Introduction: From Theory to Practice—Calculating Cable Sizes That Work

Selecting cables for industrial control panels requires more than understanding derating principles—it demands precise mathematical calculations that account for ampacity, voltage drop, and physical space constraints. While temperature and grouping derating factors establish the thermal limits (covered comprehensively in our Electrical Derating Master Guide), this guide focuses on the practical formulas and trunking capacity calculations that transform those principles into real-world cable selections.

For panel builders and industrial electricians working to IEC 60204-1 standards, three critical calculations determine cable sizing success:

- Ampacity calculations with combined correction factors

- Voltage drop formulas for AC and DC circuits

- Trunking fill capacity based on cable geometry

At VIOX Electric, we manufacture industrial-grade circuit breakers, contactors, and control components for demanding panel environments. This guide provides the calculation methodologies, formulas, and trunking capacity tables needed to size cables correctly according to IEC 60204-1.

Understanding IEC 60204-1 Cable Sizing Framework

IEC 60204-1:2016 (Safety of machinery – Electrical equipment of machines – Part 1: General requirements) establishes the calculation framework for machine-mounted electrical equipment. Unlike building wiring codes, this standard addresses confined panel spaces where precise calculations are essential.

The Three-Pillar Calculation Approach

| Calculation Type | Purpose | Failure Consequence |

|---|---|---|

| Ampacity (Current-Carrying Capacity) | Ensures cable doesn’t overheat | Insulation degradation, fire risk |

| Voltage Drop | Maintains adequate voltage at load | Equipment malfunction, nuisance trips |

| Trunking Fill | Prevents mechanical damage | Installation difficulty, cable damage |

Key IEC 60204-1 Requirements:

- Reference temperature: 40°C (not 30°C like building codes)

- Minimum cable sizes: 1.5mm² power, 1.0mm² control

- Voltage drop limits: 5% control circuits, 10% power circuits

- Continuous load factor: 1.25× for loads operating >3 hours

For detailed derating factor tables and thermal principles, see our comprehensive Electrical Derating Guide.

Section 1: Cable Ampacity Calculation Formulas

Master Formula: Adjusted Ampacity Calculation

The fundamental equation for determining safe current-carrying capacity:

Where:

- I_z = Adjusted ampacity (safe current-carrying capacity after all corrections)

- I_n = Nominal ampacity from standard tables at reference conditions (40°C, single circuit)

- k₁ = Temperature correction factor

- k₂ = Grouping/bundling correction factor

- k₃ = Installation method correction factor

- k₄ = Additional correction factors (thermal insulation, soil burial, etc.)

Reverse Calculation: Required Cable Size

To determine the minimum cable size needed for a given load:

Where:

- I_b = Design current (load current × 1.25 for continuous loads)

- I_n_required = Minimum nominal ampacity needed from tables

Then select a cable size where: I_n (from tables) ≥ I_n_required

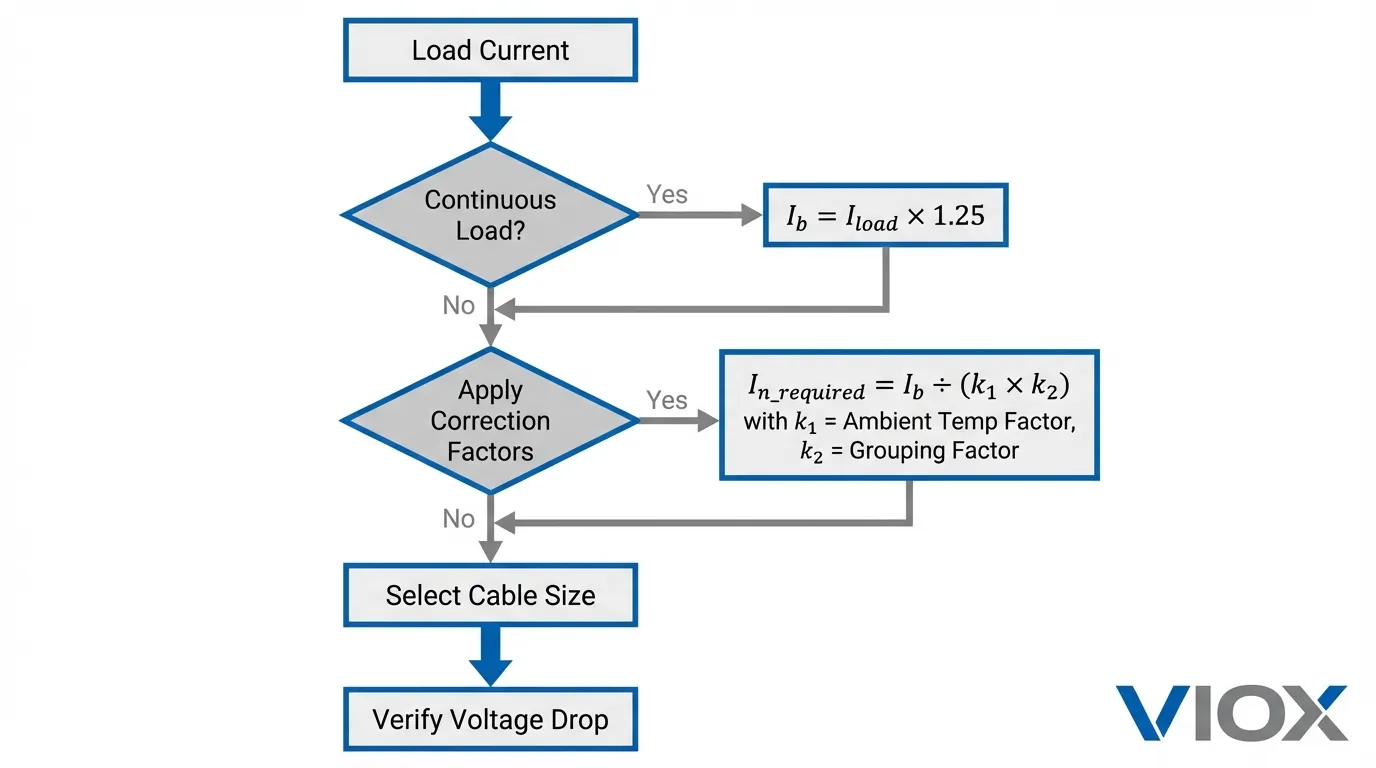

Step-by-Step Calculation Process

STEP 1: Calculate Design Current

- I_load = Actual load current (A)

- F_continuous = 1.25 for loads operating >3 hours, 1.0 otherwise

- F_safety = 1.0 to 1.1 (optional safety margin)

STEP 2: Select Protective Device Rating

Choose standard circuit breaker rating that meets or exceeds design current.

STEP 3: Determine Correction Factors

Measure or estimate:

- Panel internal temperature → k₁ (see derating guide)

- Number of current-carrying conductors → k₂ (see derating guide)

- Installation method → k₃ (typically 1.0 for panel installations)

STEP 4: Calculate Required Nominal Ampacity

STEP 5: Select Cable from Tables

Choose conductor size where I_n ≥ I_n_required

STEP 6: Verify Voltage Drop (see Section 2)

Worked Example 1: Three-Phase Motor Circuit

Given:

- Motor: 11kW, 400V three-phase, 22A full-load current

- Panel temperature: 50°C

- Installation: 8 circuits in common trunking

- Cable type: Copper XLPE (90°C insulation)

I_b = 22A × 1.25 = 27.5A

Step 2: Protective device

Select 32A circuit breaker (I_n_device = 32A)

Step 3: Correction factors

k₁ = 0.87 (50°C, XLPE from derating tables)

k₂ = 0.70 (8 circuits in trunking)

k₃ = 1.00

Step 4: Required nominal ampacity

I_n_required = 32A ÷ (0.87 × 0.70 × 1.00)

I_n_required = 32A ÷ 0.609 = 52.5A

Step 5: Cable selection

From IEC 60228 tables: 6mm² copper XLPE = 54A at 40°C

✓ Select 6mm² cable (54A > 52.5A required)

Worked Example 2: DC Control Circuit

Given:

- Load: 24VDC PLC system, 15A continuous

- Panel temperature: 55°C

- Installation: 15 circuits in cable duct

- Cable type: Copper PVC (70°C insulation)

I_b = 15A × 1.25 = 18.75A

Step 2: Protective device

Select 20A DC circuit breaker

Step 3: Correction factors

k₁ = 0.71 (55°C, PVC)

k₂ = 0.60 (15 circuits)

Step 4: Required nominal ampacity

I_n_required = 20A ÷ (0.71 × 0.60)

I_n_required = 20A ÷ 0.426 = 46.9A

Step 5: Cable selection

From tables: 4mm² copper PVC = 36A (insufficient)

Try 6mm²: 46A (insufficient)

Try 10mm²: 63A at 40°C

✓ Select 10mm² cable

Note: DC control circuits often require larger cables than AC due to strict voltage drop limits (see Section 2).

Quick Reference: Combined Correction Factor Impact

| Scenario | Temp | Cables | k₁ | k₂ | Combined | Ampacity Impact |

|---|---|---|---|---|---|---|

| Ideal | 40°C | 1-3 | 1.00 | 1.00 | 1.00 | 100% (no reduction) |

| Typical | 50°C | 6 | 0.87 | 0.70 | 0.61 | 61% (39% reduction) |

| Dense | 55°C | 12 | 0.79 | 0.60 | 0.47 | 47% (53% reduction) |

| Extreme | 60°C | 20 | 0.71 | 0.57 | 0.40 | 40% (60% reduction) |

Critical insight: In dense control panels, cables may require 2-3 times the ampacity of the protective device rating to achieve safe operation after derating.

Section 2: Voltage Drop Calculation Formulas

While ampacity ensures cables don’t overheat, voltage drop calculations ensure equipment receives adequate voltage—particularly critical for control circuits, contactors, and relays that malfunction with insufficient voltage.

IEC 60204-1 Voltage Drop Limits

| Circuit Type | Maximum VD | Typical Application |

|---|---|---|

| Control circuits | 5% | PLCs, relays, contactors, sensors |

| Power circuits | 10% | Motors, heaters, transformers |

| Lighting circuits | 5% | Panel lighting, indicator lamps |

DC Circuit Voltage Drop Formula

For DC and single-phase AC circuits (simplified resistive calculation):

Where:

- VD = Voltage drop (V)

- L = One-way cable length (m)

- I = Load current (A)

- ρ = Resistivity (Ω·mm²/m)

- Copper at 20°C: 0.0175

- Copper at 70°C: 0.0209

- Aluminum at 20°C: 0.0278

- A = Conductor cross-sectional area (mm²)

- Factor of 2 accounts for current flowing through both supply and return conductors

Percentage voltage drop:

Temperature-Adjusted Resistivity

Cable resistance increases with temperature, affecting voltage drop:

Where:

- ρ_T = Resistivity at temperature T

- ρ₂₀ = Resistivity at 20°C reference

- α = Temperature coefficient

- Copper: 0.00393 per °C

- Aluminum: 0.00403 per °C

- T = Operating temperature (°C)

Common temperature-adjusted resistivity values:

| Material | 20°C | 40°C | 60°C | 70°C | 90°C |

|---|---|---|---|---|---|

| Copper | 0.0175 | 0.0189 | 0.0202 | 0.0209 | 0.0224 |

| Aluminum | 0.0278 | 0.0300 | 0.0323 | 0.0335 | 0.0359 |

Three-Phase AC Voltage Drop Formula

For balanced three-phase circuits:

Additional parameter:

- cos φ = Power factor (typically 0.8-0.9 for motor loads, 1.0 for resistive)

For circuits with significant reactance (large cables, long runs):

- X_L = Inductive reactance (Ω/km, from cable manufacturer data)

- sin φ = √(1 – cos²φ)

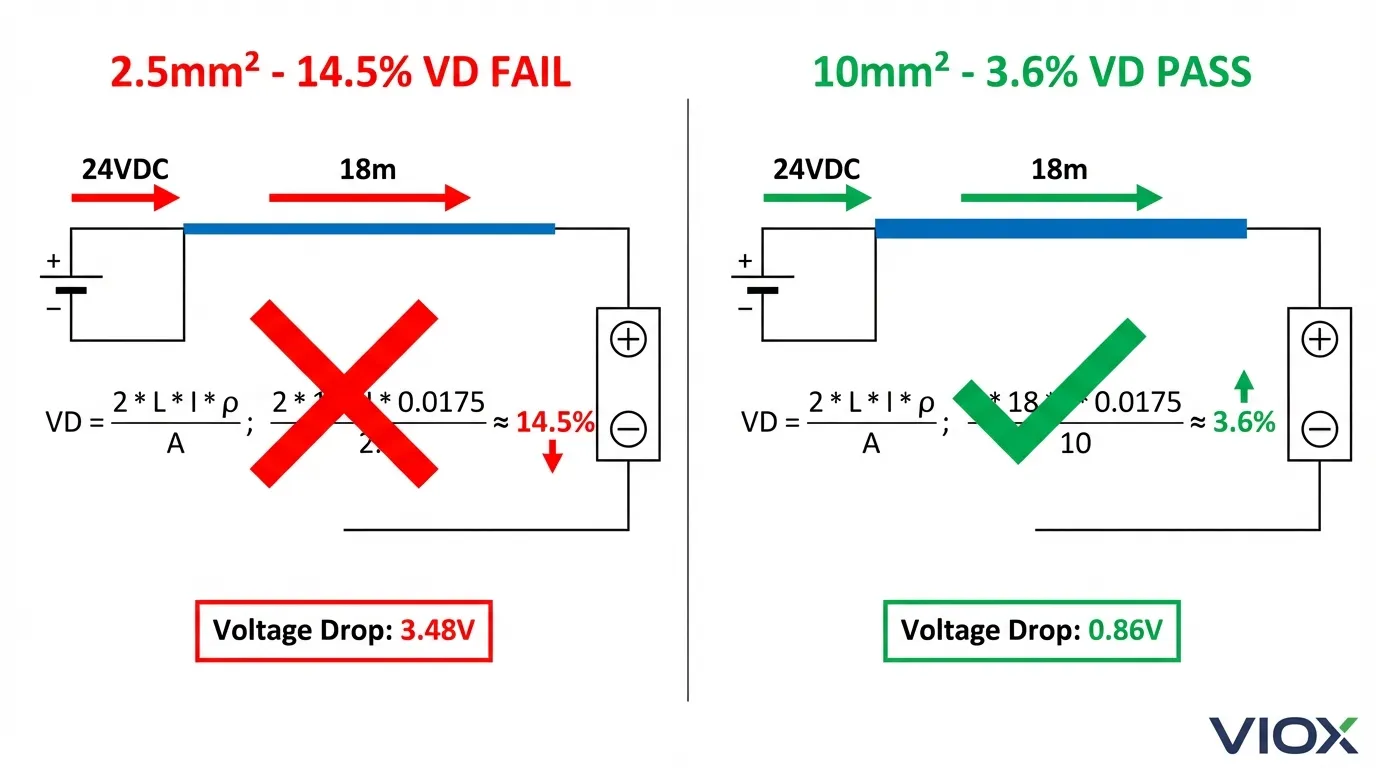

Worked Example 3: DC Control Circuit Voltage Drop

Given:

- System: 24VDC power supply to PLC rack

- Load current: 12A continuous

- Cable length: 18 meters (one-way)

- Cable: 2.5mm² copper

- Operating temperature: 60°C

- Maximum allowable VD: 5% (1.2V)

ρ₆₀ = 0.0175 × [1 + 0.00393(60 – 20)]

ρ₆₀ = 0.0175 × [1 + 0.1572]

ρ₆₀ = 0.0202 Ω·mm²/m

Step 2: Voltage drop

VD = (2 × 18m × 12A × 0.0202) ÷ 2.5mm²

VD = 8.73 ÷ 2.5

VD = 3.49V

Step 3: Percentage drop

VD% = (3.49V ÷ 24V) × 100% = 14.5%

Result: ✗ FAILS (14.5% > 5% limit)

Solution: Upsize cable

VD = 8.73 ÷ 6mm² = 1.46V

VD% = (1.46V ÷ 24V) × 100% = 6.08%

Still exceeds 5% limit

Try 10mm²:

VD = 8.73 ÷ 10mm² = 0.87V

VD% = (0.87V ÷ 24V) × 100% = 3.64%

✓ PASSES (3.64% < 5% limit)

Final selection: 10mm² cable

Critical lesson: DC control circuits with long cable runs often require significantly larger conductors than ampacity calculations suggest.

Worked Example 4: Three-Phase Motor Circuit

Given:

- Motor: 15kW, 400V three-phase, 30A, cos φ = 0.85

- Cable length: 25 meters

- Cable: 6mm² copper XLPE

- Operating temperature: 70°C

ρ₇₀ = 0.0209 Ω·mm²/m

Step 2: Voltage drop (simplified resistive)

VD = (√3 × 25m × 30A × 0.0209 × 0.85) ÷ 6mm²

VD = (1.732 × 25 × 30 × 0.0209 × 0.85) ÷ 6

VD = 23.09 ÷ 6 = 3.85V

Step 3: Percentage drop (line-to-line)

VD% = (3.85V ÷ 400V) × 100% = 0.96%

✓ PASSES (0.96% < 10% limit)

Voltage Drop Quick Reference Tables

Maximum cable length (meters) for 5% voltage drop in DC circuits:

| Current | 24VDC (1.2V drop) | 48VDC (2.4V drop) | ||||||

|---|---|---|---|---|---|---|---|---|

| (A) | 1.5mm² | 2.5mm² | 4mm² | 6mm² | 1.5mm² | 2.5mm² | 4mm² | 6mm² |

| 5A | 13.7m | 22.9m | 36.6m | 54.9m | 27.4m | 45.7m | 73.1m | 109.7m |

| 10A | 6.9m | 11.4m | 18.3m | 27.4m | 13.7m | 22.9m | 36.6m | 54.9m |

| 15A | 4.6m | 7.6m | 12.2m | 18.3m | 9.1m | 15.2m | 24.4m | 36.6m |

| 20A | 3.4m | 5.7m | 9.1m | 13.7m | 6.9m | 11.4m | 18.3m | 27.4m |

(Based on copper at 70°C, ρ = 0.0209 Ω·mm²/m)

Maximum cable length (meters) for 10% voltage drop in 400V three-phase circuits:

| Current | 2.5mm² | 4mm² | 6mm² | 10mm² | 16mm² |

|---|---|---|---|---|---|

| 16A | 119m | 190m | 285m | 475m | 760m |

| 25A | 76m | 122m | 182m | 304m | 486m |

| 32A | 59m | 95m | 142m | 237m | 380m |

| 40A | 48m | 76m | 114m | 190m | 304m |

| 63A | 30m | 48m | 72m | 120m | 193m |

(Based on copper at 70°C, cos φ = 0.85, resistive calculation only)

Parallel Conductor Voltage Drop

For installations using multiple conductors in parallel per phase:

Where: n = Number of conductors per phase

Example: Two 10mm² cables in parallel have the same voltage drop as one 20mm² cable.

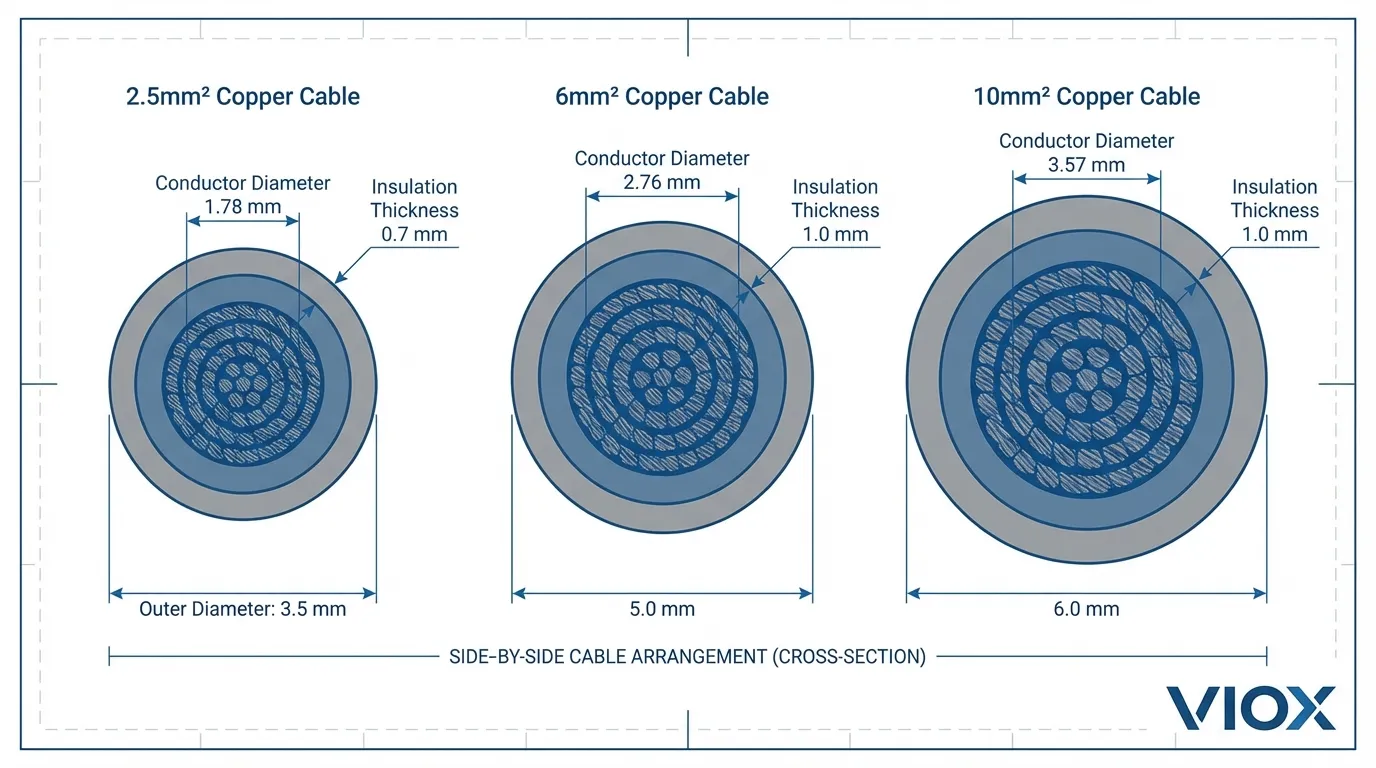

Section 3: Cable Outer Diameter and Physical Dimensions

Before calculating trunking capacity, you must know the actual physical dimensions of cables—not just their conductor cross-sectional area. Cable outer diameter (OD) varies significantly based on insulation type, voltage rating, and construction.

Cable Outer Diameter Formula (Approximate)

For single-core cables:

Where:

- OD = Overall outer diameter (mm)

- d_conductor = Conductor diameter = 2 × √(A/π)

- A = Conductor cross-sectional area (mm²)

- t_insulation = Insulation thickness (mm, varies by voltage and type)

- t_sheath = Sheath thickness (mm, if present)

Standard Cable Outer Diameters (IEC 60228)

Single-core copper cables, PVC insulation, 300/500V:

| Conductor Size | Conductor Ø | Insulation Thickness | Approx. Outer Ø | Cross-Sectional Area |

|---|---|---|---|---|

| 0.75 mm² | 1.0 mm | 0.8 mm | 3.6 mm | 10.2 mm² |

| 1.0 mm² | 1.1 mm | 0.8 mm | 3.8 mm | 11.3 mm² |

| 1.5 mm² | 1.4 mm | 0.8 mm | 4.1 mm | 13.2 mm² |

| 2.5 mm² | 1.8 mm | 0.8 mm | 4.5 mm | 15.9 mm² |

| 4 mm² | 2.3 mm | 0.8 mm | 5.0 mm | 19.6 mm² |

| 6 mm² | 2.8 mm | 0.8 mm | 5.5 mm | 23.8 mm² |

| 10 mm² | 3.6 mm | 1.0 mm | 6.7 mm | 35.3 mm² |

| 16 mm² | 4.5 mm | 1.0 mm | 7.6 mm | 45.4 mm² |

| 25 mm² | 5.6 mm | 1.2 mm | 9.2 mm | 66.5 mm² |

| 35 mm² | 6.7 mm | 1.2 mm | 10.3 mm | 83.3 mm² |

Single-core copper cables, XLPE insulation, 0.6/1kV:

| Conductor Size | Approx. Outer Ø | Cross-Sectional Area |

|---|---|---|

| 1.5 mm² | 4.3 mm | 14.5 mm² |

| 2.5 mm² | 4.8 mm | 18.1 mm² |

| 4 mm² | 5.4 mm | 22.9 mm² |

| 6 mm² | 6.0 mm | 28.3 mm² |

| 10 mm² | 7.3 mm | 41.9 mm² |

| 16 mm² | 8.4 mm | 55.4 mm² |

| 25 mm² | 10.2 mm | 81.7 mm² |

| 35 mm² | 11.5 mm | 103.9 mm² |

Multicore cables (3-core + PE, PVC, 300/500V):

| Conductor Size | Approx. Outer Ø | Cross-Sectional Area |

|---|---|---|

| 1.5 mm² | 9.5 mm | 70.9 mm² |

| 2.5 mm² | 11.0 mm | 95.0 mm² |

| 4 mm² | 12.5 mm | 122.7 mm² |

| 6 mm² | 14.0 mm | 153.9 mm² |

| 10 mm² | 16.5 mm | 213.8 mm² |

| 16 mm² | 19.0 mm | 283.5 mm² |

Important notes:

- Actual diameters vary by manufacturer (±5-10%)

- Flexible cables have larger OD than solid conductors

- Armored cables add 2-4mm to outer diameter

- Always verify dimensions from manufacturer datasheets for critical applications

Cable Cross-Sectional Area Calculation

For trunking fill calculations, you need the cable’s cross-sectional area (not conductor area):

Example: 6mm² conductor with 5.5mm outer diameter

A_cable = π × 2.75² = 23.8 mm²

Bending Radius Requirements

IEC 60204-1 specifies minimum bending radius to prevent conductor damage:

| Cable Type | Minimum Bending Radius |

|---|---|

| Single-core, non-armored | 4 × OD |

| Multicore, non-armored | 6 × OD |

| Armored cables | 8 × OD |

| Flexible/trailing cables | 5 × OD |

Example: 10mm² single-core cable (OD = 6.7mm) requires minimum 26.8mm bending radius in trunking corners.

Section 4: Trunking and Cable Duct Fill Capacity Calculations

Physical space constraints in control panels demand precise trunking capacity calculations. Unlike conduit fill rules that focus on installation ease, trunking fill in panels must balance space efficiency with thermal management.

IEC 60204-1 and IEC 60614-2-2 Fill Limits

Maximum fill percentages for enclosed trunking:

| Number of Cables | Maximum Fill | Rationale |

|---|---|---|

| 1 cable | 60% | Allows easy installation |

| 2 cables | 53% | Prevents binding during pulling |

| 3+ cables | 40% | Standard limit for multiple cables |

| Nipples <600mm | 60% | Short length exception |

Formula:

Where:

- Σ A_cables = Sum of all cable cross-sectional areas (mm²)

- A_trunking = Internal cross-sectional area of trunking (mm²)

Standard Trunking Sizes and Capacities

Solid-wall PVC trunking (internal dimensions):

| Trunking Size (W×H) | Internal Area | 40% Fill Capacity | 53% Fill Capacity |

|---|---|---|---|

| 25mm × 25mm | 625 mm² | 250 mm² | 331 mm² |

| 38mm × 25mm | 950 mm² | 380 mm² | 504 mm² |

| 50mm × 25mm | 1,250 mm² | 500 mm² | 663 mm² |

| 50mm × 38mm | 1,900 mm² | 760 mm² | 1,007 mm² |

| 50mm × 50mm | 2,500 mm² | 1,000 mm² | 1,325 mm² |

| 75mm × 50mm | 3,750 mm² | 1,500 mm² | 1,988 mm² |

| 75mm × 75mm | 5,625 mm² | 2,250 mm² | 2,981 mm² |

| 100mm × 50mm | 5,000 mm² | 2,000 mm² | 2,650 mm² |

| 100mm × 75mm | 7,500 mm² | 3,000 mm² | 3,975 mm² |

| 100mm × 100mm | 10,000 mm² | 4,000 mm² | 5,300 mm² |

Slotted/perforated cable tray (effective width):

| Tray Width | Typical Depth | Recommended Max Cables | Notes |

|---|---|---|---|

| 50mm | 25-50mm | Single layer | Control circuits only |

| 100mm | 50-75mm | 10-15 cables | Mixed sizes |

| 150mm | 50-75mm | 20-30 cables | Power + control segregation |

| 200mm | 75-100mm | 40-50 cables | Main distribution |

| 300mm | 100mm | 60-80 cables | High-density installations |

Note: Cable tray fill is typically limited by single-layer arrangement rather than percentage fill, to maintain thermal dissipation.

Trunking Fill Calculation Examples

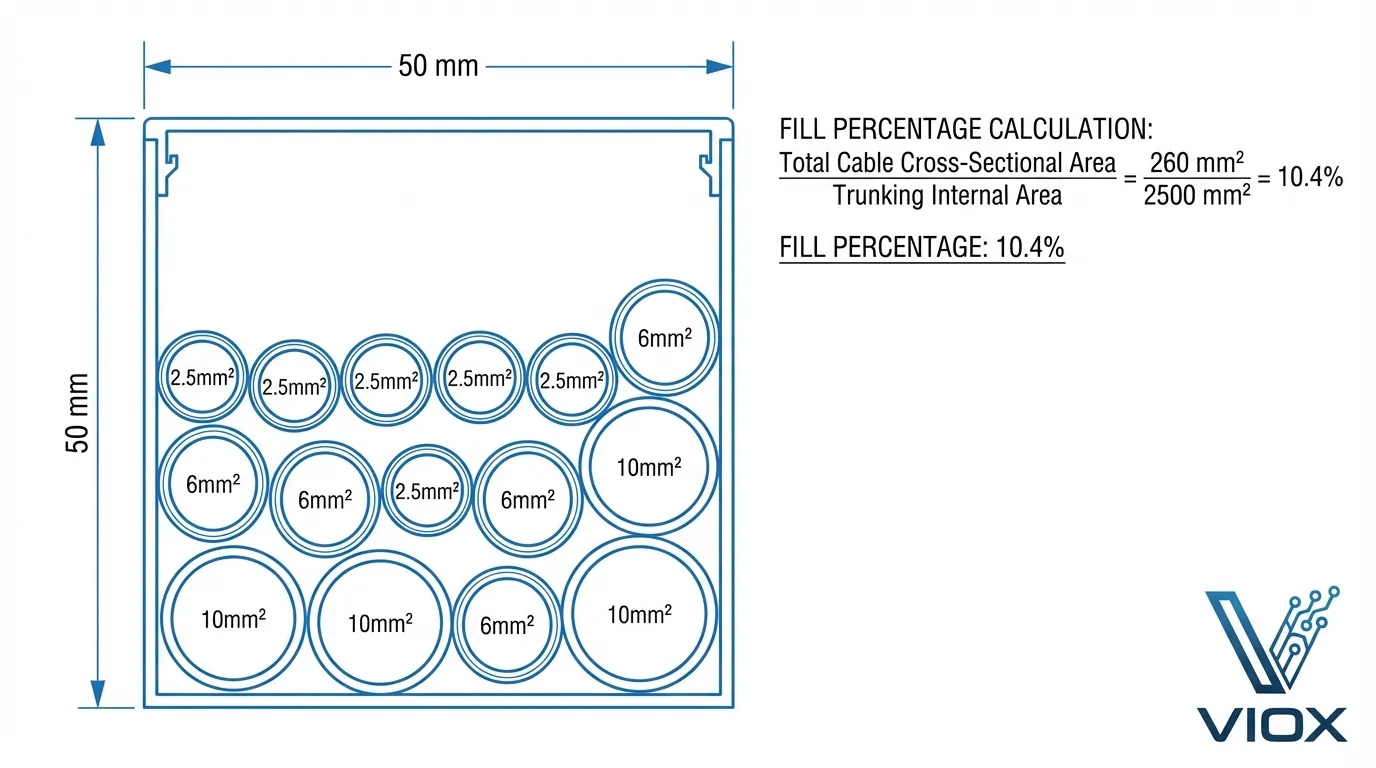

Example 1: Mixed Cable Sizes in 50mm × 50mm Trunking

Cables to install:

- 6 × 2.5mm² cables (OD 4.5mm each)

- 4 × 6mm² cables (OD 5.5mm each)

- 2 × 10mm² cables (OD 6.7mm each)

A_2.5 = π × (4.5/2)² = 15.9 mm² per cable

A_6 = π × (5.5/2)² = 23.8 mm² per cable

A_10 = π × (6.7/2)² = 35.3 mm² per cable

Step 2: Sum total cable area

Σ A_cables = (6 × 15.9) + (4 × 23.8) + (2 × 35.3)

Σ A_cables = 95.4 + 95.2 + 70.6 = 261.2 mm²

Step 3: Trunking internal area

A_trunking = 50mm × 50mm = 2,500 mm²

Step 4: Calculate fill percentage

Fill% = (261.2 ÷ 2,500) × 100% = 10.4%

Result: ✓ PASSES (10.4% < 40% limit) Large safety margin allows future expansion

Example 2: High-Density Control Panel

Scenario: 20 × 2.5mm² cables in 50mm × 25mm trunking

A_cable = π × (4.5/2)² = 15.9 mm² per cable

Σ A_cables = 20 × 15.9 = 318 mm²

Step 2: Trunking area

A_trunking = 50mm × 25mm = 1,250 mm²

Step 3: Fill percentage

Fill% = (318 ÷ 1,250) × 100% = 25.4%

Result: ✓ PASSES (25.4% < 40% limit)

Example 3: Oversized Cable in Small Trunking

Scenario: 3 × 16mm² cables (OD 7.6mm) in 50mm × 38mm trunking

A_cable = π × (7.6/2)² = 45.4 mm² per cable

Σ A_cables = 3 × 45.4 = 136.2 mm²

Step 2: Trunking area

A_trunking = 50mm × 38mm = 1,900 mm²

Step 3: Fill percentage

Fill% = (136.2 ÷ 1,900) × 100% = 7.2%

Result: ✓ PASSES (7.2% < 40% limit) However, check physical fit: 3 cables × 7.6mm = 22.8mm width minimum Trunking width = 50mm ✓ adequate Trunking height = 38mm vs. cable OD 7.6mm ✓ adequate

Maximum Cable Count Tables

Maximum number of cables in standard trunking (40% fill limit):

50mm × 50mm trunking (2,500mm² internal, 1,000mm² capacity):

| Cable Size | Outer Ø | Cable Area | Max Quantity |

|---|---|---|---|

| 1.5 mm² | 4.1mm | 13.2 mm² | 75 cables |

| 2.5 mm² | 4.5mm | 15.9 mm² | 62 cables |

| 4 mm² | 5.0mm | 19.6 mm² | 51 cables |

| 6 mm² | 5.5mm | 23.8 mm² | 42 cables |

| 10 mm² | 6.7mm | 35.3 mm² | 28 cables |

| 16 mm² | 7.6mm | 45.4 mm² | 22 cables |

100mm × 100mm trunking (10,000mm² internal, 4,000mm² capacity):

| Cable Size | Max Quantity |

|---|---|

| 1.5 mm² | 303 cables |

| 2.5 mm² | 251 cables |

| 4 mm² | 204 cables |

| 6 mm² | 168 cables |

| 10 mm² | 113 cables |

| 16 mm² | 88 cables |

| 25 mm² | 60 cables |

Practical note: These are theoretical maximums. Real installations should target 60-70% of maximum to allow for:

- Cable routing flexibility

- Future additions

- Maintenance access

- Reduced installation labor

Segregation Requirements in Trunking

IEC 60204-1 requires segregation between circuit types to prevent interference and ensure safety:

| Circuit Separation | Minimum Requirement | Implementation |

|---|---|---|

| Power (>50V) vs. Control (<50V) | Physical barrier or separate trunking | Use divided trunking or separate ducts |

| AC vs. DC circuits | Recommended separation | Separate trunking preferred |

| Shielded vs. unshielded | No specific requirement | Group shielded cables together |

| High-frequency (VFD) vs. analog | Minimum 200mm separation | Separate trunking mandatory |

Divided trunking example:

│ Power Circuits (>50V) │ ← 60% of trunking width

├─────────────────────────────┤ ← Solid divider

│ Control Circuits (<50V) │ ← 40% of trunking width └─────────────────────────────┘

Cable Tray Layer Calculation

For perforated cable tray, calculate maximum cables per layer:

Where:

- W_tray = Tray effective width (mm)

- clearance = Edge clearance (typically 10mm per side)

- OD_cable = Cable outer diameter (mm)

- spacing = Minimum spacing between cables (typically 5mm)

Example: 100mm wide tray with 6mm² cables (OD 5.5mm)

N_max = 80mm ÷ 10.5mm = 7.6

→ Maximum 7 cables per layer

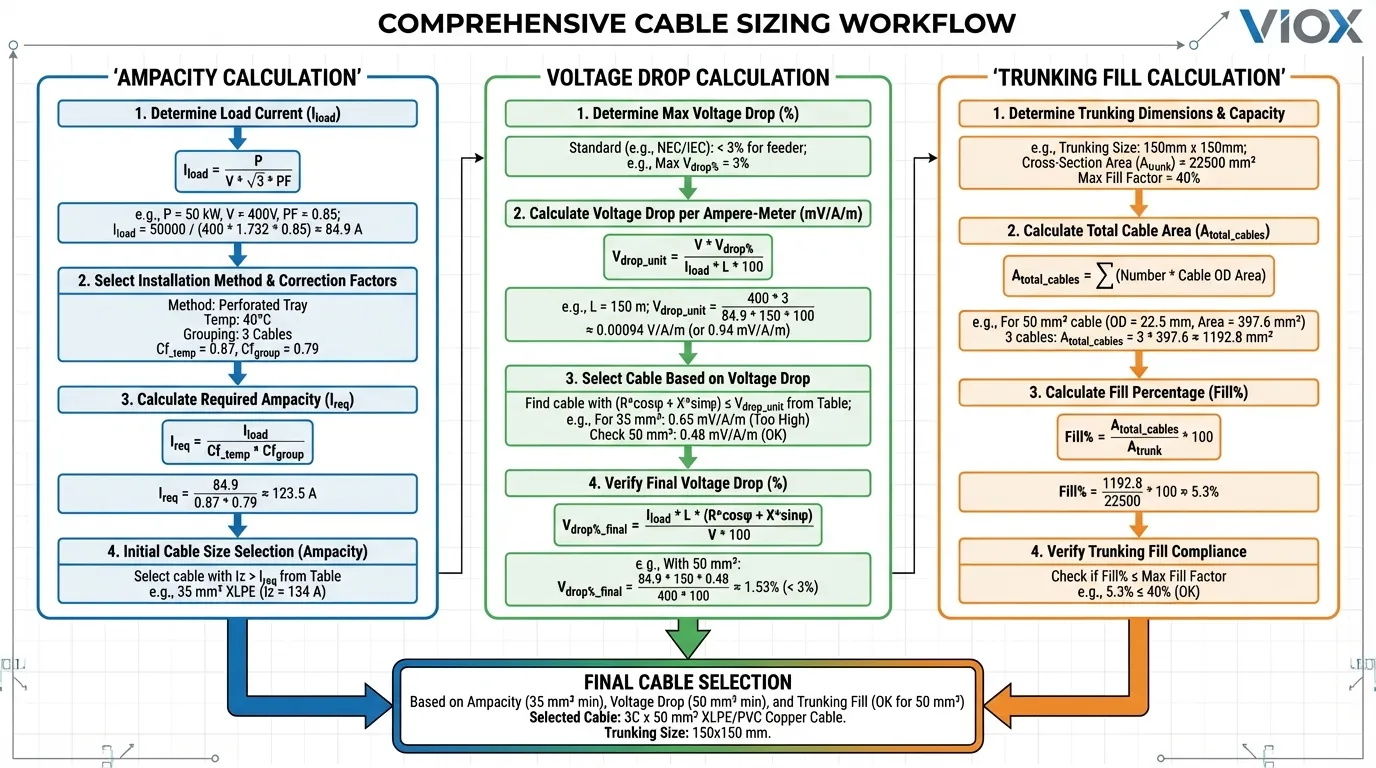

Section 5: Integrated Sizing Methodology—Combining All Calculations

Real-world cable sizing requires simultaneous consideration of ampacity, voltage drop, and trunking capacity. This section provides integrated examples demonstrating the complete calculation workflow.

Comprehensive Calculation Workflow

↓

2. Apply Derating Factors → Required Ampacity (I_n_required)

↓

3. Select Preliminary Cable Size (from ampacity)

↓

4. Calculate Voltage Drop with Selected Size

↓

5. If VD > limit: Upsize cable, return to step 4

↓

6. Calculate Trunking Fill with Final Cable Sizes

↓

7. If Fill > limit: Upsize trunking or redistribute cables

↓

8. Document Final Selection

Worked Example 5: Complete Panel Design

Scenario: Industrial control panel with multiple circuits

Circuits:

- Circuit A: 15kW motor, 30A, 20m cable run

- Circuit B: 7.5kW motor, 16A, 15m cable run

- Circuit C: 24VDC power supply, 20A, 25m cable run

- Circuit D: 10× control relays, 5A total, 10m cable run

Panel conditions:

- Internal temperature: 55°C

- All circuits in common 75mm × 50mm trunking

- Voltage: 400V three-phase (A, B), 24VDC (C, D)

- Cable type: Copper XLPE for power, PVC for control

Circuit A Calculation (15kW Motor):

I_b = 30A × 1.25 = 37.5A

Step 2: Protective device

Select 40A MCCB

Step 3: Derating (initially 4 circuits total)

k₁ = 0.79 (55°C, XLPE)

k₂ = 0.70 (4-6 circuits estimated)

I_n_required = 40A ÷ (0.79 × 0.70) = 72.3A

Step 4: Preliminary cable selection

10mm² XLPE rated 75A → Select 10mm²

Step 5: Voltage drop check

VD = (√3 × 20m × 30A × 0.0209 × 0.85) ÷ 10mm²

VD = 15.4 ÷ 10 = 1.54V = 0.39% ✓ OK

Final: Circuit A = 10mm² XLPE (OD 7.3mm)

Circuit B Calculation (7.5kW Motor):

Select 25A MCCB

I_n_required = 25A ÷ (0.79 × 0.70) = 45.2A

Select 6mm² XLPE (rated 54A)

Voltage drop:

VD = (√3 × 15m × 16A × 0.0209 × 0.85) ÷ 6mm²

VD = 6.2 ÷ 6 = 1.03V = 0.26% ✓ OK

Final: Circuit B = 6mm² XLPE (OD 6.0mm)

Circuit C Calculation (24VDC Power):

Select 32A DC breaker

k₁ = 0.71 (55°C, PVC)

k₂ = 0.70

I_n_required = 32A ÷ (0.71 × 0.70) = 64.4A

Try 10mm² PVC (rated 63A) – insufficient

Select 16mm² PVC (rated 85A) ✓

Voltage drop (critical for DC):

VD = (2 × 25m × 20A × 0.0209) ÷ 16mm²

VD = 20.9 ÷ 16 = 1.31V = 5.45% ✗ EXCEEDS 5%

Upsize to 25mm²:

VD = 20.9 ÷ 25 = 0.84V = 3.48% ✓ OK

Final: Circuit C = 25mm² PVC (OD 9.2mm)

Circuit D Calculation (Control Relays):

Select 10A MCB

I_n_required = 10A ÷ (0.71 × 0.70) = 20.1A

Select 1.5mm² PVC (rated 19.5A) – marginal

Select 2.5mm² PVC (rated 27A) ✓

Voltage drop:

VD = (2 × 10m × 5A × 0.0209) ÷ 2.5mm²

VD = 2.09 ÷ 2.5 = 0.84V = 3.48% ✓ OK

Final: Circuit D = 2.5mm² PVC (OD 4.5mm)

Trunking Fill Verification:

40% fill limit = 1,500 mm² capacity

Cable areas:

Circuit A: 1× 10mm² XLPE (OD 7.3mm) = 41.9 mm²

Circuit B: 1× 6mm² XLPE (OD 6.0mm) = 28.3 mm²

Circuit C: 1× 25mm² PVC (OD 9.2mm) = 66.5 mm²

Circuit D: 1× 2.5mm² PVC (OD 4.5mm) = 15.9 mm²

Note: Three-phase circuits require 3 conductors + PE

Circuit A: 4 cables × 41.9 = 167.6 mm²

Circuit B: 4 cables × 28.3 = 113.2 mm²

Circuit C: 2 cables × 66.5 = 133.0 mm² (DC: +/- only)

Circuit D: 2 cables × 15.9 = 31.8 mm²

Total: 167.6 + 113.2 + 133.0 + 31.8 = 445.6 mm²

Fill% = (445.6 ÷ 3,750) × 100% = 11.9%

✓ PASSES (11.9% < 40% limit)

Adequate capacity for future expansion

Decision Matrix: When Each Factor Dominates

| Dominant Factor | Typical Scenarios | Solution Approach |

|---|---|---|

| Ampacity | High current, short runs, hot panels | Focus on derating, consider XLPE insulation |

| Voltage Drop | Low voltage DC, long cable runs, precision equipment | Upsize significantly beyond ampacity requirements |

| Trunking Fill | High circuit density, small panels, pre-existing trunking | Use smaller cables where possible, add trunking |

| All Three | Complex industrial panels | Iterative calculation, may require panel redesign |

Common Calculation Errors and Solutions

| Error | Consequence | Prevention |

|---|---|---|

| Using 30°C base temperature | Undersized cables overheat | Always use 40°C for IEC 60204-1 |

| Ignoring voltage drop in DC circuits | Equipment malfunction | Calculate VD separately for all DC circuits |

| Counting PE as current-carrying | Over-conservative grouping derating | Exclude PE and balanced neutrals |

| Using conductor area for trunking fill | Massive overfill | Use cable outer diameter, not conductor size |

| Forgetting continuous load factor | Breaker nuisance trips | Apply 1.25× to all loads >3 hours |

| Mixing cable types in calculations | Inconsistent results | Verify insulation type for each circuit |

Section 6: Quick Reference Tables and Selection Tools

Cable Ampacity Quick Reference (Copper, 40°C Reference)

| Size | PVC 70°C | XLPE 90°C | Typical Application |

|---|---|---|---|

| 1.5 mm² | 19.5A | 24A | Control circuits, pilot lights |

| 2.5 mm² | 27A | 33A | Relay coils, small contactors |

| 4 mm² | 36A | 45A | Medium contactors, small motors |

| 6 mm² | 46A | 54A | VFD control, 3-phase motors up to 5.5kW |

| 10 mm² | 63A | 75A | Motors 7.5-11kW, main distribution |

| 16 mm² | 85A | 101A | Motors 15-18.5kW, high-current feeders |

| 25 mm² | 112A | 133A | Motors 22-30kW, panel main supply |

| 35 mm² | 138A | 164A | Large motors, high-power distribution |

Note: These are base values at 40°C with single circuit. Apply derating factors for actual installations.

Voltage Drop Quick Calculator

Formula rearranged to find maximum cable length:

For DC and single-phase AC:

For three-phase AC:

Example: Maximum length for 2.5mm² cable, 10A load, 5% VD in 24VDC system

L_max = (1.2V × 2.5mm²) ÷ (2 × 10A × 0.0209)

L_max = 3.0 ÷ 0.418 = 7.2 meters

Trunking Selection Guide

Step 1: Calculate total cable cross-sectional area

Step 2: Determine required trunking area

Step 3: Select next standard size

Example: Total cable area = 850 mm²

Standard sizes:

– 50mm × 38mm = 1,900 mm² (too small)

– 50mm × 50mm = 2,500 mm² ✓ SELECT

Cable Size Conversion Reference

| mm² | AWG Equivalent | Typical Ø (mm) | Metric Trade Name |

|---|---|---|---|

| 0.75 | 18 AWG | 3.6 | 0.75mm² |

| 1.0 | 17 AWG | 3.8 | 1mm² |

| 1.5 | 15 AWG | 4.1 | 1.5mm² |

| 2.5 | 13 AWG | 4.5 | 2.5mm² |

| 4 | 11 AWG | 5.0 | 4mm² |

| 6 | 9 AWG | 5.5 | 6mm² |

| 10 | 7 AWG | 6.7 | 10mm² |

| 16 | 5 AWG | 7.6 | 16mm² |

| 25 | 3 AWG | 9.2 | 25mm² |

| 35 | 2 AWG | 10.3 | 35mm² |

For detailed AWG conversion information, see our Cable Size Types Guide.

Minimum Cable Sizes per IEC 60204-1

| Circuit Type | Minimum Copper | Minimum Aluminum | Notes |

|---|---|---|---|

| Power circuits | 1.5 mm² | 2.5 mm² | Continuous duty |

| Control circuits | 1.0 mm² | Not recommended | Relays, contactors |

| Extra-low voltage (<50V) | 0.75 mm² | Not permitted | Signal circuits only |

| Equipment grounding (PE) | Per protective device | Per protective device | Minimum 2.5mm² recommended |

Key Takeaways

Critical Success Factors for Cable Sizing:

- Use the complete calculation sequence: Ampacity → Voltage Drop → Trunking Fill—never skip steps

- DC circuits demand special attention: Voltage drop often dominates sizing, requiring cables 2-3 sizes larger than ampacity suggests

- Cable outer diameter ≠ conductor size: Always use actual cable OD for trunking calculations, not conductor cross-section

- Temperature-adjusted resistivity matters: Use ρ at operating temperature (typically 70°C), not 20°C reference values

- 40% trunking fill is maximum: Target 25-30% for practical installations with future expansion capacity

- Segregate circuit types: Use divided trunking or separate ducts for power vs. control circuits

- Document all calculations: Maintain records showing design current, derating factors, voltage drop, and trunking fill for future modifications

- Verify during commissioning: Measure actual voltage drop and temperature rise to confirm design assumptions

- Three-phase requires 4 cables: Don’t forget PE conductor when calculating trunking fill

- When in doubt, upsize: Cable is cheap compared to panel redesign or equipment damage

Calculation Checklist:

- [ ] Design current calculated with 1.25× continuous factor

- [ ] Derating factors applied (temperature + grouping)

- [ ] Protective device rating selected

- [ ] Cable size chosen from ampacity tables

- [ ] Voltage drop calculated at operating temperature

- [ ] Cable outer diameter verified from datasheet

- [ ] Trunking fill percentage calculated

- [ ] Segregation requirements met

- [ ] Bending radius requirements checked

- [ ] Future expansion capacity considered

VIOX Electric’s industrial control components are engineered for demanding panel environments, with terminal blocks, circuit breakers, and contactors rated for continuous operation at elevated temperatures. Our technical support team provides application-specific guidance for complex cable sizing calculations.

Frequently Asked Questions

Q1: Why do my DC control circuits require much larger cables than AC power circuits of similar current?

DC circuits are highly sensitive to voltage drop because there’s no RMS voltage—every volt lost is a direct reduction in available voltage. A 5% drop in a 24VDC system (1.2V) significantly affects relay and contactor operation, while a 5% drop in 400VAC (20V) is barely noticeable to most equipment. Additionally, DC circuits lack the “averaging” effect of AC waveforms, making voltage drop more critical. This often results in DC control cables being 2-3 sizes larger than ampacity alone would suggest.

Q2: Can I use the 40% trunking fill limit as a design target?

No—40% is the maximum permitted fill, not a design target. Professional installations should target 25-30% fill to allow for:

- Future circuit additions without trunking replacement

- Easier cable pulling during installation (reduced labor costs)

- Better thermal dissipation (lower operating temperatures)

- Maintenance access (ability to add/remove cables)

Designing to maximum fill creates inflexible installations that require costly modifications for even minor changes.

Q3: Do I need to count the PE (protective earth) conductor when calculating trunking fill?

Yes for trunking fill calculations—PE conductors occupy physical space regardless of whether they carry current. However, no for grouping derating factors—PE conductors don’t generate heat under normal operation and are excluded from thermal derating calculations. This is a common source of confusion: PE counts for physical space but not for thermal calculations.

Q4: Why does IEC 60204-1 use 40°C reference temperature instead of 30°C like building codes?

Control panels create confined spaces with heat-generating components (VFDs, power supplies, transformers) that routinely operate 10-15°C above room temperature. The 40°C reference reflects real-world panel conditions, making cable selections more conservative and appropriate for industrial environments. If you mistakenly use 30°C-based tables (like IEC 60364), you’ll undersize cables and risk thermal failures.

Q5: How do I handle cables that are partially in trunking and partially in free air?

Apply the most restrictive condition for the entire cable run. If 80% of a cable is in free air but 20% passes through densely packed trunking, the entire circuit must be sized for the trunking section’s derating factors. The trunking segment creates a thermal “bottleneck” that limits the entire cable’s capacity. Conservative engineering always uses worst-case conditions for complete cable routes.

Q6: Can I mix different cable types (PVC and XLPE) in the same trunking?

Yes, but apply derating factors appropriate to each cable type individually. PVC cables (70°C rating) require more aggressive temperature derating than XLPE (90°C rating) in the same environment. For trunking fill calculations, simply sum the outer diameters regardless of insulation type. However, for motor control applications requiring high reliability, using consistent cable types throughout simplifies calculations and reduces errors.

Q7: What’s the difference between cable cross-sectional area and conductor cross-sectional area?

Conductor cross-sectional area (e.g., 6mm²) refers to the copper/aluminum conductor itself and determines current-carrying capacity. Cable cross-sectional area refers to the entire cable including insulation and sheath, calculated from outer diameter: A = π × (OD/2)². For example:

- 6mm² conductor = 6mm² conductor area

- Same cable with 5.5mm OD = 23.8mm² cable area

Always use cable area for trunking fill, conductor area for ampacity calculations.

Q8: How do I calculate trunking fill when cables have different shapes (round vs. flat)?

For round cables, use the circular area formula: A = π × (OD/2)². For flat/ribbon cables, use rectangular area: A = width × thickness. For irregular shapes, use the manufacturer’s specified “equivalent circular diameter” or measure the cable’s bounding rectangle (width × height) and use that as a conservative estimate. When mixing shapes, sum all individual areas and compare to trunking capacity.

Q9: Do flexible cables require different calculations than fixed installation cables?

Ampacity: Flexible cables typically have 10-15% lower ampacity than solid conductors of the same size due to increased resistance from stranding. Apply an additional 0.85-0.90 derating factor.

Trunking fill: Flexible cables have larger outer diameters (more insulation layers for flexibility), so verify actual OD from datasheets.

Bending radius: Flexible cables require minimum 5× OD bending radius vs. 4× OD for solid cables.

For festoon systems and mobile machinery, always specify flexible cable ratings explicitly.

Q10: How do I size cables for circuits with high starting currents like motors?

Size cables based on full-load running current (not starting current), applying appropriate derating factors. The protective device (motor starter or circuit breaker) handles short-term starting transients. However, verify voltage drop during starting to ensure it doesn’t cause:

- Contactor dropout (voltage sag drops out holding coil)

- Nuisance trips of voltage-sensitive equipment

- Excessive starting time

If starting voltage drop exceeds 15-20%, consider upsizing cables beyond ampacity requirements or using soft-start/VFD control.

Conclusion: Precision Through Systematic Calculation

Accurate cable sizing for industrial control panels demands rigorous application of three interconnected calculations: ampacity with derating factors, voltage drop at operating temperature, and trunking fill based on actual cable dimensions. While derating principles establish thermal limits (detailed in our comprehensive derating guide), the formulas and methodologies in this guide transform those principles into precise cable selections that meet IEC 60204-1 requirements.

Professional Installation Best Practices:

- Calculate systematically: Follow the complete workflow—never skip voltage drop or trunking fill checks

- Use actual dimensions: Verify cable outer diameters from manufacturer datasheets, not assumptions

- Design for expansion: Target 25-30% trunking fill, not the 40% maximum

- Document thoroughly: Maintain calculation records for future modifications

- Verify during commissioning: Measure voltage drop and temperature rise to confirm design assumptions

- Segregate circuit types: Use divided trunking or separate ducts for power vs. control circuits

When Calculation Accuracy Matters:

The difference between adequate and inadequate cable sizing often comes down to methodical application of formulas—particularly for DC control circuits where voltage drop dominates, and high-density panels where trunking capacity limits design flexibility. The examples throughout this guide demonstrate that real-world installations frequently require cables 2-3 sizes larger than initial estimates, making systematic calculation essential for safety, reliability, and long-term performance.

VIOX Electric’s comprehensive line of industrial circuit protection devices and control components are engineered for demanding panel environments. Our technical support team provides application-specific guidance for complex cable sizing calculations and panel designs worldwide.

For technical consultation on your next control panel project, contact VIOX Electric’s engineering team or explore our complete industrial electrical solutions.

Related Technical Resources:

- Electrical Derating Master Guide: Temperature, Altitude, and Grouping Factors

- 50 Amp Wire Size Guide: NEC Standards & Breaker Selection

- Cable Size Types Explained: mm, mm², AWG & B&S Guide

- Control Panels: Understanding Control Panel Components

- What Is a Molded Case Circuit Breaker (MCCB)?

- Terminal Block Selection Guide: Types & Uses

- Star Delta Starter Wiring Diagram: Sizing & Selection Guide

- What Is a DC Circuit Breaker?