Leading Terminal Block Manufacturer & Supplier

Since 2010, VIOX ELECTRIC has been a premier terminal block manufacturer specializing in high-performance electrical connection solutions. Our ISO, UL, and CE certified terminal blocks deliver superior conductivity, durability, and safety for industrial, commercial, and residential applications worldwide. With manufacturing facilities in China and a global distribution network, we offer one of the market’s most comprehensive ranges of terminal blocks, including DIN rail terminal blocks, barrier terminal blocks, and plastic terminal blocks—all engineered to meet international safety standards.

Certified By

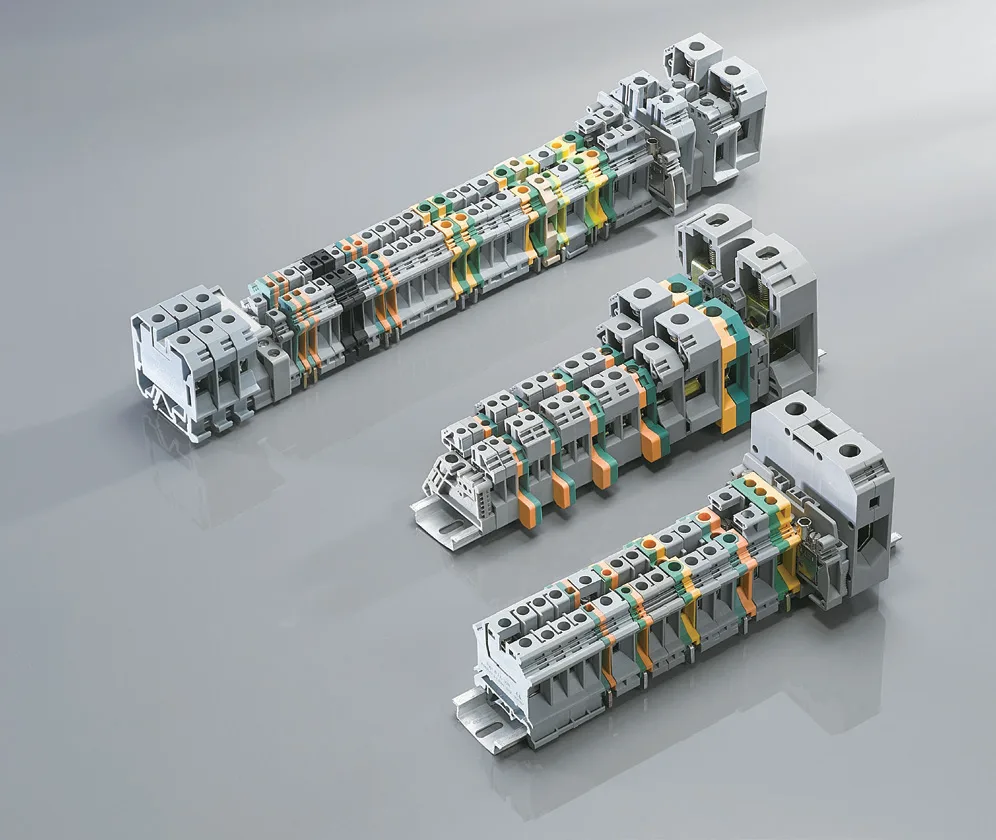

DIN RAIL Terminal Blocks: Industrial-Grade Connectivity Solutions

The industry standard for modular connectivity in control panels and electrical enclosures. Our DIN rail terminal blocks feature superior conductivity, vibration resistance, and tool-free installation options.

Barrier Terminal Blocks: High-Power Connection Solutions

Perfect for high-power applications requiring robust connections and superior isolation. Our barrier terminal blocks provide exceptional thermal stability and vibration resistance.

Plastic Terminal Blocks: Versatile & Cost-Effective Solutions

Versatile, cost-effective solutions for general-purpose applications with excellent electrical properties and durability.

Why Partner with VIOX Electric for Your Terminal Block Needs?

VIOX ELECTRIC has established itself as a global leader in terminal block manufacturing through our commitment to quality, innovation, and customer satisfaction.

Custom Engineering Solutions: Our engineering team specializes in creating customized terminal block solutions tailored to your specific electrical requirements, voltage specifications, and installation environments.

Industry-Leading Expertise: With over 18 years of experience manufacturing terminal blocks, our technical team provides unmatched guidance on selection, installation, and troubleshooting.

Comprehensive Quality Assurance: Every terminal block undergoes rigorous testing including thermal cycling, vibration resistance, and current capacity verification to exceed international safety standards.

Terminal Block Accessories & Components

VIOX ELECTRIC offers a complete range of terminal block accessories designed to enhance functionality and installation efficiency:

1. TS-K small insert

2. UBE-D marking seat

3.ATP-UK Partition

4. ZB6 marking strip

5. FBI10-6 connection strip

6. B1 Marking Seat

7. KLM-A marker folder

8. Din Rail

9. E/UK Terminal Fasteners

10. USLKG2.5 Ground terminal block

11. EB10-6 Side connection strip

12. UK Terminal Block

Precision Craftsmanship & Superior Materials

VIOX Terminal Block Size Chart

| MODEL | CROSS-SECTION | VOLTAGE RATING | CURRENT RATING | HOUSING MATERIAL | CONDUCTOR MATERIAL |

|---|---|---|---|---|---|

| MRK-2.5 | 2.5MM² | 750V | 24A | Nylon | Copper |

| MRK-4 | 4MM² | 750V | 32A | Nylon | Copper |

| MRK-6 | 6MM² | 750V | 40A | Nylon | Copper |

| MRK-10 | 10MM² | 750V | 57A | Nylon | Copper |

| MRK-16 | 16MM² | 750V | 82A | Nylon | Copper |

| MRK-25 | 25MM² | 750V | 100A | Nylon | Copper |

| MRK-35 | 35MM² | 750V | 125A | Nylon | Copper |

| MRK-50 | 50MM² | 750V | 150A | Nylon | Copper |

| MRK-70 | 70MM² | 750V | 192A | Nylon | Copper |

| MRK-95 | 95MM² | 1000V | 232A | Nylon | Copper |

| MRK-120 | 120MM² | 1000V | 269A | Nylon | Copper |

| MODEL | LENGTH (MM) | HEIGHT (MM) | THICKNESS (MM) | BOLT SIZE | VOLTAGE (V) | CURRENT (A) | SECTIONAL AREA OF CONDUCTOR |

|---|---|---|---|---|---|---|---|

| UK1.5N | 42.5mm | 41mm | 4.2mm | M2 | 500V | 17.5A | 1.5mm² |

| UK2.5B | 42.5mm | 41mm | 4.2mm | M3 | 500V | 24A | 2.5mm² |

| UK3N | 42.5mm | 46mm | 5.2mm | M3 | 800V | 24A | 2.5mm² |

| UK16N | 42.2mm | 42.6mm | 12.2mm | M4 | 800V | 76A | 16mm² |

| UK25N | 42.2mm | 46mm | 12.2mm | M4 | 800V | 100A | 25mm² |

| UK35N | 50.5mm | 50.5mm | 15mm | M6 | 1000V | 125A | 35mm² |

| UK5N | 42.5mm | 46mm | 5.1mm | M3 | 800V | 32A | 4.0mm² |

| UK6N | 42.5mm | 46mm | 5.1mm | M4 | 800V | 41A | 6mm² |

| UK10N | 42.5mm | 46mm | 10.2mm | M4 | 800V | 57A | 10mm² |

| UKH50 | 71.9mm | 78.8mm | 20.7mm | M6 | 1000V | 150A | 50mm² |

| UKH95 | 83.5mm | 90.6mm | 25mm | M8 | 1000V | 232A | 95mm² |

| UKH150 | 101.2mm | 111.4mm | 31mm | M10 | 1000V | 309A | 150mm² |

| URTK/S | 72.8mm | 51mm | 8.2mm | M4 | 400V | 41A | 6mm² |

| MBKKB2.5 | 62.5mm | 41mm | 5.2mm | M3 | 500V | 24A | 2.5mm² |

| UKK3 | 57mm | 61.2mm | 5.2mm | M3 | 500V | 24A | 2.5mm² |

| UK5-MTK | 51.2mm | 61.2mm | 6.2mm | M3 | 500V | 16A | 4mm² |

| UDK4 | 64mm | 46mm | 6.2mm | M3 | 630V | 32A | 4mm² |

| UK5-HESI | 74mm | 56mm | 8.2mm | M3 | 800V | 6.3A | 4mm² |

| UKKB3 | 68mm | 61.2mm | 5.3mm | M3 | 500V | 24A | 2.5mm² |

| UKK5 | 57mm | 61.2mm | 6.1mm | M3 | 500V | 32A | 4mm² |

| UKKB5 | 68mm | 61.2mm | 5.3mm | M3 | 500V | 32A | 4mm² |

| UK10-DREHSI | 62.4mm | 56mm | 12.2mm | M4 | 500V | 10A | 10mm² |

| USLKG2.5 | 42.5mm | 41mm | 6.3mm | M3 | – | – | 2.5mm² |

| USLKG3 | 42.5mm | 46mm | 5.2mm | M3 | – | – | 2.5mm² |

| USLKG5 | 42.5mm | 46mm | 5.2mm | M3 | – | – | 4mm² |

| USLKG6 | 42.5mm | 46mm | 8.2mm | M4 | – | – | 6mm² |

| USLKG10 | 42.5mm | 46mm | 10.2mm | M4 | – | – | 10mm² |

| USLKG16 | 42.5mm | 52.5mm | 10.2mm | M4 | – | – | 16mm² |

| USLKG35 | 50.5mm | 61.5mm | 15.2mm | M6 | – | – | 35mm² |

| USLKG50 | 71.5mm | 76.8mm | 20.2mm | M6 | – | – | 50mm² |

| MODEL | RATED VOLTAGE (V) | RATED CURRENT (A) | RATED CROSS-SECTION (MM²) | RIGID WIRE RANGE (MM²) | FLEXIBLE WIRE RANGE (MM²) | STRIPPING LENGTH (MM) | THICKNESS (MM) | MOUNTING RAIL | END PLATE MODEL | PLUG-IN BRIDGE ACCESSORIES (EXAMPLES) | MARKING STRIPS (EXAMPLES) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| SJ-1.5 | 500V | 17.5A | 1.5 | 0.14-1.5 | 0.14-1.5 | 10 | 4.2 | TH35-7.5, TH35-15 | SJ-1.5G | UFBS 2-4, UFBS 3-4, UFBS 4-4, UFBS 5-4, UFBS 10-4 | ZB4 (Blank/Printed) |

| SJ-2.5 | 800V | 24A | 2.5 | 0.2-4 | 0.2-2.5 | 10 | 5.2 | TH35-7.5, TH35-15 | SJ-2.5G | UFBS 2-5, UFBS 3-5, UFBS 4-5, UFBS 5-5, UFBS 10-5 | ZB5 (Blank/Printed) |

| SJ-4 | 800V | 32A | 4 | 0.2-6 | 0.2-4 | 10 | 6.2 | TH35-7.5, TH35-15 | SJ-4G | UFBS 2-6, UFBS 3-6, UFBS 4-6, UFBS 5-6, UFBS 10-6 | ZB6 (Blank/Printed) |

| SJ-6 | 800V | 41A | 6 | 0.5-10 | 0.5-6 | 12 | 8.2 | TH35-7.5, TH35-15 | SJ-6G | UFBS 2-8, UFBS 3-8, UFBS 4-8, UFBS 5-8, UFBS 10-8 | ZB8 (Blank/Printed) |

| SJ-10 | 800V | 57A | 10 | 1.5-16 | 1.5-10 | 16 | 10.2 | TH35-7.5, TH35-15 | SJ-10G | UFBS 2-10, UFBS 3-10 (example), UFBS 4-10 (example), UFBS 5-10 (example), UFBS 10-10 (example) | ZB10 (Blank/Printed) |

| SJ-16 | 800V | 90A | 16 | 2.5-25 | 2.5-16 | 18 | 12.2 | TH35-7.5, TH35-15 | SJ-16G | (Refer to catalog for specific high-current bridges) | ZB10 (Blank/Printed) or larger |

| SJ-2.5/1×2 | 800V | 24A | 2.5 | 0.2-4 | 0.2-2.5 | 10 | 5.2 | TH35-7.5, TH35-15 | SJ-1x2G (example) | UFBS 2-5, UFBS 3-5, UFBS 4-5, UFBS 5-5, UFBS 10-5 | ZB5 (Blank/Printed) |

| SJ-2.5/2×2 | 800V | 24A | 2.5 | 0.2-4 | 0.2-2.5 | 10 | 5.2 | TH35-7.5, TH35-15 | SJ-2x2G / SJ-2.5/2x2G | UFBS 2-5, UFBS 3-5, UFBS 4-5, UFBS 5-5, UFBS 10-5 | ZB5 (Blank/Printed) |

| SJ-2.5JD | 2.5 | 0.2-4 | 0.2-2.5 | 10 | 5.2 | TH35-7.5, TH35-15 | SJ-2.5G | UFBS 2-5, UFBS 3-5, UFBS 4-5, UFBS 5-5, UFBS 10-5 | ZB5 (Blank/Printed) | ||

| SJ-4JD | 4 | 0.2-6 | 0.2-4 | 10 | 6.2 | TH35-7.5, TH35-15 | SJ-4G | (Refer to UFBS 2-6 etc.) | ZB6 (Blank/Printed) | ||

| SJ-6JD | 6 | 0.5-10 | 0.5-6 | 12 | 8.2 | TH35-7.5, TH35-15 | SJ-6G | (Refer to UFBS 2-8 etc.) | ZB8 (Blank/Printed) | ||

| SJ-10JD | 10 | 0.5-16 (Typo in doc as 0.5-10 for rigid, using SJ-10 data) | 0.5-10 (Typo in doc as 0.5-10 for flex, using SJ-10 data) | 16 (Using SJ-10 data) | 10.2 | TH35-7.5, TH35-15 | SJ-10G | (Refer to UFBS 2-10 etc.) | ZB10 (Blank/Printed) | ||

| SJ-16JD | 16 | 2.5-25 | 2.5-16 | 18 (Typo in doc as 12, using SJ-16 data) | 12.2 | TH35-7.5, TH35-15 | SJ-16G | (Refer to high-current bridges) | ZB10 (Blank/Printed) or larger |

| MODEL NUMBER | DIMENSIONS (MM) | RATED VOLTAGE | RATED CURRENT | WIRE RANGE (MM²) | SOLID WIRE (MM²) | STRANDED WIRE (MM²) | STRIP LENGTH (MM) |

|---|---|---|---|---|---|---|---|

| SAK-2.5EN | 41 x 32.5 x 6 | 800V | 24A | 2.5 | 0.5-4 | 1.5-4 | 10 |

| SAK-4EN | 41 x 32.5 x 6.5 | 800V | 32A | 4 | 0.5-6 | 1.5-6 | 12 |

| SAK-6EN | 41 x 32.5 x 8 | 800V | 41A | 6 | 0.5-10 | 1.5-10 | 12 |

| SAK-10EN | 51 x 47 x 10 | 800V | 57A | 10 | 1.5-16 | 1.5-16 | 12 |

| SAK-16EN | 51 x 47 x 12 | 800V | 76A | 16 | 2.5-16 | 2.5-16 | 15 |

| SAK-25EN | 51 x 47 x 15 | 800V | 101A | 25 | 4-25 | 10-25 | 15 |

| SAK-35EN | 59 x 62.5 x 18 | 800V | 125A | 35 | 6-35 | 10-35 | 20 |

| SAK-70EN | 76.5 x 71.5 x 22.5 | 800V | 192A | 70 | 16-50 | 25-50 | 24 |

| SAK-DK4G | 50.5 x 56.5 x 6 | 500V | 32A | 4 | 0.5-4 | 1.5-4 | 10 |

| SAK-WTL6 | 66 x 56.5 x 8 | 500V | 41A | 4 | 0.5-4 | 1.5-4 | 10 |

| SAK-2.5RD | 58.5 x 56.5 x 8 | 500V | 6.3A | 1 | 0.5-4 | 0.5-4 | 10 |

| SAK-2.5RD/X | 58.5 x 56.5 x 8 | 500V | 6.3A | 1 | 0.5-4 | 0.5-4 |

| MODEL | LENGTH (MM) | HEIGHT (MM) | THICKNESS (MM) | TERMINAL CURRENT | TERMINAL VOLTAGE | CONNECTION MODE | NUMBER OF HOLES | WIRE CROSS-SECTION | STRIP LENGTH |

|---|---|---|---|---|---|---|---|---|---|

| ST1.5 | 49.2mm | 35.7mm | 4.2mm | 17.5A | 500V | pull-back | 1 in/1 in out | 0.08mm²-1.5mm² | 8mm-10mm |

| ST2.5 | 49.2mm | 35.7mm | 5.2mm | 24A | 800V | pull-back | 1 in/1 in out | 0.08mm²-2.5mm² | 8mm-10mm |

| ST4 | 56.2mm | 35.7mm | 6.2mm | 32A | 800V | pull-back | 2 in hole | 0.08mm²-4mm² | 8mm-10mm |

| ST2.5/3 | 60.4mm | 35.7mm | 5.2mm | 24A | 800V | pull-back | 1 in/1 in out | 0.08mm²-4mm² | 8mm-10mm |

| ST4/3 | 72.2mm | 35.7mm | 6.2mm | 32A | 800V | pull-back | 2 in hole | 0.08mm²-6mm² | 8mm-10mm |

| ST2.5/4 | 73mm | 35.7mm | 5.2mm | 24A | 800V | pull-back | 1 in/1 in out | 0.08mm²-4mm² | 8mm-10mm |

| ST6 | 70.7mm | 42.8mm | 8.1mm | 41A | 1000V | pull-back | 2 in hole | 0.2mm²-6mm² | 12mm |

| ST10 | 71.2mm | 49.6mm | 10.2mm | 57A | 1000V | pull-back | 2 in hole | 0.2mm²-10mm² | 16mm |

| ST16 | 80.5mm | 50.8mm | 12.2mm | 76A | 1000V | pull-back | 2 in hole | 0.2mm²-25mm² | 16mm |

| ST4/4 | 83mm | 35.7mm | 6.2mm | 32A | 800V | pull-back | 2 in hole | 0.08mm²-6mm² | 8mm-10mm |

| ST6/3 | 90.5mm | 42.8mm | 8.1mm | 41A | 1000V | pull-back | 2 in hole | 0.2mm²-10mm² | 12mm |

| ST10/3 | 95.3mm | 49.6mm | 10.2mm | 57A | 1000V | pull-back | 2 in hole | 0.2mm²-16mm² | 16mm |

| STTB1.5 | 49mm | 46mm | 4.2mm | 17.5A | 500V | pull-back | double layer | 0.08mm²-1.5mm² | 10mm |

| STTB2.5 | 49mm | 46mm | 5.2mm | 22A | 500V | pull-back | double layer | 0.08mm²-4mm² | 8mm-10mm |

| STTB4 | 49mm | 45.8mm | 6.2mm | 30A | 500V | pull-back | double layer | 0.08mm²-6mm² | 8mm-10mm |

| ST1.5-PE | 49.2mm | 35.7mm | 4.2mm | / | / | pull-back | 1 in/1 in out | 0.08mm²-1.5mm² | 10mm |

| ST2.5-PE | 49.2mm | 35.7mm | 5.2mm | / | / | pull-back | 2 in hole | 0.08mm²-4mm² | 8mm-10mm |

| ST4-PE | 56.2mm | 35.7mm | 6.2mm | / | / | pull-back | 2 in hole | 0.08mm²-6mm² | 8mm-10mm |

| ST4-HESI | 52mm | 64mm | 6.1mm | 0.5-10A | 500V | pull-back | 2 in hole | 0.08mm²-6mm² | 8mm-10mm |

| ST2.5-3L | 104mm | 52mm | 5.3mm | 20A | 500V | pull-back | 3-layer | 0.08mm²-4mm² | 8mm-10mm |

| ST2.5-3LPV | 104mm | 52mm | 5.3mm | 20A | 500V | pull-back | 3-layer | 0.08mm²-4mm² | 8mm-10mm |

| ST6-PE | 70.7mm | 42.8mm | 8.2mm | / | / | pull-back | 2 in hole | 0.2mm²-10mm² | 12mm |

| ST10-PE | 71.2mm | 49.6mm | 10.2mm | / | / | pull-back | 2 in hole | 0.2mm²-16mm² | 16mm |

| ST16-PE | 80.5mm | 50.8mm | 12.2mm | / | / | pull-back | 2 in hole | 0.2mm²-16mm² | 16mm |

| ST2.5/3-PE | 60.4mm | 35.7mm | 5.2mm | / | / | pull-back | 1 in/1 in out | 0.08mm²-4mm² | 8mm-10mm |

| ST2.5/4-PE | 73mm | 35.7mm | 5.2mm | / | / | pull-back | 2 in/2 in out | 0.08mm²-4mm² | 8mm-10mm |

| ST4/3-PE | 72.2mm | 35.7mm | 6.2mm | / | / | pull-back | 2 in hole | 0.08mm²-6mm² | 8mm-10mm |

| STTB1.5-PE | 49mm | 46mm | 4.2mm | / | / | pull-back | double layer | 0.08mm²-1.5mm² | 10mm |

| STTB2.5-PE | 49mm | 46mm | 5.2mm | / | / | pull-back | double layer | 0.08mm²-4mm² | 8mm-10mm |

| STTB4-PE | 49mm | 45.8mm | 6.2mm | / | / | pull-back | double layer | 0.08mm²-6mm² | 8mm-10mm |

| ST4/4-PE | 83mm | 35.7mm | 6.2mm | / | / | pull-back | 2 in/1 in out | 0.08mm²-6mm² | 8mm-10mm |

| ST6/3-PE | 90.5mm | 42.8mm | 8.1mm | / | / | pull-back | 2 in hole | 0.2mm²-10mm² | 12mm |

| ST10/3-PE | 95.3mm | 49.6mm | 10.2mm | / | / | pull-back | 2 in hole | 0.2mm²-16mm² | 16mm |

| ST2.5-3LPE | 104mm | 52mm | 5.2mm | / | / | pull-back | three layer | 0.14-2.5mm² | 8mm-10mm |

| MODEL | LENGTH/WIDTH (MM) | HEIGHT (MM) | THICKNESS (MM) | TERMINAL CURRENT | TERMINAL VOLTAGE | CONNECTION MODE | NUMBER OF HOLES | WIRE CROSS-SECTION | STRIP LENGTH |

|---|---|---|---|---|---|---|---|---|---|

| PT1.5S | 45.8mm | 31.2mm | 3.5mm | 17.5A | 500V | In-line | 1 in, 1 out | 0.14-1.5mm² | 8mm-10mm |

| PT2.5 | 49mm | 35.5mm | 5.2mm | 24A | 800V | In-line | 2 in, hole | 0.14-4mm² | 8mm-10mm |

| PT4 | 56.5mm | 36.8mm | 6.2mm | 32A | 800V | In-line | 2 in, hole | 0.2-6mm² | 10mm-12mm |

| PT1.5S/3 | 55mm | 31.2mm | 3.5mm | 17.5A | 500V | In-line | 2 in, 2 out | 0.14-1.5mm² | 8mm-10mm |

| PT1.5S/4 | 64.2mm | 31.2mm | 3.5mm | 17.5A | 500V | In-line | 4 in, hole | 0.14-1.5mm² | 8mm-10mm |

| PT2.5/3 | 61mm | 35.5mm | 5.2mm | 24A | 800V | In-line | 3 in, 2 out | 0.14-4mm² | 8mm-10mm |

| PT6 | 58mm | 42.5mm | 8.2mm | 41A | 1000V | In-line | 2 in, hole | 0.5-10mm² | 10mm-12mm |

| PT10 | 68mm | 50mm | 10.2mm | 57A | 1000V | In-line | 2 in, hole | 0.5-16mm² | 18mm-20mm |

| PT16N | 76mm | 53mm | 12.2mm | 76A | 1000V | In-line | 2 in, hole | 0.5-25mm² | 18mm-20mm |

| PT2.5/4 | 72.8mm | 35.5mm | 5.2mm | 24A | 800V | In-line | 4 in, hole | 0.14-4mm² | 8mm-10mm |

| PT4/3 | 67.5mm | 36.8mm | 6.2mm | 32A | 800V | In-line | 3 in, hole | 0.2-6mm² | 10mm-12mm |

| PT4/4 | 78mm | 36.8mm | 6.2mm | 32A | 800V | In-line | 4 in, hole | 0.2-6mm² | 10mm-12mm |

| PT6/3 | 74.5mm | 42.5mm | 8.2mm | 41A | 1000V | In-line | 3 in, hole | 0.5-10mm² | 10mm-12mm |

| PTTB1.5S | 65.9mm | 41.5mm | 3.5mm | 16A | 500V | In-line | Double layer | 0.14-1.5mm² | 8mm-10mm |

| PTTB2.5 | 68.8mm | 46mm | 5.2mm | 22A | 500V | In-line | Double layer | 0.14-4mm² | 8mm-10mm |

| PT4-PE | 56.5mm | 36.8mm | 6.2mm | / | / | In-line | 2 in, hole | 0.2-6mm² | 10mm-12mm |

| PT6-PE | 58mm | 42.5mm | 8.2mm | / | / | In-line | 2 in, hole | 0.5-10mm² | 10mm-12mm |

| PT10-PE | 68mm | 50mm | 10.2mm | / | / | In-line | 2 in, hole | 0.5-16mm² | 18mm-20mm |

| PTC4-HESI | 86mm | 40mm | 8.2mm | Fuse wire 0.5A-10A | 500V | Safety terminal | 2 in, hole | 0.2-6mm² | 10mm-12mm |

| PT1.5S-PE | 45.8mm | 31.2mm | 3.5mm | / | / | In-line | 1 in, 1 out | 0.14-1.5mm² | 8mm-10mm |

| PT2.5-PE | 49mm | 35.5mm | 5.2mm | / | / | In-line | 2 in, hole | 0.14-4mm² | 8mm-10mm |

| PT16N-PE | 76mm | 53mm | 12.2mm | / | / | In-line | 2 in, hole | 0.5-25mm² | 18mm-20mm |

| PT2.5/3-PE | 61mm | 35.5mm | 5.2mm | / | / | In-line | 3 in, hole | 0.14-4mm² | 8mm-10mm |

| PT2.5/4-PE | 72.8mm | 35.5mm | 5.2mm | / | / | In-line | 4 in, hole | 0.14-4mm² | 8mm-10mm |

| PT4/3-PE | 67.5mm | 36.8mm | 6.2mm | / | / | In-line | 3 in, hole | 0.2-6mm² | 10mm-12mm |

| PT4/4-PE | 78mm | 36.8mm | 6.2mm | / | / | In-line | 4 in, hole | 0.2-6mm² | 10mm-12mm |

| PT6/3-PE | 74.5mm | 42.5mm | 8.2mm | / | / | In-line | 3 in, hole | 0.5-10mm² | 10mm-12mm |

| PT2.5-3LPE | 103.5mm | 37.5mm | 5.2mm | / | / | In-line | Three layer | 0.14-4mm² | 8mm-10mm |

| PTTB2.5-PE | 68.8mm | 46mm | 5.2mm | / | / | In-line | Double layer | 0.14-4mm² | 8mm-10mm |

| PTTB4-PE | 84.5mm | 46mm | 6.2mm | / | / | In-line | Double layer | 0.2-6mm² | 10mm-12mm |

| MODEL | TYPE | DIMENSIONS (MM) | INSTALLATION CENTER DISTANCE (MM) | INSTALLATION HOLE DIAMETER (MM) | RATED CURRENT (A) |

|---|---|---|---|---|---|

| CM1-F15 | Fixed | 225×40×40 | 208 | 6.8 | 15 |

| CM1-F15L | Fixed | 228×50×30 | 215 | 6.8 | 15 |

| CM1-A15 | Activity | – | – | – | 15 |

| CM1-A30 | Activity | – | – | – | 30 |

| MODEL | VOLTAGE RATING | CURRENT RATING | WIRE CROSS-SECTION | APPLICABLE WIRE | SCREW TYPE | MOUNTING RAIL | THICKNESS (MM) |

|---|---|---|---|---|---|---|---|

| TK-010 | 600V | 10A | 0.75-1.5 mm² | 22-16 AWG | M3 | TH35-7.5 | 8 |

| TK-020 | 600V | 20A | 1.5-2.5 mm² | 22-14 AWG | M3.5 | TH35-7.5 | 9.5 |

| TK-030 | 600V | 30A | 2.5-4 mm² | 18-10 AWG | M4 | TH35-7.5 | 12 |

| TK-040 | 600V | 40A | 4-6 mm² | 16-8 AWG | M4 | TH35-7.5 | 14 |

| TK-060 | 600V | 60A | 6-10 mm² | 16-6 AWG | M5 | TH35-7.5 | 15.5 |

| TK-100 | 600V | 100A | 10-25 mm² | 16-4 AWG | M6 | TH35-7.5 | 19.5 |

| MODEL NO. | RATED CURRENT (A) | POLE NUMBER | CONDUCTOR CROSS SECTION (MM²) | MOUNTING SIZE L1 (MM) | OUTLINE SIZE L×W×H (MM) | CRIMPING TERMINAL (MM) | SCREW TYPE |

|---|---|---|---|---|---|---|---|

| TB-1503 | 15 | 3 | 0.5-1.5 | 34 | 45.3/22/15 | M3 | – |

| TB-1504 | 15 | 4 | 0.5-1.5 | 44 | 54.3/22/15 | M3 | – |

| TB-1505 | 15 | 5 | 0.5-1.5 | 57 | 63.3/22/15 | M3 | – |

| TB-1506 | 15 | 6 | 0.5-1.5 | 61 | 72/22/15 | M3 | – |

| TB-1510 | 15 | 10 | 0.5-1.5 | 96 | 108/22/15 | M3 | – |

| TB-1512 | 15 | 12 | 0.5-1.5 | 114 | 125/22/15 | M3 | – |

| TB-2503 | 25 | 3 | 0.5-2.5 | 44 | 55/30/17 | M4 | – |

| TB-2504 | 25 | 4 | 0.5-2.5 | 57 | 67/30/17 | M4 | – |

| TB-2505 | 25 | 5 | 0.5-2.5 | – | 80/30/17 | M4 | – |

| TB-2506 | 25 | 6 | 0.5-2.5 | 81 | 91/30/17 | M4 | – |

| TB-2510 | 25 | 10 | 0.5-2.5 | 129 | 139/30/17 | M4 | – |

| TB-2512 | 25 | 10 | 0.5-2.5 | 154 | 164.5/30/17 | M4 | – |

| TB-4503 | 45 | 3 | 1.5-4 | 58.5 | 69.5/68/21 | M5 | – |

| TB-4504 | 45 | 4 | 1.5-4 | 75 | 86/38/21 | M5 | – |

| TB-4505 | 45 | 5 | 1.5-4 | 91.5 | 102.5/38/21 | M5 | – |

| TB-4506 | 45 | 6 | 1.5-4 | 108 | 119/38/21 | M5 | – |

| TB-4510 | 45 | 10 | 1.5-4 | 174 | 185/38/21 | M5 | – |

| TB-4512 | 45 | 12 | 1.5-4 | 207 | 218/38/21 | M5 | – |

| TBC-603 | 60 | 3 | 2.5-6 | 60.5 | 84.5/54.5/31.5 | M6 | – |

| TBC-604 | 60 | 4 | 2.5-6 | 82.5 | 113/54.5/31.5 | M6 | – |

| TBC-605 | 60 | 6 | 2.5-6 | 118 | 129/54.5/31.5 | M6 | – |

| TBC-1003 | 100 | 3 | 2.5-6 | 75.5 | 86.5/43.5/35 | M6 | – |

| TBC-1004 | 100 | 4 | 2.5-6 | 96 | 108/43.5/35 | M6 | – |

| TBC-1006 | 100 | 6 | 2.5-6 | 140 | 153/43.5/35 | M6 | – |

| MODEL NO. | RATED CURRENT (A) | POLE NUMBER | CONDUCTOR CROSS SECTION (MM²) | MOUNTING SIZE (MM) | L1 (MM) | OUTLINE SIZE L×W×H (MM) | CRIMPING TERMINAL (MM) |

|---|---|---|---|---|---|---|---|

| TC-603 | 60 | 3 | 6-14² | 28.5 | 5.4 | 85/42/33 | M6 |

| TC-604 | 60 | 4 | 6-14² | 57 | 5.4 | 114/42/33 | M6 |

| TC-1003 | 100 | 3 | 10-12² | 34 | 6 | 102/54/38 | M6 |

| TC-1004 | 100 | 4 | 10-12² | 68 | 6 | 136/54/38 | M6 |

| TC-1503 | 150 | 3 | 40-60² | 38 | 6 | 115/66/42 | M8 |

| TC-1504 | 150 | 4 | 40-60² | 76 | 6 | 153/66/42 | M8 |

| TC-2003 | 200 | 3 | 60-100² | 44 | 8.3 | 131/71/47 | M8 |

| TC-2004 | 200 | 4 | 60-100² | 88 | 8.3 | 177/71/47 | M8 |

| TC-3003 | 300 | 3 | 100-150² | 55 | 8.3 | 164/90/53 | M10 |

| TC-3004 | 300 | 4 | 100-150² | 110 | 8.3 | 220/90/53 | M10 |

| TC-4003 | 400 | 3 | 100-200² | 55 | 8.3 | 164/90/53 | M10 |

| TC-4004 | 400 | 4 | 100-200² | 110 | 8.3 | 220/90/53 | M10 |

| TC-6003 | 600 | 3 | 200-300² | 68.5 | 8.7 | 206/100/72 | M12 |

| TC-6004 | 600 | 4 | 200-300² | 137 | 8.7 | 275/100/72 | M12 |

| MODEL NO. | RATED CURRENT (A) | POLE NUMBER | OUTLINE SIZE L×W×H (MM) | CONDUCTOR CROSS SECTION (MM²) |

|---|---|---|---|---|

| TD-1510 | 10 | 10 | 108/30.1/30 | 1.5² |

| TD-2010 | 20 | 10 | 150/40/38 | 2.5² |

| TD-3010 | 30 | 10 | 173/43/45.6 | 6² |

| TD-6010 | 60 | 10 | 216/52.5/52.5 | 10² |

| TD-10010 | 100 | 10 | 247/60/51.5 | 25² |

| TD-15010 | 150 | 10 | 315/68/58 | 35² |

| TD-20010 | 200 | 10 | 315/68/58 | 35² |

Professional Terminal Block Wiring Guide

The installation process for terminal blocks requires careful preparation and attention to detail. Begin by selecting the appropriate terminal block for your application and ensure you have the correct wire gauge. Follow these four simple steps for secure, reliable connections every time.

Strip the insulation of the wires, Put the wire into the tube terminal

Insert a flat-blade screwdriver and rotate the wire clamp frame counterclockwise to the bottom

Easily insert wires into the bottom of the terminal hole

Turn clockwise to tighten the wire,Take out a flat-blade screwdriver, And complete the wiring

Get Your Free Terminal Block Sample!

We provide samples for free, you just need to tell us what you need

More Than Just a Terminal Block Manufacturer

At VIOX, we pride ourselves on providing timely support, adhering to high standards, and offering tailor-made solutions that meet our customers’ needs, forming the foundation of our growing reputation with Terminal Block.

Service Consultation

If your Terminal Block requirements are straightforward and you don’t need an external consultation, our team can offer expert advice and guidance for a reasonable fee.

Terminal Block Recommendations

Unsure which Terminal Block to choose for your project? We provide personalized recommendations based on your specific needs, free of charge for all our customers.

Logistics Support

If you lack a suitable freight forwarder, we can help arrange the transportation of your Switch Position Indicators from our factory to your project site without any extra service fees.

Installation Support

If you have questions about installing Terminal Block, feel free to reach out to us. We offer installation assistance and can even send an engineer to your project site for hands-on support.

VIOX Terminal Block Technical Workshop

Frequently Asked Questions

We have compiled some common questions from our clients. If your question isn’t included here, our customer service is always available to help. We’d love to talk with you.

How Can I Get a Quote for the Terminal Block?

To get a quote for our Terminal Block, contact our customer service team. We are available 24/7. Just provide the specifics of your order like the type, size, and quantity. We’ll guide you through the entire ordering process.

What is Your MOQ for the Order?

We have a low MOQ or minimum order quantity. You can order as little as one unit, and we will deliver according to your specifications.

What Is the Turnaround Time for My Order?

The standard turnaround time for our Terminal Blocks is 7 to 10 business days. Delivery time may extend by up to 15 business days due to transit. For custom or bulk orders, we can discuss the turnaround time before finalizing your order.

Can I Get a Sample Before Placing the Order?

Yes, we provide samples for evaluation and approval. Creating samples typically takes 3 to 7 business days.

Can You Make Customized Terminal Blocks?

Yes, we offer customized Terminal Blocks. Let us know your requirements, and our expert customer service team will work with you through the design process.

What is Your Warranty for the Terminal Blocks?

We offer a 5-year warranty on all Terminal Blocks we produce. This ensures we deliver high-quality products. Every product is thoroughly tested before delivery.

Expert Terminal Blocks Knowledge Resources

What is a terminal block and what is its function?

A terminal block is an electrical connector that securely joins multiple wires together in an organized manner. It provides a safe and reliable means to connect, disconnect, and redistribute electrical circuits without splicing or taping wires. Terminal blocks serve as junction points in electrical systems, allowing for efficient installation, maintenance, and troubleshooting.

How do I choose the right terminal block for my application?

Select a terminal block based on:

- Current and voltage requirements

- Wire size and type

- Available mounting space

- Environmental conditions (temperature, vibration, moisture)

- Connection type preference (screw, spring cage, push-in)

- Special functions needed (grounding, fusing, disconnection)

Our technical team can provide personalized recommendations based on your specific application requirements.

What is the difference between screw, spring cage, and push-in terminal blocks?

Screw Terminal Blocks: Use a screw mechanism to compress the wire, providing high clamping force and excellent conductivity. Best for applications where connections remain in place for extended periods.

Spring Cage Terminal Blocks: Utilize a spring mechanism that maintains constant pressure on the wire. Offers vibration resistance and maintenance-free connections. Ideal for applications subject to movement or thermal cycling.

Push-In Terminal Blocks: Feature a spring-loaded design that allows for tool-free wire insertion. Provides quick installation and space savings. Perfect for high-density applications where installation speed is important.

How do I determine the proper wire strip length?

The proper strip length is typically marked on the terminal block or specified in the product documentation. As a general rule:

- For small terminal blocks (≤16A): 6-8mm strip length

- For medium terminal blocks (16-35A): 8-10mm strip length

- For large terminal blocks (>35A): 10-12mm strip length

Using the correct strip length ensures a secure connection without exposed conductors that could create short circuits.

What torque specifications should I use when tightening terminal block screws?

Proper torque ensures optimal electrical connection without damaging the terminal. Recommended torque values are typically marked on the terminal block or listed in the product documentation. General guidelines:

- Small terminals (≤16A): 0.5-0.8 Nm

- Medium terminals (16-35A): 0.8-1.2 Nm

- Large terminals (>35A): 1.5-2.5 Nm

Always use a calibrated torque screwdriver for the most reliable connections.

How do I address different voltage levels in the same terminal block assembly?

When different voltage levels must be included in the same terminal block assembly:

- Physically separate different voltage groups

- Install partition plates between voltage groups

- Use end plates at the beginning and end of each group

- Apply clear warning labels indicating voltage levels

- Consider using different colored terminal blocks for visual identification

This approach ensures safety and compliance with electrical codes.

Are VIOX terminal blocks suitable for high-temperature environments?

VIOX offers specialized high-temperature terminal blocks designed for environments up to 120°C (248°F). These terminals feature:

- Special polyamide compounds with enhanced thermal stability

- Higher-grade metal components

- Advanced plating for improved heat resistance

- Modified designs for optimal heat dissipation

For extreme temperature applications, please consult with our engineering team for customized solutions.

How do I create a multi-level terminal block configuration?

Multi-level terminal blocks allow for higher connection density in limited space:

- Select compatible multi-level terminal blocks (dual, triple, or quad level)

- Mount on standard DIN rail

- Interconnect levels as needed using jumpers designed for multi-level configurations

- Label each level clearly to prevent confusion during maintenance

- Consider access requirements for each connection level

Our technical team can assist with designing optimal multi-level configurations for your specific application.

Historical Development

Terminal blocks have evolved significantly since their introduction in the early 20th century:

- 1900s: Early barrier strips with screw connections

- 1950s: Introduction of modular DIN rail mounting systems

- 1970s: Development of tool-free spring connection technology

- 1990s: Push-in connection technology emerges

- 2000s: Integration of electronic components within terminal blocks

- Present: Smart terminals with monitoring and communication capabilities

This evolution reflects the industry’s drive toward greater efficiency, reliability, and functionality.

Terminal Block Operating Principles

Understanding how terminal blocks work helps ensure proper selection and application:

Electrical Conductivity: Terminal blocks provide a low-resistance path for current flow through:

- Direct metal-to-metal contact between wire and terminal

- Sufficient contact surface area to handle specified current

- Proper clamping force to maintain connection integrity

Electrical Isolation: Terminal blocks prevent unintended current paths through:

- High-quality insulating materials between adjacent terminals

- Proper creepage and clearance distances

- Raised barriers to prevent arc formation

Mechanical Security: Terminal blocks maintain connection reliability through:

- Robust clamping mechanisms resistant to vibration

- Secure mounting systems preventing terminal movement

- Strain relief features protecting the electrical connection

Terminal Block Safety Considerations

Proper terminal block selection and installation is critical for electrical safety:

- Voltage Rating: Always select terminals rated for your system’s maximum voltage

- Current Capacity: Size terminals appropriately for maximum circuit current plus safety margin

- Wire Compatibility: Ensure terminals accept the wire gauge and type used in your application

- Temperature Rating: Select terminals rated for the ambient temperature of your installation

- Environmental Protection: Consider IP ratings for installations exposed to dust or moisture

- Flammability: Verify UL94 flammability rating appropriate for your application

- Creepage/Clearance: Ensure adequate spacing for your voltage level and pollution degree

Industry Standards and Certifications

Terminal blocks are subject to various international standards:

- UL 1059: Terminal blocks for industrial use (North America)

- IEC 60947-7-1: Terminal blocks for copper conductors

- IEC 60947-7-2: Protective conductor terminal blocks

- CSA C22.2 No. 158: Terminal blocks

- UL 486E: Equipment wiring terminals

- EN 60998-1/2: Connecting devices for low-voltage circuits

These standards ensure safety, performance, and interoperability across manufacturers.

Advanced Terminal Block Technologies

The terminal block industry continues to innovate with technologies like:

- Smart Terminals: Integrated sensors for temperature and current monitoring

- IoT Connectivity: Terminal blocks with network communication capabilities

- Hybrid Terminals: Combinations of power and signal connections in single blocks

- Surge Protection: Integrated surge suppression for sensitive electronics

- Predictive Maintenance: Terminals that can detect potential connection failures

- Miniaturization: Ultra-compact designs for space-critical applications

- Sustainable Materials: Eco-friendly compounds reducing environmental impact

VIOX Electric remains at the forefront of these technological advancements, continuously incorporating the latest innovations into our product offerings.

YUEQING: China’s Terminal Block Manufacturing Hub

Yueqing, located in China’s eastern Zhejiang Province, has emerged as a significant manufacturing center for electrical components, particularly terminal blocks. The region boasts a concentrated industrial ecosystem specializing in electrical components, with numerous manufacturers producing a wide range of terminal block types from standard DIN rail models to specialized industrial varieties. As a manufacturing base in Yueqing, VIOX ELECTRIC benefits from the region’s established supply chain network, skilled workforce, and deep technical expertise in electrical component production. The region’s manufacturers collectively serve global markets, supplying terminal blocks for applications in industrial automation, power distribution, renewable energy systems, and advanced manufacturing facilities worldwide.

Custom OEM Terminal Blocks

VIOX Electric is ready to assist you with your OEM Terminal Blocks needs. We offer high-quality and cost-effective solutions.