A surge protection device (SPD) is an electrical safety component that protects equipment and electrical systems from voltage spikes caused by lightning, power grid switching, or electrical faults. SPDs automatically divert excess electrical energy to ground, preventing damage to sensitive electronics, appliances, and electrical infrastructure. Understanding SPD technology, proper selection criteria, and installation requirements is critical for protecting your electrical investments, ensuring code compliance, and maintaining electrical safety in residential, commercial, and industrial applications.

What is a Surge Protection Device: Technical Definition

A surge protection device (SPD), also known as a surge protective device or transient voltage surge suppressor (TVSS), is an electrical component designed to protect circuits and connected equipment from voltage transients and surges. The device sits between your power source and your equipment, continuously monitoring voltage.

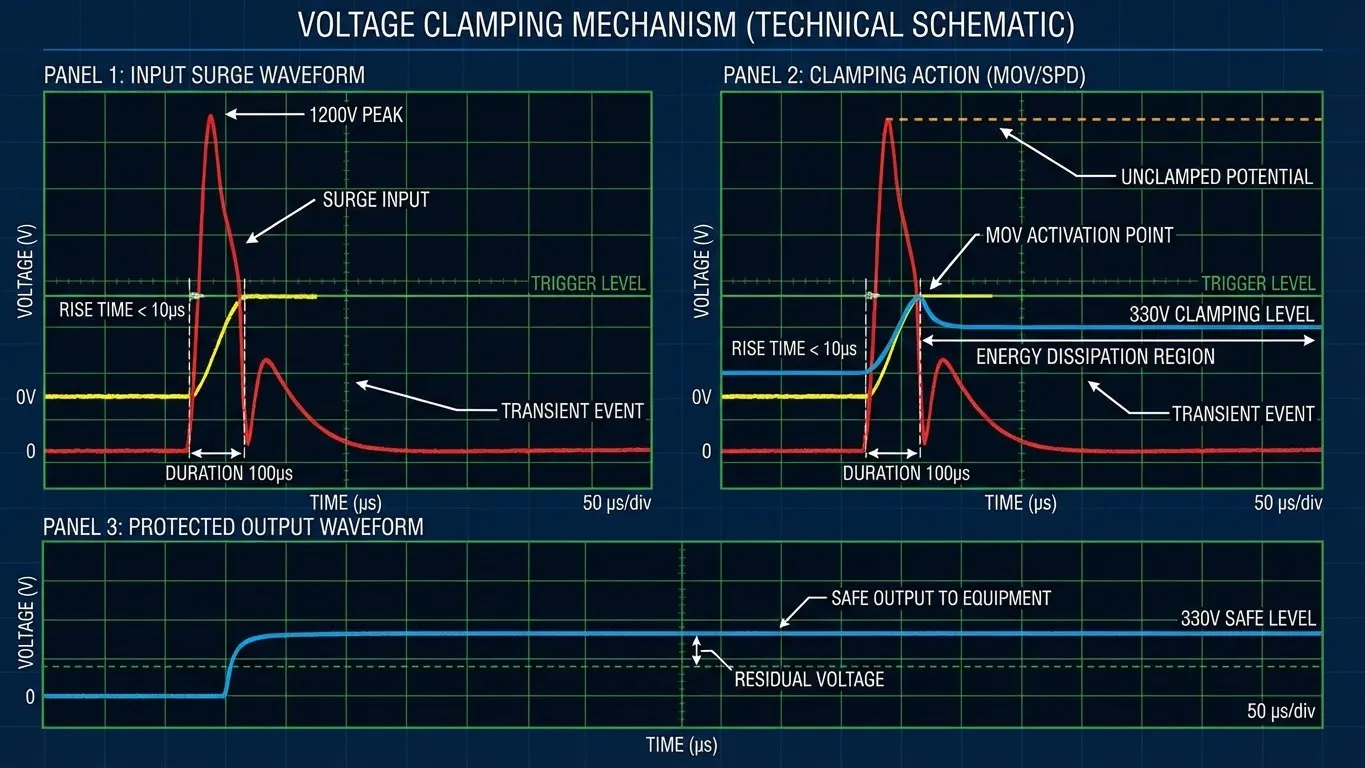

Under normal conditions (120V AC in North America, for example), the SPD remains electrically invisible—it presents high impedance and allows power to flow unimpeded to connected loads. The moment voltage rises above the SPD’s activation threshold—its clamping voltage or breakdown voltage—the device transitions to a low-impedance state and shunts the excess energy to ground or dissipates it internally.

Key Technical Characteristics:

- Voltage clamping: Limits maximum voltage to safe levels (typically 330V-500V for 120V circuits per UL 1449)

- Response time: Activates in nanoseconds to microseconds depending on technology

- Energy absorption: Rated in joules, indicating total surge energy the device can handle

- Maximum Continuous Operating Voltage (MCOV): Highest voltage the SPD can withstand continuously without activation

This clamping action holds the voltage seen by your equipment to a safer level, preventing damage to sensitive electronics. Once the transient passes, the SPD automatically returns to its high-impedance standby state, ready for the next event.

Understanding Electrical Surges: Sources and Impact

Electrical surges originate from two broad categories: external events originating outside your facility and internal transients generated by equipment within your own electrical system.

External Surge Sources

Lightning is the most dramatic external source. A direct strike to a power line can inject currents exceeding 100,000 amperes and voltages reaching tens of thousands of volts. Even indirect lightning—a strike a mile away—couples energy into utility distribution lines through electromagnetic induction, sending kilovolt-level surges into homes and businesses.

Utility switching operations generate surges when the power company opens or closes circuit breakers, switches capacitor banks, or clears faults on the grid. These events produce voltage spikes typically in the 600V to 1,000V range—less severe than lightning but far more frequent.

Internal Surge Sources

Your own facility generates transients every day. Large three-phase motors, HVAC compressors, elevators, and industrial machinery produce back-EMF (electromotive force) voltage spikes when they start or stop. Switching power supplies, variable-frequency drives (VFDs), and power factor correction capacitors create oscillatory transients. These internal surges are typically lower in peak voltage than lightning but occur far more frequently—dozens or hundreds of times per day in industrial settings.

How Surge Protection Devices Work: The Science Behind Protection

SPDs function as voltage-activated switches or clamps. They remain in a high-impedance (non-conductive) state during normal operation, then rapidly transition to a low-impedance (conductive) state when voltage exceeds their activation threshold.

The Protection Sequence

- Normal operation: Line voltage is 120V AC. The SPD presents extremely high resistance, drawing only microamperes of leakage current. Your equipment receives clean power.

- Surge event begins: A lightning strike or switching operation injects a transient. Voltage rises rapidly from 120V to 1,000V or higher within microseconds.

- SPD activates: When voltage crosses the component’s breakdown threshold, the device’s electrical properties change dramatically. Components like MOVs decrease resistance by orders of magnitude in nanoseconds.

- Energy diversion: Now in a low-impedance state, the SPD creates a path to ground. Surge current flows through the SPD instead of your equipment. The voltage is clamped to a safe level (e.g., 330V).

- Reset: As the surge waveform decays, voltage drops back toward normal. The SPD automatically returns to its high-impedance state, ready for the next event.

SPD Technologies: MOV, GDT, and TVS Comparison

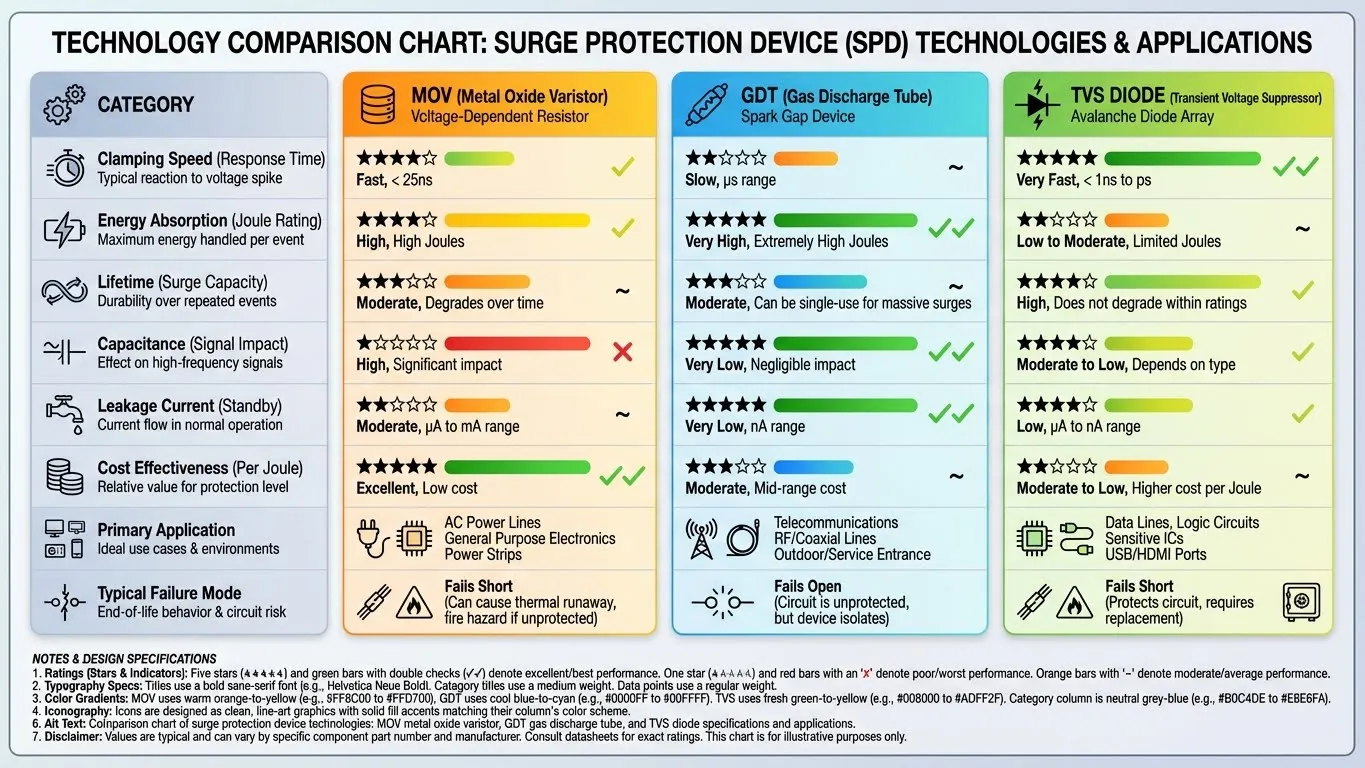

Surge protection devices rely on three core component technologies, each with distinct operating principles and performance characteristics.

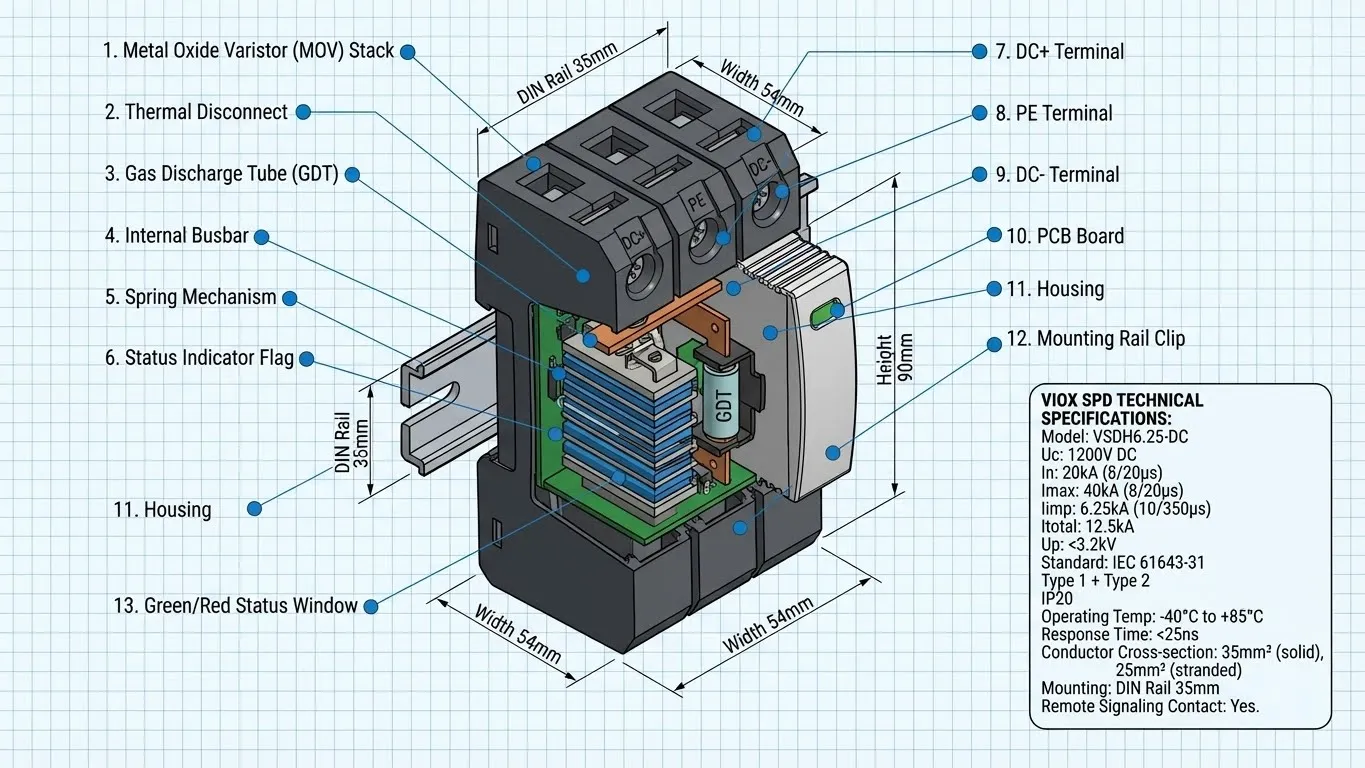

Metal Oxide Varistor (MOV)

Operating principle: A voltage-dependent resistor made from sintered zinc oxide grains. Each grain boundary acts like a microscopic diode junction. At low voltages, it acts as an insulator; above its rated voltage, the junctions break down and resistance drops to milliohms.

Performance characteristics: Fast response (nanoseconds), high energy capacity (kilojoules), and moderate clamping voltage. MOVs degrade cumulatively with each surge event, which is why they are often paired with thermal fuses.

Applications: The workhorse of surge protection. Found in power strips, whole-house SPDs, and industrial panels. Learn more about MOV aging and lifespan considerations.

Gas Discharge Tube (GDT)

Operating principle: A sealed tube filled with inert gas. Under normal voltage, it is an insulator. When voltage exceeds the sparkover threshold, the gas ionizes into a conductive plasma arc, creating a short circuit (crowbar action) that handles massive current.

Performance characteristics: Slower response (microseconds) but extremely high energy capacity (tens of kiloamperes). Excellent longevity but requires a “follow current” to be extinguished.

Applications: Service entrances and telecom/datacom primary protection.

Transient Voltage Suppressor (TVS) Diode

Operating principle: A silicon avalanche diode. It operates in reverse bias and enters avalanche breakdown when voltage exceeds its limit, clamping voltage precisely.

Performance characteristics: Fastest response (picoseconds), very precise clamping, but lower energy capacity compared to MOVs or GDTs.

Applications: Protecting sensitive electronics, data lines, and low-voltage DC circuits.

Technology Comparison Table

| Technology | Response Time | Energy Capacity | Clamping Precision | Typical Application |

|---|---|---|---|---|

| MOV | Nanoseconds | High (kJ) | Moderate | General AC/DC surge protection |

| GDT | Microseconds | Very High (kJ+) | Low initial, then crowbar | Service entrance, telecom primary |

| TVS Diode | Picoseconds | Low-Medium (J) | Very High | Data lines, DC circuits |

For detailed comparison, see our guide on MOV vs GDT vs TVS technologies.

SPD Classification: Types 1, 2, and 3

International standards such as IEC 61643-11 (AC systems), IEC 61643-31 (DC/PV systems), and UL 1449 (North America) define different SPD classes based on test waveforms, energy capability, and installation location.

Type 1 SPD (Class I)

Installation location: Service entrance, between meter and main panel

Protection level: Primary protection against direct lightning strikes

Test waveform: 10/350 μs current impulse

Surge rating: Typically 50-160 kA

Applications: Main electrical panels, outdoor installations, critical infrastructure

Type 2 SPD (Class II)

Installation location: Main electrical panel, subpanels

Protection level: Secondary protection against conducted surges

Test waveform: 8/20 μs current impulse

Surge rating: Typically 20-80 kA

Applications: Distribution panels, branch circuits, most residential and commercial installations

Type 3 SPD (Class III)

Installation location: Point of use, individual outlets

Protection level: Final protection for sensitive equipment

Test waveform: Combination wave (1.2/50 μs voltage, 8/20 μs current)

Surge rating: Typically 1-15 kA

Applications: Electronic devices, computers, appliances, home entertainment systems

SPD Type Selection Table

| Application Type | Recommended SPD Type | Minimum Surge Rating | Key Features Required |

|---|---|---|---|

| Residential Main Panel | Type 2, MOV technology | 40 kA per mode | UL 1449 listing, visual indicators |

| Commercial Distribution | Type 2, MOV or hybrid | 80-160 kA per mode | Remote monitoring, replaceable modules |

| Industrial Critical Loads | Type 1 + Type 2 coordination | 100+ kA per mode | Fail-safe design, backup protection |

| Point-of-Use Electronics | Type 3, SAD or MOV | 1-6 kA | Low clamping voltage, EMI filtering |

Understanding where to install SPDs is crucial for effective protection.

Critical SPD Specifications Explained

Joules Rating (Energy Absorption)

Indicates how much total energy the device can absorb before failure. Higher ratings generally mean longer service life. However, joules alone don’t indicate clamping performance—a device can have high joule rating but poor voltage clamping.

Clamping Voltage (VPR – Voltage Protection Rating)

The maximum voltage the SPD allows to pass through to your equipment. For 120V circuits, look for UL 1449 VPR ratings of 330V, 400V, or 500V. Lower is better for sensitive electronics. This is the most critical specification for equipment protection.

Maximum Continuous Operating Voltage (MCOV)

The highest voltage the SPD can withstand continuously without activation. Proper MCOV selection ensures the device doesn’t nuisance-trip during normal voltage variations.

Response Time

How quickly the device reacts to voltage spikes. While often marketed, standard MOVs (nanoseconds) are fast enough for almost all power-line surges. TVS diodes (picoseconds) are needed for data lines.

Short Circuit Current Rating (SCCR)

Maximum fault current the SPD can safely withstand without creating a fire hazard. Must be coordinated with upstream overcurrent protection devices.

SPD Applications by Industry

Residential Applications

Whole-house protection: Type 2 SPDs installed at the main panel protect the entire building from external surges (lightning, utility switching). They handle high energy (20-50 kA) but have higher clamping voltages (600-1000V).

Point-of-use protection: Type 3 power strips and plug-in units protect specific sensitive devices from residual voltage and internal surges. They offer tighter clamping (330-400V) but lower energy capacity.

Layered protection strategy: The best practice is to use both. A whole-house unit absorbs the bulk energy, while point-of-use units clean up the residual voltage for sensitive electronics. This approach is more effective than relying on surge protection vs GFCI or grounding alone.

Commercial and Industrial Applications

Critical infrastructure protection:

- Data centers: Multiple coordinated SPD stages protecting servers, network equipment, and cooling systems

- Manufacturing facilities: Protection for PLCs, motor drives, robotics, and process control systems

- Healthcare facilities: Medical imaging equipment, patient monitoring systems, and life-safety equipment

- Telecommunications: Protection for switching equipment, base stations, and fiber optic terminal equipment

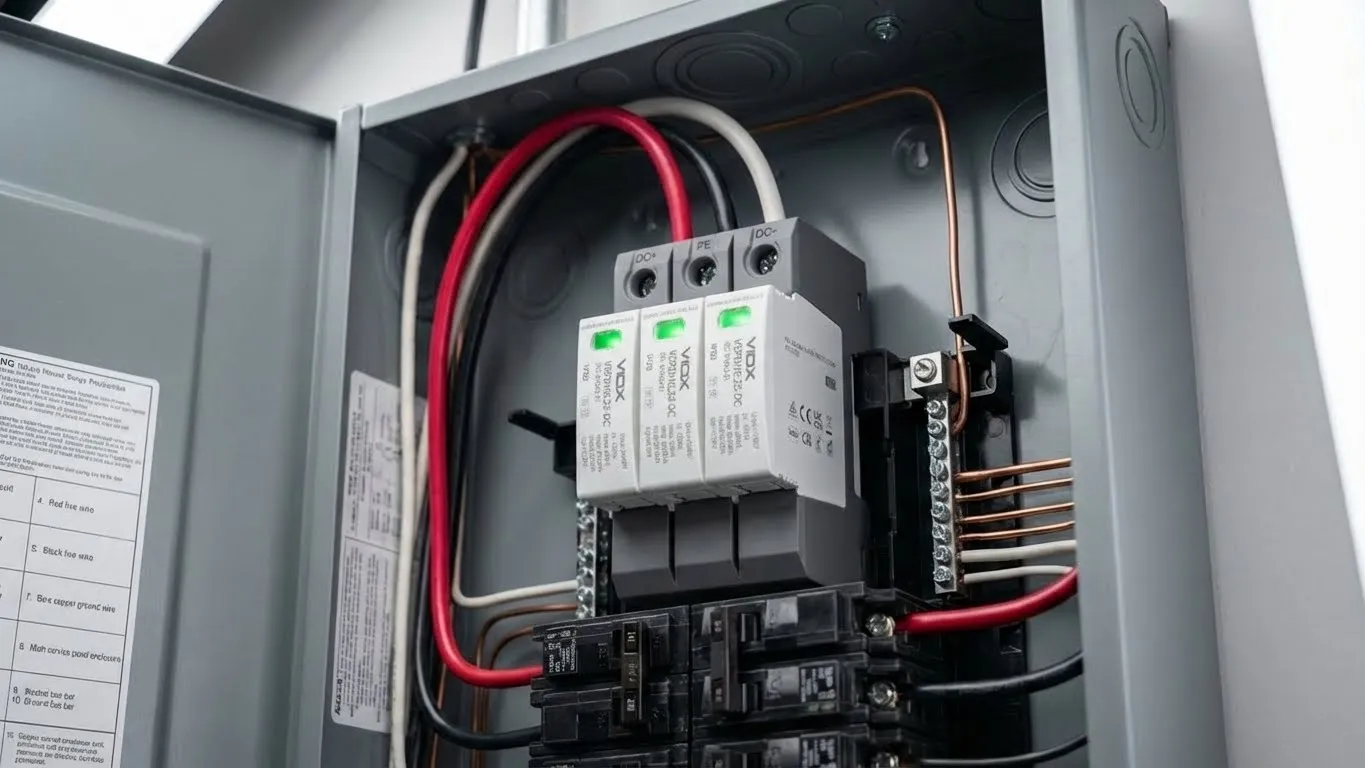

Solar PV systems: Specialized DC-rated SPDs for combiner boxes, inverters, and AC distribution. Must comply with IEC 61643-31 standards for photovoltaic applications.

Installation Requirements and Code Compliance

National Electrical Code (NEC) Requirements

Article 285 – Surge Protective Devices (SPDs):

- SPDs must be listed and labeled for the intended application (UL 1449)

- Installation must comply with manufacturer’s instructions

- SPDs require proper overcurrent protection coordination

- Grounding conductor length must be minimized (ideally less than 12 inches)

- Type 1 SPDs require disconnect means accessible to qualified persons

Avoiding common SPD installation mistakes is essential for effective protection.

Installation Best Practices

- Proper grounding: Use shortest possible ground path with minimum bends. Ground wire length directly impacts protection effectiveness.

- Coordination between SPD types: When using multiple protection stages, ensure proper coordination to prevent one device from being overwhelmed.

- Monitoring and maintenance: Install SPDs with visual indicators or remote monitoring capability. Regular inspection ensures continued protection.

⚠️ SAFETY WARNING: SPD installation must be performed by qualified electricians and inspected by local authorities. Working with electrical service equipment poses serious shock and arc flash hazards.

When to Replace Your Surge Protection Device

Visual Status Monitoring

Modern quality SPDs include visual indicators showing operational status:

- Green LED: Device is operating normally and providing protection

- Red LED or off: MOVs are compromised, device requires immediate replacement

- Blinking: Some models indicate degraded but still functional state

Replacement Indicators

- Indicator shows failure: If the “Protected” LED is off or red, the internal components are compromised. Replace immediately.

- After major surge events: Even if the indicator remains green, a massive event (like nearby lightning strike) can compromise internal components.

- Time-based replacement: In high-lightning areas or industrial environments with frequent internal surges, replace SPDs every 3-5 years as preventive maintenance.

- Physical damage: Any signs of overheating, discoloration, burned smell, or physical deformation indicate immediate replacement is needed.

SPD Lifespan Considerations

| SPD Type | Expected Service Life | Replacement Trigger |

|---|---|---|

| Whole-house Type 2 | 5-10 years | Indicator failure, major event, time-based |

| Point-of-use Type 3 | 3-5 years | Indicator failure, physical damage |

| Industrial high-exposure | 2-5 years | Regular preventive replacement schedule |

Learn more about SPD aging mechanisms and replacement strategies.

Selecting the Right SPD: Expert Decision Framework

Essential Selection Factors

- System voltage and configuration: Match SPD voltage rating to system nominal voltage (120V, 208V, 240V, 277V, 480V, etc.)

- Expected surge environment: Lightning exposure, utility reliability, internal load characteristics

- Protected equipment value: High-value equipment justifies higher-grade protection

- Compliance requirements: Verify UL 1449 or IEC 61643-11 certification, insurance requirements, local codes

- Installation location: Type selection based on optimal SPD placement

- Monitoring requirements: Remote monitoring for critical applications, visual indicators for standard installations

Quick Selection Guide

For residential main panel protection:

- Type 2 SPD, MOV technology

- 40-80 kA surge current rating

- VPR 600V or lower

- UL 1449 listed

- Visual status indicator

For commercial distribution panels:

- Type 2 SPD, MOV or hybrid technology

- 80-160 kA surge current rating

- Replaceable modules preferred

- Remote monitoring capability

- Coordinated with Type 1 at service entrance if required

For industrial critical loads:

- Coordinated Type 1 + Type 2 protection

- 100+ kA surge current rating

- Fail-safe design with thermal disconnect

- Network monitoring integration

- Redundant protection for critical circuits

Understanding the differences between TVSS and SPD terminology under UL 1449 standards helps ensure proper specification.

Frequently Asked Questions

What makes an SPD different from a basic power strip?

A true SPD is designed and tested specifically for surge protection with UL 1449 certification, proper clamping voltages, and adequate surge current capacity. Basic power strips often provide minimal or no actual surge protection—they’re just multi-outlet extension cords. Look for UL 1449 listing and specific surge ratings (kA and joules) to verify genuine protection capability.

How do I know if my SPD is working properly?

Most quality SPDs include visual status indicators (LED lights) showing operational status. Green typically means protecting, red means replace. If no indicator is present, the device should be tested by a qualified electrician using proper test equipment. Never assume an old SPD is still functional without verification.

Can I install an SPD myself?

Type 3 point-of-use SPDs (plug strips) can typically be installed by homeowners. However, Type 1 and Type 2 devices installed at electrical panels require installation by licensed electricians due to electrical code requirements, proper grounding techniques, and safety considerations when working with service equipment.

What size SPD do I need for my home?

For whole-house protection, a Type 2 SPD with 40-80 kA surge current rating is typically adequate for residential applications. The specific rating depends on your location’s lightning exposure, home size, and connected equipment value. Consult with a qualified electrician for recommendations based on your electrical system.

Do SPDs need to be replaced after a surge event?

Not necessarily. Quality SPDs are designed to handle multiple surge events. However, you should check status indicators and have the device inspected after any significant electrical event like nearby lightning strikes. MOV-based devices degrade cumulatively, so multiple moderate surges can eventually require replacement even if no single event causes immediate failure.

What electrical codes apply to SPD installation?

The National Electrical Code (NEC) Article 285 governs SPD installations in the United States. IEC 61643 standards apply internationally. Local codes may have additional requirements. Always verify current code requirements with local electrical authorities and ensure installations are performed by licensed professionals.

Conclusion: Protecting Your Electrical Investment

Surge protection devices offer an asymmetric return on investment: a modest cost for professional SPD installation can protect tens of thousands of dollars in equipment and prevent costly downtime. The Texas facility manager’s $45,000 HVAC replacement could have been prevented with a $500 whole-house SPD installation.

Whether using MOV, GDT, or TVS technology, modern SPDs provide proven, cost-effective protection when properly selected and installed. By understanding the three SPD types (Type 1, 2, and 3), key specifications (clamping voltage, surge current rating, MCOV), and employing a layered protection strategy, you can ensure your facility is resilient against the inevitable electrical transients of the modern grid.

Key takeaways for effective surge protection:

- Implement coordinated multi-level protection (whole-building + point-of-use)

- Select SPDs based on specific application requirements, not just lowest price

- Ensure proper installation by qualified electricians following NEC Article 285

- Monitor SPD status indicators and replace proactively

- Document SPD installations for insurance and maintenance records

For industrial facilities and commercial buildings, surge protection isn’t optional—it’s essential infrastructure that pays for itself the first time it prevents equipment damage. In residential applications, SPDs provide peace of mind that your home’s electrical system and connected devices are protected from unpredictable transient events.

The technology is mature, the standards are well-established, and the protection is proven. The only question is whether you’ll install comprehensive surge protection before or after experiencing costly equipment failure.