Introduction: The Margin Killer You Don’t See on the Invoice

For solar EPCs and installers, the bill of materials (BOM) is often the primary focus when bidding on commercial and utility-scale projects. On paper, buying empty enclosures, DIN rails, fuse holders, and circuit breakers separately seems like a cost-saving strategy. The raw component cost for a DIY assembly might be 15-20% lower than a factory pre-wired unit. However, this calculation omits the single most volatile variable in solar construction: skilled labor.

In the field, “assembly” is not just screwing components onto a rail. It involves procurement logistics, inventory management, drilling, wiring, labeling, testing, and troubleshooting. When high-wage electricians spend hours assembling boxes instead of installing panels, project margins evaporate. As a Senior Electrical Engineer at VIOX Electric, I have analyzed data from hundreds of installations. The conclusion is stark: the hidden labor costs of field-assembled combiner boxes often exceed the price of the hardware itself.

This guide provides a forensic accounting of those costs, comparing the true Total Cost of Ownership (TCO) between pre-wired solutions and field assembly.

Key Takeaways

- Labor Costs Outweigh Material Savings: The 15% saved on components is typically offset by a 40% increase in labor hours for assembly and testing.

- Procurement Complexity: Managing 15+ individual SKUs per box increases the risk of supply chain delays and incompatible parts compared to a single SKU for a pre-wired unit.

- Quality & Liability: Factory-wired boxes undergo automated Hi-Pot and continuity testing; field assemblies rely on variable human execution, increasing fire and fault risks.

- Installation Velocity: Pre-wired units reduce on-site time by up to 2.5 hours per box, allowing faster system commissioning.

- Warranty gaps: DIY assemblies often void individual component warranties if integration issues arise; pre-wired boxes carry a system-level warranty.

The True Cost of DIY Combiner Box Assembly

The “DIY” approach is a misnomer in professional solar; it is actually “Field Manufacturing.” When you ask a licensed electrician to assemble a combiner box on-site, you are paying skilled labor rates (often $80-$120/hour) for manufacturing tasks that could be done by factory automation at a fraction of the cost.

This is not just about wiring solar panels safely. It involves:

- Enclosure Prep: Measuring and drilling cable gland holes (risk of cracking IP65 enclosures).

- Mechanical Assembly: Cutting DIN rails, mounting fuse holders, SPDs, and breakers.

- Internal Wiring: Cutting, stripping, ferrule crimping, and routing wires.

- Labeling: Creating and applying NEC-compliant labels.

VIOX Manufacturer Insight: In our time-motion studies, we found that field drilling cable entries into polycarbonate enclosures without a jig results in a 4% scrap rate due to cracking or misalignment. This wasted material cost is rarely factored into initial estimates.

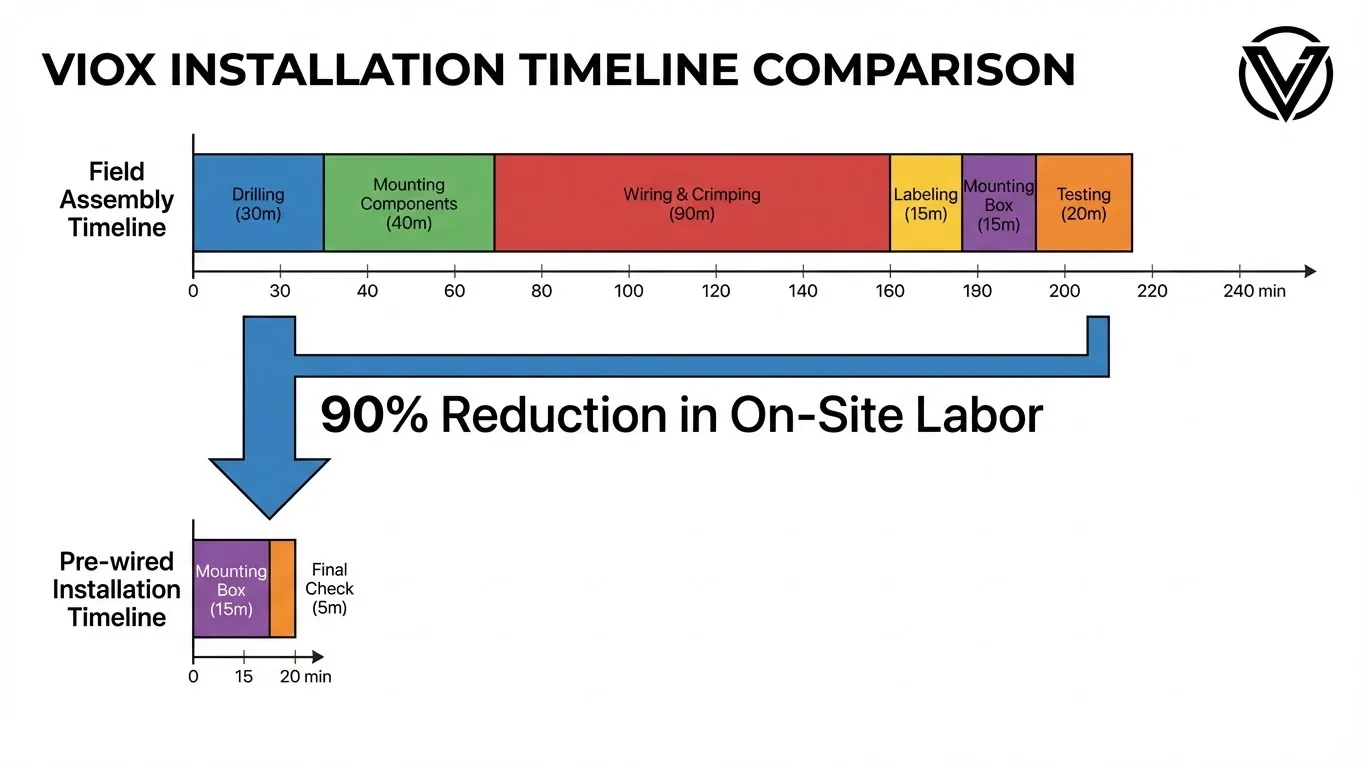

Labor Time Comparison: Pre-wired vs. Field Assembly

Let’s break down the installation of a standard 6-string combiner box. We assume a skilled electrician is performing the work in an outdoor environment.

Efficiency Analysis Table

| Task Category | Field Assembly (DIY) Time | Pre-Wired VIOX Unit Time | Time Savings |

|---|---|---|---|

| Procurement & Receiving | 45 mins (Verify 15+ SKUs) | 5 mins (Verify 1 SKU) | 40 mins |

| Enclosure Mod (Drilling) | 30 mins | 0 mins (Pre-drilled/knockouts) | 30 mins |

| Component Mounting | 40 mins | 0 mins (Factory mounted) | 40 mins |

| Internal Wiring (Crimp/Route) | 90 mins | 0 mins (Factory wired) | 90 mins |

| Labeling | 15 mins | 0 mins (Factory labeled) | 15 mins |

| Mounting to Structure | 15 mins | 15 mins | 0 mins |

| Field Testing (Continuity) | 20 mins | 5 mins (Verify only) | 15 mins |

| TOTAL TIME PER UNIT | 4 hours 15 mins | 25 mins | ~3.8 Hours |

Financial Impact: At a labor rate of $100/hr, Field Assembly costs $425 in labor per box, while Pre-wired installation costs roughly $42. Even if the pre-wired box costs $150 more upfront, you are still netting a $233 profit per unit by choosing pre-wired.

For a deeper dive into these configurations, refer to our guide on pre-wired vs. custom combiner boxes.

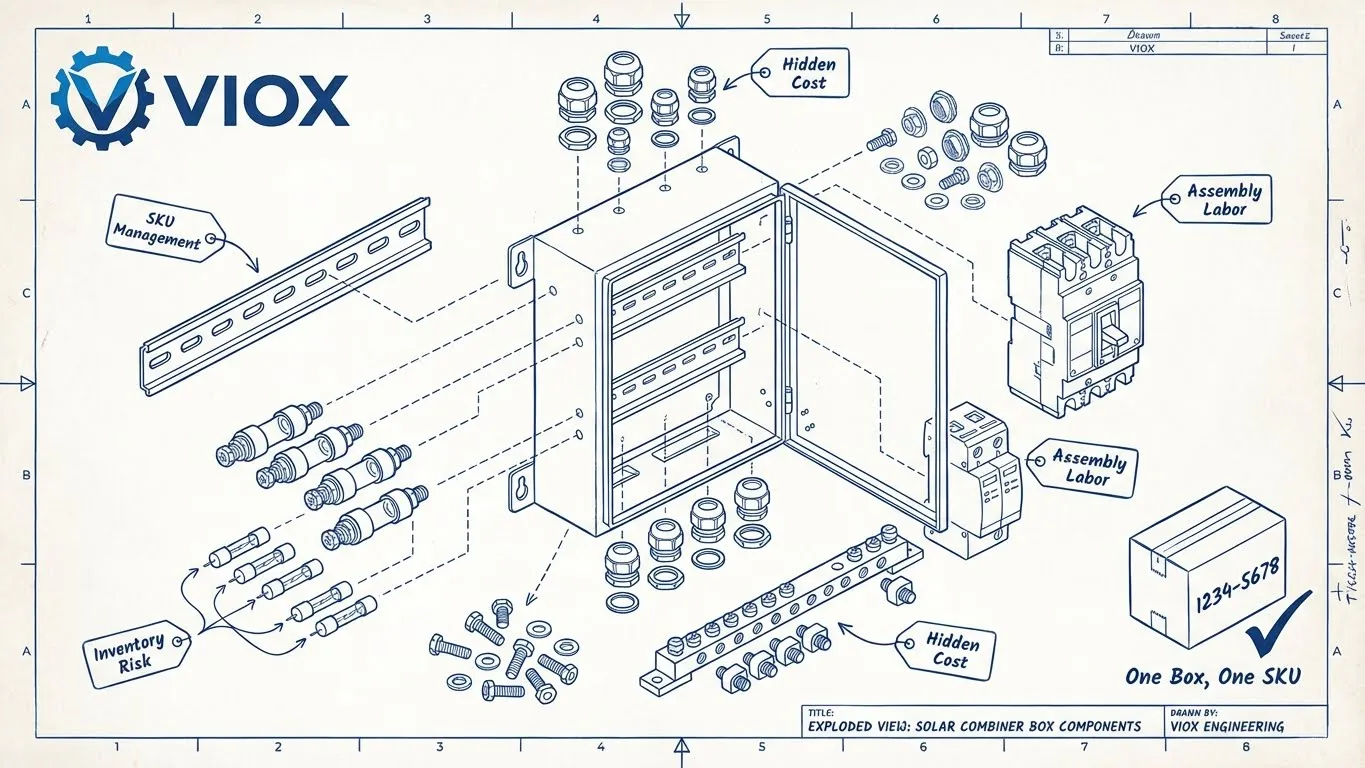

The Component Procurement Trap

Field assembly requires purchasing individual components: enclosures, DIN rails, fuse holders, fuses, circuit breakers, SPDs, glands, and internal wiring. This introduces the “Procurement Trap”:

- Inventory Mismatch: You have 50 fuse holders but only 48 fuses. Work stops.

- Incompatibility: The DC circuit breaker you bought is 5mm too tall for the enclosure door to close properly.

- Waste: Electricians drop screws in the dirt or cut wires too short. Field waste typically runs at 5-10%.

When you buy a VIOX pre-wired box, you manage one SKU. The responsibility for sizing components correctly and ensuring fitment lies with the manufacturer, not your procurement manager.

Installation Error Costs That Never Make It Into Quotes

Field assembly is prone to human error, especially in harsh weather conditions. Common errors that lead to troubleshooting nightmares include:

- Improper Torque: Under-torqued connections create hotspots; over-torqued screws strip threads.

- Poor Crimping: Field crimping without calibrated tools leads to high resistance connections and potential arcs.

- Waterproofing Failures: Improperly seated gaskets or glands drilled at wrong angles compromise the IP65 rating.

- Thermal Crowding: Arranging components without adequate spacing causes overheating, leading to nuisance tripping of breakers.

These errors don’t just cost money to fix; they delay inspection approvals and grid interconnection.

Quality Assurance: Factory Testing vs. Field Assembly

A critical differentiator is validation. A DIY box is tested for the first time when you turn the system on. A VIOX pre-wired box is tested before it leaves the factory.

QA Comparison Matrix

| Testing Protocol | VIOX Pre-Wired Factory Process | DIY Field Process |

|---|---|---|

| Continuity Check | Automated 100% verification | Manual multimeter (spot check) |

| Torque Verification | Calibrated electric drivers | Hand tools (variable force) |

| Insulation Resistance | 1000V Hi-Pot Testing | Rarely performed |

| Ingress Protection | Vacuum/Pressure decay test | Visual inspection only |

Proper inspection protocols are vital. If you proceed with DIY, you must implement a rigorous inspection checklist to mitigate liability.

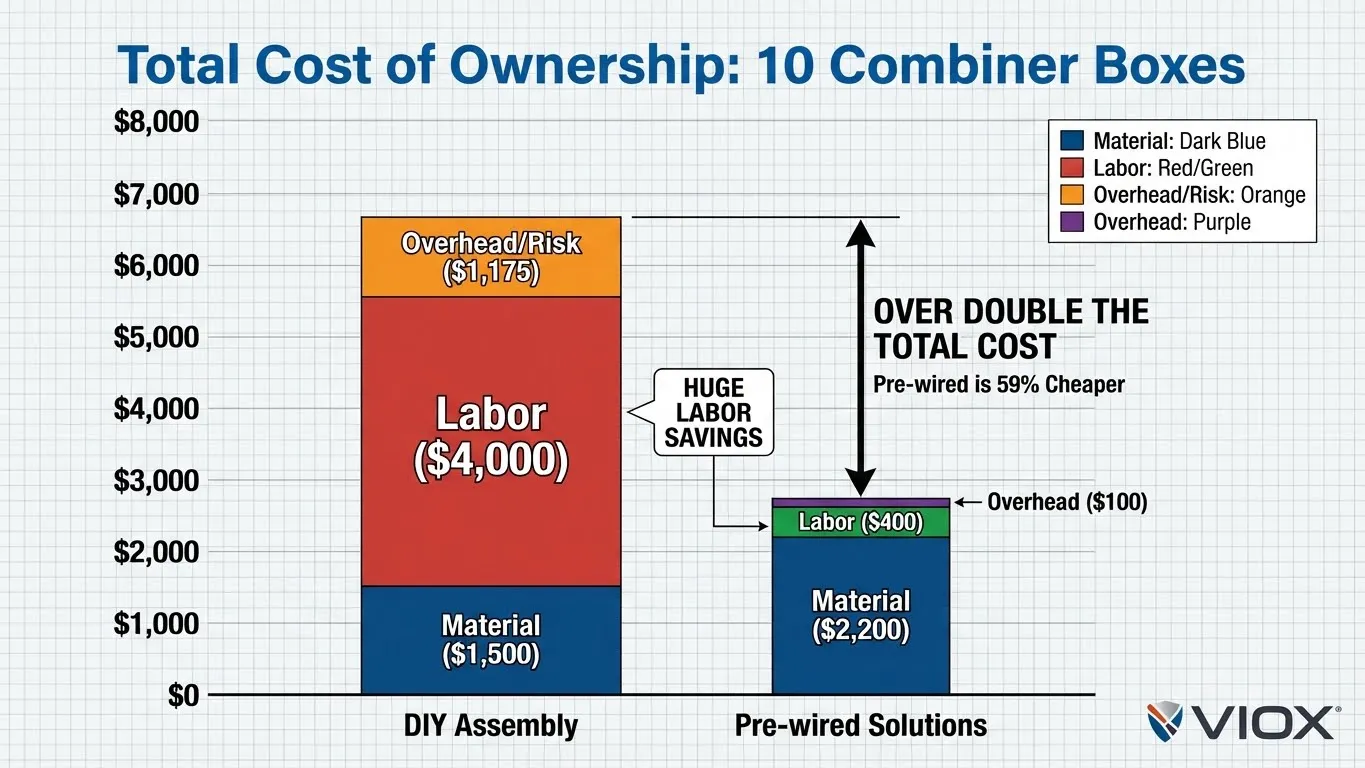

Total Cost of Ownership (TCO) Analysis

When evaluating the manufacturer selection, you must look beyond the sticker price.

Scenario: 100kW Commercial Rooftop Project (Requires 10 Combiner Boxes).

| Cost Driver | DIY / Field Assembly | VIOX Pre-Wired Solution |

|---|---|---|

| Material Cost (10 units) | $1,500 | $2,200 |

| Assembly Labor (40 hrs vs 4 hrs) | $4,000 (@$100/hr) | $400 (@$100/hr) |

| Procurement/Logistics Overhead | $500 | $100 |

| Waste & Scrap (5%) | $75 | $0 |

| Rework/Troubleshooting (Est.) | $600 | $0 |

| TOTAL PROJECT COST | $6,675 | $2,700 |

| COST PER BOX | $667.50 | $270.00 |

Conclusion: The pre-wired solution delivers a 59% savings in total project cost, despite the higher material price tag. Additionally, factory assembly ensures better thermal management, preventing premature derating of circuit breakers in hot climates.

When DIY Assembly Actually Makes Financial Sense

Despite the advantages of pre-wired units, there are specific scenarios where field assembly is valid:

- Emergency Repairs: If a unique box fails and lead times for a custom replacement are too long, assembling one on-site gets the system back online faster.

- Highly Custom Prototypes: For R&D projects with non-standard fusing or voltage monitoring requirements not yet available in mass production.

- Educational Purposes: Training new technicians on the internal architecture of solar distribution.

For standard commercial and residential projects, however, the DIY approach is rarely justifiable on a cost basis.

Frequently Asked Questions (FAQ)

1. Are pre-wired combiner boxes UL listed?

Yes, reputable pre-wired boxes like those from VIOX are UL 1741 listed as a complete assembly. DIY boxes are comprised of UL-listed components, but the final assembly itself is not UL listed unless inspected by a field evaluation body, which can be a code compliance headache.

2. Can I customize a pre-wired box?

Absolutely. Most manufacturers allow you to specify the number of strings, fuse ratings (e.g., 15A vs 20A), and SPD types (Type 1 or Type 2) before ordering. This gives you a “custom” solution with factory-standard quality.

3. Does pre-wired eliminate all fieldwork?

No. You still need to mount the box and terminate the PV string wires (input) and the home run wires (output). However, you skip the internal wiring between fuse holders, busbars, and breakers.

4. How do I verify the quality of a pre-wired box?

Look for clean cable routing, ferrules on all wire ends, proper labeling, and a test report included in the box. Check that the IP rating (e.g., IP65/NEMA 4X) matches your site requirements.

5. Is a metal or plastic enclosure better for pre-wired boxes?

It depends on the environment. Metal provides better heat dissipation for high-current applications, while UV-stabilized polycarbonate is lighter and easier to install. See our guide on enclosure selection for more details.

Manufacturer Insight: At VIOX Electric, we bridge the gap between custom needs and mass-production efficiency. By standardizing the internal architecture, we help installers reduce labor risks and project timelines. For your next project, do the math on labor—not just materials—and you’ll see why pre-wired is the professional choice.