Introduction

When a solar combiner box fails in the field, revenue stops. Every hour of downtime translates directly to lost generation and frustrated stakeholders. For field service engineers and O&M teams managing photovoltaic installations, understanding how to systematically diagnose and resolve combiner box faults is essential to maintaining system uptime and performance.

A solar combiner box serves as the electrical junction point where multiple PV string circuits converge before feeding the inverter. This critical component houses protective devices—circuit breakers or fuses—along with terminals, busbars, and often surge protection. Because it handles significant DC current and operates in harsh outdoor conditions, the combiner box is particularly vulnerable to several common failure modes that can compromise system safety and efficiency.

This guide provides field-tested troubleshooting procedures for the six most frequent solar combiner box failures, from circuit breaker nuisance tripping to terminal overheating and water ingress. Each section details the symptoms, diagnostic measurements, root causes, and proven remediation strategies developed through years of field experience. Safety Note: Before performing any diagnostic work, always follow proper lockout/tagout procedures and verify the absence of voltage with calibrated test equipment.

Essential Tools and Safety Procedures

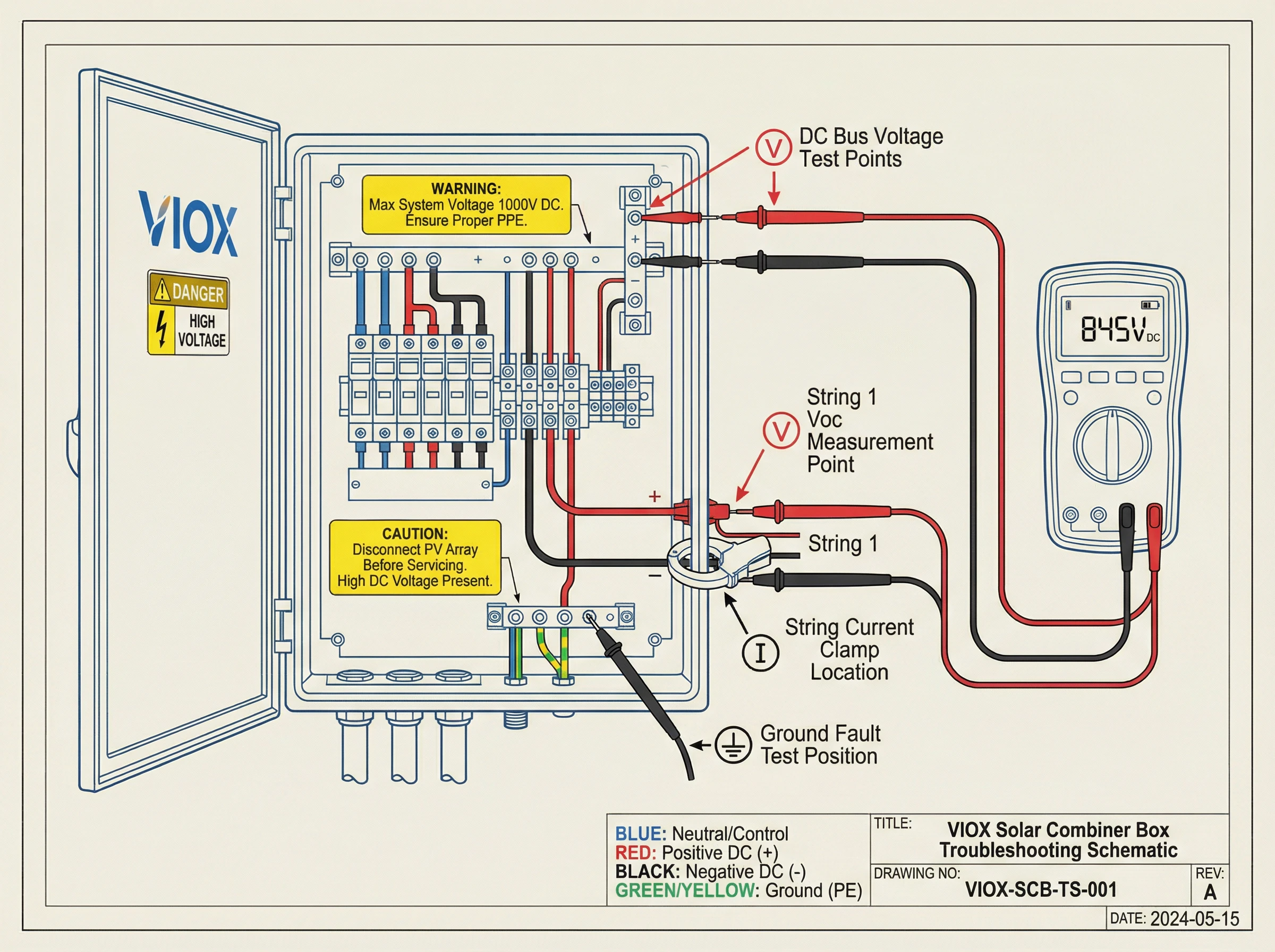

Effective troubleshooting requires proper equipment and strict safety protocols. Field technicians should carry a standardized diagnostic toolkit: True RMS Digital Multimeter (DC voltage to 1500V), Thermal Imaging Camera (minimum 160×120 resolution), Calibrated Torque Screwdriver (7-25 in-lbs range), Insulation Resistance Tester (500-1000V), and Lockout/Tagout Equipment.

Before opening any solar combiner box, establish a zero-energy state. Rotate the DC disconnect to OFF and apply lockout/tagout per NFPA 70E. Verify zero voltage with a multimeter—remember that array-side terminals remain energized even with the disconnect open. Wear arc-rated PPE (minimum ATPV 8 cal/cm²), voltage-rated gloves, and safety glasses. Never work alone on combiner box diagnostics.

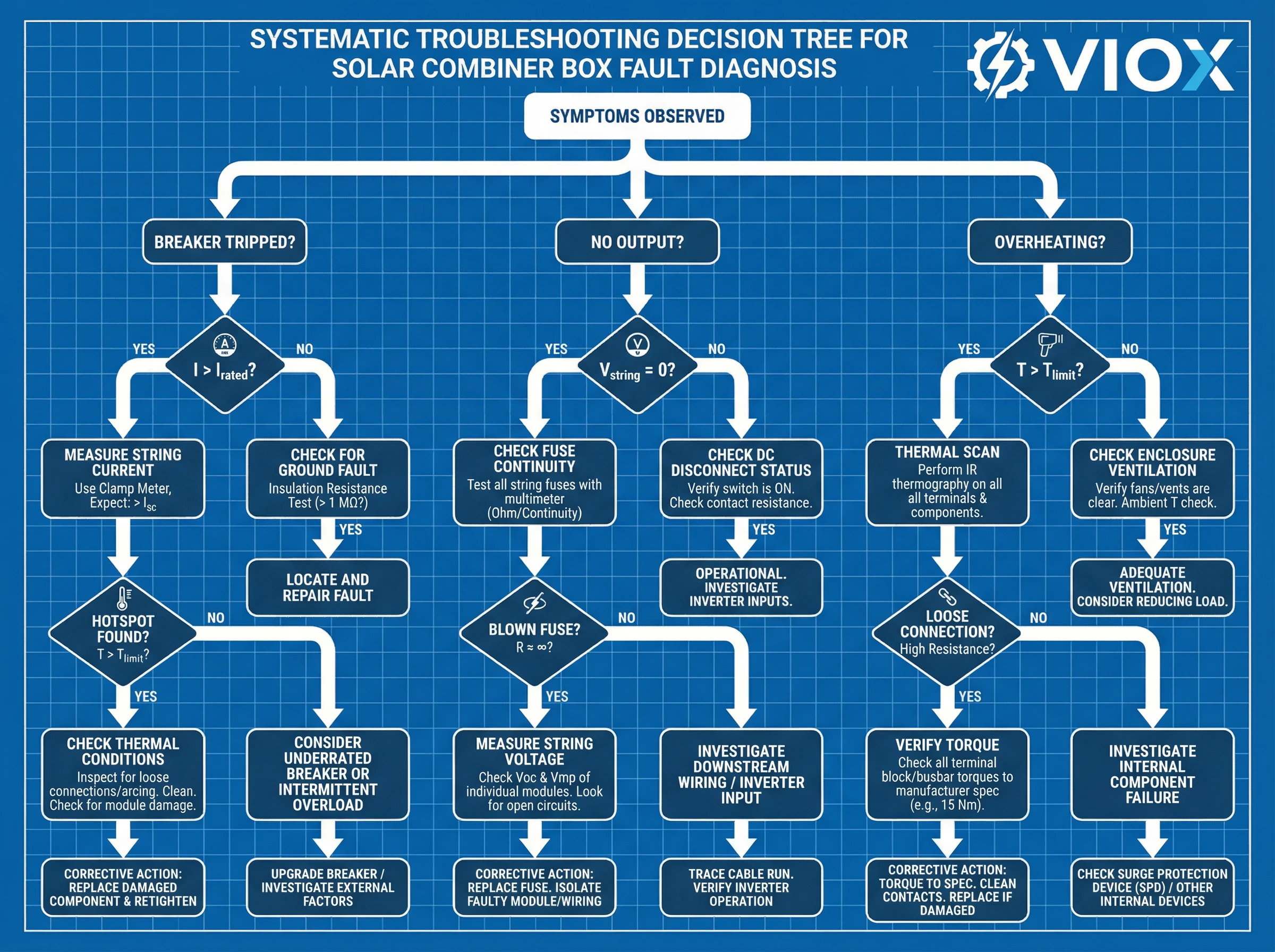

Fault #1: Circuit Breaker Nuisance Tripping

Symptoms: String circuit breaker in OFF position with no obvious fault. Generation drops proportionally. May trip intermittently during peak hours.

Diagnostic Procedure: Document breaker rating and measure string open-circuit voltage (Voc)—typical 600-1000V range confirms string integrity. Measure string current under load with a DC clamp meter. A 15A breaker trips at approximately 12-13A continuous (80-87% rating) under elevated temperatures. Thermal scan the breaker with IR camera—temperature differences exceeding 15°C compared to adjacent breakers indicate poor connections or degradation.

Root Causes: Thermal derating in high-temperature enclosures (above 40°C) reduces breaker capacity significantly. String current mismatch from shading or module degradation overloads higher-performing strings. Loose terminal connections generate heat, triggering thermal trips. Aged breakers experience calibration drift.

Fixes: Improve ventilation by clearing vents, adding louvers, or installing sunshades. Upsize breakers if chronic overload exists. Re-torque terminals to 8-12 in-lbs (0.9-1.4 Nm). Replace damaged breakers. VIOX solar combiner boxes feature optimized spacing and ventilation to maintain proper breaker operating temperatures.

Fault #2: Blown Fuses

Symptoms: No output from affected strings. Visual inspection shows broken fuse element or continuity test confirms open circuit. Multiple simultaneous failures suggest system-level fault.

Diagnostic Procedure: After confirming the blown fuse, identify the root cause before replacement. Measure string Voc (typical 600-1000V) and short-circuit current (Isc, typically 8-12A). Properly sized fuses should be rated at 156% of string Isc per NEC 690.9—a string with 9A Isc requires minimum 15A fuse. Measure current from each string; variations exceeding 10% suggest imbalance issues.

Root Causes: String imbalance redistributes current to parallel strings, exceeding ratings. Short circuits from damaged cables or junction box failures blow fuses instantly. Ground faults create alternate current paths. Undersized fuses from specification errors.

Fixes: Replace with correct DC-rated fuses (1000V or 1500V rating). Never use AC fuses in DC circuits. Investigate string imbalance, ground faults, or cable damage before reenergizing. Document replacements for warranty tracking. VIOX combiner boxes use finger-safe fuse holders with clear rating labels.

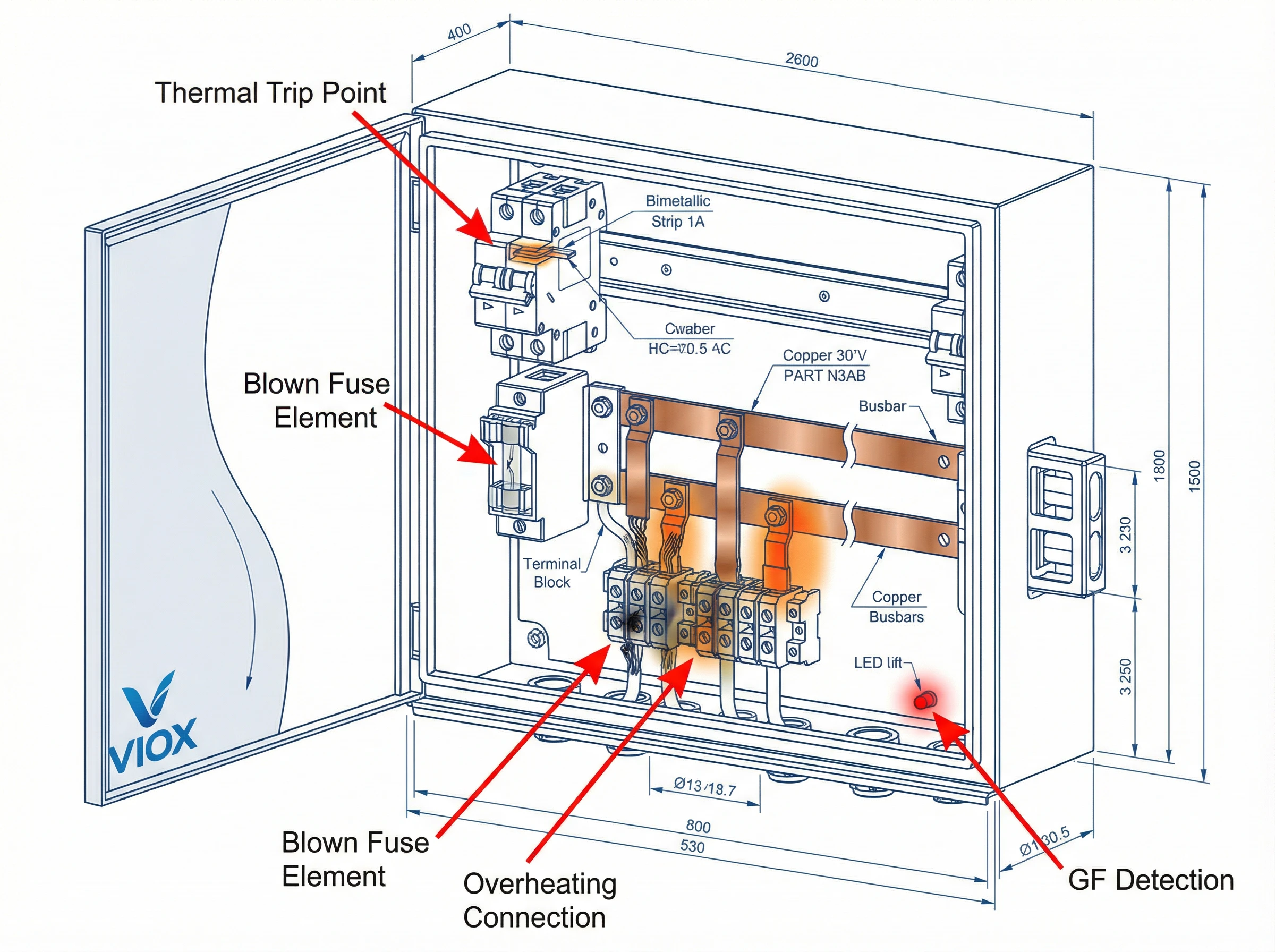

Fault #3: Terminal Overheating and Burn Marks

Symptoms: Discoloration or melting of terminals, burnt insulation, or electrical burning odor. Thermal imaging shows hot spots 20-50°C above ambient. Severe cases show arcing damage or melted housings.

Diagnostic Procedure: De-energize completely before inspection—overheated terminals indicate fire hazard. Inspect for discoloration, melted components, or carbon tracking. Measure terminal resistance; properly torqued terminals should exhibit less than 0.5 milliohms. Voltage drop should be under 200 mV across connection points at full current. Check for conductor strand breakage or oxidation.

Root Causes: Loose terminals from improper torque create high-resistance contact points that worsen through thermal cycling. Oversized conductors in small terminals compress unevenly. Corrosion from moisture increases resistance. Undersized terminals cause chronic overheating.

Fixes: Replace thermally damaged terminals. Re-terminate using calibrated torque tools (7-15 in-lbs / 0.8-1.7 Nm). Apply anti-oxidant compound for dissimilar metals. Schedule annual thermal imaging inspections. VIOX combiner boxes feature 125°C-rated terminals with clear torque specifications marked on enclosure labels.

Fault #4: Voltage Imbalance Between Strings

Symptoms: Unequal string voltages despite identical configurations. Voltage differences exceeding 5% between parallel strings. Lower than expected power output.

Diagnostic Procedure: Measure open-circuit voltage (Voc) of each string within a 5-minute window under stable irradiance. Strings should match within 2-3%. A 10%+ lower voltage indicates shading, module failure, or wiring faults. Higher voltage suggests open-circuit condition. Verify string configuration matches design—count modules per string.

Root Causes: Partial shading reduces voltage through bypass diode activation. Module degradation or failure within strings. Wiring errors including polarity issues or loose connections. Failed bypass diodes cause voltage depression.

Fixes: Document shading patterns; address with tree trimming or array modifications. Use IV curve testing to isolate failed modules. Replace with matched specifications. Re-verify all connections. VIOX combiner boxes provide labeled terminals for simplified voltage measurement and fault isolation.

Fault #5: Ground Fault Indicators

Symptoms: Ground fault detection triggered or inverter alarm activated. System shutdown or compromised safety operation. LED indicators show red or fault status display.

Diagnostic Procedure: Systematically isolate circuits to identify compromised insulation. Measure insulation resistance of combiner box output using megohmmeter (500V or 1000V test voltage) between DC bus and ground. Healthy systems measure above 1 megohm; below 100 kilohms requires immediate attention. Isolate strings individually by opening protection devices and retesting to identify faulted circuit.

Root Causes: Cable insulation damage from rodents, abrasion, or UV degradation. Moisture in junction boxes creating conductive paths. Module delamination exposing energized components. Installation errors damaging insulation during wire stripping or cable clamping.

Fixes: Conduct physical inspection after isolation. Megger test progressively smaller sections to localize faults. Replace damaged conductors—use rated connectors per NEC 110.14(B). Dry moisture-affected equipment and repair seals. Replace delaminated modules. Document incidents with measurements and root causes. VIOX combiner boxes incorporate integrated ground fault detection with visual indicators per NEC 690.41.

Fault #6: Corrosion and Water Ingress

Symptoms: Visible moisture, condensation, or water pooling inside the enclosure. White powdery deposits (aluminum oxide) or rust on metal components. Green verdigris on copper conductors. Intermittent faults that worsen during rain or high humidity. Gasket compression set or visible gaps in enclosure seals.

Diagnostic Procedure:

Visual inspection immediately reveals most water ingress issues. Open the combiner box during dry conditions and look for water staining, corrosion products, or mineral deposits that indicate past moisture presence. Check the integrity of all gaskets by running your finger along the seal while the door is open—gaskets should be pliable, not hardened or cracked.

Inspect all cable entry points. Conduit seals and cable glands are common failure points. Verify that all cable entries slope downward exiting the enclosure to prevent water wicking along conductors into the box. Check for missing or improperly installed cable gland seals.

Use a moisture meter or hygrometer to measure internal humidity. Readings consistently above 70% RH indicate inadequate sealing or ventilation design that allows moisture accumulation.

Root Causes:

- Failed Gaskets and Seals: UV exposure, ozone, and thermal cycling degrade elastomer gaskets over 5-10 years. Hardened gaskets lose sealing effectiveness and allow water intrusion.

- Improper Cable Entry Installation: Missing cable gland seals, oversized knockouts not properly sealed, or conduit installations that allow water to drain into the enclosure.

- Condensation: Temperature differentials between day and night cause internal condensation in sealed enclosures, particularly in humid climates. Poor ventilation design traps moisture.

- Physical Damage: Impact damage to the enclosure, cracked viewing windows, or missing fasteners compromise the weatherproof integrity.

Fixes and Remediation:

Address water ingress immediately—prolonged moisture exposure accelerates corrosion and creates ground fault hazards. Remove all moisture using compressed air or absorbent materials. Replace corroded terminals, conductors, and components that show oxidation or structural degradation.

Replace all gaskets showing compression set, cracking, or hardening. Use UV-resistant EPDM or silicone gaskets rated for outdoor service. Apply dielectric grease to gasket surfaces to improve sealing and extend service life.

Repair or properly seal all cable entries. Install new cable glands with proper compression seals. For conduit entries, use sealing bushings and ensure conduits slope away from the enclosure. Consider installing a small drain hole at the lowest point of the enclosure with a breather vent to allow condensation drainage and pressure equalization.

For installations in high-humidity environments, specify combiner boxes with NEMA 4X or IP66 ratings and stainless steel construction. VIOX solar combiner boxes feature multi-stage gasket systems with UV-resistant seals, pre-sealed cable entry plates, and corrosion-resistant powder coatings to ensure long-term weatherproof performance in harsh outdoor environments.

Preventive Maintenance Best Practices

Proactive maintenance prevents the majority of combiner box failures before they impact system performance. Establishing a systematic inspection schedule reduces mean time between failures (MTBF) and extends equipment service life.

Quarterly Visual Inspections: Conduct external visual checks every three months. Look for physical damage to the enclosure, signs of insect or rodent activity, vegetation growth blocking ventilation, and proper door closure. Verify that labeling remains legible and safety signage is intact.

Annual Thermal Scanning: Schedule thermal imaging inspections during peak generation hours when current flow is maximum. Scan all terminals, busbars, breakers, and fuses. Establish baseline thermal signatures and flag any connections showing temperature rise above 10°C compared to adjacent components. Address hot spots immediately before they progress to failures.

Biannual Connection Retorquing: Every two years, de-energize the system and verify torque on all power connections. Thermal cycling causes gradual loosening even in properly installed terminals. Use calibrated torque tools and record torque verification in maintenance logs. This simple procedure prevents 70% of terminal overheating failures.

Gasket and Seal Inspection: Annually inspect all gaskets, cable glands, and enclosure seals. Replace any gaskets showing hardening, compression set, or cracking. In coastal or high-humidity environments, increase inspection frequency to twice annually.

Documentation Requirements: Maintain comprehensive maintenance records including inspection dates, thermal imaging results, torque verification, component replacements, and any fault incidents. This documentation supports warranty claims, tracks reliability trends, and demonstrates due diligence for insurance purposes. Use standardized checklists to ensure consistent inspection quality across multiple sites.

Properly maintained solar combiner boxes provide 25+ years of reliable service. VIOX offers field service training programs, technical documentation, and replacement parts support to help O&M teams maintain peak system performance throughout the equipment lifecycle.

Conclusion: VIOX Troubleshooting Support

Systematic troubleshooting transforms combiner box failures from costly emergencies into manageable maintenance events. By following the diagnostic procedures outlined in this guide—from circuit breaker tripping to water ingress—field teams can quickly isolate root causes, implement proven fixes, and return systems to full generation capacity.

VIOX Electric designs solar combiner boxes with field serviceability in mind. Our products incorporate features that simplify troubleshooting: clearly labeled terminals, accessible test points, integrated thermal management, and weatherproof construction that reduces failure rates. Every VIOX combiner box undergoes factory thermal testing and quality control to ensure reliable performance in real-world conditions.

For technical support, diagnostic assistance, or replacement parts, contact VIOX Electric’s field service team. We provide application engineering consultation, on-site training for O&M personnel, and comprehensive technical documentation to support your solar assets throughout their operational life. Visit viox.com or call our technical hotline for expert troubleshooting guidance.