical contacts, 2A-63A, used in control circuits

- Blade/Knife Type: Flat blade contacts, 63A-1250A, industrial power distribution

- Bolt-Down Type: Threaded studs, 200A-6000A, high-current applications

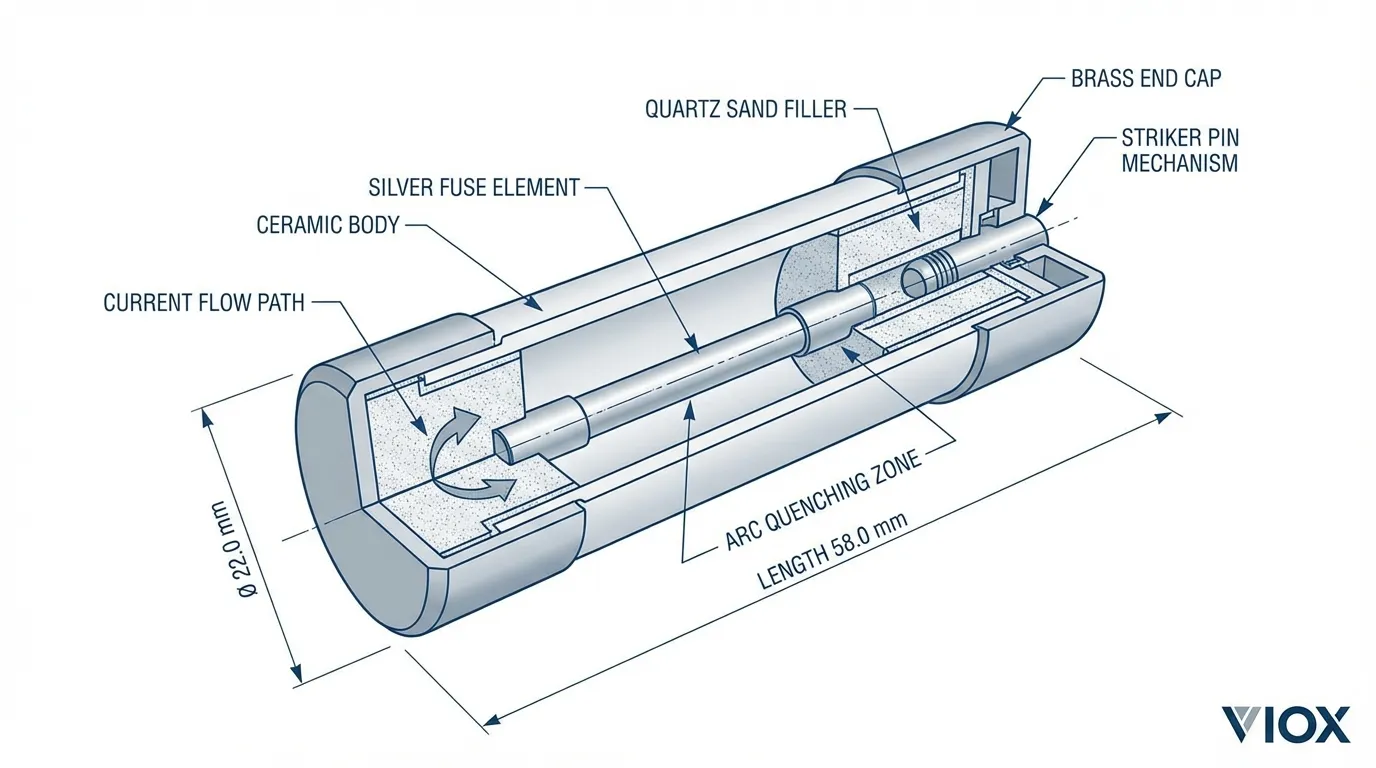

2. High Rupturing Capacity (HRC) Fuses

Specialized fuses capable of safely interrupting fault currents up to 120kA at 500V:

- Construction: Ceramic body filled with quartz sand, silver fuse element

- Arc quenching: Quartz sand absorbs heat and forms fulgurite (glass), extinguishing arc

- Standards: IEC 60269-2 (gG/gL types for general use, aM types for motor protection)

- Voltage ratings: Up to 33kV for power distribution applications

3. Automotive Blade Fuses

Color-coded plug-in fuses for 12V/24V/42V vehicle electrical systems:

| Type | Size | Current Range | Color Coding |

|---|---|---|---|

| Mini | 10.9mm × 16.3mm | 2A-30A | Standard automotive colors |

| Standard (ATO/ATC) | 19.1mm × 18.5mm | 1A-40A | Tan (1A) to Green (30A) |

| Maxi | 29.2mm × 34.3mm | 20A-100A | Yellow (20A) to Blue (100A) |

| Mega | 58.0mm × 34.0mm | 100A-500A | High-current EV applications |

4. Semiconductor Fuses (Ultra-Fast)

Designed specifically for protecting power electronics with I²t values < 100 A²s:

- Response time: < 0.001 seconds at 10× rated current

- Applications: VFD drives, solar inverters, UPS systems, EV chargers

- Construction: Multiple parallel silver ribbons for redundancy

- Coordination: Must coordinate with MCCB trip curves for selective protection

5. Rewirable vs. Non-Rewirable Fuses

| Feature | Rewirable (Kit-Kat) | Non-Rewirable (Cartridge) |

|---|---|---|

| Element replacement | User can replace fuse wire | Complete unit replacement required |

| Safety | Risk of incorrect wire gauge | Factory-calibrated, no tampering |

| Cost | Lower initial, higher maintenance | Higher initial, lower long-term |

| Modern use | Obsolete in new installations | Standard for all applications |

| Standards compliance | Not IEC/UL compliant | Meets IEC 60269, UL 248 |

Section 3: Critical Fuse Selection Parameters

The Six-Step Engineering Selection Process

STEP 1: Determine Normal Operating Current (I_n)

I_fuse = I_normal × 1.25 (minimum safety factor)

For motor circuits with high starting currents:

I_fuse = (I_FLA × 1.25) to (I_FLA × 1.5)

Where I_FLA = Full Load Amperes

STEP 2: Calculate Required Voltage Rating

Critical rule: Fuse voltage rating must exceed maximum system voltage:

| System Voltage | Minimum Fuse Rating |

|---|---|

| 120V AC single-phase | 250V AC |

| 240V AC single-phase | 250V AC |

| 415V AC three-phase | 500V AC |

| 12V DC automotive | 32V DC |

| 24V DC control | 60V DC |

| 48V DC telecom | 80V DC |

| 600V DC solar | 1000V DC |

| 1500V DC solar | 1500V DC |

STEP 3: Determine Breaking Capacity (Interrupting Rating)

The fuse must safely interrupt the maximum prospective short-circuit current at the installation point:

- Residential: 10kA typical

- Commercial: 25kA-50kA

- Industrial: 50kA-100kA

- Utility substations: 120kA+

Calculate prospective fault current using:

I_fault = V_system / Z_total

Where Z_total includes transformer impedance, cable impedance, and source impedance. Reference

STEP 4: Select Fuse Characteristic (Time-Current Curve)

| Fuse Type | I²t Value | Response Time | Application |

|---|---|---|---|

| FF (Ultra-Fast) | < 100 A²s | < 0.001s | Semiconductors, IGBTs, thyristors |

| F (Fast-Acting) | 100-1,000 A²s | 0.001-0.01s | Electronics, sensitive equipment |

| M (Medium) | 1,000-10,000 A²s | 0.01-0.1s | General purpose, lighting |

| T (Time-Delay) | 10,000-100,000 A²s | 0.1-10s | Motors, transformers, inrush loads |

STEP 5: Verify I²t Coordination

For selective coordination with upstream/downstream devices:

I²t_downstream < 0.25 × I²t_upstream

This ensures the branch fuse clears before the feeder fuse begins to melt.

STEP 6: Consider Environmental Factors

- Ambient temperature: Derate 10% for every 10°C above 25°C reference

- Altitude: Derate 3% per 1000m above sea level for breaking capacity

- Enclosure type: Confined spaces reduce heat dissipation

- Vibration: Use spring-loaded fuse holders for mobile equipment

Fuse Selection Quick Reference Table

| Load Type | Fuse Type | Sizing Factor | Example |

|---|---|---|---|

| Resistive heating | Fast-acting (F) | 1.25 × I_normal | 10A load → 12.5A fuse (use 15A) |

| Inductive motor | Time-delay (T) | 1.5-2.0 × I_FLA | 20A FLA → 30-40A fuse |

| Transformer | Time-delay (T) | 1.5-2.5 × I_primary | 15A primary → 25-40A fuse |

| Capacitor bank | Time-delay (T) | 1.65 × I_rated | 30A rated → 50A fuse |

| LED lighting | Fast-acting (F) | 1.25 × I_normal | 8A load → 10A fuse |

| VFD/Inverter | Ultra-fast (FF) | Per manufacturer spec | Consult VFD manual |

| Solar PV string | DC rated, gPV type | 1.56 × I_sc | 10A I_sc → 15A DC fuse |

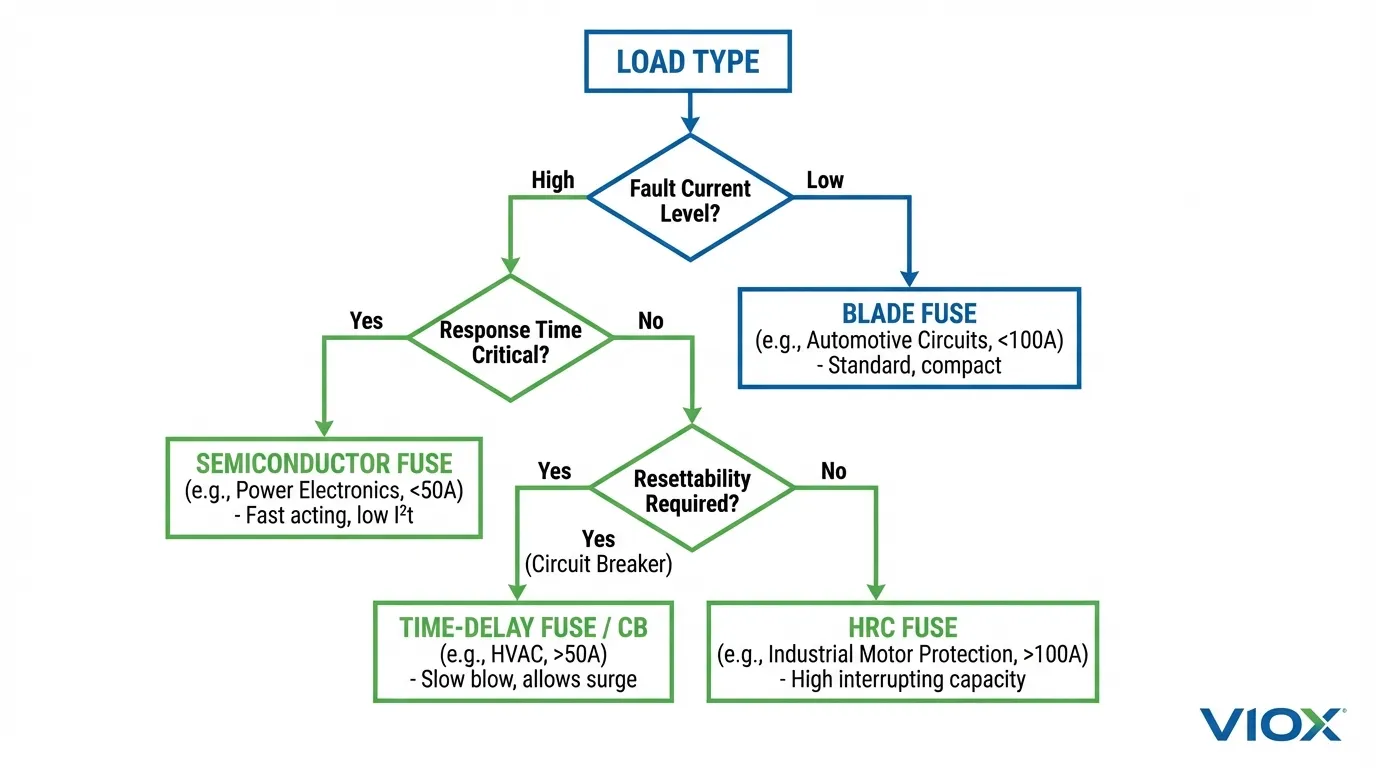

Section 4: Fuse vs. Circuit Breaker—When to Use Each

Comparative Analysis for Engineering Decisions

| Factor | Electrical Fuses | Circuit Breakers |

|---|---|---|

| Response time | 0.002-0.004s (ultra-fast) | 0.08-0.25s (thermal-magnetic) |

| Breaking capacity | Up to 120kA+ | Typically 10-100kA |

| Current limiting | Yes (I²t < 10,000 A²s) | Limited (depends on type) |

| Reusability | Single-use, must replace | Resettable, reusable |

| Initial cost | $2-$50 per fuse | $20-$500 per breaker |

| Maintenance | Replace after operation | Periodic testing required |

| Selectivity | Excellent (precise I²t curves) | Good (requires coordination study) |

| Physical size | Compact (1-6 inches) | Larger (2-12 inches) |

| Installation | Fuse holder required | Direct panel mounting |

| Arc flash energy | Lower (faster clearing) | Higher (slower clearing) |

When Fuses Are the Better Choice

- Semiconductor protection: VFDs, solar inverters, EV chargers require ultra-fast fuse response

- High fault currents: Breaking capacities > 100kA economically achieved with HRC fuses

- Precise coordination: Fuse I²t curves provide better selectivity than breaker trip curves

- Space-constrained installations: Fuses occupy 50-70% less panel space

- Cost-sensitive applications: Initial fuse + holder costs significantly less than equivalent breaker

- Infrequent fault conditions: Where replacement cost is acceptable

When Circuit Breakers Are Preferred

- Frequent overloads: Resettable breakers eliminate replacement costs

- Remote operation: Shunt trip breakers enable automatic control

- Maintenance accessibility: Easier testing and verification without replacement

- User convenience: Non-technical personnel can reset breakers

- Multi-function protection: RCBOs combine overcurrent and earth leakage protection

Hybrid approach: Many industrial installations use fuses for high-current feeders (cost-effective, high breaking capacity) and circuit breakers for branch circuits (convenience, resettability). Reference Reference

Section 5: Installation and Safety Best Practices

Critical Installation Requirements

1. Fuse Holder Selection

- Contact resistance: Must be < 0.001Ω to prevent overheating

- Vibration resistance: Spring-loaded clips for mobile equipment

- IP rating: IP20 minimum for indoor, IP54+ for outdoor installations

- Voltage isolation: Adequate creepage/clearance distances per IEC 60664

2. Series Connection Rules

Always install fuses on the line (hot) conductor, never on neutral or ground:

- Single-phase: One fuse on line conductor

- Three-phase: Three fuses (one per phase), or four-pole for TN-C systems

- DC circuits: Fuse on positive conductor (negative can be fused for isolation)

3. Coordination with Downstream Devices

Ensure proper selectivity with contactors, thermal overload relays, and branch circuit protection:

I²t_fuse < 0.75 × I²t_contactor_withstand

This prevents nuisance fuse operation during motor starting. Reference

Common Installation Mistakes to Avoid

| Mistake | Consequence | Correct Practice |

|---|---|---|

| Oversizing fuse | Cable overheating, fire risk | Size fuse to protect cable, not load |

| Using AC fuse in DC circuit | Sustained arc, explosion | Always use DC-rated fuses for DC systems |

| Poor contact pressure | Overheating, premature failure | Torque to manufacturer specification |

| Mixing fuse types | Loss of coordination | Use consistent fuse family for selectivity |

| Ignoring ambient temperature | Nuisance blowing or under-protection | Apply temperature derating factors |

Key Takeaways

Essential Engineering Principles for Fuse Selection:

- Fuses provide faster protection (0.002s) than circuit breakers (0.08s), critical for semiconductor and sensitive electronics

- I²t value determines selectivity—ultra-fast (< 100 A²s) for semiconductors, time-delay (> 10,000 A²s) for motors

- DC fuses require higher breaking capacity than AC equivalents due to continuous arc without zero-crossing

- HRC fuses handle fault currents up to 120kA, making them ideal for high-capacity industrial installations

- Proper sizing requires 1.25× safety factor for resistive loads, 1.5-2.0× for inductive motor loads

- Voltage rating must exceed system voltage—use 250V fuses for 120V circuits, 500V for 415V systems

- Coordination requires I²t_downstream < 0.25 × I²t_upstream for selective fault isolation

- Temperature derating: 10% reduction per 10°C above 25°C ambient reference

- Never use AC-rated fuses in DC circuits—DC requires specialized arc-quenching construction

- Fuse + holder costs 60-80% less than equivalent circuit breaker for high-current applications

When Specification Accuracy Matters:

Proper fuse selection isn't just about meeting current ratings—it's about engineering systems that provide reliable, selective protection while minimizing downtime and equipment damage. The combination of ultra-fast response times, precise I²t characteristics, and high breaking capacity makes fuses indispensable for protecting modern electrical systems from solar PV arrays to industrial motor control centers.

VIOX Electric's comprehensive line of industrial fuses, fuse holders, and circuit protection devices are engineered for demanding industrial environments. Our technical support team provides application-specific guidance for complex protection coordination and fuse selection.

Frequently Asked Questions

Q1: Can I replace a blown fuse with a higher-rated fuse if it keeps blowing?

No—this is extremely dangerous. Repeated fuse blowing indicates an underlying problem: overloaded circuit, short circuit, or failing equipment. Installing a higher-rated fuse removes the protection, allowing cables to overheat beyond their ampacity, creating fire risk. Instead, investigate the root cause: measure actual load current, check for short circuits, and verify cable sizing. The fuse rating should be 1.25× normal operating current or sized to protect the smallest cable in the circuit, whichever is lower. Reference

Q2: What's the difference between gG, gL, and aM fuse types in IEC 60269?

- gG (general purpose): Full-range breaking capacity from 1.3× to 100× rated current, protects cables and general loads

- gL (cable protection): Optimized for cable protection, similar to gG but with slightly different time-current characteristics

- aM (motor protection): Partial-range protection, only interrupts high fault currents (typically > 8× rated), requires separate overload protection like thermal relays

For motor circuits, use aM fuses with contactor and overload relay for complete protection. For general circuits, use gG/gL fuses alone.

Q3: Why do solar PV systems require special DC fuses?

Solar PV systems present unique challenges: high DC voltage (up to 1500V), continuous current without zero-crossing, and reverse current from parallel strings. Standard AC fuses cannot safely interrupt DC arcs. PV-specific fuses (gPV type per IEC 60269-6) feature:

- Enhanced arc-quenching capability for DC voltages

- Voltage ratings up to 1500V DC

- Sizing per NEC 690.9: 1.56 × string short-circuit current (I_sc)

- Reverse current rating for parallel string protection

Never substitute AC fuses in solar applications—the sustained DC arc can cause catastrophic failure. Reference Reference

Q4: How do I calculate the correct fuse size for a three-phase motor?

For three-phase motors, fuse sizing depends on starting method and fuse type:

Direct-On-Line (DOL) starting with time-delay fuses:

I_fuse = (1.5 to 2.0) × I_FLA

Star-Delta starting:

I_fuse = (1.25 to 1.5) × I_FLA

With VFD/Soft-starter:

I_fuse = (1.25 to 1.4) × I_FLA

Example: 15kW motor, 415V, FLA = 30A, DOL starting:

I_fuse = 1.75 × 30A = 52.5A → Select 63A time-delay fuse

Always verify coordination with motor starter components and consult motor manufacturer recommendations. Reference

Q5: What does the I²t rating mean and why is it important?

I²t (ampere-squared seconds) represents the thermal energy a fuse lets through before clearing a fault:

I²t = ∫(i²)dt

This value determines:

- Selectivity/Coordination: Downstream fuse I²t must be < 25% of upstream fuse I²t

- Component protection: Fuse I²t must be less than protected device's withstand rating

- Arc flash energy: Lower I²t = less arc flash hazard

Example: Protecting an IGBT with 5,000 A²s withstand rating requires a semiconductor fuse with I²t < 4,000 A²s at maximum fault current. Standard fuses with I²t > 10,000 A²s would allow IGBT destruction before clearing.

Q6: Can I use automotive blade fuses in industrial control panels?

Not recommended. While both are fuses, they're designed for different environments:

| Parameter | Automotive Blade | Industrial Cartridge |

|---|---|---|

| Voltage rating | 32V DC maximum | 250V-1000V AC/DC |

| Breaking capacity | 1kA-2kA | 10kA-120kA |

| Environmental rating | Automotive (vibration, temperature) | Industrial (IP ratings, pollution degree) |

| Standards | SAE J1284, ISO 8820 | IEC 60269, UL 248 |

| Certification | Not UL/CE for industrial | UL/CE/IEC certified |

Industrial control panels require IEC 60269 or UL 248 certified fuses with adequate breaking capacity for the installation's prospective fault current. Use automotive fuses only in vehicle electrical systems. Reference

Q7: How often should fuses be replaced even if they haven't blown?

Fuses don't have a fixed replacement interval if they haven't operated. However, inspect fuses during scheduled maintenance:

- Visual inspection: Annually for discoloration, corrosion, or mechanical damage

- Contact resistance: Every 2-3 years using micro-ohmmeter (should be < 0.001Ω)

- Thermal imaging: Annually to detect hot spots indicating poor contact

- After fault clearing: Always replace fuses that have operated

- Environmental exposure: More frequent inspection in corrosive, high-temperature, or high-vibration environments

Replace fuses immediately if:

- Contact resistance exceeds manufacturer specification

- Thermal imaging shows > 10°C temperature rise above ambient

- Visual signs of overheating (discoloration, melted holder)

- After any fault operation (fuses are single-use devices)

Q8: What's the difference between fast-acting and time-delay fuses, and when should I use each?

Fast-acting (F) fuses blow quickly at overcurrents, providing sensitive protection:

- Response: 0.001-0.01 seconds at 10× rated current

- Applications: Electronics, semiconductors, sensitive equipment without inrush currents

- I²t value: 100-1,000 A²s

Time-delay (T) fuses tolerate temporary overloads (motor starting, transformer inrush):

- Response: 0.1-10 seconds at 5× rated current, but still fast at high fault currents

- Applications: Motors, transformers, capacitors, any inductive load

- I²t value: 10,000-100,000 A²s

Selection rule: Use time-delay for any load with inrush current > 5× steady-state, fast-acting for loads with minimal inrush. When in doubt, consult equipment manufacturer specifications. Reference

Conclusion: Engineering Reliable Protection Through Proper Fuse Selection

Electrical fuses remain the most cost-effective, reliable, and fastest-responding overcurrent protection devices for applications ranging from 12V automotive systems to 33kV power distribution networks. Their fundamental advantage—ultra-fast response times of 0.002-0.004 seconds—makes them irreplaceable for protecting sensitive semiconductors, coordinating selective fault isolation, and minimizing arc flash hazards in industrial installations.

Professional Selection Best Practices:

- Calculate precisely: Use 1.25× factor for resistive loads, 1.5-2.0× for motors, verify I²t coordination

- Specify correctly: Match fuse type (AC/DC), voltage rating, breaking capacity, and time-current characteristic to application

- Install properly: Ensure adequate contact pressure, correct polarity, and environmental protection

- Coordinate systematically: Verify selectivity with upstream/downstream devices using I²t curves

- Maintain regularly: Inspect contacts, measure resistance, use thermal imaging to detect degradation

When Protection Reliability Matters:

The difference between adequate and inadequate fuse selection often comes down to understanding the relationship between load characteristics, fault current levels, and fuse I²t curves. Modern electrical systems—from solar PV installations to industrial motor control centers—demand precise protection coordination that only properly selected fuses can provide.

VIOX Electric's comprehensive range of HRC fuses, fuse holders, and industrial circuit protection devices are engineered for demanding applications worldwide. Our technical support team provides application-specific guidance for complex protection coordination, fuse selection, and system design.

For technical consultation on your electrical protection requirements, contact VIOX Electric's engineering team or explore our complete industrial electrical solutions.

Related Technical Resources:

- What is the Difference Between Fuse and Circuit Breaker?

- Fuse vs MCB Response Time Comparison

- What is a High Rupturing Capacity (HRC) Fuse?

- The Complete Guide to Fuse Holders

- AC Fuse vs DC Fuse: Critical Differences

- DC Circuit Breaker vs Fuse for Solar Systems

- How to Properly Fuse a Solar Photovoltaic System

- Solar PV Fuse Requirements: NEC 690.9 Parallel Strings

- Understanding Circuit Breaker Trip Curves

- Types of Circuit Breakers: Complete Guide