In photovoltaic (PV) power generation systems, a combiner box serves as a critical electrical junction point that consolidates the DC output from multiple solar panel strings into a single feed line before connecting to the inverter. This essential component not only simplifies system wiring but also provides crucial overcurrent protection, surge protection, and centralized monitoring capabilities that enhance both safety and efficiency.

For electrical contractors, solar installers, and project managers, selecting the right combiner box configuration—pre-wired or custom—can significantly impact installation time, project costs, system safety, and long-term maintenance requirements. This comprehensive guide examines both approaches to help you make informed decisions for your solar installations.

What Is a Combiner Box and Why Is It Essential?

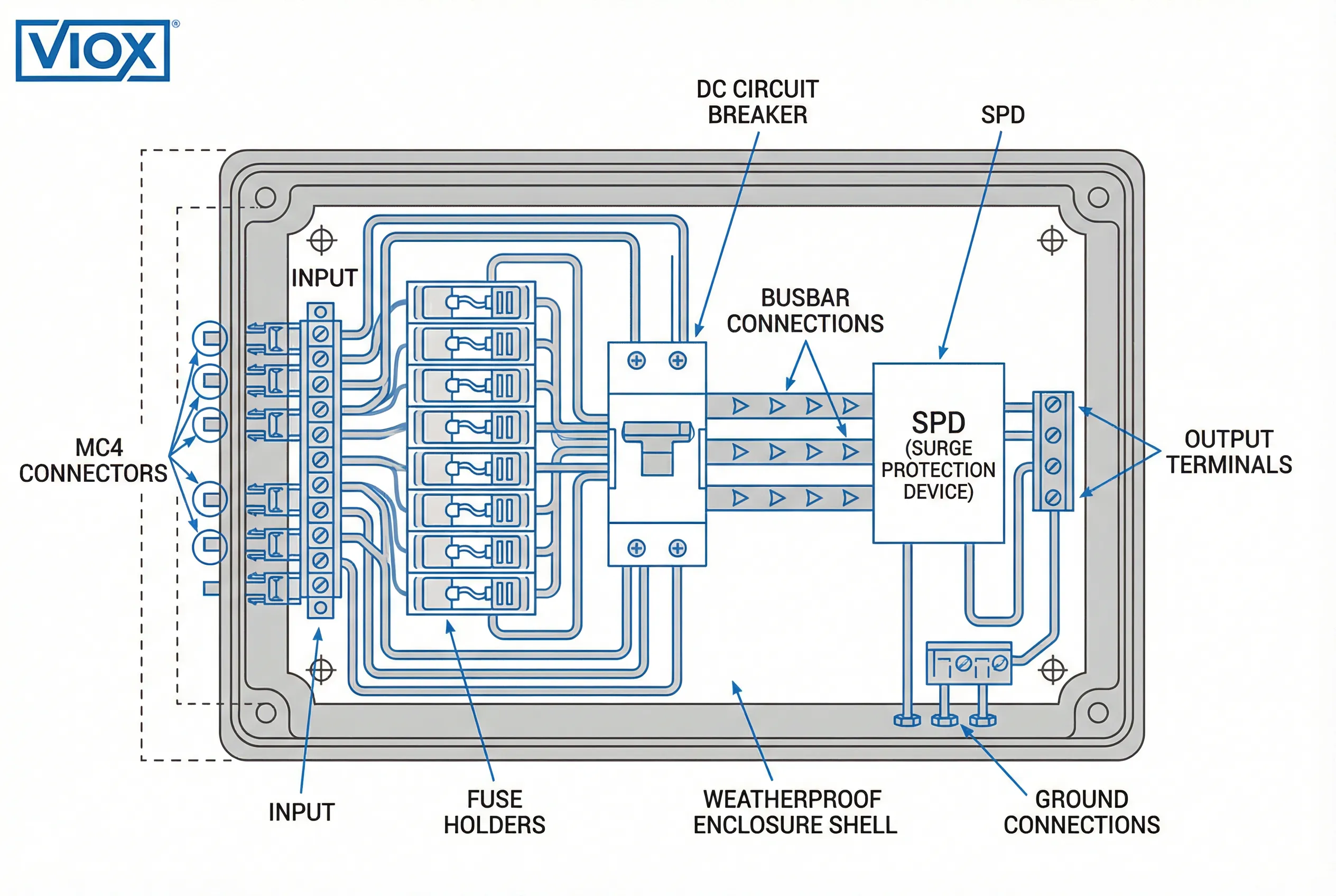

A solar combiner box, also known as a PV combiner box or array combiner box, acts as a central hub where positive and negative conductors from multiple solar panel strings converge. Instead of running dozens of individual wires from each string directly to the inverter—creating a tangled, expensive, and potentially hazardous situation—the combiner box consolidates these connections into a single, manageable output circuit.

Core Functions of Combiner Boxes

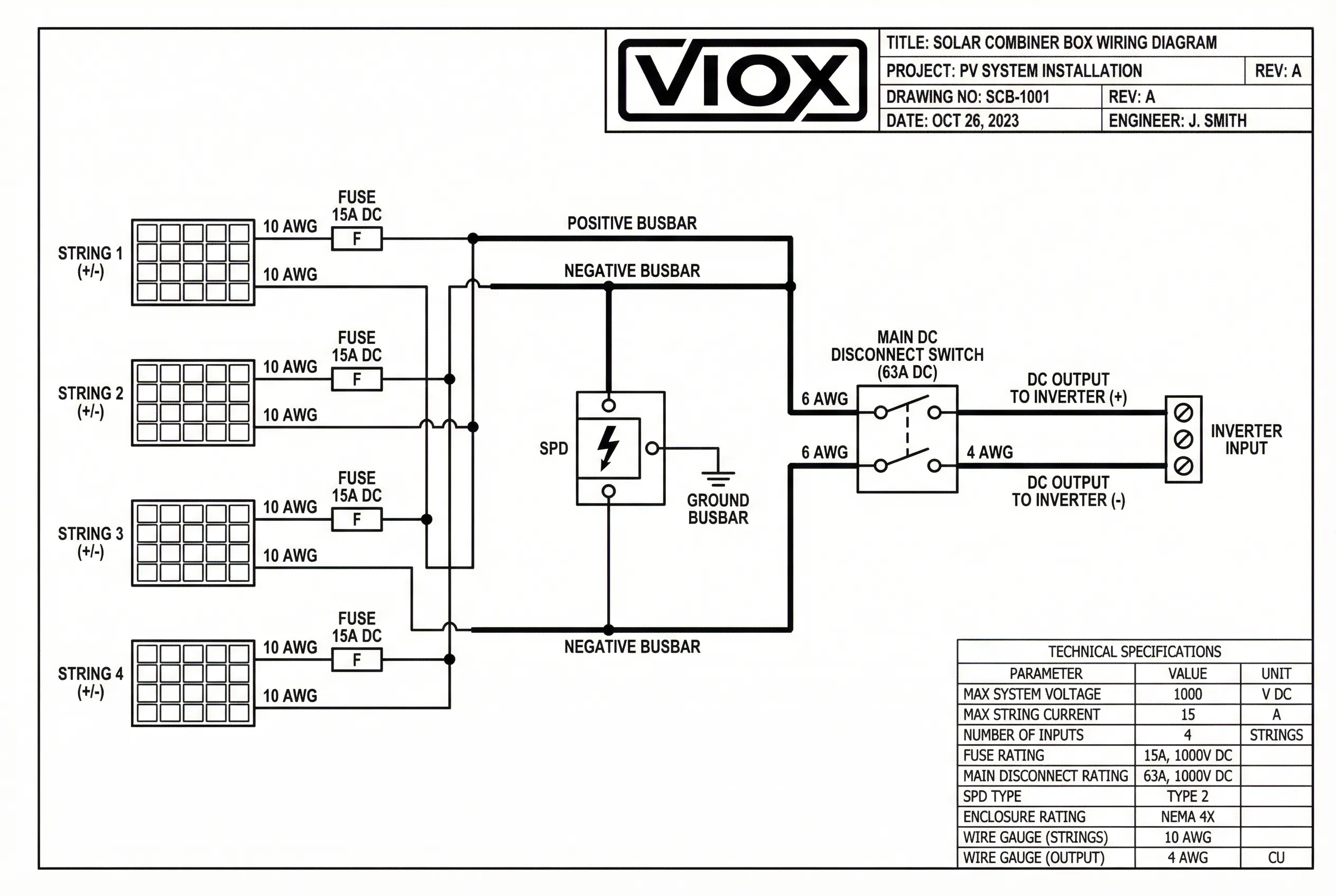

- Current Consolidation: Combines output from 4 to 24+ individual strings into one main feed, reducing wire runs and material costs.

- Overcurrent Protection: Houses fuses or circuit breakers (typically rated at 1.5× string short-circuit current) that isolate faulty strings and prevent damage to downstream equipment.

- Surge Protection: Integrates surge protective devices (SPDs) compliant with IEC/EN 61643-11 standards to safeguard against lightning strikes and voltage spikes.

- System Monitoring: Advanced models include current sensors and voltage monitoring for real-time performance tracking and fault detection.

- Safety Disconnection: Provides manual disconnect switches for safe maintenance and emergency shutdown procedures.

According to recent industry data, properly specified combiner boxes can reduce installation labor by 30-40% while improving overall system reliability. They represent less than 1% of total system cost yet handle 100% of the generated current, making their selection critical to project success.

Pre-Wired Combiner Box: The Plug-and-Play Solution

Pre-wired combiner boxes arrive from the manufacturer with all internal components factory-installed, tested, and ready for immediate deployment. These turnkey solutions feature pre-wired fuse holders with pigtails, strain-relief cable glands, touch-safe distribution blocks, and bidirectional connections.

Advantages of Pre-Wired Combiner Boxes

- Rapid Installation: Reduces on-site installation time by 50-70% compared to field-wiring traditional boxes. Most residential installations complete in 2-4 hours with basic electrical knowledge.

- Lower Labor Costs: Eliminates the need for licensed electricians to perform complex internal wiring, significantly reducing labor expenses on commercial projects.

- Factory Quality Assurance: All connections undergo 100% testing at the manufacturing facility, ensuring proper wire sizing, secure terminations, and correct polarity before shipping.

- Reduced Installation Errors: Pre-wired configurations minimize the risk of incorrect wiring, reversed polarity, or improper fuse ratings that can cause system failures or safety hazards.

- Simplified Compliance: Manufactured to UL 1741, UL 508A, NEC, and IEC standards with proper certifications, streamlining inspection and approval processes.

- Plug-and-Play Convenience: MC4 connectors on inputs allow direct connection to solar panel strings without crimping tools or special equipment.

- Consistent Quality: Every unit matches the same high manufacturing standards, eliminating variability in field construction quality.

Disadvantages of Pre-Wired Combiner Boxes

- Limited Customization: Available in fixed configurations (typically 4, 6, 8, or 12 strings), which may not perfectly match unique project requirements.

- Voltage Restrictions: Standard models usually rated for 1000V DC; upgrading to 1500V DC systems requires specialized pre-wired options with limited availability.

- Configuration Constraints: Cannot easily accommodate special requirements like dual outputs, integrated monitoring systems, or non-standard string counts (e.g., 15, 20, or 24 strings).

- Higher Unit Cost: Pre-wired boxes typically cost 20-40% more per unit than equivalent custom-configured boxes due to factory labor and testing.

- Scalability Limitations: Future system expansion may require purchasing additional complete units rather than simply adding components to existing enclosures.

- Standardized Features Only: May include unnecessary components or lack specific features required for specialized applications.

Custom Combiner Box: Tailored Engineering Solutions

Custom combiner boxes are designed and assembled to meet specific project requirements, with component selection, enclosure size, input/output configurations, and protection devices tailored to exact system specifications. These solutions excel in large-scale commercial, industrial, and utility-scale solar installations.

Advantages of Custom Combiner Boxes

- Perfect System Integration: Engineered to match exact string counts (even unusual numbers like 22 or 28), voltage ratings, and current specifications without compromise.

- Application-Specific Design: Can incorporate specialized features including dual outputs, integrated communication modules, advanced monitoring systems, and remote diagnostics.

- Voltage Flexibility: Supports evolving standards from 1000V to 1500V DC systems with appropriate component ratings and insulation levels.

- Environmental Optimization: Enclosure materials, IP/NEMA ratings, and protective coatings selected for specific climatic conditions—from desert heat to coastal corrosion environments.

- Cost Efficiency at Scale: For large projects (5MW+), custom engineering often proves more economical than purchasing multiple standardized pre-wired units.

- Future-Proof Design: Can include additional terminal capacity, spare fuse positions, and expansion provisions for potential system upgrades.

- Advanced Protection: Integrates sophisticated surge protection, arc fault detection, and string-level monitoring unavailable in standard pre-wired solutions.

- Unique Site Requirements: Accommodates special mounting configurations, extreme temperature ranges (-40°C to +80°C), and harsh environmental conditions.

Disadvantages of Custom Combiner Boxes

- Extended Lead Times: Engineering, component sourcing, and manufacturing typically require 4-8 weeks compared to 1-2 weeks for pre-wired options.

- Higher Initial Engineering Costs: Design fees, technical drawings, and custom specifications add upfront expenses, especially for smaller projects.

- Installation Complexity: Requires experienced licensed electricians for proper field assembly, testing, and commissioning, increasing labor costs.

- Quality Variability: Performance depends heavily on installer skill level; poor workmanship can introduce loose connections, thermal issues, and safety risks.

- On-Site Testing Required: Every custom assembly needs comprehensive testing after installation, adding time and requiring specialized equipment.

- Documentation Burden: Custom configurations require detailed as-built drawings, component specifications, and maintenance documentation for regulatory compliance.

- Longer Project Timelines: Extended manufacturing and installation periods can delay overall project completion and commissioning schedules.

Comprehensive Comparison Table

| Feature | Pre-Wired Combiner Box | Custom Combiner Box |

|---|---|---|

| Installation Time | 2-4 hours | 6-12 hours |

| Labor Skill Required | Basic electrical knowledge | Licensed electrician mandatory |

| Lead Time | 1-2 weeks | 4-8 weeks |

| Typical Cost (8-string) | $800-$1,500 | $600-$1,200 (materials + labor) |

| String Count Options | Fixed (4, 6, 8, 12) | Any configuration (1-32+) |

| Voltage Rating | Typically 1000V DC | 1000V-1500V DC customizable |

| Quality Control | 100% factory tested | Dependent on installer |

| Customization | Limited to available models | Fully customizable |

| Warranty | 5-10 years manufacturer | Varies by components |

| Best For | Residential, small commercial | Large commercial, utility-scale |

| Monitoring Integration | Standard models only | Fully integrated available |

| Compliance Certification | Pre-certified (UL, IEC) | Requires field inspection |

Application-Specific Selection Guide

| Project Type | System Size | Recommended Solution | Key Considerations |

|---|---|---|---|

| Residential | 5-15 kW (2-4 strings) | Pre-Wired | Fast installation, homeowner-friendly |

| Small Commercial | 25-100 kW (6-12 strings) | Pre-Wired | Cost-effective, reliable |

| Large Commercial | 250 kW-1 MW (16-24 strings) | Custom | Optimized for specific requirements |

| Utility-Scale | 5+ MW (32+ strings) | Custom | Advanced monitoring, scalability |

| Remote/Off-Grid | Varies | Pre-Wired | Simplified maintenance, reliability |

| Harsh Environment | Varies | Custom | Special enclosures, protection ratings |

Technical Specifications Comparison

| Component | Pre-Wired Standard | Custom Options |

|---|---|---|

| Enclosure Material | ABS/Polycarbonate blend | ABS, Polycarbonate, Stainless Steel 304/316 |

| Protection Rating | NEMA 4X / IP65 | NEMA 3R to 4X / IP54 to IP67 |

| Fuse Size | 10×38mm standard | 10×38mm, 14×51mm, custom sizes |

| Fuse Rating | 15A typical (fixed) | 10A-63A based on Isc × 1.5 |

| Operating Temperature | -40°C to +60°C | -40°C to +85°C available |

| Input Terminals | MC4 connectors | MC4, MC3, H4, or terminal blocks |

| Output Wire Size | 4-14 AWG fixed | 14 AWG to 500 MCM customizable |

| SPD Type | Type 2 (standard models) | Type 1, Type 2, or combined |

| Breaker Options | Fixed 63A typical | 20A-630A MCCB available |

| Monitoring | Optional on select models | Fully integrated systems available |

Cost Analysis: Total Project Economics

Understanding the true cost comparison requires analyzing both initial investment and long-term operational expenses across typical project scenarios.

Small Residential Project (10 kW, 3 Strings)

Pre-Wired Solution:

- Equipment: $600

- Installation labor (3 hours): $300

- Total: $900

- Timeline: 1 day

Custom Solution:

- Materials: $400

- Design/Engineering: $200

- Installation labor (6 hours): $600

- Total: $1,200

- Timeline: 4-6 weeks

Winner: Pre-Wired (saves $300 and 5+ weeks)

Medium Commercial Project (250 kW, 18 Strings)

Pre-Wired Solution:

- Equipment (2× 12-string units): $3,000

- Installation labor (6 hours): $600

- Total: $3,600

- Limitations: Non-optimal configuration

Custom Solution:

- Materials: $2,400

- Design/Engineering: $400

- Installation labor (10 hours): $1,000

- Total: $3,800

- Perfect configuration match

Winner: Tie (similar costs, custom offers better integration)

Utility-Scale Project (5 MW, 120 Strings)

Pre-Wired Solution:

- Equipment (10× 12-string units): $18,000

- Installation labor (30 hours): $3,000

- Total: $21,000

- Multiple interconnection points required

Custom Solution:

- Materials: $12,000

- Design/Engineering: $2,000

- Installation labor (60 hours): $6,000

- Integrated monitoring: $2,000

- Total: $22,000

- Single optimized system with advanced monitoring

Winner: Custom (better long-term value despite similar upfront cost)

When to Choose Pre-Wired Combiner Boxes

Select pre-wired solutions when your project meets these criteria:

- Fast-Track Schedules: Projects requiring immediate deployment without waiting for custom engineering and manufacturing lead times.

- Standard Configurations: System designs with common string counts (4, 6, 8, or 12) that match available pre-wired models perfectly.

- Budget Constraints: Projects with limited budgets prioritizing lower labor costs over customized features.

- Remote Locations: Sites where bringing specialized electricians for field assembly proves difficult or expensive.

- Residential Installations: Homeowner projects benefiting from simplified installation and straightforward compliance.

- Multiple Similar Sites: Portfolio installations where standardization across sites simplifies maintenance and spare parts inventory.

- Limited Technical Staff: Organizations without in-house electrical engineering resources for custom specification development.

When to Choose Custom Combiner Boxes

Opt for custom-engineered solutions in these scenarios:

- Unique String Counts: Systems requiring non-standard configurations like 15, 20, 24, or 32+ strings that don’t match pre-wired options.

- 1500V DC Systems: High-voltage installations requiring specialized components and enhanced insulation not available in standard pre-wired models.

- Harsh Environments: Extreme climate conditions (desert heat, coastal corrosion, arctic cold) demanding special enclosure materials and protection ratings.

- Advanced Monitoring: Projects requiring integrated string-level monitoring, remote diagnostics, or SCADA system integration.

- Dual Output Requirements: Systems feeding multiple inverters or requiring separate positive and negative bus configurations.

- Utility-Scale Projects: Large installations (5MW+) where custom engineering provides better economics and system optimization.

- Future Expansion Plans: Sites with planned capacity increases requiring pre-installed expansion capacity and spare terminal positions.

- Special Regulatory Requirements: Projects subject to unique local codes, utility specifications, or military/government standards.

Installation Best Practices

Regardless of your combiner box choice, following proper installation procedures ensures optimal performance and safety:

Location Selection

- Install within 3-5 meters of the solar array to minimize wire runs and voltage drop

- Position north-facing or in shaded areas to reduce heat exposure

- Ensure accessibility for maintenance with minimum 1-meter clearance

- Avoid locations prone to water accumulation or flooding

- Mount at comfortable working height (1.5-2 meters) for easy inspection

Electrical Considerations

- Verify all string voltages match before connecting to combiner terminals

- Confirm proper polarity using multimeter testing before energizing

- Size fuses at 1.5× maximum string short-circuit current (Isc)

- Install SPDs with proper grounding per manufacturer specifications

- Use wire rated for 90°C minimum in accordance with NEC 690.31

Environmental Protection

- Apply UV-resistant cable glands for all conduit entries

- Seal all unused knockouts to maintain IP/NEMA rating

- Install breather vents in high-humidity environments to prevent condensation

- Use stainless steel hardware in coastal applications to resist corrosion

- Consider protective awnings or covers for extreme sun exposure

Testing and Commissioning

- Perform insulation resistance testing (megohmmeter) before energizing: minimum 1MΩ

- Verify all fuses rated correctly and seated properly in holders

- Confirm SPD indicator lights show normal operation

- Test disconnect switches under no-load conditions

- Measure and document open-circuit voltage and short-circuit current for each string

- Conduct thermal imaging inspection after 24 hours of operation to identify hot spots

Maintenance Requirements and Long-Term Considerations

Pre-Wired Combiner Box Maintenance

Quarterly Inspections:

- Visual examination of enclosure for cracks, UV degradation, or water intrusion

- Verify SPD indicator lights show normal operation

- Check for insect nests or debris accumulation inside enclosure

Annual Maintenance:

- Thermal imaging of all connections to identify developing hot spots

- Re-torque all terminals to manufacturer specifications

- Test fuse continuity and replace any that show discoloration

- Clean ventilation openings and inspect gasket condition

5-Year Service:

- Replace SPDs per manufacturer recommendations

- Comprehensive electrical testing including insulation resistance

- Consider upgrading monitoring systems if available

Custom Combiner Box Maintenance

Monthly Inspections (first year):

- Detailed thermal imaging to verify proper installation quality

- Monitor for any signs of loose connections or overheating

- Document baseline performance data for future comparison

Quarterly Inspections (after first year):

- Visual inspection of all accessible components

- Verify all indicator lights and monitoring systems function properly

- Check torque on critical connections

Annual Maintenance:

- Complete thermal survey of entire system

- Replace any components showing signs of degradation

- Update as-built documentation with any changes

- Test backup monitoring and communication systems

Component Replacement Schedule:

- Fuses: Replace immediately upon operation; inspect every 2 years

- SPDs: Replace every 5 years or after lightning strike

- Breakers: Test annually; replace every 10 years

- Terminals: Inspect every 2 years; replace if showing corrosion

Industry Standards and Compliance Requirements

Combiner boxes must comply with multiple overlapping standards depending on installation location and application:

United States:

- NEC Article 690: Solar Photovoltaic Systems

- UL 1741: Inverters, Converters, Controllers and Interconnection System Equipment

- UL 508A: Industrial Control Panels

- NEMA 250: Enclosure Types and Environmental Protection Ratings

International:

- IEC 61439: Low-voltage switchgear and control gear assemblies

- IEC 61643-11: Surge protective devices for low-voltage systems

- IEC 60529: Degrees of protection (IP ratings)

- IEC 62305: Protection against lightning

Certification Considerations:

- Pre-wired units typically carry UL listing for entire assembly

- Custom boxes may require field evaluation or special inspection

- Some jurisdictions mandate specific certifications for utility interconnection

- Export projects must meet destination country requirements (CE marking, CCC, etc.)

Frequently Asked Questions

Q: How many strings can a combiner box handle?

A: Pre-wired combiner boxes typically accommodate 4-12 strings in standard configurations, while custom solutions can handle 1-32+ strings depending on design. Selection depends on your total system current (sum of all string Isc values) and the combiner box’s maximum rated capacity. For residential systems (3-6 strings), pre-wired options work well. Commercial installations (12-24 strings) often benefit from custom designs.

Q: Can I mix pre-wired and custom combiner boxes in the same system?

A: Yes, hybrid approaches work well for large installations. Use pre-wired boxes for standard array sections to save costs and installation time, while deploying custom boxes for areas requiring specialized configurations, advanced monitoring, or unique environmental protection. Ensure all units meet the same voltage rating and grounding requirements.

Q: What’s the typical lifespan of a combiner box?

A: Quality combiner boxes last 20-25 years with proper maintenance, matching typical solar panel warranties. The enclosure usually outlasts internal components. Expect to replace SPDs every 5-7 years, fuses as needed after operation, and circuit breakers every 10-15 years. Pre-wired units from reputable manufacturers often include 5-10 year warranties, while custom assemblies’ warranty depends on component selection.

Q: Do I need a combiner box for systems with microinverters?

A: Generally no. Microinverter systems convert DC to AC at each panel, eliminating the need for DC string combining. However, you may still need an AC combiner box to consolidate multiple inverter outputs before connecting to the main service panel or utility connection point. This is particularly common in commercial microinverter installations.

Q: How do I calculate the correct fuse size for my combiner box?

A: Use this formula: Fuse Rating = 1.5 × String Short-Circuit Current (Isc). For example, if your solar panels have an Isc of 10A, calculate 10A × 1.5 = 15A. Always round up to the next standard fuse size. Never use lower ratings (causes nuisance trips) or higher ratings (reduces protection). Account for temperature effects: Isc increases approximately 0.05% per degree Celsius above 25°C.

Q: What’s the difference between Type 1 and Type 2 surge protection devices in combiner boxes?

A: Type 1 SPDs (Class I) protect against direct lightning strikes and are installed at the service entrance. Type 2 SPDs (Class II) protect against indirect surges and switching overvoltages, typically installed in combiner boxes. For comprehensive protection, some systems use coordinated Type 1+2 combined SPDs. In high-lightning areas, consider upgrading from standard Type 2 to combined protection.

Q: Can I upgrade a pre-wired combiner box with additional strings later?

A: This depends on the specific model. Some pre-wired units include spare fuse positions or terminal capacity for future expansion, but many are configured for their rated string count only. If you anticipate system growth, either select a larger pre-wired model initially (e.g., 8-string box for 6-string system) or choose a custom solution designed with expansion capacity. Adding strings beyond rated capacity violates safety standards and voids warranties.

Conclusion: Making the Right Choice for Your Solar Project

The decision between pre-wired and custom combiner boxes ultimately depends on your specific project parameters: timeline, budget, system configuration, technical requirements, and long-term operational goals. Pre-wired solutions excel in speed, simplicity, and standardization—ideal for residential installations and fast-track commercial projects with conventional designs. Custom combiner boxes provide unmatched flexibility, optimized integration, and specialized capabilities essential for utility-scale installations, harsh environments, and unique system requirements.

For most residential and small commercial projects up to 100 kW with standard string counts, pre-wired combiner boxes offer the best value proposition through reduced labor costs, faster deployment, and factory-assured quality. Medium-sized commercial projects (100-500 kW) benefit from careful evaluation of both options based on specific site conditions and configuration requirements. Large commercial and utility-scale installations above 1 MW almost always justify custom-engineered solutions through superior system integration, advanced monitoring capabilities, and long-term operational advantages.

Partner with VIOX Electric for Your Combiner Box Solutions

At VIOX Electric, we manufacture both premium pre-wired combiner boxes and custom-engineered solutions for solar installations of any scale. Our products meet all major international standards (UL, IEC, NEC compliance) and undergo rigorous 100% factory testing before shipment. With over 15 years of experience serving electrical contractors, solar installers, and project developers worldwide, we provide expert technical support from initial specification through long-term maintenance.

Whether you need rapid-deployment pre-wired units for residential portfolios or sophisticated custom designs for utility-scale projects, our engineering team delivers solutions optimized for your specific requirements. Contact VIOX Electric today for technical consultation, product specifications, and competitive pricing on your next solar combiner box project. Let us help you build safer, more efficient, and more reliable solar installations.