Why Motor Starting Current Matters (And Costs You Money)

When a three-phase induction motor starts directly online (DOL), it draws 5-8 times its rated current for several seconds. For a 30kW motor, this means a brutal 150-240A inrush that:

- Triggers nuisance breaker trips in undersized installations

- Causes voltage sags affecting sensitive equipment on the same bus

- Accumulates thermal stress on motor windings, reducing service life by 20-30%

- Violates utility connection agreements for motors above 7.5kW in many regions

Star-Delta starters solve this by limiting inrush to 1.8-2.5× rated current—a 65% reduction that pays for itself in avoided downtime and extended equipment life.

What Is Star-Delta Starting?

A Star-Delta starter is a reduced voltage starting method that exploits the dual-winding configuration of three-phase motors. Here’s the physics in 30 seconds:

Star (Y) Configuration: Motor windings connected in series receive 1/√3 (58%) of line voltage, producing 1/3 of full-load torque but drawing only 1/3 of DOL starting current.

Delta (Δ) Configuration: Windings connected in parallel receive full line voltage, delivering 100% rated torque and current.

The starter automatically transitions from Star → Delta after a preset delay (typically 5-15 seconds), allowing the motor to accelerate smoothly before switching to full power.

Why It Matters for Your Projects

For Solar EPCs: When sizing inverters and AC couplers, Star-Delta starting prevents false trips from pump or compressor inrush. A 22kW pump on a 30kW inverter? No problem with Star-Delta—but it’ll trip immediately on DOL.

For Panel Builders: Star-Delta is the sweet spot between cost and performance:

- 40% cheaper than VFDs for fixed-speed applications

- Zero harmonics (unlike VFDs that require expensive filters)

- Requires only standard components—no proprietary spares

Core Components: The VIOX BOM Strategy

A complete Star-Delta starter requires 6 essential components. Here’s the critical insight most guides miss: you can downsize components strategically without compromising safety.

Component Breakdown

| Component | Function | Sizing Rule | VIOX Part Example |

|---|---|---|---|

| Main Contactor (K1) | Connects motor to supply | AC3 rating ≥ motor FLC | VX-CJX2-6511 (65A) |

| Star Contactor (K2) | Creates Y connection during start | AC3 rating ≥ 0.58× motor FLC | VX-CJX2-4011 (40A) |

| Delta Contactor (K3) | Creates Δ connection at full speed | AC3 rating ≥ motor FLC | VX-CJX2-6511 (65A) |

| Timer Relay | Controls transition timing | 5-15s adjustable delay | VX-H3CR-A8 |

| Thermal Overload | Motor protection | Set to motor nameplate current | VX-LR2-D3353 |

| Circuit Breaker | Short-circuit protection | Motor power per NEC tables | VX-DZ47-63 C63 |

Cost Breakdown (30kW Motor Example):

- Main Contactor (65A): $45

- Star Contactor (40A): $32

- Delta Contactor (65A): $45

- Timer Relay: $28

- Thermal Overload: $35

- Circuit Breaker: $18

- Total: $203 vs. $850+ for a 30kW VFD

The Star Contactor Downsizing Trick

Here’s the engineering insight that saves you 20% on component costs:

During Star connection, each motor winding carries only 1/√3 of phase current. This means:

- K2 (Star contactor) can be rated at 58% of motor FLC

- K3 (Delta contactor) must match motor FLC because it switches under full load

Example for 30kW/400V motor (FLC = 57A):

- K1 & K3: 65A contactors (AC3 category)

- K2: 40A contactor is sufficient (57A × 0.58 = 33A)

Understanding AC3 contactor utilization categories is critical here—never use AC1-rated contactors for motor starting.

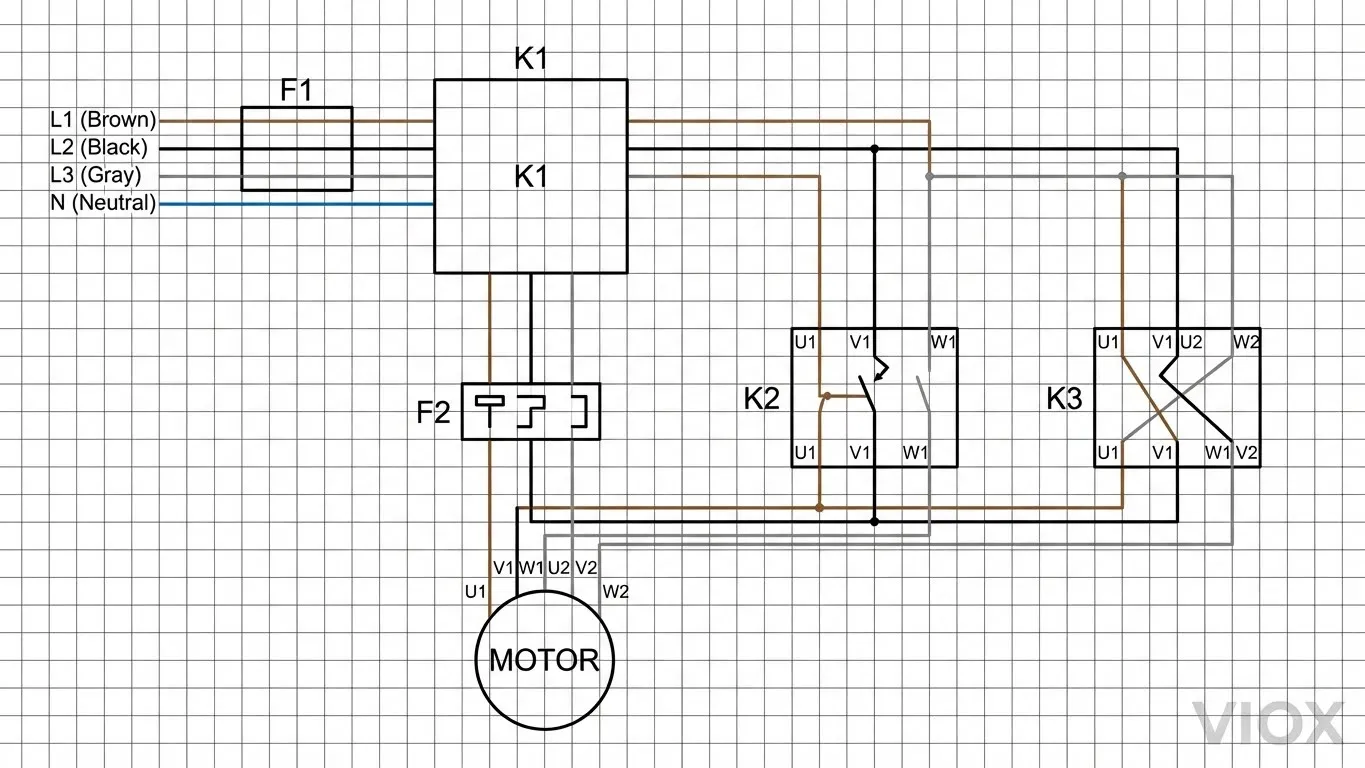

Complete Wiring Diagrams

Power Circuit (3-Phase Connections)

Critical Wiring Notes:

- Motor terminals U2, V2, W2 (winding ends) must be accessible—standard for motors rated >5.5kW

- Never close K2 and K3 simultaneously—this creates a dead short across phases

- Thermal overload F2 must protect the common path (between K1 and motor), not individual windings

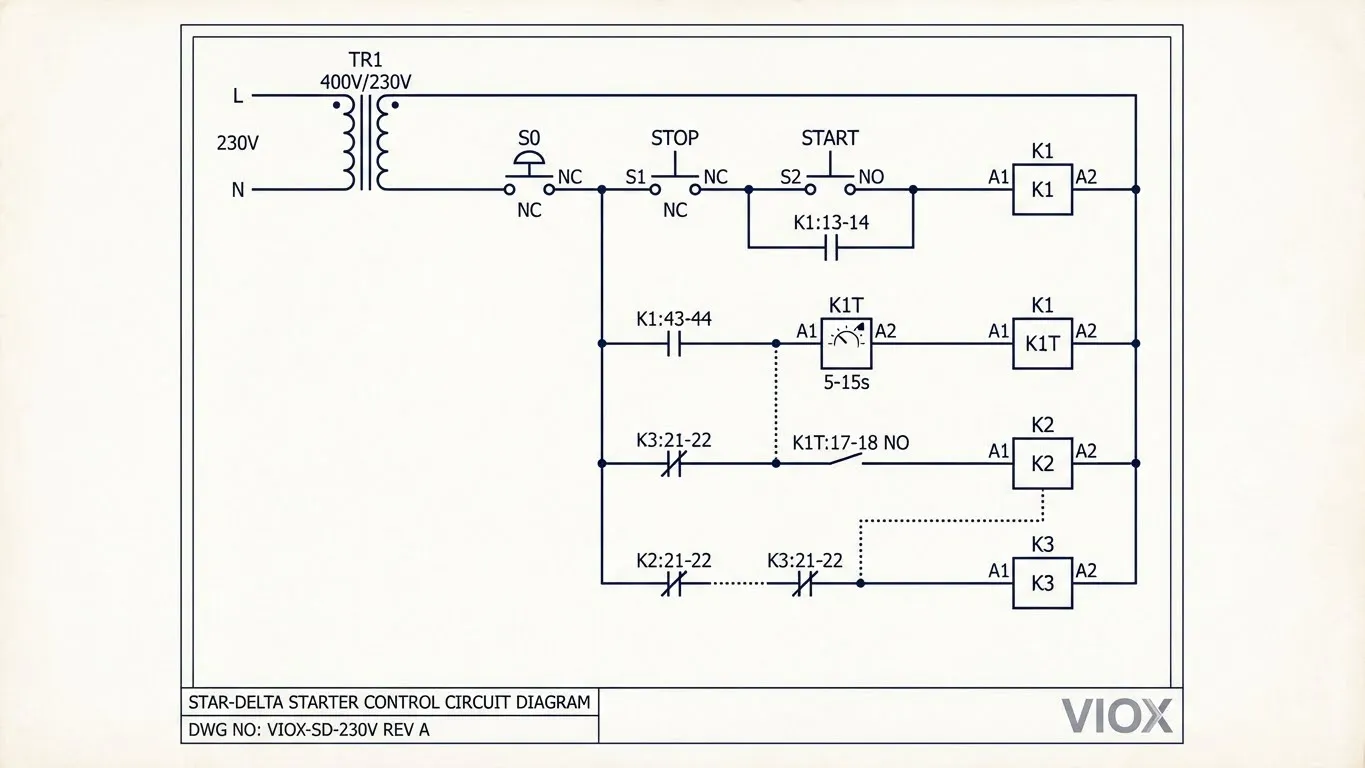

Control Circuit (Low-Voltage Logic)

Control Logic Sequence:

- Press START: K1 energizes → K1 auxiliary contact (13-14) latches → K2 energizes (Star mode)

- After timer delay: K1T contacts switch → K2 de-energizes, K3 energizes (Delta mode)

- Press STOP: K1 de-energizes → entire circuit resets

Interlocking Safeguards:

- K2 normally-closed contact (21-22) in series with K3 coil

- K3 normally-closed contact (21-22) in series with K2 coil

- This ensures mechanical impossibility of simultaneous closure

For a detailed walkthrough of timer relay wiring principles, see our dedicated guide.

Sizing Guide: Real-World Calculations

Motor Power to Component Rating (400V, 50Hz)

| Motor Power | Full-Load Current | K1/K3 Rating | K2 Rating | Breaker | Thermal Overload |

|---|---|---|---|---|---|

| 15kW | 29A | 32A (AC3) | 20A (AC3) | C40 | 30-32A |

| 22kW | 42A | 50A (AC3) | 25A (AC3) | C63 | 40-44A |

| 30kW | 57A | 65A (AC3) | 40A (AC3) | C80 | 55-60A |

| 45kW | 85A | 95A (AC3) | 50A (AC3) | C125 | 80-88A |

| 55kW | 105A | 115A (AC3) | 65A (AC3) | C160 | 100-110A |

Voltage Derating: For 380V systems, multiply currents by 1.05. For 440V, multiply by 0.91.

Timer Setting Rules of Thumb

The Star → Delta transition must occur after motor reaches 85-90% rated speed (typically 5-15 seconds depending on load inertia):

- Light loads (fans, centrifugal pumps): 5-8 seconds

- Medium loads (conveyors, compressors): 8-12 seconds

- Heavy loads (crushers, piston pumps): 12-15 seconds

Warning: Switching too early causes a secondary current spike (4-5× FLC) that defeats the purpose. Monitor motor speed with a tachometer during commissioning.

Component Selection Strategy

When to Choose Each Contactor Class

Understanding the difference between contactors and relays is fundamental, but here’s the motor-specific guidance:

AC3 Category (Motor Switching):

- Breaking capacity: 6-10× rated current

- Electrical life: 100,000-200,000 operations

- Use for: K1, K2, K3 in all motor starters

AC1 Category (Resistive Loads):

- Breaking capacity: Only 1.5× rated current

- Never use for motor starting—contacts will weld after 50-100 starts

Thermal Overload Sizing

Thermal overload relays must be set to motor nameplate current, not contactor rating. Common mistakes:

- ❌ Setting to 1.25× motor FLC (this is breaker sizing, not overload)

- ❌ Using contactor-integrated overloads without separate adjustment

- ✅ Adjustable range covering 90-110% of nameplate current

- ✅ Class 10 trip for motors with normal starting times (<10s)

Comparison Table: Star-Delta vs. Alternatives

| Parameter | DOL Starter | Star-Delta Starter | VFD (Fixed Speed) | Soft Starter |

|---|---|---|---|---|

| Starting Current | 5-8× FLC | 1.8-2.5× FLC | 1.5-2× FLC | 2-4× FLC |

| Starting Torque | 100% | 33% (may fail heavy loads) | 100% | 50-80% |

| Component Cost (30kW) | $65 | $203 | $850+ | $420 |

| Installation Time | 2 hours | 4 hours | 6 hours | 3 hours |

| Common Failure Points | None (simple) | Timer relay, K2/K3 contacts | Power module, PCB | Thyristor, cooling fan |

| Harmonics | None | None | 15-40% THD (requires filters) | Minimal |

| Maintenance Frequency | Annual | Annual | Quarterly | Semi-annual |

| Motor Cable Requirement | 6-core (3+PE) | 6-core (6+PE) | 4-core (3+PE) | 4-core (3+PE) |

| Best Application | <7.5kW or unlimited inrush OK | 7.5-75kW fixed speed | Variable speed critical | Gentle ramp priority |

Cost-Benefit Analysis (5-Year TCO for 30kW Motor):

- Star-Delta: $203 upfront + $50/year maintenance = $453 total

- VFD: $850 upfront + $180/year maintenance + $200 harmonics filter = $2,150 total

For fixed-speed applications, Star-Delta delivers 79% cost savings with zero performance compromise.

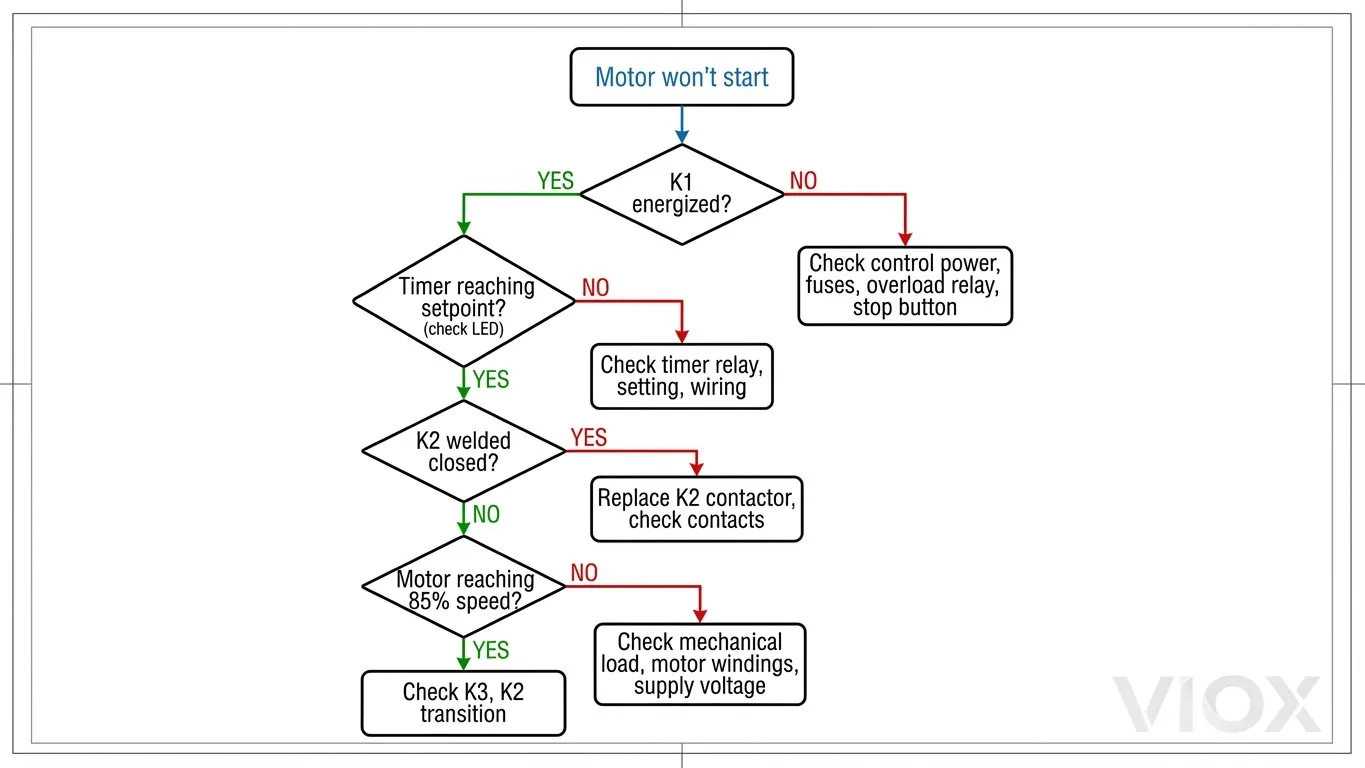

Common Mistakes & Troubleshooting

Design Errors That Cause Failures

1. Wrong Timer Delay (40% of field issues)

Symptom: Heavy current spike during Star → Delta transition, nuisance breaker trips.

Root Cause: Timer set <5 seconds on high-inertia loads. Motor speed only reaches 60-70% before switching.

Fix: Extend to 12-15 seconds. Verify with clamp meter during transition—current should drop to 1.2× FLC before switching.

2. Missing Interlocks (25% of commissioning failures)

Symptom: Loud bang, blown fuses, damaged contactors.

Root Cause: Both K2 and K3 closed simultaneously due to missing mechanical/electrical interlock.

Fix:

- Add normally-closed auxiliary contacts as shown in control diagram

- Consider contactors with built-in mechanical interlocks (VIOX VX-CJX2-IK series)

3. Undersized Star Contactor (15% of premature failures)

Symptom: K2 contacts welded after 6-12 months.

Root Cause: Used 50% motor FLC instead of 58% rule. Marginal during cold starts.

Fix: Upgrade K2 to next standard size. For 57A motor, use 40A (not 32A) contactor.

4. Motor Not Star-Delta Compatible

Symptom: Starter works, motor doesn’t start.

Root Cause: Motor terminals only bring out U1, V1, W1 (Delta-only configuration).

Fix: Verify motor nameplate shows “Δ/Y” or “400V/690V”. If not, Star-Delta is impossible—use soft starter instead.

Diagnostic Flowchart

Frequently Asked Questions

What is the difference between Star-Delta and DOL starting?

Direct-On-Line (DOL) connects the motor at full voltage immediately, drawing 5-8× rated current. Star-Delta starts the motor at 58% voltage (1/√3), limiting inrush to 1.8-2.5× FLC. Trade-off: Star-Delta provides only 33% starting torque, so it won’t work for high-inertia loads like loaded conveyors or piston compressors.

Can I use Star-Delta starting for all motor sizes?

Practical range: 7.5kW to 75kW. Below 7.5kW, DOL is sufficient and cheaper. Above 75kW, the mechanical stress of Star → Delta transition becomes problematic—VFDs or auto-transformer starters are preferred. Additionally, motors must have six accessible terminals (U1/U2, V1/V2, W1/W2).

How long should the Star-Delta timer be set?

General rule: 5-15 seconds, but validate during commissioning:

- Clamp meter on any motor terminal during start

- Current should drop from starting peak to 1.2-1.5× FLC before timer expires

- If current still high when switching, extend timer by 2-3 seconds

Light loads (fans, centrifugal pumps): 5-8s

Medium loads (conveyors, compressors): 8-12s

Heavy loads (crushers, piston pumps): 12-15s

What happens if both Star and Delta contactors close simultaneously?

Instant short circuit. L1, L2, L3 are directly connected through motor windings, creating a phase-to-phase fault. This will:

- Weld contactor contacts beyond repair

- Trip upstream breakers (if sized correctly)

- Potentially damage motor insulation from fault current (10-20kA)

Prevention: Always use electrical interlocks (NC auxiliary contacts) and mechanical interlocks where available.

Why does my Star-Delta starter trip the breaker during transition?

Two common causes:

1. Timer too short: Motor still accelerating (70-80% speed) when switching. The sudden reconnection at Delta creates a 3-4× current spike. Fix: Extend timer to 12-15 seconds.

2. Star contactor welded closed: If K2 fails to open, switching to K3 creates the short-circuit condition above. Fix: Replace K2, investigate why it welded (undersized? Dust ingress?).

Can Star-Delta starters handle reversing motors?

Not directly. Standard Star-Delta starters provide unidirectional control only. For reversing:

- Add a forward/reverse contactor pair before the Star-Delta circuit

- Ensure mechanical/electrical interlocking between forward and reverse

- This adds 2 more contactors (typically 25A-32A range)

See our guide on motor control circuits for reversing logic.

What’s the typical lifespan of Star-Delta starter components?

Electrical life (before contact replacement):

- Contactors (K1, K3): 100,000-200,000 operations (AC3 duty)

- Star Contactor (K2): 150,000-300,000 operations (lower stress)

- Timer Relay: 10-15 years (solid-state) or 5-8 years (electromechanical)

- Thermal Overload: 15-20 years (rarely fails unless severely overloaded)

Mechanical life: Contactors can handle 1-5 million no-load operations. The limiting factor is always electrical arcing during motor switching.

Conclusion: When Star-Delta Makes Sense

For fixed-speed motors between 7.5kW and 75kW, Star-Delta starting offers the optimal balance of cost, reliability, and inrush current reduction. It costs 75% less than VFDs, generates zero harmonics, and uses commodity components with global availability.

When to choose Star-Delta:

- ✅ Fixed-speed applications (pumps, fans, compressors)

- ✅ Budget constraints prohibit VFDs

- ✅ Utility limits inrush current >3× motor FLC

- ✅ Motor has accessible six terminals (Δ/Y configuration)

When to avoid Star-Delta:

- ❌ High starting torque required (>50% FLT)

- ❌ Variable speed operation needed

- ❌ Motors <7.5kW (use DOL) or >75kW (use soft starter/VFD)

For complete component selection guidance, reference our circuit breaker and contactor sizing tables—and contact VIOX for project-specific BOMs with volume pricing.