Understanding voltage classifications is fundamental to electrical engineering, power distribution, and equipment selection. Whether you’re designing a residential circuit, managing an industrial facility, or planning a power transmission network, knowing the differences between low, medium, and high voltage is essential for safety, efficiency, and compliance with international standards.

This comprehensive guide explores the technical distinctions, applications, and safety considerations across all voltage classifications, helping electrical professionals make informed decisions about system design and equipment selection.

What is Voltage and Why Does Classification Matter?

Voltage, measured in volts (V), represents the electrical potential difference between two points in a circuit. It’s the “pressure” that pushes electrical current through conductors, similar to how water pressure moves water through pipes.

Voltage classification serves three critical purposes:

- Safety Standardization: Different voltage levels require specific insulation, protective equipment, and handling procedures to prevent electrical hazards

- Equipment Compatibility: Manufacturers design equipment for specific voltage ranges, ensuring proper operation and longevity

- Efficiency Optimization: Higher voltages reduce transmission losses over long distances, while lower voltages are safer for end-user applications

The classification system enables engineers worldwide to communicate clearly about electrical systems and select appropriate components for their specific applications.

International Standards for Voltage Classification

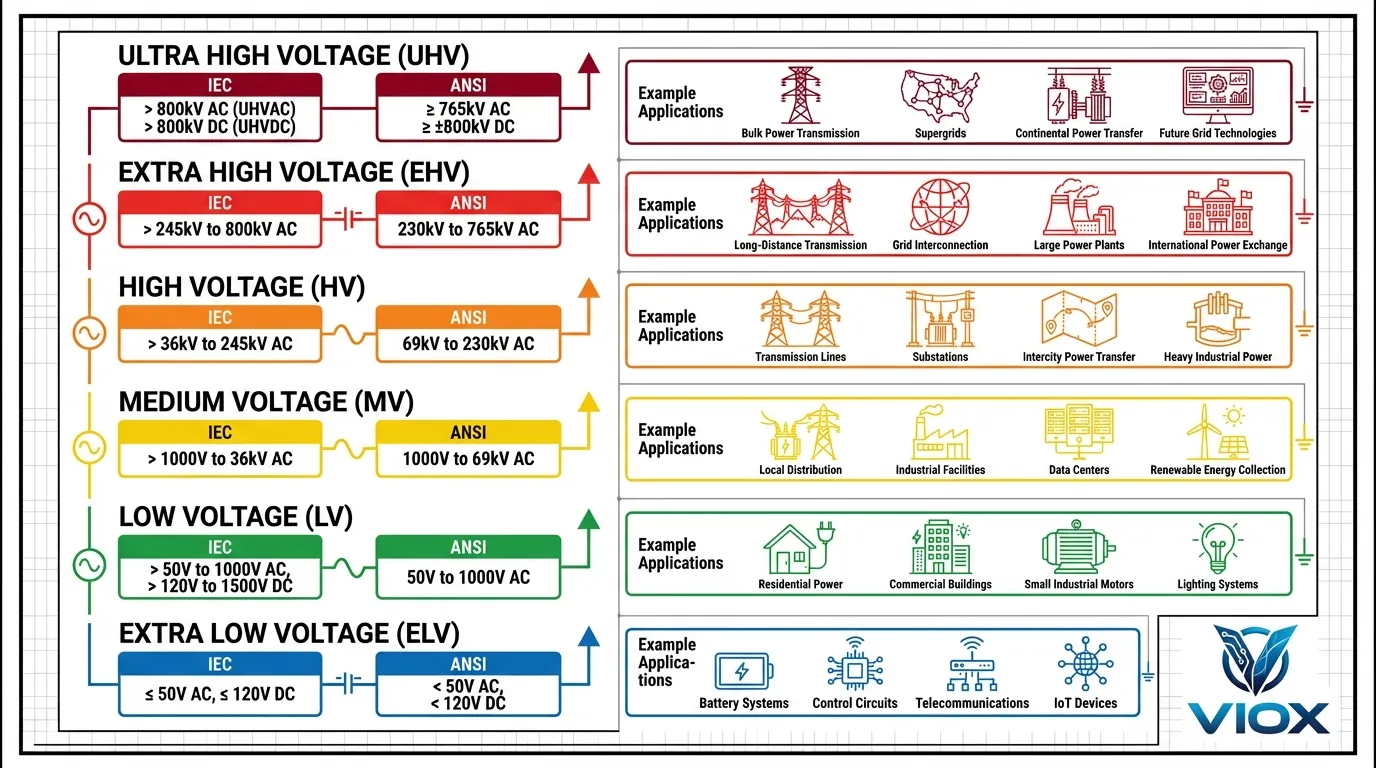

Voltage classifications are not universally standardized—they vary by region and governing body. The two primary standards organizations are:

IEC (International Electrotechnical Commission) Standards

The IEC standards, particularly IEC 60038 and IEC 61140, are used globally outside North America. These standards define voltage ranges for electrical systems and equipment:

- Extra Low Voltage (ELV): Below 50V AC or 120V DC

- Low Voltage (LV): 50V to 1,000V AC or 120V to 1,500V DC

- Medium Voltage (MV): 1kV to 35kV (sometimes extended to 52kV)

- High Voltage (HV): 35kV to 230kV

- Extra High Voltage (EHV): 230kV to 800kV

- Ultra High Voltage (UHV): Above 800kV

ANSI/NEC Standards (North America)

The American National Standards Institute (ANSI) and National Electrical Code (NEC) use slightly different classifications:

- Low Voltage: Up to 600V AC

- Medium Voltage: 601V to 69kV

- High Voltage: 69kV to 230kV

- Extra High Voltage: 230kV to 500kV

- Ultra High Voltage: Above 500kV

This table compares the two major standards:

| Voltage Classification | IEC Standard (International) | ANSI/NEC Standard (North America) |

|---|---|---|

| Extra Low Voltage | < 50V AC / < 120V DC | < 30V AC / < 60V DC |

| Low Voltage | 50V – 1,000V AC | Up to 600V AC |

| Medium Voltage | 1kV – 35kV (52kV) | 601V – 69kV |

| High Voltage | 35kV – 230kV | 69kV – 230kV |

| Extra High Voltage | 230kV – 800kV | 230kV – 500kV |

| Ultra High Voltage | > 800kV | > 500kV |

Understanding which standard applies to your region is crucial for equipment selection, safety compliance, and project planning.

Low Voltage (LV): The Foundation of Everyday Electrical Systems

Definition and Range

Low voltage systems operate at 50V to 1,000V AC (IEC) or up to 600V AC (ANSI/NEC). This classification encompasses the vast majority of electrical systems that people interact with daily.

Key Characteristics

- Safety: Relatively safe for trained personnel with proper precautions

- Insulation Requirements: Standard insulation materials sufficient

- Distribution: Short-distance power distribution (typically under 1 km)

- Current Levels: Higher current for equivalent power compared to higher voltages

- Equipment Cost: Generally less expensive than higher voltage equipment

Common Applications

Low voltage systems power:

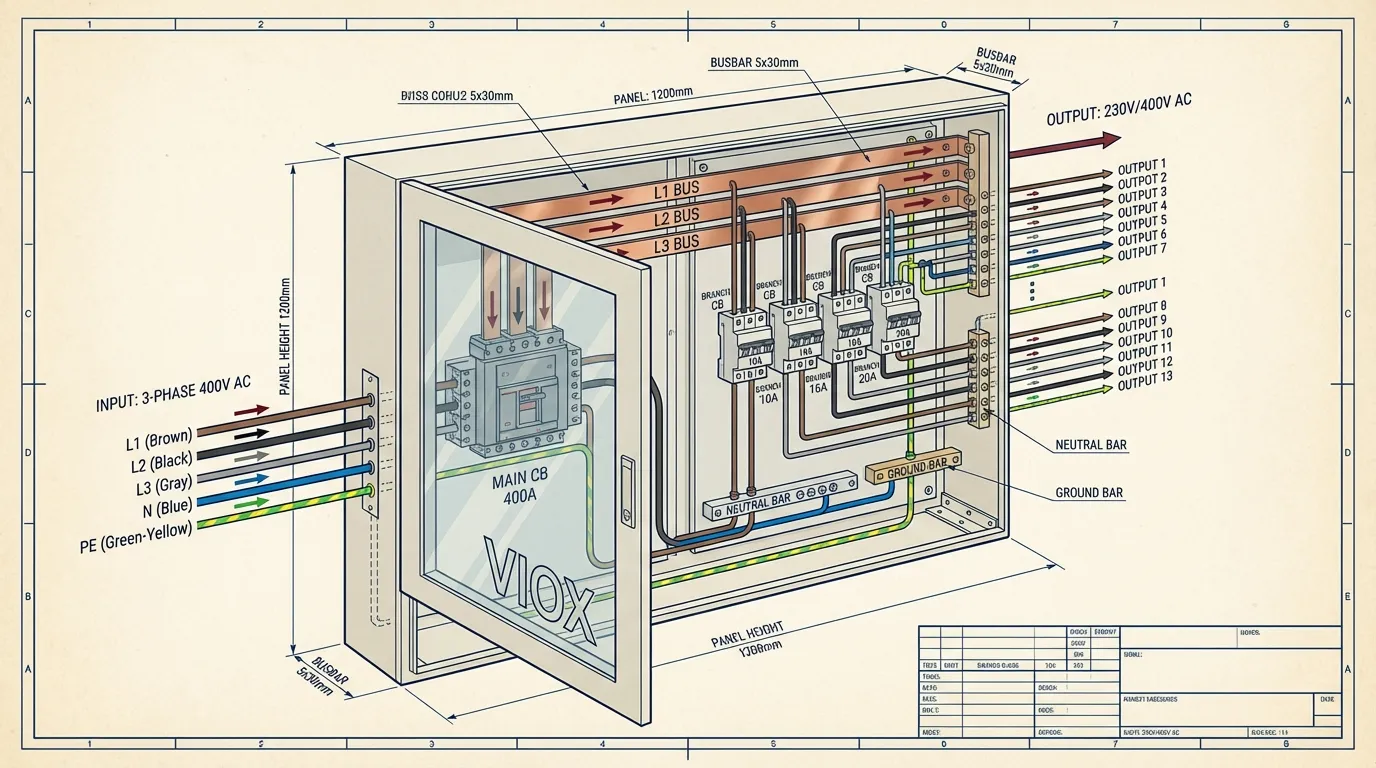

- Residential Buildings: 120V/240V single-phase systems (North America) or 230V/400V three-phase systems (Europe/Asia)

- Commercial Buildings: Lighting, HVAC systems, office equipment, elevators

- Light Industrial: Small motors, control systems, machinery

- Control Circuits: PLCs, automation systems, instrumentation

- Renewable Energy: Inverter outputs, battery energy storage systems, solar distribution boxes

Equipment Examples

- Miniature Circuit Breakers (MCBs)

- Molded Case Circuit Breakers (MCCBs)

- Residual Current Circuit Breakers (RCCBs)

- Contactors and Motor Starters

- Distribution Boards and Panelboards

Safety Considerations

While low voltage is safer than higher classifications, it still poses significant risks:

- Electric Shock: Can be fatal, especially in wet conditions or with prolonged contact

- Arc Flash: Short circuits can produce dangerous arc flash events

- Fire Hazard: Overloaded circuits or faulty equipment can cause electrical fires

- Protective Equipment: Basic PPE including insulated gloves and safety glasses required

According to OSHA standards, any voltage above 50V is considered hazardous and requires appropriate safety measures and training.

Medium Voltage (MV): The Bridge Between Generation and Distribution

Definition and Range

Medium voltage systems operate between 1kV and 35kV (IEC) or 601V to 69kV (ANSI/NEC). This classification serves as the critical link between high-voltage transmission and low-voltage distribution networks.

Key Characteristics

- Efficiency: Significantly reduced transmission losses compared to low voltage

- Distance: Can transmit power economically over 5-50 km

- Current: Lower current for equivalent power, reducing conductor size requirements

- Insulation: Requires enhanced insulation and specialized equipment

- Switching: Needs specialized switchgear and protection devices

Common Applications

Medium voltage systems are essential for:

- Industrial Facilities: Large manufacturing plants, refineries, mining operations

- Commercial Complexes: Shopping centers, hospitals, airports, data centers

- Utility Distribution: Neighborhood substations, rural distribution networks

- Large Motors: Industrial drives, pumps, compressors (typically 1-10 MW)

- Renewable Energy: Wind farms, large-scale solar installations

- Transportation: Electric railway systems, metro networks

Equipment Examples

- Medium Voltage Switchgear (IEC 62271 compliant)

- Vacuum Circuit Breakers (VCBs)

- Ring Main Units (RMUs)

- Power Transformers (MV/LV)

- Medium Voltage Surge Protection Devices

- Isolator Switches

Safety Considerations

Medium voltage requires significantly enhanced safety protocols:

- Specialized Training: Personnel must be specifically trained and certified for MV work

- PPE Requirements: Arc-rated clothing, insulated gloves (Class 2-4), face shields

- Switching Procedures: Formal lockout/tagout procedures mandatory

- Clearance Distances: Minimum approach distances must be maintained

- Arc Flash Risk: Potential for severe arc flash incidents requiring comprehensive risk assessment

The higher energy levels at medium voltage mean that accidents can be catastrophic, making strict adherence to safety standards absolutely critical.

High Voltage (HV): Long-Distance Power Transmission

Definition and Range

High voltage systems operate between 35kV and 230kV (IEC) or 69kV to 230kV (ANSI/NEC). These systems form the backbone of regional power transmission networks.

Key Characteristics

- Transmission Efficiency: Minimal power losses over distances of 50-300 km

- Power Capacity: Can transmit hundreds of megawatts

- Infrastructure: Requires transmission towers, specialized substations

- Insulation: Extensive insulation and clearance requirements

- Environmental Impact: Electromagnetic fields (EMF) and visual impact considerations

Common Applications

High voltage systems enable:

- Regional Transmission: Connecting power plants to distribution networks

- Inter-City Connections: Power transfer between urban centers

- Industrial Complexes: Very large facilities with dedicated substations

- Renewable Integration: Connecting remote wind/solar farms to the grid

- Cross-Border Transmission: International power exchange

Equipment Examples

- Air Circuit Breakers (ACBs) and SF6 Circuit Breakers

- Power Transformers (HV/MV step-down)

- Current and Voltage Transformers (CTs/VTs)

- Lightning Arresters and Surge Protection

- Transmission Line Hardware and Insulators

Safety Considerations

High voltage work demands the highest level of safety protocols:

- Specialized Certification: Only highly trained personnel allowed

- Remote Operation: Most operations performed remotely or with specialized tools

- Clearance Zones: Extensive safety clearances required (meters, not centimeters)

- Electromagnetic Hazards: EMF exposure limits must be observed

- Arc Flash Energy: Potential for extremely high incident energy levels

High voltage systems are typically located away from populated areas and require restricted access with multiple layers of safety controls.

Extra High Voltage (EHV) and Ultra High Voltage (UHV)

Extra High Voltage (230kV – 800kV)

EHV systems transmit power across provinces, states, or even countries with minimal losses. Common voltages include 345kV, 500kV, and 765kV.

Applications:

- National grid interconnections

- Bulk power transmission over 300-1,000 km

- Connecting major generation facilities to load centers

Ultra High Voltage (Above 800kV)

UHV represents the cutting edge of power transmission technology, with systems operating at 1,000kV (1 MV) and above. China has pioneered UHV technology with operational 1,100kV AC and ±1,100kV DC lines.

Applications:

- Transcontinental power transmission

- Connecting remote renewable resources to urban centers

- Reducing transmission corridor requirements

Comparative Analysis: LV vs. MV vs. HV

Understanding the practical differences between voltage classifications helps in system design and equipment selection:

| Parameter | Low Voltage | Medium Voltage | High Voltage |

|---|---|---|---|

| Voltage Range (IEC) | 50V – 1kV | 1kV – 35kV | 35kV – 230kV |

| Typical Transmission Distance | < 1 km | 5 – 50 km | 50 – 300 km |

| Power Capacity | Up to 1 MW | 1 – 50 MW | 50 – 500+ MW |

| Current Levels | High (hundreds to thousands of amps) | Medium (tens to hundreds of amps) | Low (tens to hundreds of amps) |

| Conductor Size | Larger for equivalent power | Medium | Smaller for equivalent power |

| Insulation Requirements | Standard | Enhanced | Extensive |

| Equipment Cost | Lower | Medium | Higher |

| Installation Complexity | Simple | Moderate | Complex |

| Safety Training Required | Basic electrical | Specialized MV | Highly specialized HV |

| Maintenance Frequency | Regular | Periodic | Scheduled/Preventive |

| Typical Applications | Buildings, small industry | Large industry, distribution | Transmission, bulk power |

| Protection Devices | MCBs, MCCBs, RCCBs | VCBs, Switchgear | ACBs, SF6 Breakers |

| Standards Compliance | IEC 60947, UL 489 | IEC 62271, IEEE C37 | IEC 62271-100 |

Power Loss Comparison

The relationship between voltage and power loss is governed by the formula: Power Loss = I²R

Where:

- I = Current (amperes)

- R = Resistance (ohms)

For transmitting the same amount of power:

- Doubling the voltage reduces current by half

- Halving the current reduces power loss by 75%

This is why high voltage is essential for long-distance transmission. For example, transmitting 100 MW:

- At 10kV (MV): Current = 10,000A, very high losses

- At 100kV (HV): Current = 1,000A, losses reduced by 99%

- At 500kV (EHV): Current = 200A, losses reduced by 99.96%

Selecting the Right Voltage Level for Your Application

Choosing the appropriate voltage classification depends on several factors:

1. Power Requirements

- Under 100 kW: Low voltage typically sufficient

- 100 kW to 10 MW: Medium voltage often optimal

- Above 10 MW: High voltage may be required

2. Transmission Distance

- Under 500 meters: Low voltage economical

- 500 meters to 20 km: Medium voltage recommended

- Above 20 km: High voltage necessary for efficiency

3. Load Type

- Residential/Commercial: Low voltage standard

- Industrial Motors: Medium voltage for large motors (>200 HP)

- Bulk Power: High voltage for transmission

4. Cost Considerations

Initial Investment:

- LV: Lowest equipment and installation costs

- MV: Moderate costs, specialized equipment required

- HV: Highest costs, complex infrastructure

Operating Costs:

- LV: Higher losses for long distances

- MV: Balanced efficiency and cost

- HV: Lowest transmission losses

5. Safety and Regulatory Requirements

Each voltage level has specific safety standards:

- Circuit protection requirements

- Grounding and earthing standards

- Arc flash protection

- Personnel training and certification

6. Future Expansion

Consider growth potential:

- Can the system accommodate increased loads?

- Is voltage upgrade feasible if needed?

- What are the infrastructure limitations?

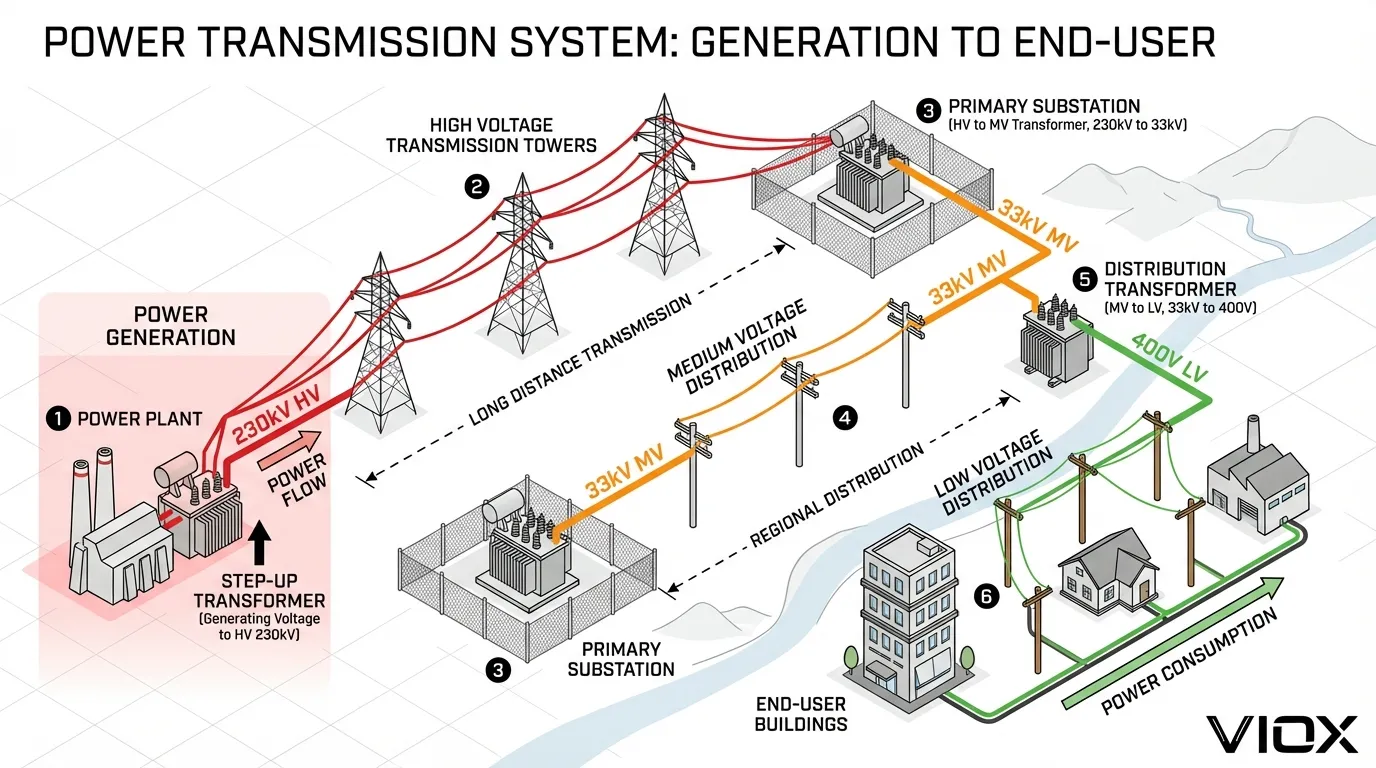

Voltage Transformation and Distribution Networks

Modern electrical systems use multiple voltage levels in a coordinated hierarchy:

- Generation: Power plants generate at medium voltage (typically 11-25kV)

- Step-Up: Transformers increase voltage to HV/EHV for transmission

- Transmission: Long-distance transport at high voltage

- Primary Substations: Step-down to medium voltage for regional distribution

- Distribution Substations: Further reduction to low voltage

- End Users: Final transformation to utilization voltage

This multi-stage approach optimizes efficiency at each level while maintaining safety at the point of use. Transformers play a crucial role in this voltage transformation process.

Safety Standards and Compliance

International Standards

- IEC 60364: Low-voltage electrical installations

- IEC 62271: High-voltage switchgear and controlgear

- IEC 61140: Protection against electric shock

- IEEE C37: Circuit breakers and switchgear standards

- NFPA 70E: Electrical safety in the workplace

Personal Protective Equipment (PPE)

Required PPE varies by voltage level:

Low Voltage:

- Insulated gloves (Class 00 or 0)

- Safety glasses

- Arc-rated clothing (for arc flash hazard areas)

Medium Voltage:

- Insulated gloves (Class 2-4)

- Leather protectors

- Arc-rated suit (minimum 8 cal/cm²)

- Face shield

- Insulated tools

High Voltage:

- Maximum PPE including Class 4 gloves

- Full arc-rated suit (40+ cal/cm²)

- Remote operation preferred

- Hot stick tools

- Specialized training mandatory

Arc Flash Hazard Analysis

All electrical systems above 50V require arc flash hazard analysis per NFPA 70E. This analysis determines:

- Incident energy levels

- Arc flash boundary distances

- Required PPE categories

- Safety labeling requirements

Emerging Trends in Voltage Technology

HVDC (High Voltage Direct Current)

HVDC technology is gaining prominence for:

- Ultra-long distance transmission (>500 km)

- Undersea cable connections

- Asynchronous grid interconnections

- Renewable energy integration

Smart Grid Integration

Modern voltage systems incorporate:

- Digital monitoring and control

- Smart circuit breakers

- Automated voltage regulation

- Real-time load management

Renewable Energy Considerations

Solar and wind installations require careful voltage planning:

- Solar combiner boxes for DC collection

- Inverter output voltage selection

- Grid interconnection requirements

- Surge protection across voltage levels

Key Takeaways

Understanding voltage classifications is essential for electrical professionals. Here are the critical points to remember:

- Voltage classifications vary by region: IEC and ANSI/NEC standards define different ranges—always verify which standard applies to your project

- Low voltage (50V-1kV) powers everyday applications: From residential buildings to light industrial equipment, LV systems are the most common and require standard safety precautions

- Medium voltage (1kV-35kV) bridges generation and distribution: MV systems enable efficient power distribution to industrial facilities and neighborhoods while requiring specialized equipment and training

- High voltage (35kV-230kV) enables long-distance transmission: HV systems minimize power losses over hundreds of kilometers but demand extensive safety protocols and infrastructure

- Higher voltage means lower current and losses: For equivalent power transmission, doubling voltage reduces current by half and power losses by 75%, making HV essential for efficiency

- Each voltage level requires specific equipment: From MCBs in LV to SF6 breakers in HV, proper equipment selection is critical for safety and performance

- Safety requirements escalate with voltage: Personnel training, PPE, and operational procedures become progressively more stringent as voltage increases

- System design must consider multiple factors: Power requirements, transmission distance, load type, costs, and future expansion all influence optimal voltage selection

- Transformers enable multi-voltage networks: Modern electrical systems use coordinated voltage levels from generation to end-use, with transformers facilitating efficient conversion

- Compliance with standards is mandatory: IEC, IEEE, ANSI, and NFPA standards ensure safety, compatibility, and reliability across all voltage classifications

- Emerging technologies are reshaping voltage applications: HVDC transmission, smart grid integration, and renewable energy systems are driving innovation in voltage technology

- Proper voltage classification prevents costly mistakes: Using incorrect voltage levels leads to equipment failure, safety hazards, inefficiency, and regulatory non-compliance

Short FAQ Section

What is the main difference between low, medium, and high voltage?

The primary differences are voltage range, transmission distance capability, and safety requirements. Low voltage (50V-1kV) is used for short-distance distribution in buildings and light industry. Medium voltage (1kV-35kV) enables efficient regional distribution over 5-50 km. High voltage (35kV-230kV) allows long-distance transmission over hundreds of kilometers with minimal losses. Each level requires progressively more sophisticated equipment and safety protocols.

Why do we use different voltage levels instead of just one?

Using multiple voltage levels optimizes efficiency and safety throughout the power system. High voltage minimizes transmission losses over long distances (power loss = I²R, so higher voltage = lower current = lower losses). However, high voltage is dangerous and impractical for end-use applications. Stepping down through medium to low voltage provides safe, usable power while maintaining overall system efficiency. This multi-stage approach balances transmission efficiency, equipment costs, and user safety.

Is 480V considered low or medium voltage?

480V is classified as low voltage under IEC standards (which define LV as up to 1,000V) and also under ANSI/NEC standards (which define LV as up to 600V). However, 480V three-phase systems carry significant power and require more stringent safety precautions than 120V/240V residential systems. In industrial settings, 480V is commonly used for large motors, HVAC systems, and heavy machinery.

What voltage is used in homes?

Residential voltage varies by region: 120V/240V single-phase in North America, 230V/400V in Europe and most of Asia, and 100V in Japan. These are all low voltage systems designed for safety in occupied spaces. The lower voltage (120V or 230V) is used for lighting and small appliances, while the higher voltage (240V or 400V) powers large appliances like electric dryers, ranges, and air conditioners.

What safety equipment is required for working with medium voltage?

Medium voltage work requires specialized safety equipment including: Class 2-4 insulated rubber gloves with leather protectors, arc-rated clothing (minimum 8-12 cal/cm²), face shields, insulated tools, and voltage detectors. Personnel must complete specialized MV training and follow strict lockout/tagout procedures. Arc flash hazard analysis is mandatory to determine specific PPE requirements for each installation.

How do you choose between low and medium voltage for an industrial facility?

The decision depends on several factors: total power demand (MV typically justified above 500-1000 kW), motor sizes (MV preferred for motors above 200 HP), distribution distances (MV more economical beyond 500 meters), and utility connection point voltage. Consider both initial costs (MV equipment is more expensive) and operating costs (MV has lower losses). Consult with electrical engineers and utility providers to evaluate the total cost of ownership for your specific application.

Can you convert low voltage to medium voltage?

Yes, through step-up transformers that increase voltage from LV to MV. This is common in distributed generation applications like solar farms, where inverters produce low voltage AC that’s then stepped up to medium voltage for grid connection. However, the conversion requires proper transformer sizing, protection equipment, and compliance with utility interconnection standards.

What causes the most confusion about voltage classifications?

The primary source of confusion is the difference between IEC and ANSI/NEC standards, which define voltage ranges differently. Additionally, terminology varies—some regions use “high tension” (HT) instead of “high voltage,” and definitions of “medium voltage” vary significantly. Industry-specific standards (like those for railways or mining) may also use different classifications. Always clarify which standard applies to your project and region.

Conclusion

Voltage classification forms the foundation of modern electrical engineering and power systems design. Understanding the distinctions between low, medium, and high voltage—and the international standards that govern them—is essential for safe, efficient, and compliant electrical installations.

From the residential circuit breakers protecting homes to the massive transmission lines spanning continents, each voltage level serves a specific purpose in our interconnected electrical infrastructure. By selecting the appropriate voltage classification for each application and following established safety standards, electrical professionals ensure reliable power delivery while protecting personnel and equipment.

As electrical systems evolve with smart grid technology, renewable energy integration, and HVDC transmission, the fundamental principles of voltage classification remain constant. Whether you’re designing a distribution board, specifying switchgear, or planning a transmission network, proper understanding of voltage levels ensures optimal system performance, safety, and longevity.

At VIOX Electric, we manufacture a comprehensive range of electrical equipment across all voltage classifications, from miniature circuit breakers to medium voltage switchgear, helping electrical professionals worldwide build safer, more efficient power systems.