You’re comparing two MCCBs with identical current ratings—both are 100A, three-pole devices. But the voltage specifications read differently: one shows “Ue 400V, Ui 690V, Uimp 8kV” while the other lists “Ue 690V, Ui 800V, Uimp 6kV.” Which one fits your 400V three-phase system? Can you safely use the first breaker even though its Ue matches your system voltage but the Uimp is different?

These three voltage parameters—Ue, Ui, and Uimp—appear on every electrical equipment datasheet from MCCBs and contactors to relays and terminal blocks. But confusion about what they actually mean leads to under-specified equipment that fails prematurely, over-specified components that waste budget, and compliance issues during project approval.

The problem isn’t just reading three numbers. Each rating tests a different electrical stress: steady-state operation, insulation integrity, and transient surge withstand. They’re governed by different IEC standards, verified through different test procedures, and serve distinct roles in equipment selection. Treating them as interchangeable—or worse, ignoring two of them—creates real safety and reliability risks.

This guide decodes all three voltage ratings with precision. You’ll learn exactly what Ue, Ui, and Uimp measure, which IEC tests validate each parameter, how they relate to insulation coordination standards, and most importantly—which rating matters for which specification decision. By the end, you’ll read equipment datasheets with confidence and select components that match both your system voltage and the complete electrical stress profile your installation faces.

What is Ue (Rated Operational Voltage)?

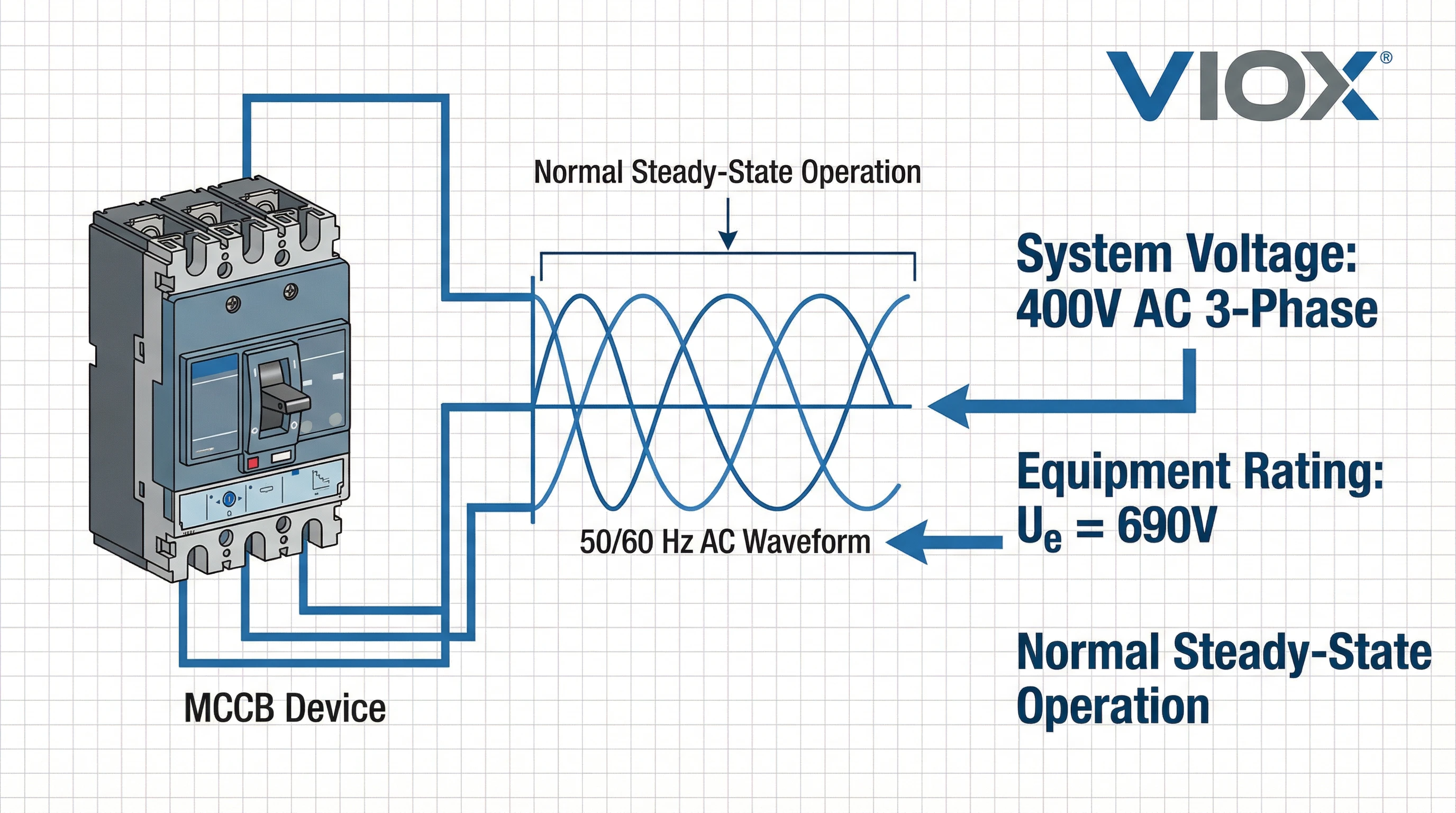

Ue is the rated operational voltage—the voltage at which electrical equipment is designed to operate under normal, undisturbed conditions. This is the number you match to your system’s nominal voltage when selecting MCCBs, contactors, relays, or other control gear.

In IEC 60947 terminology, Ue defines the equipment’s application voltage domain. It works in conjunction with two other critical parameters: Ie (rated operational current) and utilization category (like AC-3 for motors or AC-23 for mixed loads). Together, these three specifications describe the device’s operational performance envelope.

What Ue Actually Tests

Ue doesn’t correspond to a specific standalone test voltage. Instead, it establishes the reference voltage for performance testing:

- Operational endurance tests: Equipment must complete rated operational cycles (making and breaking rated current) at Ue without failure

- Temperature rise verification: At rated current and operational voltage, device temperatures must stay within limits

- Performance coordination: Manufacturers declare current-switching capability, short-circuit performance, and coordination data at specific Ue values

For a contactor rated Ue 400V AC-3 with Ie 95A, that means it has been tested to switch 95A inductive motor loads at 400V for its declared mechanical and electrical endurance.

Typical Ue Values for Industrial Equipment

Standard Ue ratings follow common system voltages:

- 230V / 240V AC: Single-phase European and international systems

- 400V / 415V AC: Three-phase European, Asian, and many industrial systems

- 480V AC: North American three-phase industrial systems

- 690V AC: High-voltage industrial applications, mining equipment

- 24V / 48V / 110V DC: Control circuits, automation systems, battery-backed installations

You select equipment where the declared Ue matches or exceeds your system’s nominal voltage. A device rated Ue 690V can operate in a 400V system (it’s overrated for voltage), but a device rated Ue 230V cannot be used in a 400V application—it’s under-specified.

The Ue-Ie-Category Relationship

Ue never exists in isolation. An MCCB might show Ue 400V with multiple Ie ratings (40A, 63A, 100A) depending on frame size and thermal trip settings. A contactor might list different Ie values at different Ue levels—for example, Ie 95A at Ue 400V but only Ie 80A at Ue 690V, because higher voltage stresses the contacts during arc interruption.

Always verify all three specifications. A device rated for your voltage but wrong utilization category can fail even if the Ue matches perfectly.

What is Ui (Rated Insulation Voltage)?

Ui is the rated insulation voltage—the voltage reference used to determine dielectric test levels and minimum creepage distances. Unlike Ue (which describes operational performance), Ui defines the equipment’s insulation capability. It’s not a permissible operating voltage; it’s a design reference that ensures adequate insulation strength.

The fundamental rule: Ue must never exceed Ui. Equipment datasheets show this relationship explicitly—a contactor rated Ue 400V will typically show Ui 690V or 800V, meaning it can operate at any voltage up to 400V while maintaining insulation designed for 690V or 800V stress levels.

What Ui Actually Tests: Dielectric Strength

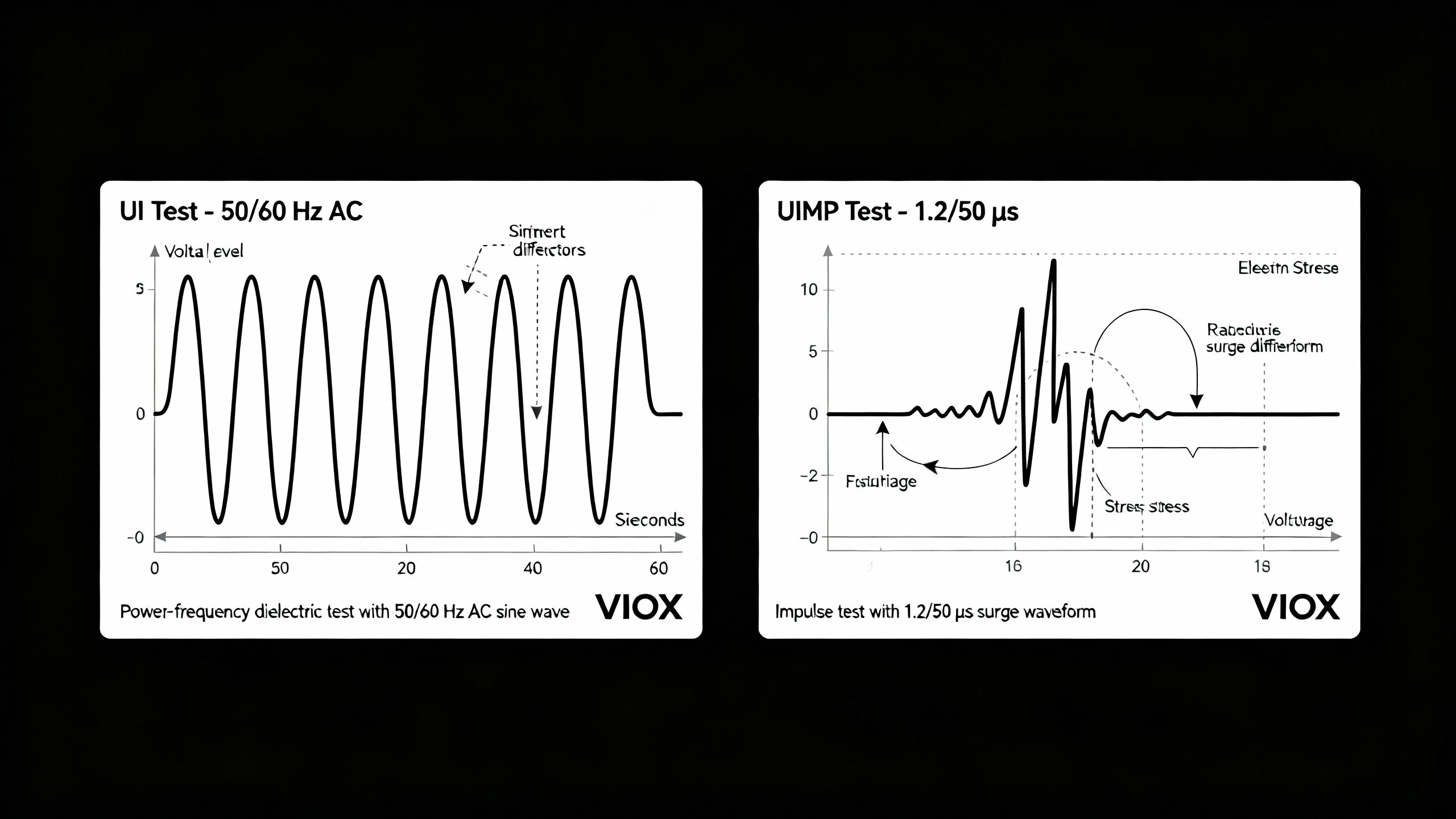

Ui determines the power-frequency dielectric withstand test voltage. This test verifies that insulation can withstand sustained electrical stress without breakdown:

- Test voltage: Typically 2 × Ui + 1000V for equipment with Ui ≤ 690V (per IEC 60947-1)

- Test duration: 60 seconds (1 minute of sustained AC voltage)

- Test frequency: 50 Hz or 60 Hz AC (power frequency)

- Pass criteria: No disruptive discharge, no breakdown, creepage current within specified limits

For example, terminal blocks rated Ui 690V undergo dielectric testing at approximately 2,380V AC for one minute. This simulates years of insulation aging and stress condensed into a single controlled test.

Why Ui Exceeds Ue: The Safety Margin

Electrical equipment experiences voltage stress beyond nominal levels:

- Transient overvoltages: Switching surges, capacitor bank operations

- System voltage variations: Grid fluctuations, generator regulation issues

- Insulation aging: Moisture, contamination, thermal cycling degrade insulation over time

- Safety margin: IEC standards require insulation designed for higher stress than operational voltage

A 400V system rarely sees exactly 400V continuously. Voltage can swing ±10% under normal conditions, and transient events push it higher. Specifying equipment with Ui substantially above Ue ensures insulation integrity throughout the equipment’s service life.

Ui and Creepage Distance Requirements

Ui directly determines minimum creepage distances—the shortest path between conductive parts measured along the insulating surface. IEC 60664-1 tables specify required creepage based on:

- Rated insulation voltage (Ui)

- Pollution degree (level of contamination: clean, normal, conductive)

- Insulating material group (resistance to tracking: I, II, IIIa, IIIb)

Higher Ui demands greater creepage. Terminal blocks for Ui 1000V need significantly more spacing than Ui 400V blocks, even if both operate in the same 400V system. This affects physical size and terminal density.

Common Ui Values

Standard Ui ratings for low-voltage equipment:

- 300V: Light-duty control components, lower-voltage applications

- 500V / 690V: Most common for industrial MCCBs, contactors, relays in 400V/480V systems

- 800V / 1000V: Higher insulation for demanding applications, extended voltage range coverage

Always verify that selected equipment shows Ui ≥ your maximum expected system voltage. For a 480V system, choosing components with Ui 500V provides minimal margin; Ui 690V or 800V offers better long-term reliability.

What is Uimp (Rated Impulse Withstand Voltage)?

Uimp is the rated impulse withstand voltage—the peak voltage value that equipment can withstand when subjected to standardized transient overvoltage impulses without insulation failure. While Ui tests power-frequency dielectric strength, Uimp validates equipment’s ability to survive fast, high-energy surges from lightning strikes, switching events, and grid disturbances.

Uimp is expressed in kilovolts (kV) peak and uses a standardized impulse waveform: 1.2/50 μs (1.2 microsecond rise time to peak, 50 microsecond decay to half-value). This waveform simulates the electrical signature of lightning-induced surges and switching transients.

What Uimp Actually Tests: Surge Immunity

The impulse withstand test subjects equipment to high-voltage transient pulses:

- Test waveform: 1.2/50 μs voltage impulse (standard IEC shape)

- Test voltage: Equipment’s declared Uimp (6 kV, 8 kV, 12 kV, etc.)

- Test procedure: Multiple impulses applied with both polarities (positive and negative)

- Interval between impulses: Minimum 1 second

- Pass criteria: No flashover, no insulation breakdown, no degradation of clearances

For a circuit breaker rated Uimp 8 kV, test engineers apply 8,000-volt peak impulses repeatedly to verify that internal clearances and insulation withstand these transient stresses without failure.

The Overvoltage Category Connection

Uimp values aren’t arbitrary—they’re coordinated with overvoltage categories defined in IEC 60664-1. These categories classify installations by their exposure to transient overvoltages:

- Category I: Equipment with reduced transient exposure (protected electronic circuits)

- Category II: Appliances and portable equipment (typical residential loads)

- Category III: Fixed installations (distribution panels, industrial machinery)

- Category IV: Origin of installation (service entrance, utility meters, overhead lines)

Higher categories face more severe transients. IEC 60664-1 tables map system nominal voltages to required impulse withstand levels for each category. For a 400V three-phase system:

- Category II: Uimp 2.5 kV typical

- Category III: Uimp 6 kV typical

- Category IV: Uimp 8 kV typical

Industrial equipment installed in fixed distribution systems (Category III) needs higher Uimp than appliances plugged into wall outlets (Category II), even though both operate at the same nominal voltage.

Typical Uimp Values for Industrial Equipment

Standard Uimp ratings for low-voltage switchgear and control equipment:

- 4 kV: Lower-category applications, residential equipment

- 6 kV: Common for domestic/residential MCCBs, Category II/III equipment

- 8 kV: Standard for industrial MCCBs, contactors, Category III/IV fixed installations

- 12 kV: Demanding industrial applications, utility-grade equipment, high-exposure locations

Equipment datasheets typically show Uimp values corresponding to the intended installation category. Industrial-grade components default to 8 kV or higher, while residential products may show 4-6 kV.

Why Uimp Matters: Real-World Surge Events

Electrical systems face transient overvoltages regularly:

- Lightning strikes: Direct or nearby strikes induce high-voltage surges into distribution networks

- Switching operations: Opening/closing of large loads, capacitor banks, or transformers creates voltage spikes

- Grid faults: Fault clearing and reclosing operations generate transients

- Motor starting: Inductive load switching produces localized voltage spikes

Equipment with inadequate Uimp fails unpredictably—sometimes immediately after a lightning storm, sometimes after cumulative surge damage weakens insulation over months. Proper Uimp specification ensures equipment survives the transient environment specific to its installation location and category.

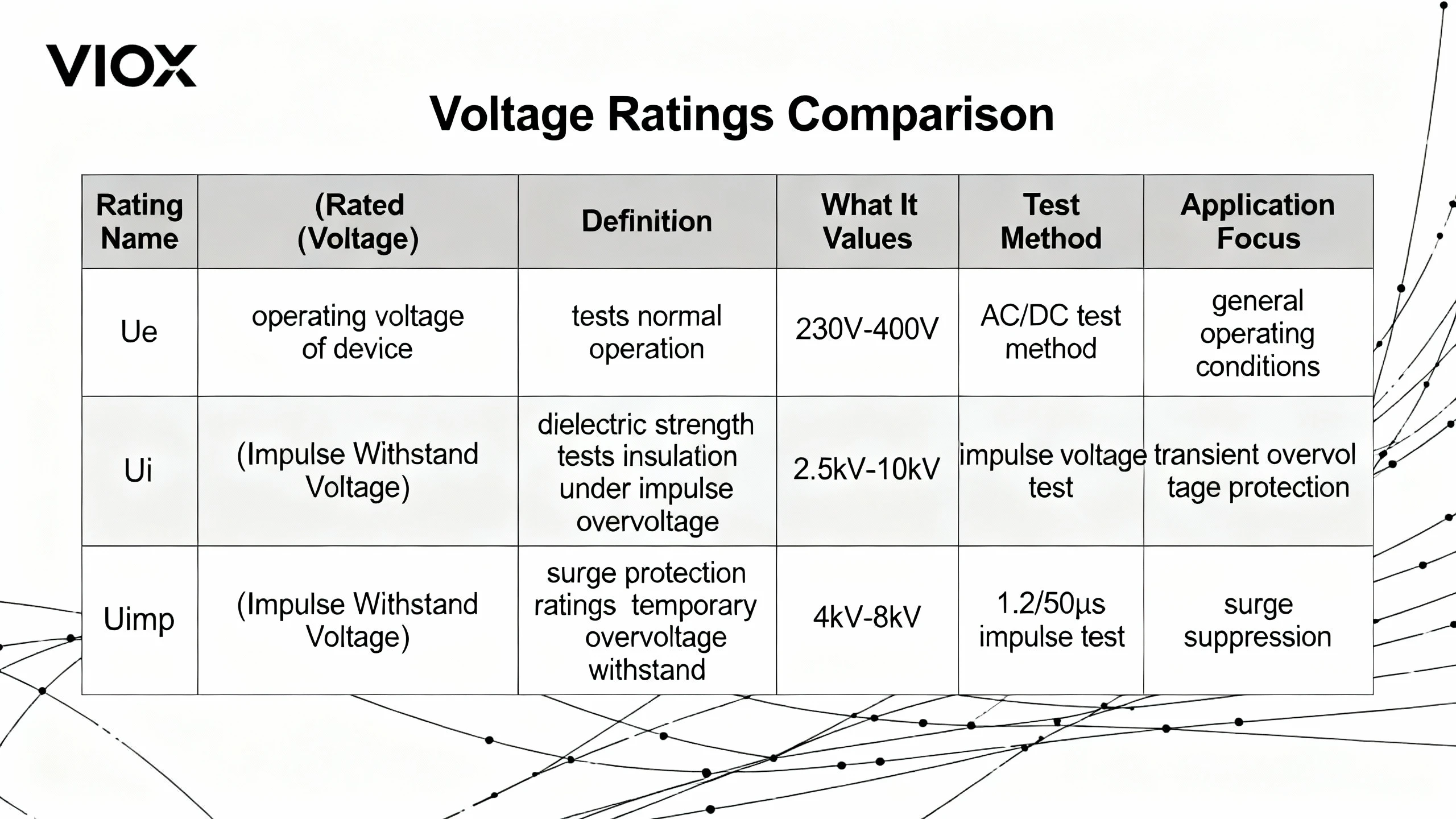

Key Differences: Ue vs Ui vs Uimp

These three voltage ratings measure fundamentally different electrical stresses. Understanding their distinctions prevents specification errors and helps you match equipment to actual operating conditions.

Operational vs. Insulation vs. Surge: Different Questions

Each rating answers a specific design question:

- Ue (Operational Voltage): “What system voltage can this device operate in under normal, continuous conditions?”

- Ui (Insulation Voltage): “What voltage reference determines this device’s insulation strength and creepage distances?”

- Uimp (Impulse Withstand Voltage): “What peak transient voltage can this device survive without insulation breakdown?”

They’re complementary, not interchangeable. You can’t substitute Ui for Ue, and a high Uimp doesn’t compensate for inadequate Ue. All three must align with your application requirements.

Test Method Differences

| Rating | Test Type | Test Voltage | Duration | What It Validates |

| Ue | Operational performance tests | System nominal voltage | Thousands of cycles | Switching capability, endurance, temperature rise |

| Ui | Power-frequency dielectric withstand | ~2 × Ui + 1000V AC | 60 seconds | Insulation integrity against sustained AC stress |

| Uimp | Impulse withstand test | Rated impulse kV peak | Microseconds (multiple shots) | Clearance adequacy against fast transient surges |

Ui tests use 50/60 Hz AC sustained for one minute—a slow, grinding stress on insulation. Uimp tests use 1.2/50 μs impulses—fast, sharp voltage spikes that stress clearances and air gaps differently. Passing one test doesn’t guarantee passing the other.

Voltage Magnitude Relationships

Typical equipment shows a specific voltage hierarchy:

Ue ≤ Ui < Uimp

Example: An industrial MCCB for a 400V system might show:

- Ue = 400V (operational voltage matches system)

- Ui = 690V (insulation designed for higher stress)

- Uimp = 8 kV (impulse withstand for Category III installations)

Notice the order of magnitude: Ue and Ui are in hundreds of volts, while Uimp jumps to thousands of volts. This reflects the different nature of transient surges versus steady-state operation.

Which Rating Governs Which Decision?

Different specification decisions depend on different ratings:

Use Ue to determine:

- System compatibility (does equipment match your nominal voltage?)

- Current rating coordination (Ie values declared at specific Ue levels)

- Utilization category applicability (AC-3, AC-23, etc.)

- Parallel/series configurations (voltage sharing considerations)

Use Ui to verify:

- Adequate insulation safety margin (Ui should exceed Ue significantly)

- Compliance with creepage distance requirements for pollution degree

- Long-term insulation reliability in your environment

- Equipment suitability across voltage ranges (one device, multiple applications)

Use Uimp to ensure:

- Transient surge protection for installation overvoltage category

- Coordination with upstream surge protective devices

- Adequate clearance design for high-exposure locations

- Compliance with insulation coordination standards (IEC 60664-1)

IEC Standards and Testing Requirements

The three voltage ratings aren’t arbitrary manufacturer claims—they’re governed by rigorous IEC international standards that define testing procedures, minimum performance criteria, and documentation requirements.

IEC 60947 Series: Low-Voltage Switchgear and Controlgear

The IEC 60947 series provides the foundation for voltage rating definitions across MCCBs, contactors, relays, motor starters, and control equipment:

- IEC 60947-1: General rules establishing Ue, Ui, Uimp definitions, insulation coordination requirements, and test procedures applicable to all low-voltage switchgear

- IEC 60947-2: Specific requirements for circuit-breakers (MCCBs, ACBs), including short-circuit breaking capacity, selectivity categories, and voltage rating application

- IEC 60947-4-1: Contactors and motor starters, defining utilization categories (AC-3, AC-4, etc.) and how Ue relates to motor switching capability

- IEC 60947-5-1: Control circuit devices and switching elements (limit switches, selector switches, push-buttons)

All parts reference IEC 60947-1 for fundamental voltage rating definitions, then add product-specific test details.

IEC 60947-7-1: Terminal Blocks for Copper Conductors

Terminal blocks follow related standards:

- IEC 60947-7-1: Defines temperature rise, dielectric withstand (validating Ui), short-time current withstand, and impulse tests (validating Uimp) for terminal blocks

- Testing includes: Power-frequency dielectric test (60 seconds at test voltage derived from Ui) and impulse voltage test (1.2/50 μs waveform at rated Uimp)

Terminal blocks use the same fundamental Ui and Uimp framework as MCCBs and contactors, ensuring insulation coordination consistency across all panel components.

IEC 60664-1: Insulation Coordination Within Low-Voltage Systems

IEC 60664-1 provides the engineering tables that connect system voltage to required Uimp and clearances:

- Overvoltage categories (I through IV) classify installation exposure to transients

- Pollution degrees (1 through 4) classify environmental contamination levels

- Rated impulse voltage tables: Map nominal system voltage and overvoltage category to minimum required Uimp

- Clearance and creepage tables: Specify minimum air and surface distances based on Ui, pollution degree, and insulating material group

Engineers use IEC 60664-1 to determine what Uimp and clearances their application demands, then select equipment with datasheets showing adequate ratings.

IEC 61810-1: Electromechanical Relays

Electromechanical relays follow their own standard but use identical voltage rating concepts:

- IEC 61810-1: Defines Ue (switching voltage), Ui (insulation voltage), and Uimp (impulse withstand voltage) for relay contacts and coils

- Test procedures: Power-frequency dielectric tests and impulse tests mirror IEC 60947-1 methodology

A relay rated Ue 400V, Ui 690V, Uimp 6 kV uses the same interpretive framework as an MCCB with those ratings—only the product type differs.

Type Testing vs. Routine Testing

Voltage rating validation involves two test levels:

Type testing (performed once per design):

- Comprehensive validation including dielectric withstand, impulse tests, temperature rise, endurance cycles

- Conducted on representative samples in accredited test laboratories

- Results documented in type test reports and published on datasheets

- Expensive, time-consuming—manufacturers don’t repeat for every production unit

Routine testing (performed on every unit or production batch):

- Basic verification: visual inspection, dimensional checks, simplified dielectric test (lower voltage, shorter duration)

- Ensures manufacturing consistency without repeating full type test battery

- Quick, cost-effective quality control

When you read a datasheet showing Ue, Ui, and Uimp, those values represent type-tested, certified performance. Routine testing confirms each production unit meets the type-tested design.

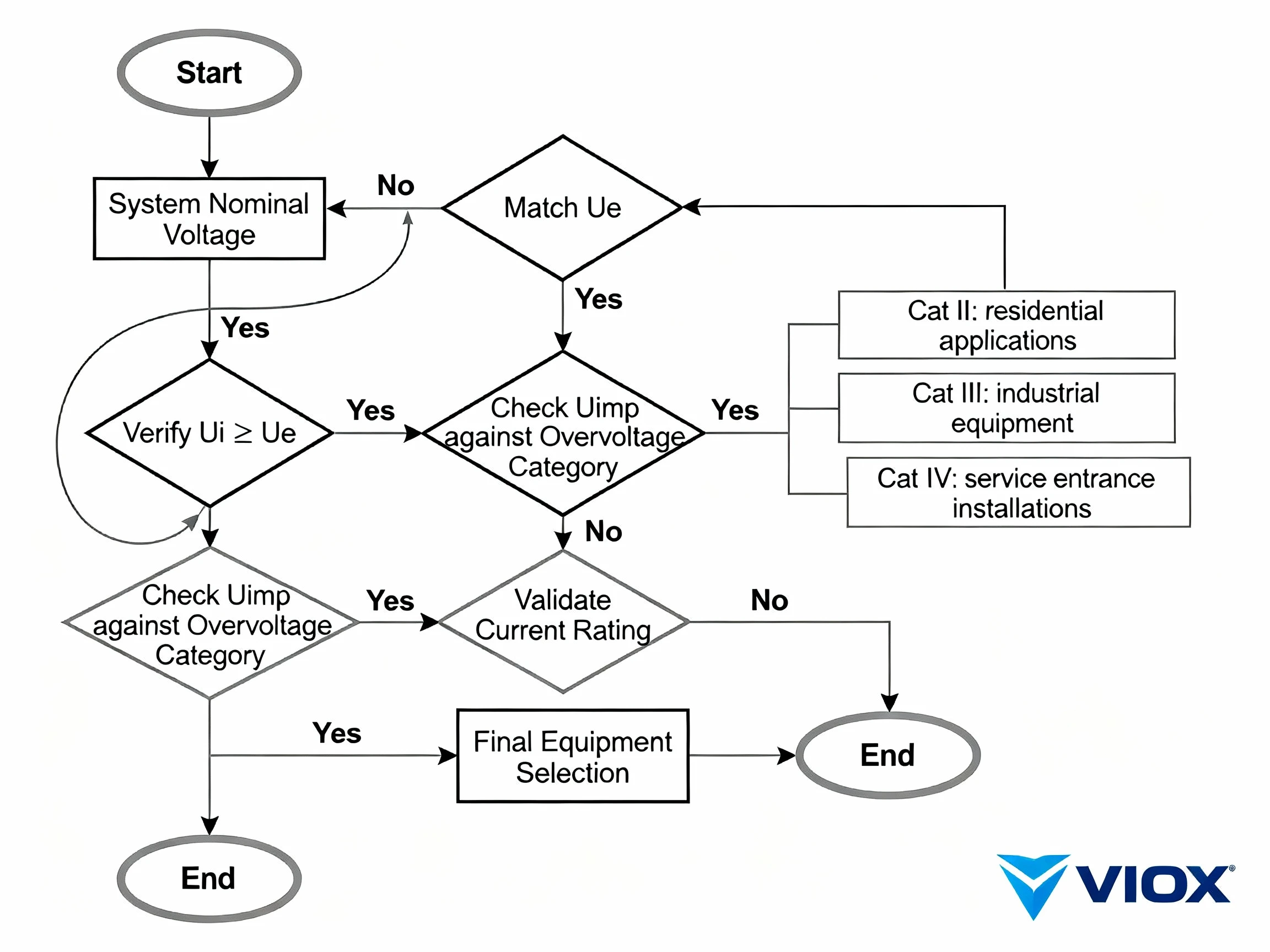

Practical Selection Guide: Using Voltage Ratings Correctly

Selecting equipment with appropriate voltage ratings requires a systematic approach. Follow this decision framework to match ratings to your installation requirements.

Step 1: Identify Your System Nominal Voltage

Start with basic system facts:

- Single-phase systems: 120V, 230V, 240V AC

- Three-phase systems: 208V, 380V, 400V, 415V, 480V, 600V, 690V AC

- DC systems: 24V, 48V, 110V, 220V DC (common in control/battery applications)

This is your minimum Ue requirement. Equipment rated Ue lower than your system voltage cannot be used; equipment rated Ue equal to or higher than system voltage is acceptable from an operational voltage standpoint.

Step 2: Determine Installation Overvoltage Category

Consult IEC 60664-1 or local electrical codes to classify your installation:

Category I: Sensitive electronic equipment with local surge protection (rare in industrial applications)

Category II: Appliance and socket-outlet circuits, portable equipment at least 10 meters from Category III sources (residential, light commercial)

Category III: Fixed equipment in buildings, distribution panels, industrial machinery (most common industrial application)

Category IV: Origin of installation, service entrance equipment, utility meters, overhead lines

Your installation category determines the minimum required Uimp. For a 400V system:

- Category II → Uimp ≥ 2.5 kV

- Category III → Uimp ≥ 6 kV (often specified as 8 kV for better margin)

- Category IV → Uimp ≥ 8 kV

Step 3: Assess Environmental Pollution Degree

Evaluate contamination levels per IEC 60664-1:

- Pollution Degree 1: Clean environments, sealed enclosures (rare)

- Pollution Degree 2: Normal indoor conditions, only non-conductive pollution (most control cabinets)

- Pollution Degree 3: Conductive pollution or dry non-conductive pollution that becomes conductive when wet (industrial environments, outdoor installations)

- Pollution Degree 4: Persistent conductive pollution from rain, snow, or severe contamination

Higher pollution degrees require equipment with greater creepage distances, which means higher Ui ratings for the same clearance capability. A 400V system in Pollution Degree 3 needs larger creepage than the same voltage in Degree 2.

Step 4: Select Equipment Ui with Adequate Margin

General rule: Specify equipment with Ui at least 1.5× your system nominal voltage, preferably higher.

For common systems:

- 400V three-phase system: Specify Ui ≥ 690V (1.73× margin)

- 480V three-phase system: Specify Ui ≥ 690V or 800V

- 230V single-phase system: Specify Ui ≥ 400V or 500V

This margin accounts for voltage variations, transient overvoltages, and insulation aging over equipment service life.

Step 5: Verify Uimp Matches Installation Category

Cross-check equipment datasheets against your installation category from Step 2:

- Ensure declared Uimp ≥ IEC 60664-1 minimum for your system voltage and category

- Industrial fixed installations (Category III) typically need Uimp 6-8 kV minimum

- Don’t under-specify to save cost—surge failures are unpredictable and expensive

Step 6: Validate Current Ratings at Selected Ue

Equipment current ratings (Ie, In) are declared at specific Ue values. Verify that:

- Current rating is adequate for your load at the declared Ue

- If equipment lists multiple Ue options, check that current doesn’t derate at your chosen voltage

- Contactors especially show reduced Ie at higher Ue levels—don’t assume current stays constant

Step 7: Document Selections for Compliance Verification

Maintain a specification record showing:

- System nominal voltage and installation category

- Selected equipment Ue, Ui, Uimp values

- Pollution degree and required creepage distances

- Justification for any deviations from standard practice

This documentation supports approval processes, inspection reviews, and future maintenance/replacement decisions.

Decision Flowchart Summary

- System voltage → Defines minimum Ue

- Installation category (IEC 60664-1) → Defines minimum Uimp

- Pollution degree + Voltage → Defines required creepage (validates Ui selection)

- Load characteristics + Ue → Defines required Ie and utilization category

- Cross-check all ratings → Ensures Ue ≤ Ui, Uimp adequate, current sufficient

If any rating is marginal or unclear, specify the next higher standard rating. The cost difference is minimal compared to field failures and emergency replacements.

Common Specification Mistakes to Avoid

Even experienced engineers make voltage rating errors when working under time pressure or dealing with unfamiliar equipment types. Here are the most frequent mistakes and how to avoid them.

Mistake 1: Using Only Ue and Ignoring Ui/Uimp

Error: Specifying equipment based solely on Ue matching system voltage, without checking Ui and Uimp.

Why it’s wrong: Ue confirms operational compatibility but says nothing about insulation strength or surge withstand. Equipment with correct Ue but inadequate Uimp fails unpredictably after transient events.

Correct approach: Always verify all three ratings. For a 400V system, check that Ue ≥ 400V and Ui ≥ 690V and Uimp ≥ 6-8 kV (depending on installation category).

Mistake 2: Treating Ui as Maximum Operating Voltage

Error: Assuming equipment rated Ui 690V can operate continuously at 690V.

Why it’s wrong: Ui is an insulation reference voltage, not an operational limit. The fundamental rule is Ue ≤ Ui—operational voltage must not exceed the declared Ue, regardless of Ui value.

Correct approach: Match system voltage to Ue, not Ui. For a 690V system, select equipment rated Ue 690V (or higher) with Ui 800V or 1000V. Don’t use equipment rated Ue 400V just because its Ui is 690V.

Mistake 3: Overlooking Installation Category When Selecting Uimp

Error: Specifying residential-grade equipment (Uimp 4-6 kV) for industrial fixed installations (Category III).

Why it’s wrong: IEC 60664-1 requires higher Uimp for installations closer to the electrical supply origin. Category III industrial environments face more severe transients than Category II appliance circuits. Equipment with inadequate Uimp suffers cumulative insulation degradation and unexpected failures.

Correct approach: Determine installation category first, then select equipment with appropriate Uimp. For most industrial applications (Category III), specify Uimp ≥ 8 kV. For service entrance equipment (Category IV), use Uimp ≥ 12 kV.

Mistake 4: Ignoring Pollution Degree Impact on Creepage

Error: Selecting equipment based only on voltage ratings without considering environmental contamination.

Why it’s wrong: Higher pollution degrees require greater creepage distances between conductive parts. Equipment adequate for Pollution Degree 2 (clean control cabinet) may have insufficient creepage for Degree 3 (industrial environment with dust/moisture). This causes tracking and flashover failures.

Correct approach: Assess environment honestly (most industrial sites are Degree 3, not Degree 2), then select equipment with adequate Ui and verified creepage distances for your pollution degree. When in doubt, specify the next higher Ui rating to ensure adequate spacing.

Mistake 5: Assuming Current Ratings Are Voltage-Independent

Error: Selecting a contactor rated Ie 95A at Ue 400V and expecting the same 95A capability at Ue 690V.

Why it’s wrong: Higher voltages stress contact arc interruption more severely. Contactors and switches typically show reduced current capability at higher voltages. Datasheets list multiple Ue/Ie combinations—the Ie value decreases as Ue increases.

Correct approach: Always read current ratings at your specific operating voltage. If you’re designing for 690V operation, use the Ie value declared at Ue 690V, not the (higher) value declared at Ue 400V.

Mistake 6: Mixing Residential and Industrial Equipment

Error: Specifying residential MCCBs (rated Uimp 6 kV) in industrial control panels to save cost.

Why it’s wrong: Residential equipment is tested and certified for Category II applications with lower transient exposure. Industrial environments (Category III/IV) exceed residential equipment’s design envelope. Mixing residential and industrial components creates coordination gaps and compliance issues.

Correct approach: Match equipment grade to installation type. Use industrial-rated components (Uimp 8 kV minimum) for factory, plant, and fixed building installations. Reserve residential-grade equipment (Uimp 4-6 kV) for actual residential applications.

Mistake 7: Forgetting to Verify Replacement Equipment Ratings

Error: Replacing failed equipment with “equivalent” devices that match current ratings but have lower voltage ratings.

Why it’s wrong: Original equipment was specified with complete voltage ratings (Ue, Ui, Uimp) for a reason. Replacement devices with inadequate Ui or Uimp may physically fit and initially work, but fail prematurely under electrical stress.

Correct approach: Document original equipment specifications including all voltage ratings. Verify replacements match or exceed all three ratings (Ue, Ui, Uimp), not just current capacity and physical footprint.

Conclusion

Ue, Ui, and Uimp aren’t three ways of saying the same thing. They’re three distinct measurements addressing different electrical stresses: operational capability (Ue), insulation strength (Ui), and transient surge withstand (Uimp). Equipment selection requires evaluating all three against your system voltage, installation category, and environmental conditions.

The opening question—which MCCB fits a 400V system when one shows “Ue 400V, Ui 690V, Uimp 8kV” and another “Ue 690V, Ui 800V, Uimp 6kV”—now has a clear answer. The first MCCB matches your operational voltage (Ue 400V) with proper insulation margin (Ui 690V) and industrial-grade surge withstand (Uimp 8 kV) suitable for Category III installations. The second is over-specified for operational voltage (Ue 690V exceeds your 400V need) and under-specified for surge protection (Uimp 6 kV is marginal for industrial Category III). The first device is the correct choice.

Proper specification means systematic evaluation: identify system voltage to determine minimum Ue, classify installation category to define required Uimp, assess pollution degree to validate Ui and creepage adequacy, and cross-check current ratings at your operating voltage. When ratings are marginal, specify the next higher standard value—over-engineering voltage ratings costs far less than premature failures and emergency replacements.

Most importantly, document your selections. Equipment datasheets showing Ue, Ui, and Uimp represent tested, certified performance. Those three numbers tell you whether a device can handle your application’s complete electrical stress profile—not just today’s steady-state operation, but years of voltage variations, environmental contamination, and transient surges. Read them correctly, specify them carefully, and your electrical systems will deliver the reliable performance those standards promise.