Introduction: Why Inspection Standards Matter for Solar Combiner Boxes

Solar combiner boxes serve as critical safety junctions in photovoltaic systems, consolidating DC current from multiple solar panel strings before routing power to inverters or battery systems. Despite their relatively simple function, these enclosures are among the most scrutinized components during PV system inspections—and for good reason. A faulty solar combiner box can lead to arc faults, fire hazards, system downtime, and costly warranty claims.

For inspectors, engineers, and Authority Having Jurisdiction (AHJ) personnel, navigating the overlapping requirements of UL and IEC standards presents a persistent challenge. UL 1741 dominates North American installations, while IEC 60364-7-712 and IEC 62852 govern projects in Europe, Asia, and much of the developing world. Many manufacturers, including VIOX Electric, pursue dual certification to serve global markets—but this creates additional complexity during field verification.

This inspector’s guide provides practical, checklist-based frameworks for verifying solar combiner box compliance against both UL and IEC standards. Whether you’re approving a residential rooftop array in California or a utility-scale installation in Germany, these checklists will help you identify non-conformities, reduce inspection time, and protect system integrity from the start.

UL Standards Framework for Solar Combiner Boxes

UL 1741: The North American Benchmark

UL 1741, titled “Inverters, Converters, Controllers and Interconnection System Equipment for Use With Distributed Energy Resources,” serves as the primary certification standard for solar combiner boxes in the United States and Canada. While often associated with inverters, UL 1741 explicitly covers balance-of-system components, including DC combiner enclosures.

Combiner boxes listed to UL 1741 have been tested by Nationally Recognized Testing Laboratories (NRTLs) for electrical safety, fire containment, fault current withstand, and environmental durability. The standard addresses both the product design and the markings that must appear on certified equipment.

Key UL 1741 requirements inspectors verify:

- NRTL marking presence: The UL or ETL mark must be permanently affixed to the enclosure.

- Voltage and current ratings: Maximum DC voltage (1000V or 1500V) and current capacity must be clearly marked.

- DC disconnect integration: If present, disconnect switches must meet UL 98B.

- Fuse specifications: String fusing (when required) must use DC-rated fuses with visible ampere/voltage markings.

- Grounding and bonding compliance: Per NEC Article 690 requirements.

- Warning labels: Ungrounded conductor warnings and shock hazard notices must be legible.

UL 50: Enclosure Environmental Ratings

UL 50 defines NEMA (National Electrical Manufacturers Association) enclosure ratings used throughout North America. For solar combiner boxes, two ratings dominate:

- NEMA 3R: Weather-resistant, suitable for most outdoor installations; protects against rain and sleet.

- NEMA 4X: Corrosion-resistant, required for coastal or harsh industrial environments; provides superior protection against windblown dust and hose-directed water.

Inspectors should verify that the enclosure rating matches the installation environment. A NEMA 3R box installed 500 feet from the ocean will fail prematurely due to salt spray corrosion.

IEC Standards Framework for Solar Combiner Boxes

IEC 60364-7-712: Installation Requirements for PV Systems

IEC 60364-7-712 establishes electrical installation standards for photovoltaic power supply systems worldwide. Section 712.422 specifically addresses protection against overcurrent in PV arrays, while Section 712.537 covers isolation and switching requirements—both directly applicable to combiner box inspections.

Key IEC 60364-7-712 provisions:

- Overcurrent protection sizing: String fuse ratings must fall between 1.5x and 2.4x the string short-circuit current (Isc_mod); sub-array protection must be between 1.25x and 2.4x the sub-array Isc.

- Double insulation requirement: For systems exceeding 120V DC open-circuit voltage, Class II (double or reinforced insulation) is mandatory.

- Disconnecting device specifications: Load-break switch-disconnectors must be capable of interrupting maximum DC current under load.

- Conductor polarity: For grounded arrays, overcurrent devices must be on the ungrounded conductor; floating arrays require protection on both poles.

- Enclosure compliance: Combiner box enclosures must meet IEC 61439 standards for low-voltage switchgear assemblies, addressing temperature rise and internal clearances.

IEC 62852 and IP Rating System

While IEC 62852 primarily addresses DC connectors for photovoltaic systems, it establishes environmental protection criteria that also apply to combiner box enclosures. The Ingress Protection (IP) rating system, defined in IEC 60529, uses a two-digit code:

- First Digit (Solid Ingress):

- 5 = Dust-protected (limited ingress permitted)

- 6 = Dust-tight (no ingress)

- Second Digit (Liquid Ingress):

- 5 = Protected against water jets

- 6 = Protected against powerful water jets

- 7 = Protected against temporary immersion (up to 1 meter)

For most outdoor solar installations, IP65 serves as the minimum acceptable rating. Coastal, flood-prone, or high-humidity environments typically require IP66 or IP67 protection. Inspectors should verify that the marked IP rating matches both the environmental conditions and the project specifications.

Pre-Inspection Documentation Checklist

Before conducting physical inspection, verify that the following documentation is available and complete. Missing or incomplete documentation is grounds for inspection deferral in most jurisdictions.

Required Documents (UL and IEC Installations)

- UL 1741 listing certificate (North America) or IEC 61439/60947 compliance declaration (International)

- NRTL mark verification (for UL) or CE marking verification (for IEC)

- Single-line electrical diagram showing string configuration

- String voltage and current calculations (Voc, Isc, Vmp, Imp)

- Overcurrent protection device sizing calculations

- Manufacturer’s installation guide for the specific combiner box model

- Torque specifications for all electrical terminations

- Environmental rating confirmation (NEMA or IP rating)

- NEC Article 690 compliance statement (US installations)

- Local utility interconnection approval

- Building permit and approved electrical plans

- Solar panel model specification sheets

- Maximum series fuse ratings (NFPA 70E compliance)

- Temperature coefficient data for voltage calculations

Documentation review should confirm that the installed combiner box model matches the approved plans. Any field substitutions require AHJ approval before proceeding with inspection.

Physical and Visual Inspection Checklist

The physical inspection identifies installation defects, environmental vulnerabilities, and safety hazards that may not be apparent in documentation review.

Enclosure and Mounting

- Integrity: No cracks, holes, or damage to enclosure body or cover.

- Weather seals intact with no gaps (critical for IP/NEMA rating)

- UV-resistant materials confirmed (for outdoor installations)

- No signs of rust or corrosion on metal enclosures

- Mounting: Combiner box securely fastened to structure or mounting system.

- Hardware shows no corrosion or looseness

- Mounting location provides required accessibility (NEC 110.26)

- Clearances maintained per manufacturer specifications

- Thermal Management: Ventilation ports clear of debris and obstructions.

- Box not subjected to direct concentrated solar heating (unless rated)

- Adequate spacing from other heat-generating equipment

Cable Entry and Strain Relief

- Sealing: All cable entries fitted with appropriate glands or connectors.

- Glands properly tightened to maintain IP/NEMA rating

- Unused cable entries sealed with blanking plugs

- Conduit connections secure and weather-sealed

- Support: Cables properly identified and labeled at entry points.

- Adequate strain relief provided for all conductors

- PV wire listing verified for exposed single-conductor DC wiring

- Cable support provided within required distances

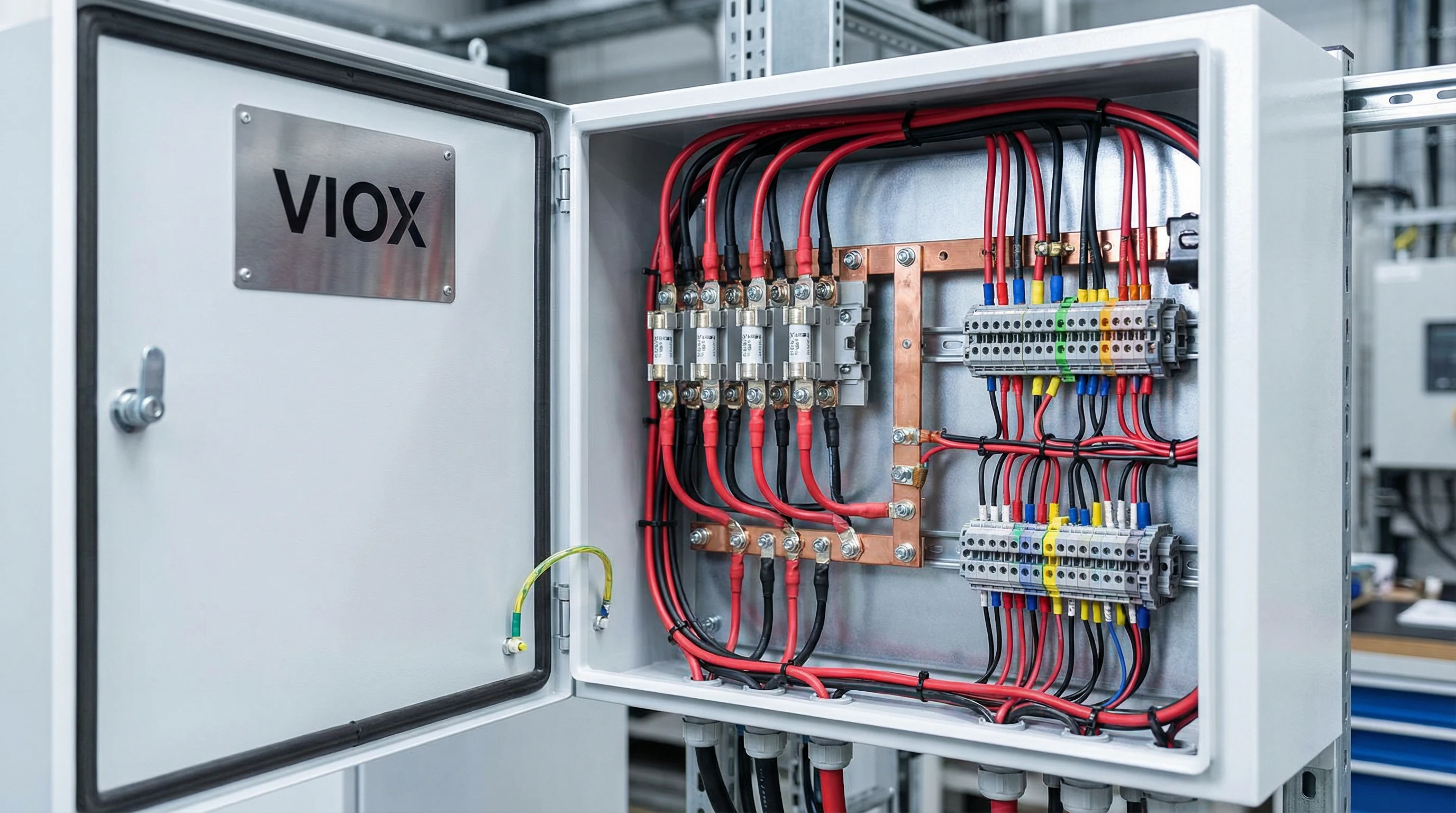

Internal Component Inspection

- Fusing: All string positions equipped with appropriate fusing (when required per NEC 690.9).

- Fuses rated for DC operation with correct voltage rating

- No evidence of overheating (discoloration, melted insulation)

- Fuse holders secure and making proper contact

- Switching: Switch operates smoothly through full travel.

- ON/OFF positions clearly marked and functional

- Handle lockout provision present and functional

- Switch contacts show no pitting or burning

- Grounding: Equipment grounding conductor present and properly terminated.

- Grounding busbar secure and adequately sized

- Bonding jumpers installed on all metallic components

- Ground resistance verified <25 ohms (per NEC requirements)

- Terminations: All terminals visibly tight (use torque wrench for verification).

- No signs of corrosion on copper terminals or busbars

- Correct polarity observed (positive to positive, negative to negative)

- Wire entry into terminals per manufacturer specifications

Electrical Testing and Verification Checklist

Safety Warning: All electrical testing must be performed with appropriate personal protective equipment (PPE) and after confirming the combiner box can be safely isolated. DC voltages in solar combiner boxes can exceed 1000V and present serious shock and arc flash hazards.

Pre-Test Safety Verification

- Disconnect switch in OFF position and locked out (if equipped).

- String inputs can be safely isolated for testing

- Warning signs posted during testing procedures

- Arc-rated PPE worn per NFPA 70E arc flash boundary calculations.

- Insulated tools and properly rated test equipment used

- Second qualified person present for high-voltage testing

Voltage and Current Measurements

- Open Circuit Voltage (Voc): Measure Voc on each string under solar irradiance.

- Verify Voc does not exceed maximum voltage rating of combiner box

- Compare measured Voc to calculated values (should be within 5%)

- Operating Current: Measure operating current from each string under load.

- Verify current balance between strings (variance <10% indicates potential issues)

- Confirm current does not exceed fuse or busbar ratings

- Polarity: Confirm positive and negative polarity on all string inputs.

- Verify consistent color coding (typically red=positive, black=negative)

- Check for reversed polarity connections (immediate fail condition)

Insulation and Grounding Tests

- Insulation Resistance:

- Test between positive conductor and ground: minimum 1 megohm

- Test between negative conductor and ground: minimum 1 megohm

- Test between positive and negative conductors: minimum 1 megohm

- Note: Consult module manufacturer before testing; some warranties exclude megger testing

- Ground Continuity: Verify ground path continuity from combiner box to system ground.

- Measure ground resistance: must be <25 ohms per NEC 250.53

- Confirm bonding between all metallic enclosure parts

- Surge Protection: Check SPD status indicator (green=good, red=replace).

- Verify SPD voltage rating matches or exceeds system Voc

- Confirm SPD is properly connected between each pole and ground

Functional Testing

- Switch Operation: Verify switch interrupts current under load conditions.

- Test mechanical lockout/tagout functionality

- Confirm visible break indication when switch is open

- Monitoring: Verify string-level current monitoring accuracy (if equipped).

- Test alarm functions for overcurrent or fault conditions

- Confirm remote monitoring communication is functional

Certification and Marking Requirements

Proper labeling and certification markings are not merely administrative formalities—they provide critical safety information and legal liability protection. Missing or incorrect markings are common reasons for inspection failure.

UL Marking Requirements (North America)

- Certification Mark: UL, ETL, CSA, or other NRTL mark permanently affixed to enclosure.

- Mark clearly visible without opening enclosure

- Control number traceable to certification database

- Rating Plate: Manufacturer name and model number.

- Maximum DC voltage rating (e.g., “1000V DC Max” or “1500V DC Max”)

- Maximum current per string and total current capacity

- Environmental rating (e.g., “NEMA 4X” or “Outdoor Use”)

- Ambient temperature rating if other than 25°C (77°F)

- Safety Warnings: “WARNING: ELECTRIC SHOCK HAZARD” prominently displayed.

- Ungrounded conductor warning (if applicable): “DC conductors may be energized”

- “ON” and “OFF” markings for disconnect switches

- Fuse replacement specifications (amperage, voltage, DC rating)

IEC Marking Requirements (International)

- CE Mark: Visible on enclosure or rating plate.

- Accompanied by declaration of conformity document

- Compliance with Low Voltage Directive 2014/35/EU

- Standard Reference: Reference to IEC 61439 or IEC 60947 on rating plate.

- IP rating clearly marked (e.g., “IP65” or “IP66”)

- Rated operational voltage (Ue) and current (Ie)

- Symbols: DC voltage warning symbol (IEC 60417 symbol).

- Multilingual warnings if required by destination market

- Grounding/bonding symbol where applicable

Field-Applied Labels

- String Identification: Each string input labeled with corresponding array location.

- Output Identification: Output terminals labeled for destination (inverter, charge controller, etc.).

- Polarity markings (+ and – symbols) on all DC terminals

- System Info: Maximum system voltage present.

- Short-circuit current rating

- Date of installation and installer identification

- Emergency contact information

Common Non-Compliance Issues

Based on field inspection data and AHJ reports, the following issues account for the majority of solar combiner box inspection failures:

- Missing or improper fusing: String fuses omitted when NEC 690.9 requires them (three or more strings), or fuses undersized/oversized relative to module maximum series fuse rating.

- Incorrect environmental rating: NEMA 3R boxes installed in corrosive coastal environments, or indoor-rated enclosures used outdoors without proper weather protection.

- Inadequate grounding: Missing equipment grounding conductors, undersized ground wires, or poor termination resulting in ground resistance >25 ohms.

- Torque specification violations: Loose terminal connections due to improper torque application, leading to hotspots and potential arc faults.

- Cable gland failures: Unused cable entries left open (compromising IP/NEMA rating), or wrong gland types used for cable sizes present.

- Insufficient labeling: Missing warning labels, faded or illegible markings, or failure to label individual string circuits for identification.

- Voltage rating mismatches: Combiner box rated for 1000V DC installed on system with calculated Voc exceeding this value due to cold temperature conditions.

Conclusion: Best Practices for Efficient Inspections

Inspecting solar combiner boxes against UL and IEC standards requires balancing thoroughness with efficiency. By following structured checklists and prioritizing safety-critical items—certification verification, overcurrent protection, grounding, and environmental ratings—inspectors can identify the most consequential non-conformities while maintaining reasonable inspection timelines.

Manufacturers like VIOX Electric who pursue dual UL/IEC certification simplify the inspector’s task by ensuring products meet both North American and international requirements. When evaluating solar combiner boxes for approval, always verify that documentation matches installed equipment, that all safety labeling is present and legible, and that electrical testing confirms system integrity.

Regular use of these checklists will reduce inspection rework, protect system reliability, and ultimately contribute to the safe deployment of solar photovoltaic installations worldwide.