Specifying terminal blocks for an industrial panel should be straightforward. But when procurement emails ask whether to use screw terminals or spring-clamp, or when specifications list “barrier blocks” without context, clarity becomes critical. Electrical engineers need precise selection criteria. Contractors need assurance they’re ordering the right hardware. Facility managers want terminations that stay secure through years of vibration and temperature cycling.

Terminal blocks—insulated modular devices that mechanically and electrically connect conductors—form the backbone of organized wiring in control panels, machinery, and building automation. Mounted on DIN rail inside enclosures, they transform chaotic point-to-point wiring into structured, labeled circuits.

This guide establishes a clear taxonomy of terminal block types, provides comparison tables for specification, and delivers practical selection guidance aligned with IEC 60947-7-1 and UL 1059 standards.

What Is a Terminal Block?

A terminal block is a modular insulated housing containing:

- Conductive element: Metal contact (typically copper or brass) that carries current between conductors

- Clamping mechanism: Screw, spring, or push-in device that secures stripped wire ends

- Insulation body: Flame-retardant plastic (polyamide, polycarbonate) providing electrical isolation and mechanical protection

- Mounting system: DIN rail clip (EN 60715) or panel screw holes for secure installation

Standards Compliance

Terminal blocks for industrial, commercial, and residential applications comply with:

- IEC 60947-7-1:2025 (Edition 4.0): Low-voltage switchgear and controlgear terminal blocks for copper conductors; covers electrical ratings, test methods, conductor sizes, and mechanical requirements

- UL 1059: Terminal blocks for North American markets; defines construction, spacing, temperature rise, and short-circuit testing

- EN 60715: DIN rail mounting profile standards ensuring mechanical compatibility across manufacturers

Terminal blocks operate in circuits up to 1000V AC (≤1000Hz) or 1500V DC, supporting conductor sizes from 0.2mm² to 300mm² (AWG 24 to 600 kcmil), with current ratings spanning 6A to 400A.

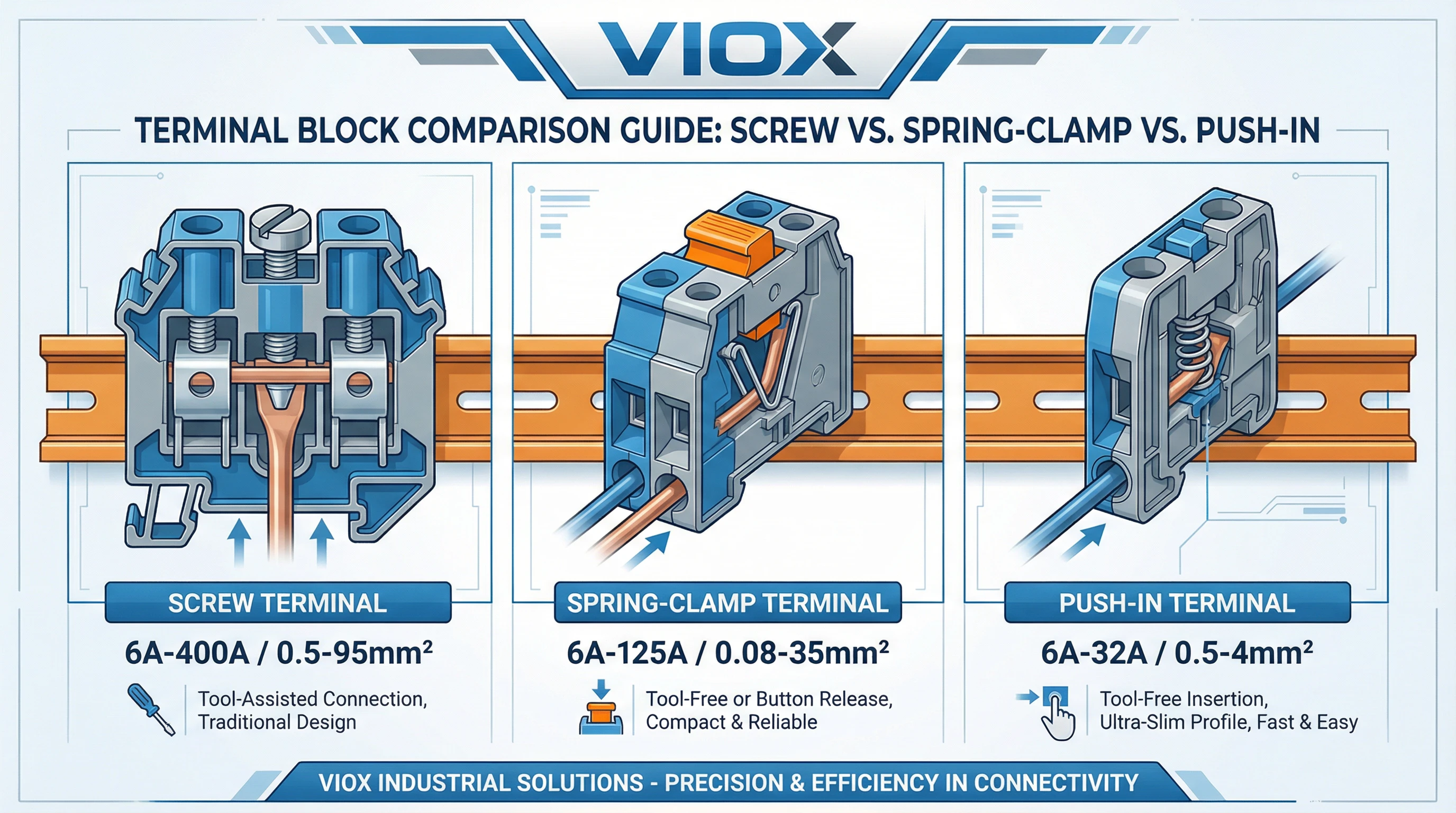

Terminal Block Types: By Clamping Method

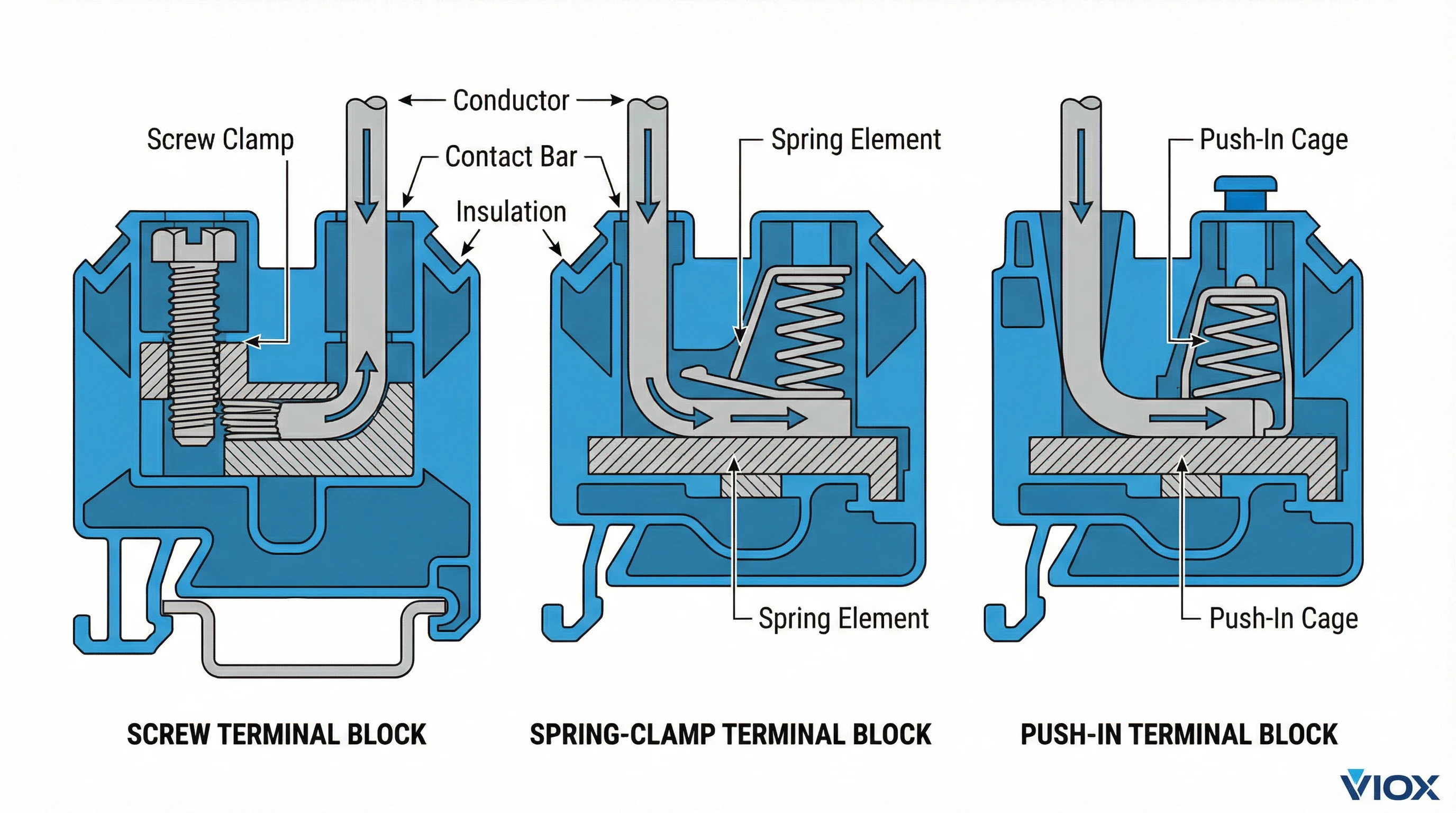

Screw Terminal Blocks

Construction: A threaded screw compresses the conductor against a contact. Tightening torque creates electrical continuity.

Advantages:

- Wide conductor range in a single device (e.g., 0.5mm² to 6mm²)

- High mechanical robustness suitable for high-current applications (up to 150A+)

- Familiar installation method; universally accepted

- Lower cost per position compared to spring technologies

Considerations:

- Installation requires calibrated torque screwdrivers (typical: 0.5-2.5 N·m depending on size)

- Vibration or thermal cycling can loosen connections; periodic re-tightening recommended

- Installation time longer than spring-clamp alternatives

- Installer skill affects connection quality

Typical Applications: Building wiring, power distribution panels, machinery control circuits, retrofit installations

Spring-Clamp Terminal Blocks

Construction: A preloaded spring element exerts constant clamping force. A screwdriver or push-button releases the spring for wire insertion/removal.

Advantages:

- Faster installation—no torque specification required

- Maintains constant pressure regardless of vibration or temperature change

- Reduced installer training requirements

- Excellent performance in high-vibration environments (motors, rail vehicles, heavy machinery)

- Lower maintenance—no periodic re-tightening

Considerations:

- Higher cost per position than screw terminals

- Wire preparation critical (strip length, ferrule use)

- Spring element can fatigue after many insertion cycles (typically rated >20 cycles)

Typical Applications: Industrial automation, control cabinets subject to vibration, installations requiring frequent circuit changes, renewable energy systems

Push-In Terminal Blocks

Construction: Tool-free insertion of a ferruled or solid conductor into a spring-cage contact. Release via push-button or screwdriver slot.

Advantages:

- Fastest installation method—no tools required for connection

- Ultra-compact design maximizes panel density

- Ideal for high-frequency wiring changes

- Excellent in harsh environments (marine, chemical, outdoor)

- Reduced wiring errors due to simple insertion

Considerations:

- Requires ferrules on stranded conductors for reliable contact

- Not suitable for very fine wire (typically ≥0.5mm²)

- Limited to lower current ratings (typically ≤32A)

Typical Applications: High-density control panels, I/O wiring, distributed automation, modular machine building

Comparison Table: Clamping Methods

| Feature | Screw Terminal | Spring-Clamp Terminal | Push-In Terminal |

|---|---|---|---|

| Installation Speed | Moderate (torque required) | Fast (no torque) | Very fast (tool-free) |

| Skill Required | Moderate (torque control) | Low | Very low |

| Vibration Resistance | Moderate (can loosen) | Excellent (constant pressure) | Excellent |

| Maintenance | Periodic re-tightening | Minimal | Minimal |

| Current Rating | 6A – 400A | 6A – 125A | 6A – 32A |

| Cost per Position | Low | Medium-High | Medium-High |

| Typical Wire Range | 0.5mm² – 95mm² | 0.08mm² – 35mm² | 0.5mm² – 4mm² |

| Best Application | Power distribution, high-power | Vibration, frequent changes | High-density, fast installation |

Terminal Block Types: By Function and Configuration

Beyond clamping method, terminal blocks are categorized by circuit function, mounting style, and special features.

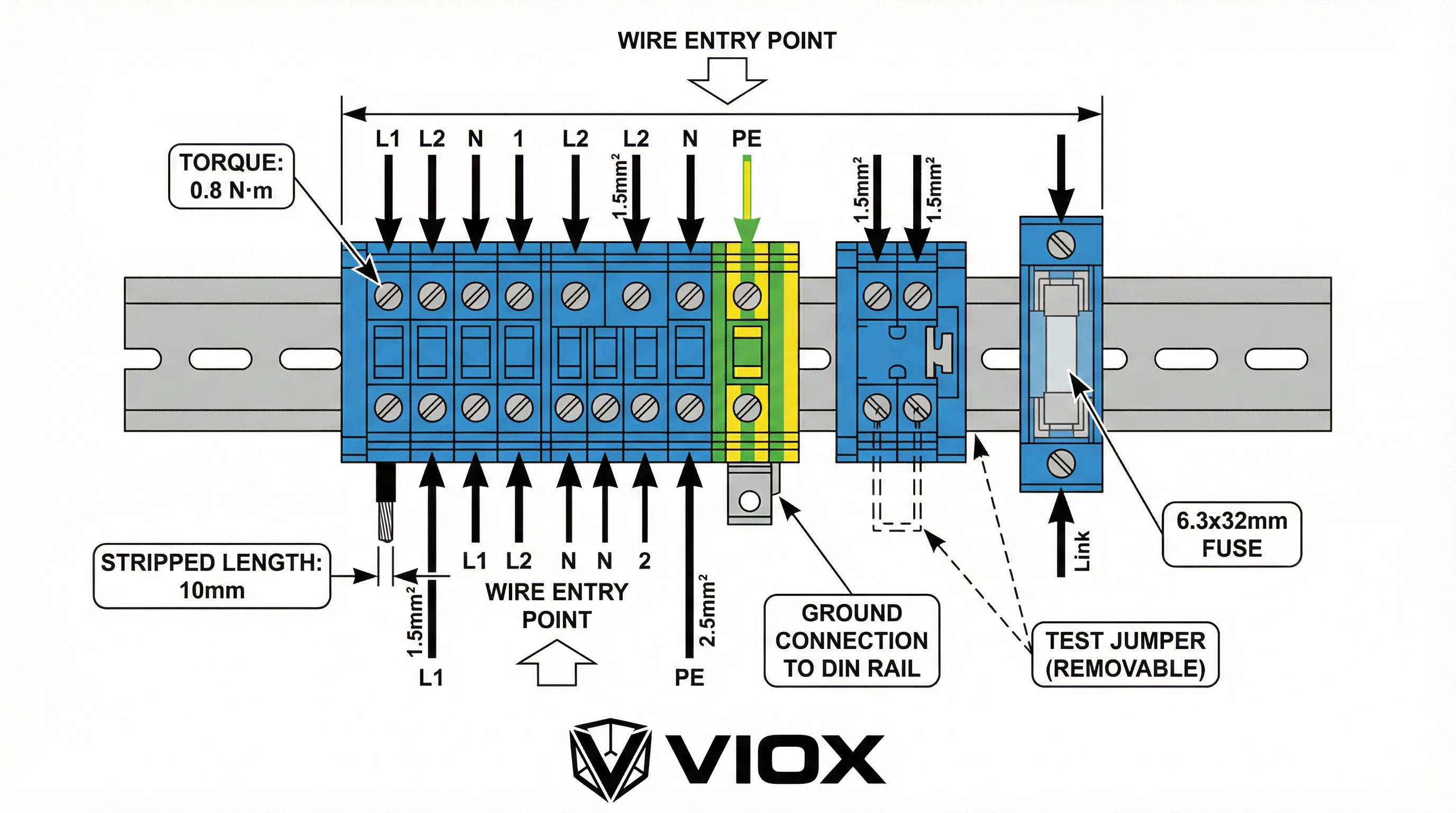

Feed-Through Terminal Blocks

Function: Provide wire-to-wire connection with entry points on opposite sides of the block. No internal jumpers or switching—pure pass-through.

Use Cases: General distribution wiring, circuit extensions, panel interconnections

Specifications: Available in all clamping types; current ratings 6A-150A; single-level or multi-level configurations

Ground Terminal Blocks

Function: Connect protective earth (PE) conductors to the DIN rail or dedicated ground bus. Often feature green/yellow insulation and direct metal contact to rail.

Use Cases: Every control panel or distribution board requires dedicated ground terminations

Disconnect (Test) Terminal Blocks

Function: Include a removable jumper, link, or knife switch that interrupts the circuit for testing or isolation without removing wires.

Use Cases: Current measurement points, sensor calibration circuits, commissioning access

Fuse Terminal Blocks

Function: Integrate a fuse holder and contacts in a single DIN rail module, providing overcurrent protection at the termination point.

Advantages: Eliminates separate fuse holders, reduces wiring, simplifies troubleshooting (blown fuse visible)

Fuse Types: Accepts 5x20mm, 6.3x32mm, or 10x38mm cylindrical fuses; some models include blown-fuse indicators

Use Cases: Branch circuit protection, equipment input protection, individual load isolation

Multi-Level Terminal Blocks

Function: Stack two or three independent circuits in a single module footprint (vertical stacking). Each level is electrically isolated.

Advantages: Saves DIN rail space (2x-3x density improvement), organizes related signals (e.g., 0V, +24V, signal)

Use Cases: High-density panels, compact enclosures, signal + power distribution in automation cabinets

Barrier Terminal Blocks (Barrier Strips)

Function: Single-row terminal strips with raised insulation barriers between each position, preventing accidental contact between adjacent circuits.

Mounting: Typically screw-mounted to panel or enclosure (not DIN rail)

Use Cases: High-voltage circuits, power supply connections, vibration-prone environments, older installations

Power Distribution Blocks

Function: Heavy-duty terminals designed for main power feeds or large load connections. Multiple output positions fed from a single input.

Specifications: High current capacity (150A-600A), large conductor acceptance (35mm²-300mm²), insulated or finger-safe covers

Use Cases: Main busbar connections, motor feeders, three-phase distribution

Function Comparison Table

| Terminal Block Type | Primary Function | Mounting | Typical Current Range | Key Feature |

|---|---|---|---|---|

| Feed-Through | Wire-to-wire pass-through | DIN rail | 6A – 150A | Simple distribution |

| Ground (PE) | Protective earth connection | DIN rail | 6A – 150A | Direct rail contact, green/yellow coding |

| Disconnect (Test) | Circuit interruption without disconnection | DIN rail | 6A – 125A | Removable jumper or knife switch |

| Fuse Terminal | Integrated overcurrent protection | DIN rail | 6A – 32A | Blown-fuse indicator, modular |

| Multi-Level | Stacked circuits (2-3 levels) | DIN rail | 6A – 32A per level | Space-saving, organized signals |

| Barrier Strip | Isolated single-row positions | Panel screw mount | 15A – 100A | Raised barriers, high-voltage isolation |

| Power Distribution | High-current main feeds | Busbar or panel mount | 150A – 600A | Heavy conductors, multi-output |

Technical Specifications and Selection Criteria

Specifying the correct terminal block requires matching electrical requirements, mechanical constraints, and installation environment.

Rated Current (In): Maximum continuous current without exceeding temperature rise limits (typically 50K above ambient).

Rated Voltage (Ue): Maximum operating voltage (AC or DC). Determines creepage and clearance distances.

Conductor Size Compatibility:

| Terminal Current Rating | Solid Wire (mm²) | Stranded Wire (mm²) | Stranded + Ferrule (mm²) | AWG Equivalent |

|---|---|---|---|---|

| 6A – 10A | 0.2 – 2.5 | 0.2 – 2.5 | 0.25 – 2.5 | 24 – 14 |

| 17A – 24A | 0.5 – 4.0 | 0.5 – 4.0 | 0.5 – 4.0 | 20 – 12 |

| 32A – 41A | 1.0 – 6.0 | 1.0 – 6.0 | 1.5 – 6.0 | 16 – 10 |

| 57A – 76A | 2.5 – 10 | 2.5 – 10 | 4.0 – 10 | 12 – 8 |

| 101A – 125A | 10 – 35 | 10 – 35 | 16 – 35 | 8 – 2 |

| 150A+ | 25 – 95+ | 25 – 95+ | 35 – 95+ | 2 – 4/0+ |

Note: Ratings per IEC 60947-7-1; actual capacity depends on conductor material, ambient temperature, and installation configuration.

Terminal Pitch: Center-to-center spacing between adjacent terminals: 2.54mm (ultra-compact signals), 5.0mm/5.08mm (standard control), 7.5mm (medium-duty), 10mm/12mm (heavy-duty), 15mm+ (high-power)

Number of Poles: How many independent circuits exist in one terminal block housing

- Single-pole (1P): One circuit per block

- Multi-pole (2P, 3P, 4P): Multiple circuits share common housing (common in power distribution)

DIN Rail Compatibility: Standard 35mm × 7.5mm or 35mm × 15mm (EN 60715)

Environmental and Installation Factors

| Selection Factor | Considerations | Recommendation |

|---|---|---|

| Vibration Environment | Motors, rail vehicles, heavy machinery | Spring-clamp or push-in; avoid screw unless torque-verified |

| Temperature Range | Outdoor, engine compartments, ovens | Check terminal block temperature rating (typically -40°C to +105°C) |

| Chemical Exposure | Marine, chemical plants, wastewater treatment | Stainless steel contacts, special polymers (e.g., PA66-GF) |

| Frequent Disconnection | Test equipment, modular machines, temporary installations | Spring-clamp or push-in (insertion cycles >20) |

| High Conductor Density | Compact enclosures, mobile equipment, distributed I/O | Push-in terminals, multi-level blocks |

| Regulatory Environment | North America (UL/CSA), Europe (CE), global projects | Verify UL 1059, IEC 60947-7-1, and CE marking |

| Maintenance Accessibility | Remote installations, sealed enclosures | Screw terminals acceptable if accessible; spring-clamp if sealed |

Application Guide: Choosing the Right Terminal Block

Match terminal block type to application requirements for optimal performance, safety, and lifecycle cost.

Industrial Control Panels

Requirements: Mixed signal and power circuits, frequent modifications, vibration from nearby motors

Recommended Solution: Spring-clamp terminals (6A-24A) for signals; screw or spring-clamp (32A-76A) for power; multi-level blocks for dense I/O

Building Automation & HVAC

Requirements: Long service life, infrequent access, moderate currents, compliance with building codes

Recommended Solution: Screw terminals (cost-effective for 10A-20A circuits); barrier strips for mains connections; fuse terminals for branch protection

Machinery & Equipment Manufacturing

Requirements: Modular design, fast assembly, global compliance, serviceability

Recommended Solution: Push-in terminals for control circuits (fast production wiring); spring-clamp for power; disconnect terminals for test points; UL + IEC certification

Renewable Energy (Solar, Wind)

Requirements: Outdoor exposure, UV resistance, high voltage (up to 1500V DC), temperature cycling

Recommended Solution: PV-rated terminal blocks (IEC 60947-7-4); high creepage distances; spring-clamp for vibration resistance

Rail & Transportation

Requirements: Extreme vibration, shock, temperature range (-40°C to +85°C), fire safety (EN 45545)

Recommended Solution: Spring-clamp or push-in terminals; halogen-free flame-retardant materials; stainless contacts; high insertion-cycle ratings

Marine & Offshore

Requirements: Corrosion resistance, high humidity, salt spray, frequent maintenance

Recommended Solution: Stainless steel contacts; special polyamide or polycarbonate housings; push-in or spring-clamp; IP67 enclosures

Installation and Maintenance

Wire Preparation

- Strip Length: Match manufacturer specification (typically 8-12mm for screw, 10-11mm for spring-clamp)

- Ferrules: Mandatory for stranded wire in spring-clamp and push-in terminals; improves contact and prevents strand breakage

- Wire Twist: Never twist stranded wire without ferrules—individual strands can break and create resistance

Screw terminals require calibrated torque screwdrivers. Under-tightening causes heating; over-tightening damages conductors.

| Terminal Current Rating | Typical Torque Range |

|---|---|

| 6A – 10A | 0.5 – 0.6 N·m |

| 17A – 24A | 0.8 – 1.2 N·m |

| 32A – 41A | 1.2 – 1.8 N·m |

| 57A – 76A | 2.0 – 2.5 N·m |

| 101A+ | 3.0 – 6.0 N·m |

Labeling and Maintenance

- Use printed labels identifying circuit function; maintain wiring diagrams

- Color-code circuits (blue for neutral, green/yellow for ground per IEC 60446)

- Screw terminals: Re-torque annually in vibration environments

- Spring-clamp/push-in: Visual inspection only; no re-tightening required

- All types: Thermal imaging during commissioning

Frequently Asked Questions

Q: What’s the difference between a terminal block and a terminal strip?

A: “Terminal strip” and “barrier strip” typically refer to single-row terminal blocks mounted directly to panels with screws, rather than DIN rail. They serve the same function but use different mounting methods.

Q: Can I mix screw and spring-clamp terminal blocks on the same DIN rail?

A: Yes. DIN rail mounting allows mixing different types and brands as long as each meets the required specifications for its circuit.

Q: Are ferrules required for stranded wire?

A: Required for spring-clamp and push-in terminals. Recommended but not always required for screw terminals, depending on manufacturer specification.

Q: Why do terminal blocks have different pitch (spacing) options?

A: Pitch determines current capacity and wire access. Narrow pitch (5mm) saves space for low-current signals; wide pitch (10mm+) accommodates larger conductors and higher currents.

Q: How do I select current rating when the conductor size is between two standard ratings?

A: Always select the terminal block rated for the next higher conductor size. Never exceed the rated current even if the wire can physically fit.

Q: What does “finger-safe” or IP20 rating mean for terminal blocks?

A: IP20 (IEC 60529) provides protection against accidental contact with live parts by fingers or objects >12.5mm diameter. Many terminal blocks include removable covers or recessed contacts to meet this requirement.

Conclusion

Terminal blocks transform panel wiring from ad-hoc point-to-point connections into organized, testable, and maintainable electrical systems. Selecting the right type—whether screw, spring-clamp, or push-in clamping; feed-through, disconnect, or fuse function; standard or multi-level configuration—depends on electrical ratings, installation environment, maintenance access, and lifecycle requirements.

VIOX Electric manufactures a comprehensive range of DIN rail terminal blocks compliant with IEC 60947-7-1 and UL 1059 standards. Our product line includes screw, spring-clamp, and push-in terminal blocks in current ratings from 6A to 400A, serving industrial automation, power distribution, building systems, and specialized applications.

Whether specifying control panel components, procuring replacement hardware, or designing new equipment, our technical team provides application guidance and custom solutions for your terminal block requirements.

Contact VIOX Electric today to discuss your project specifications and receive expert recommendations for reliable, standards-compliant terminal block solutions.