The Real Problem Behind Persistent Breaker Trips

When your Arc-Fault Circuit Interrupter (AFCI) or Ground-Fault Circuit Interrupter (GFCI) breaker trips repeatedly without an obvious cause, you’re experiencing what electricians call “nuisance tripping.” This phenomenon affects approximately 15-20% of newly installed AFCI breakers and represents one of the most frustrating challenges in modern residential electrical systems. While these safety devices are designed to protect against electrical fires and shock hazards, improper installation, incompatible devices, or environmental factors can cause them to trip unnecessarily—disrupting your daily life and potentially masking real electrical problems that need attention.

Understanding the difference between legitimate protective trips and nuisance trips is critical. A legitimate trip indicates your breaker is doing its job by detecting a dangerous arc fault or ground fault. A nuisance trip, however, occurs when the breaker misinterprets normal electrical signatures as hazardous conditions. This comprehensive guide will walk you through systematic troubleshooting methods, help you identify root causes, and provide proven solutions to restore reliable operation while maintaining the essential safety these devices provide.

Key Takeaways

- AFCI nuisance tripping is most commonly caused by incompatible electronic devices (vacuum cleaners, power tools, dimmer switches) and improper neutral wiring configurations

- GFCI nuisance tripping typically results from moisture infiltration, ground faults in connected equipment, or electromagnetic interference from nearby devices

- Shared neutral wiring on single-pole AFCI breakers causes immediate tripping and requires either 2-pole AFCI breakers or circuit separation

- Systematic diagnosis using isolation testing and insulation resistance measurements (megohmmeter testing) can identify the exact source of nuisance trips

- Modern AFCI technology with firmware update capabilities significantly reduces nuisance tripping compared to older generation devices

- NEC compliance requires AFCI protection in most living spaces per Article 210.12, making proper troubleshooting essential rather than optional

Understanding AFCI and GFCI Technology

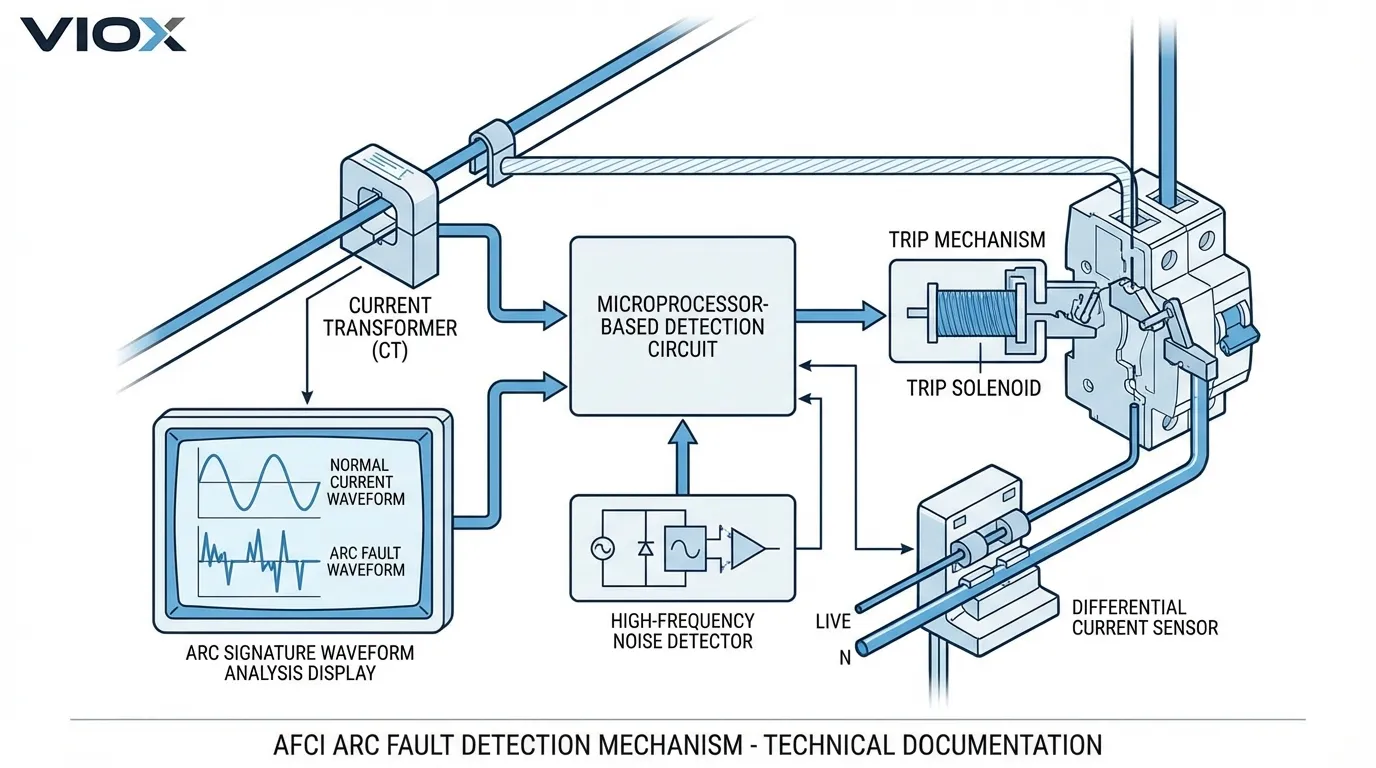

How AFCI Breakers Detect Arc Faults

Arc-Fault Circuit Interrupters use sophisticated microprocessor-based detection algorithms to identify dangerous arcing conditions that could lead to electrical fires. These devices continuously monitor the electrical waveform on the circuit, analyzing current signatures for patterns characteristic of series arcs (occurring in a single conductor) and parallel arcs (occurring between conductors). According to UL 1699 testing standards, AFCIs must detect hazardous arcing while ignoring normal arcing from switches, brushed motors, and other common household devices.

The challenge lies in the detection algorithm’s ability to distinguish between dangerous arcs and benign electrical noise. Modern combination-type AFCIs analyze multiple parameters including high-frequency noise, current irregularities, and arc duration. However, certain electronic devices—particularly those with switching power supplies, variable-speed motors, or electronic controls—can produce electrical signatures that mimic arc faults, leading to nuisance trips. Understanding AFDD IEC 62606 arc fault protection provides detailed technical specifications for these detection mechanisms.

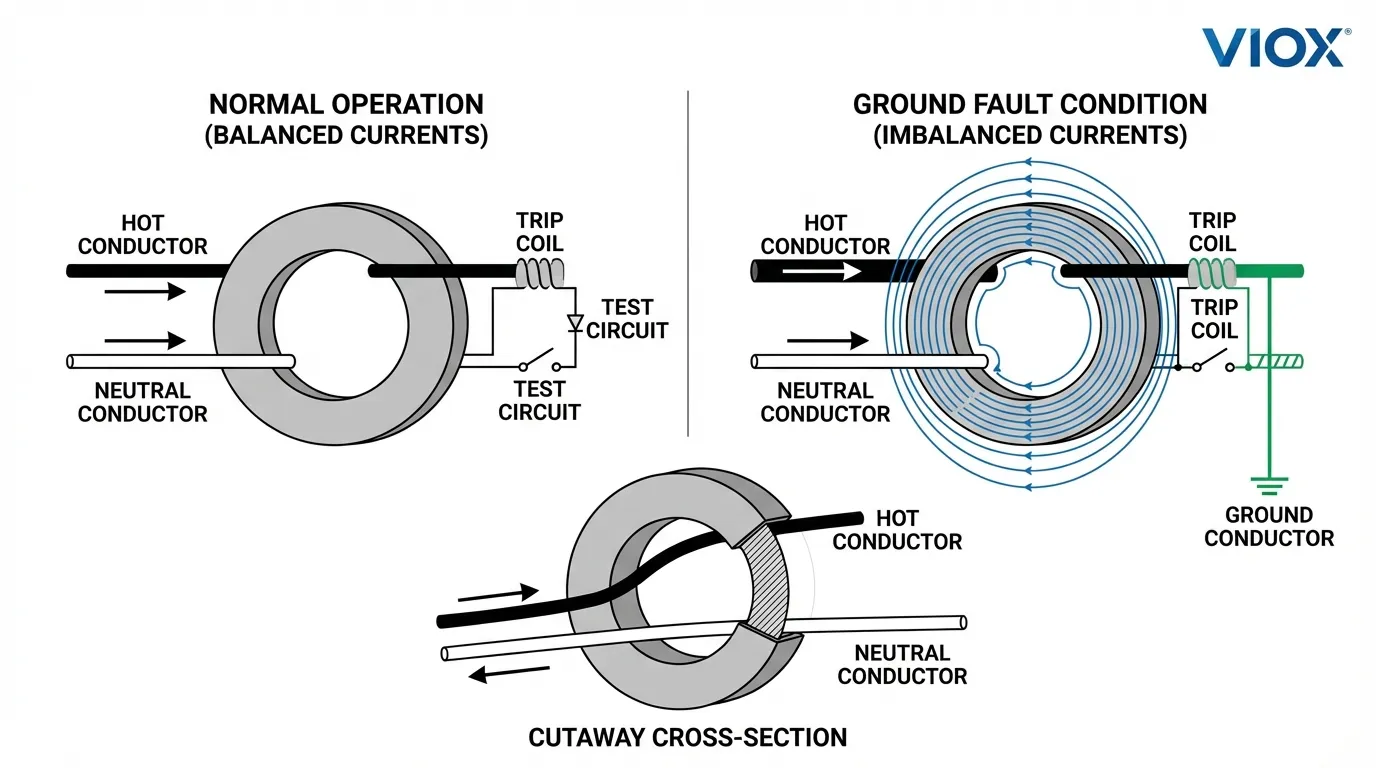

How GFCI Breakers Detect Ground Faults

Ground-Fault Circuit Interrupters operate on a fundamentally different principle than AFCIs. A GFCI contains a differential current transformer that continuously compares the current flowing through the hot conductor with the current returning through the neutral conductor. In a properly functioning circuit, these currents should be equal. When the GFCI detects a difference of 4-6 milliamperes (the trip threshold), it assumes current is leaking to ground—potentially through a person—and trips within 25 milliseconds to prevent electrocution.

This simple yet effective mechanism makes GFCIs highly reliable for their intended purpose. However, the same sensitivity that protects against shock hazards can also cause nuisance tripping. Any condition that allows even small amounts of current to bypass the normal return path—moisture in junction boxes, deteriorated insulation, capacitive coupling in long cable runs, or electromagnetic interference—can trigger a GFCI trip. Understanding the distinction between RCD vs GFCI breaker differences helps clarify regional terminology and testing standards.

Key Differences Between AFCI and GFCI Protection

| Feature | AFCI Protection | GFCI Protection |

|---|---|---|

| Primary Purpose | Prevents electrical fires from arcing faults | Prevents electrocution from ground faults |

| Detection Method | Analyzes waveform patterns and high-frequency noise | Measures current imbalance between hot and neutral |

| Trip Threshold | Complex algorithm (no single threshold) | 4-6 mA current differential |

| Response Time | Typically 0.1-0.5 seconds | 25 milliseconds (0.025 seconds) |

| Common Nuisance Causes | Electronic devices, dimmer loads, motor noise | Moisture, insulation degradation, EMI |

| NEC Requirements | Article 210.12 (bedrooms, living areas, hallways) | Article 210.8 (bathrooms, kitchens, outdoors, basements) |

| Testing Standard | UL 1699 / IEC 62606 | UL 943 / IEC 61008-1 |

| Combination Devices | AFCI/GFCI combo breakers available | AFCI/GFCI combo breakers available |

Understanding these fundamental differences is essential for effective troubleshooting. AFCI issues typically involve device compatibility and wiring configuration, while GFCI problems more often relate to environmental conditions and insulation integrity. For comprehensive protection strategies, refer to GFCI vs AFCI protection differences.

Common Causes of AFCI Nuisance Tripping

Incompatible Electronic Devices and Appliances

The most frequent cause of AFCI nuisance tripping involves electronic devices with switching power supplies or variable-speed motors. Vacuum cleaners with electronic speed controls, treadmills, power tools with soft-start features, and even some LED dimmer switches generate electrical noise that can trigger AFCI detection algorithms. The problem intensifies with older first-generation AFCI breakers, which had less sophisticated discrimination capabilities.

Specific devices known to cause frequent AFCI trips include:

- Vacuum cleaners with electronic controls (especially bagless models with cyclonic motors)

- Treadmills and exercise equipment with variable-speed DC motors

- Power tools including circular saws, routers, and drills with electronic speed control

- Dimmer switches controlling loads exceeding 1000W (per UL 1699 testing allowances)

- Microwave ovens with inverter technology

- Washing machines with electronic control boards and variable-speed pumps

The solution often involves either replacing the AFCI with a newer generation device that has updated firmware, relocating the problematic appliance to a non-AFCI circuit (where code permits), or installing an AFCI receptacle at the first outlet to provide localized protection while using a standard breaker at the panel.

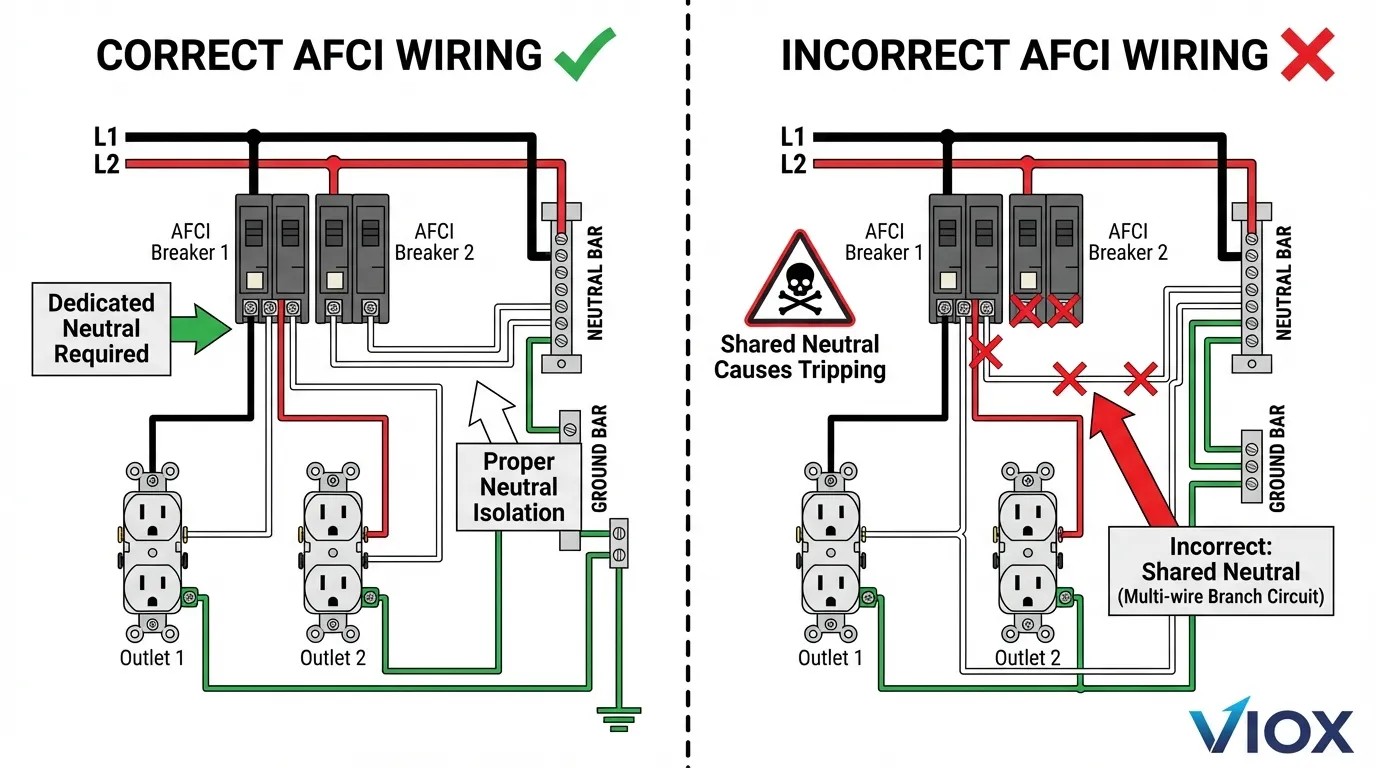

Improper Neutral Wiring Configuration

Neutral wiring errors represent the second most common cause of AFCI nuisance tripping, particularly in installations performed during the early adoption period when electricians were less familiar with AFCI requirements. The critical rule: each AFCI-protected circuit must have a dedicated neutral that connects only to that specific breaker and never shares with other circuits.

Multi-Wire Branch Circuit (MWBC) Issues: When two circuits share a common neutral (a multi-wire branch circuit), installing single-pole AFCI breakers on both circuits will cause immediate tripping when any load is applied. The AFCI detects current flowing through the neutral that doesn’t correspond to current through its hot conductor and interprets this as a fault condition. The solution requires either installing a 2-pole AFCI breaker that monitors both hot conductors sharing the neutral, or separating the circuits to provide dedicated neutrals.

Neutral-to-Ground Connections Downstream: Any connection between the neutral and ground conductors downstream of the service entrance (such as a bootleg ground or improperly bonded sub-panel) will cause AFCI tripping. These connections create parallel current paths that the AFCI interprets as ground faults. Proper installation requires isolating neutrals and grounds throughout the branch circuit system, as detailed in NEC vs IEC terminology correspondence.

Long Circuit Runs and Electromagnetic Interference

Extended circuit runs—particularly those exceeding 100 feet—can cause AFCI nuisance tripping due to increased electromagnetic interference (EMI) and capacitive coupling effects. The longer the cable run, the more susceptible it becomes to picking up electrical noise from adjacent circuits, fluorescent lighting ballasts, or even radio frequency interference from wireless devices.

Capacitive Coupling: In long parallel cable runs, capacitive coupling between conductors can create small current imbalances that trigger sensitive AFCI algorithms. This problem intensifies when multiple circuits are bundled together in the same conduit or cable tray. Proper separation and routing can minimize these effects.

EMI from External Sources: AFCI breakers can be triggered by electromagnetic interference from nearby sources. Documented cases include AFCIs tripping when two-way radios are keyed up near electrical panels, cell phones charging on nearby circuits, or even smart home devices communicating via powerline networking protocols. Shielding sensitive circuits and maintaining proper separation from EMI sources can reduce these occurrences.

Common Causes of GFCI Nuisance Tripping

Moisture and Humidity-Related Issues

Moisture represents the primary environmental factor causing GFCI nuisance tripping. Even small amounts of water creating conductive paths between hot or neutral conductors and ground can generate sufficient leakage current (above the 4-6 mA threshold) to trip a GFCI. Common moisture-related scenarios include:

Outdoor and Wet Location Circuits: GFCIs protecting outdoor receptacles, landscape lighting, or pool equipment are particularly susceptible to moisture infiltration in junction boxes, conduit fittings, and device enclosures. Condensation inside weatherproof boxes during temperature fluctuations can create temporary conductive paths. Using properly rated weatherproof enclosures with drainage provisions and applying dielectric grease to connections can significantly reduce moisture-related trips.

Bathroom and Kitchen Applications: GFCIs in bathrooms and kitchens may trip due to moisture accumulation in exhaust fan housings, under-sink junction boxes near plumbing penetrations, or in receptacle boxes behind appliances. The 2017 NEC expansion requiring GFCI protection for single-phase receptacles up to 50A and three-phase receptacles up to 100A has increased moisture-related nuisance tripping in commercial kitchens and janitorial areas. Proper sealing and ventilation are essential preventive measures.

Insulation Degradation and Cable Damage

Deteriorating wire insulation creates leakage paths that allow small amounts of current to flow to ground, triggering GFCI protection. This degradation can result from several factors:

Age-Related Insulation Breakdown: Older wiring (particularly pre-1970s installations) may have insulation that has become brittle and cracked due to heat cycling, oxidation, or environmental exposure. Even microscopic cracks can allow sufficient leakage current to trip a GFCI.

Physical Damage: Rodent damage, nail or screw penetrations during renovations, or pinched cables in junction boxes can compromise insulation integrity. These faults may be intermittent, causing seemingly random GFCI trips that are difficult to diagnose without systematic testing.

Insulation Resistance Testing: Professional diagnosis requires megohmmeter (insulation resistance) testing, which measures resistance between conductors and ground. Readings below 1 megohm typically indicate compromised insulation requiring circuit repair or replacement. Testing procedures should follow NETA (InterNational Electrical Testing Association) guidelines for residential applications.

Cumulative Leakage Current from Multiple Devices

Modern electronic devices—even when functioning normally—can generate small amounts of leakage current through their EMI filter capacitors. While individual devices may only leak 0.5-1 mA, multiple devices on a single GFCI-protected circuit can create cumulative leakage approaching the 4-6 mA trip threshold.

High Leakage Devices: Certain equipment categories are known for higher leakage currents:

- Refrigerators and freezers (1-2 mA per unit)

- Computers and networking equipment (0.5-1.5 mA per device)

- Medical equipment and aquarium pumps (variable, can exceed 3 mA)

- Variable frequency drives (VFDs) and motor controllers (2-5 mA)

When multiple high-leakage devices share a GFCI-protected circuit, their combined leakage can cause nuisance tripping. The solution involves either distributing devices across multiple GFCI circuits or using isolated ground (IG) receptacles where code permits, reducing the cumulative effect. Understanding 40A vs 63A RCD nuisance tripping provides insights into current rating selection for high-leakage applications.

Systematic Troubleshooting Methodology

Step 1: Verify Legitimate vs Nuisance Tripping

Before assuming you’re dealing with nuisance tripping, verify that the breaker isn’t responding to a genuine hazard. Examine the trip indicator on the breaker face:

AFCI Breakers: Most modern AFCI breakers have diagnostic indicators showing the trip cause:

- “ARC FAULT” indicator: Detected dangerous arcing condition

- “OVERLOAD” or “SHORT CIRCUIT” indicator: Overcurrent condition

- No indicator or “TEST” only: May indicate nuisance trip or device malfunction

GFCI Breakers: GFCI trips typically don’t distinguish between legitimate ground faults and nuisance trips, as both involve current imbalance. However, consistent tripping patterns provide clues:

- Trips immediately upon reset: Likely hard ground fault requiring immediate attention

- Trips after several minutes/hours: Possible moisture accumulation or intermittent fault

- Trips only when specific device operates: Device-related ground fault or leakage

Consult how to know if circuit breaker is bad for guidance on distinguishing breaker failures from circuit problems.

Step 2: Isolation Testing to Identify Problem Sources

Systematic isolation testing identifies whether the problem originates from the breaker itself, the circuit wiring, or connected devices:

Complete Circuit Isolation:

- Turn off the tripping breaker and disconnect all loads from the circuit (unplug devices, disconnect hardwired equipment)

- Remove wire connections from receptacles and switches, leaving only the home run connection to the breaker

- Reset the breaker and observe for 24 hours

- If tripping stops: Problem is in connected devices or downstream wiring

- If tripping continues: Problem is in the home run cable or the breaker itself

Progressive Load Addition:

- After confirming the isolated circuit doesn’t trip, reconnect one outlet or device at a time

- Wait 24-48 hours between additions to identify intermittent problems

- When tripping resumes, the last-added component is the likely culprit

- Test the identified device on a different circuit to confirm it’s the problem source

Segment Testing for Large Circuits:

- For circuits with multiple junction boxes, disconnect at each junction point

- Test each segment independently to isolate the problematic section

- This approach is particularly effective for outdoor lighting circuits or circuits with multiple rooms

Step 3: Insulation Resistance and Continuity Testing

Professional-grade testing requires specialized equipment but provides definitive diagnosis:

Megohmmeter (Insulation Resistance) Testing:

- Disconnect circuit from panel and all loads

- Test between hot-to-ground, neutral-to-ground, and hot-to-neutral

- Minimum acceptable reading: 1 megohm for residential circuits (higher is better)

- Readings below 1 megohm indicate compromised insulation requiring repair

- Readings between 1-10 megohms suggest marginal insulation that may cause intermittent trips

Ground Fault Locator Testing:

- Specialized instruments can pinpoint ground fault locations in long circuit runs

- These devices inject a signal and use a receiver to trace the fault location

- Particularly useful for buried cables or circuits in finished walls

Neutral-to-Ground Voltage Testing:

- With circuit energized and unloaded, measure voltage between neutral and ground at various points

- Readings exceeding 2-3 volts suggest improper neutral connections or shared neutrals

- This test is especially valuable for diagnosing AFCI wiring issues

Proper testing procedures ensure accurate diagnosis and prevent unnecessary circuit replacement. For comprehensive circuit protection strategies, review circuit protection selection framework.

Proven Solutions for AFCI Nuisance Tripping

Solution 1: Upgrade to Modern AFCI Technology

First-generation AFCI breakers (pre-2008) had significantly higher nuisance trip rates than modern devices. If your installation uses older AFCIs, upgrading to current-generation combination-type AFCIs can dramatically reduce nuisance tripping:

Firmware-Updatable AFCIs: Some manufacturers now offer “smart” AFCI breakers with firmware update capability. These devices can receive algorithm updates to improve discrimination between dangerous arcs and benign electrical noise, effectively future-proofing your installation against new appliance technologies.

Manufacturer-Specific Performance: Independent testing shows significant performance variations between AFCI manufacturers. Eaton’s Classified series and Square D’s QO-AFCI breakers generally receive high marks for reduced nuisance tripping compared to some budget alternatives. When replacing problematic AFCIs, research current performance reviews and consider premium options.

Solution 2: Install AFCI Receptacles for Localized Protection

When a specific appliance or circuit segment causes persistent AFCI tripping, installing an AFCI receptacle at the first outlet provides an effective alternative to panel-mounted AFCI breakers:

Branch/Feeder AFCI Configuration:

- Install standard breaker at panel (no AFCI function)

- Install AFCI receptacle at first outlet location on circuit

- All downstream outlets receive AFCI protection through the receptacle’s load terminals

- Problematic appliances can be plugged into the line side of the AFCI receptacle (before AFCI protection)

This configuration maintains NEC compliance while isolating nuisance-tripping devices from AFCI protection. However, verify local code interpretation, as some jurisdictions require panel-mounted AFCIs specifically.

Solution 3: Correct Neutral Wiring Issues

Resolving neutral wiring problems requires careful attention to NEC requirements:

Multi-Wire Branch Circuit Correction:

- Option A: Replace two single-pole AFCI breakers with one 2-pole AFCI breaker that monitors both hot conductors sharing the common neutral

- Option B: Separate the circuits by running a new neutral conductor for one circuit, eliminating the shared neutral configuration

- Option C: Use combination AFCI/GFCI breakers, which are more tolerant of shared neutral configurations (verify manufacturer specifications)

Neutral Isolation Verification:

- Ensure each circuit’s neutral connects only to its corresponding breaker terminal

- Verify no neutral-to-ground bonds exist downstream of the service entrance

- Check for shared neutrals in junction boxes using continuity testing with circuits de-energized

- Confirm proper neutral bar configuration in sub-panels (isolated from ground)

Proper neutral wiring is fundamental to AFCI operation. For panel-level considerations, consult how to ground an electrical panel.

Solution 4: Reduce EMI and Circuit Length Effects

For circuits experiencing EMI-related nuisance tripping:

Circuit Routing Optimization:

- Minimize parallel runs with other circuits, especially high-current or motor circuits

- Maintain separation from fluorescent lighting and electronic ballasts

- Use metal conduit for shielding in high-EMI environments

- Consider twisted-pair wiring techniques for long circuit runs to reduce inductive pickup

Load Redistribution:

- Move problematic high-noise devices to non-AFCI circuits where code permits

- Separate motor loads from electronic loads on different circuits

- Install dedicated circuits for devices known to cause AFCI issues

Proven Solutions for GFCI Nuisance Tripping

Solution 1: Address Moisture and Environmental Factors

Moisture control represents the most effective approach to reducing GFCI nuisance tripping:

Outdoor Circuit Protection:

- Use in-use weatherproof covers rated for wet locations (not just “while-in-use”)

- Apply dielectric grease to all outdoor connections and terminal screws

- Install junction boxes with weep holes at the bottom for condensation drainage

- Replace standard outdoor boxes with vapor-tight boxes in high-humidity environments

- Consider installing circuits with downward-facing conduit entries to prevent water infiltration

Indoor Moisture Management:

- Seal junction boxes near plumbing penetrations with appropriate caulking

- Ensure bathroom and kitchen exhaust fans vent properly to exterior

- Install GFCI receptacles with weather-resistant (WR) ratings even for indoor damp locations

- Address any water intrusion issues (roof leaks, plumbing leaks) that may affect electrical boxes

Solution 2: Repair or Replace Degraded Wiring

When insulation resistance testing reveals compromised wiring:

Targeted Repair:

- For accessible damaged sections, install properly sized junction boxes and splice in new cable

- Use appropriate wire connectors rated for the application (not electrical tape alone)

- Ensure all splices are accessible and not concealed in walls without junction boxes

Complete Circuit Replacement:

- For extensive insulation degradation, complete circuit replacement may be more cost-effective than multiple repairs

- Modern NM-B cable has superior insulation compared to older types

- Consider upgrading to larger wire gauge if the circuit is near capacity

Preventive Measures:

- Install rodent-resistant armored cable (MC or AC cable) in vulnerable areas

- Use conduit for exposed wiring in basements, crawl spaces, and attics

- Maintain proper cable support and avoid sharp bends that stress insulation

Solution 3: Manage Cumulative Leakage Current

When multiple devices create excessive cumulative leakage:

Circuit Subdivision:

- Install additional GFCI circuits to distribute high-leakage devices

- Dedicate separate circuits for refrigerators, computers, and other high-leakage equipment

- Use standard breakers for circuits serving equipment with inherently high leakage (where code permits)

Higher-Threshold GFCIs:

- For commercial/industrial applications, consider 20-30 mA GFCIs where personnel protection requirements differ from residential standards

- Verify code compliance before using higher-threshold devices

- Note: Residential applications typically require Class A GFCIs (4-6 mA threshold)

Equipment Grounding Improvements:

- Verify proper equipment grounding to minimize leakage current

- Consider isolated ground (IG) receptacles for sensitive electronic equipment (where permitted)

- Ensure ground continuity throughout the circuit

For specialized applications requiring different GFCI types, review RCCB EV charging Type B vs Type F vs Type EV.

Solution 4: Replace Defective GFCI Devices

GFCI devices can fail or become overly sensitive with age:

GFCI Lifespan Considerations:

- Typical GFCI lifespan: 10-15 years under normal conditions

- Devices in harsh environments (outdoor, high-moisture) may fail sooner

- Monthly testing using the TEST button helps identify failing devices

Replacement Indicators:

- GFCI won’t reset after tripping

- TEST button doesn’t cause trip

- Frequent nuisance tripping that started suddenly after years of normal operation

- Visible damage, corrosion, or burning on device

Quality Considerations:

- Premium GFCI devices typically have better noise immunity and longer lifespans

- Hospital-grade GFCIs offer superior construction and reliability

- Some manufacturers offer extended warranties reflecting confidence in product longevity

Advanced Diagnostic Tools and Techniques

Using AFCI Diagnostic Breakers

Several manufacturers now offer AFCI breakers with enhanced diagnostic capabilities:

Siemens Intelli-Arc Technology: These breakers provide specific fault indication through LED indicators, showing whether the trip was caused by arc fault, ground fault, or overcurrent. This diagnostic information dramatically reduces troubleshooting time.

Eaton AFCI Diagnostic Features: Eaton’s classified series includes diagnostic capabilities that help identify the specific trip cause, allowing electricians to differentiate between legitimate hazards and nuisance conditions.

Square D Smart Breakers: Connected breakers with smartphone app integration provide trip history and diagnostic data, enabling pattern analysis to identify intermittent problems.

Professional Testing Equipment

AFCI Testers: Specialized AFCI test devices (such as the Klein Tools AFCI Tester) generate controlled arc signatures to verify proper AFCI operation. These tools help distinguish between breaker malfunction and circuit problems.

Ground Fault Locators: Professional instruments can pinpoint ground fault locations by injecting a signal and using a receiver to trace the fault path. This technology is invaluable for buried cables or circuits in finished walls.

Power Quality Analyzers: Advanced troubleshooting may require power quality analysis to identify harmonic distortion, transients, or other electrical anomalies causing nuisance tripping.

NEC Requirements and Code Compliance

Current AFCI Requirements (NEC 2023)

Article 210.12 of the National Electrical Code requires AFCI protection for virtually all 120-volt, single-phase, 15- and 20-ampere branch circuits supplying outlets and devices in dwelling unit areas including:

- Bedrooms (required since 2002)

- Living rooms, family rooms, dining rooms, parlors, libraries, dens, sunrooms, recreation rooms (added 2008)

- Hallways, closets (added 2014)

- Kitchens and laundry areas (added 2020)

Exceptions: AFCI protection is not required for:

- Circuits in bathrooms (GFCI protection required instead)

- Circuits for fire alarm systems

- Certain dedicated appliance circuits

Understanding these requirements is essential when troubleshooting, as removing AFCI protection to eliminate nuisance tripping violates code and creates serious fire hazards. For comprehensive breaker selection guidance, see types of circuit breakers.

Current GFCI Requirements (NEC 2023)

Article 210.8 requires GFCI protection for:

Dwelling Units:

- Bathrooms, kitchens (countertop receptacles), garages, outdoors, crawl spaces, unfinished basements

- Laundry areas, utility rooms, wet bars

- Boathouses, bathtubs/shower spaces

Commercial and Industrial:

- Bathrooms, kitchens, rooftops, outdoors

- Indoor wet locations

- Locker rooms with showers

- Receptacles within 6 feet of sinks (commercial)

The 2017 NEC significantly expanded GFCI requirements to include single-phase receptacles up to 50A and three-phase receptacles up to 100A, leading to increased nuisance tripping challenges in commercial applications.

Combination AFCI/GFCI Breakers

Combination devices providing both AFCI and GFCI protection in a single breaker offer advantages and challenges:

Advantages:

- Single device provides dual protection, saving panel space

- Meets code requirements for areas requiring both protections

- Simplified installation compared to separate devices

Challenges:

- Troubleshooting is more complex (which protection function tripped?)

- Some models more prone to nuisance tripping due to dual sensitivity

- Higher cost than separate devices

- Limited diagnostic capabilities on some models

For applications requiring both protections, consider RCBO vs RCCB MCB comparison to understand the trade-offs between combination and separate devices.

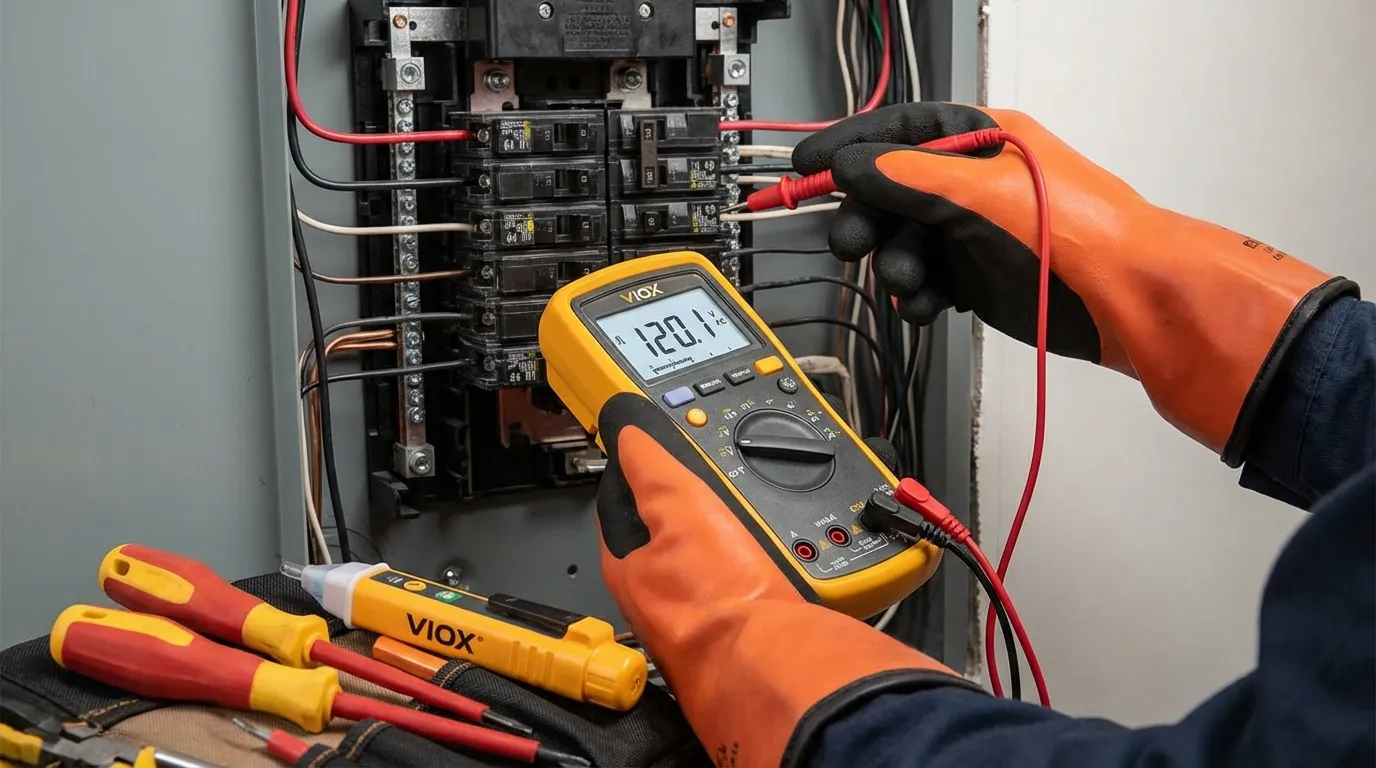

When to Call a Professional Electrician

While many nuisance tripping issues can be diagnosed and resolved by knowledgeable homeowners, certain situations require professional expertise:

Immediate Professional Assistance Required:

- Burning smell, visible damage, or signs of overheating at breaker or outlets

- Breaker trips immediately upon reset (hard fault condition)

- Multiple circuits tripping simultaneously

- Tingling sensation when touching appliances or fixtures

- Any situation involving water contact with energized electrical equipment

Professional Diagnosis Recommended:

- Intermittent tripping with no identifiable pattern after basic troubleshooting

- Suspected wiring problems requiring insulation resistance testing

- Neutral wiring issues requiring panel reconfiguration

- Situations requiring specialized diagnostic equipment

- Any work inside the electrical panel (beyond breaker replacement)

Safety Considerations:

- Never work inside an energized electrical panel without proper training and equipment

- Always verify circuits are de-energized before working on wiring

- Use appropriate personal protective equipment (PPE) including insulated tools and safety glasses

- Follow NFPA 70E guidelines for electrical safety

Professional electricians have specialized training, diagnostic equipment, and insurance to handle complex electrical problems safely. For guidance on building comprehensive maintenance programs, see how to build electrical maintenance program.

Frequently Asked Questions

Why does my AFCI breaker trip when I use my vacuum cleaner?

Vacuum cleaners with electronic speed controls or universal motors generate electrical noise and arcing at the motor brushes that can trigger AFCI detection algorithms. This is one of the most common causes of AFCI nuisance tripping. Solutions include: (1) upgrading to a newer-generation AFCI breaker with improved discrimination, (2) using the vacuum on a non-AFCI circuit where code permits, or (3) installing an AFCI receptacle configuration that allows the vacuum to plug in before AFCI protection.

Can I replace an AFCI breaker with a standard breaker to stop nuisance tripping?

No. Removing AFCI protection where required by code is a code violation and creates serious fire hazards. AFCIs are required by NEC Article 210.12 for most living areas in dwelling units. Instead of removing protection, focus on identifying and resolving the root cause of nuisance tripping through proper troubleshooting, upgrading to modern AFCI technology, or reconfiguring the circuit to address compatibility issues.

How do I know if my GFCI is tripping due to moisture or a real ground fault?

Moisture-related GFCI trips often show patterns: tripping after rain, during high humidity, or after extended periods of non-use. Real ground faults typically cause immediate tripping upon reset or trip consistently when a specific device operates. Perform systematic isolation testing by disconnecting all loads and observing for 24-48 hours. If tripping stops with loads disconnected, the problem is device-related. If tripping continues, moisture or wiring insulation issues are likely. Insulation resistance testing with a megohmmeter provides definitive diagnosis.

Can shared neutral wiring cause AFCI breakers to trip?

Yes, shared neutral wiring (multi-wire branch circuits) is a leading cause of AFCI tripping. When two circuits share a common neutral but use separate single-pole AFCI breakers, the AFCI detects neutral current that doesn’t correspond to its hot conductor current and interprets this as a fault. Solutions include: (1) installing a 2-pole AFCI breaker that monitors both hot conductors, (2) separating the circuits with dedicated neutrals, or (3) using combination AFCI/GFCI breakers that may be more tolerant of shared neutrals (verify manufacturer specifications).

Why does my GFCI trip randomly with nothing plugged in?

Random GFCI tripping with no connected loads typically indicates: (1) moisture infiltration in junction boxes or device enclosures, (2) deteriorating wire insulation allowing leakage current, (3) damaged cable from rodents or physical impact, or (4) a failing GFCI device. Perform insulation resistance testing between conductors and ground. Readings below 1 megohm indicate compromised insulation. Inspect all junction boxes for moisture, corrosion, or damaged insulation. If wiring tests good, replace the GFCI device, as internal component failure can cause overly sensitive operation.

Are some AFCI breaker brands better than others for reducing nuisance tripping?

Yes, independent testing and field experience show significant performance variations between manufacturers. Eaton’s Classified series, Square D’s QO-AFCI, and Siemens’ Intelli-Arc breakers generally receive high marks for reduced nuisance tripping compared to budget alternatives. Newer-generation devices (post-2014) have substantially improved discrimination algorithms compared to first-generation AFCIs. When replacing problematic AFCIs, research current performance reviews and consider premium options with firmware update capabilities.

Can I use an AFCI receptacle instead of an AFCI breaker?

Yes, NEC allows AFCI protection via receptacle devices installed at the first outlet location on the circuit. This “branch/feeder” AFCI configuration uses a standard breaker at the panel and an AFCI receptacle protecting all downstream outlets. This approach can reduce nuisance tripping by allowing problematic devices to connect before AFCI protection. However, verify local code interpretation, as some jurisdictions specifically require panel-mounted AFCIs. The circuit wiring from panel to first receptacle must be installed in metal conduit, MC cable, or AC cable when using this configuration.

How often should I test my AFCI and GFCI devices?

NEC and manufacturer recommendations suggest monthly testing using the TEST button on each device. This simple test verifies the device will trip when needed. For GFCIs, the TEST button creates a small ground fault; for AFCIs, it simulates an arc fault condition. If the device doesn’t trip when tested, replace it immediately. GFCI devices typically last 10-15 years, while AFCI lifespan depends on technology generation and environmental conditions. Devices in harsh environments may require more frequent testing and earlier replacement.

About VIOX Electric: VIOX Electric is a leading B2B manufacturer of electrical equipment, specializing in high-quality circuit protection devices including MCBs, MCCBs, RCCBs, and comprehensive electrical panel solutions. With decades of engineering expertise and commitment to electrical safety standards, VIOX provides reliable protection devices and technical support for residential, commercial, and industrial applications worldwide.