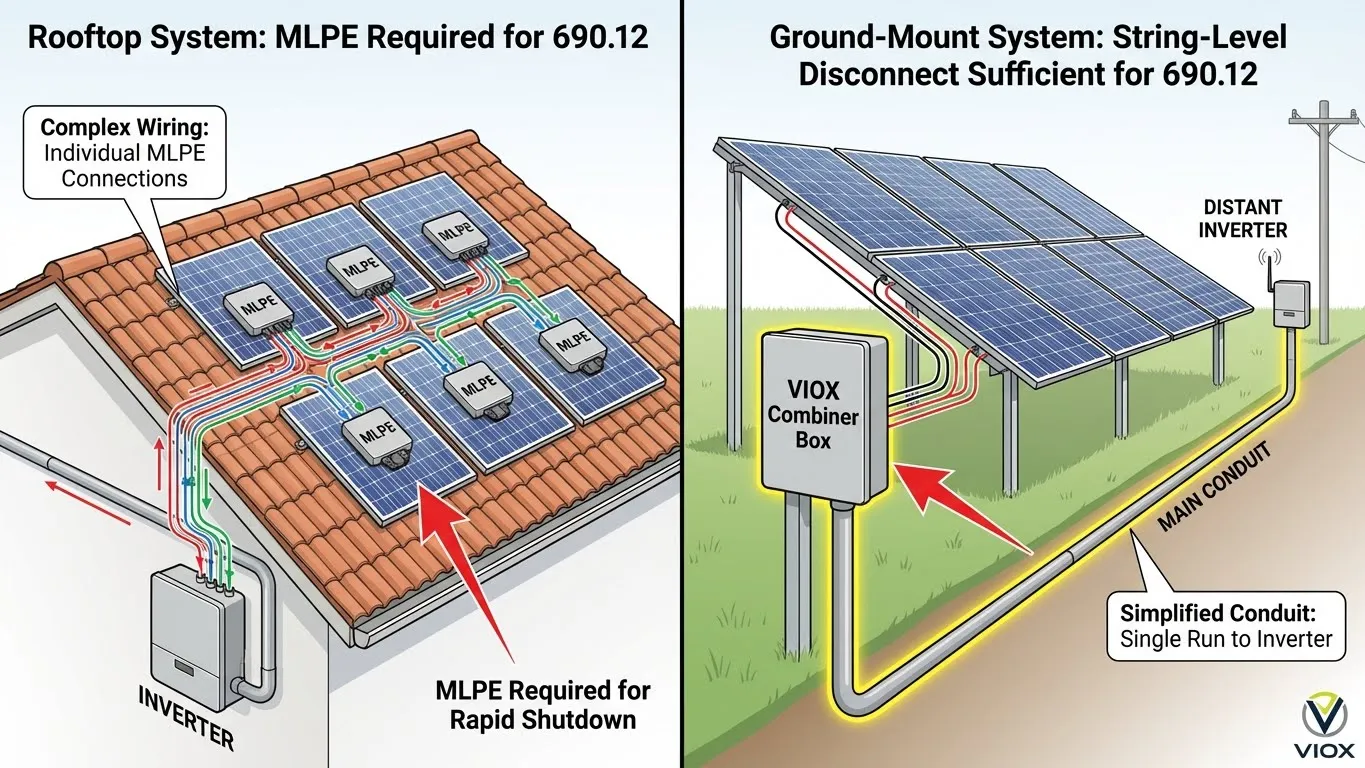

Navigating NEC 690.12 rapid shutdown (RSD) requirements often feels like a direct hit to your project’s bottom line. Many solar installers and EPCs believe that expensive Module-Level Power Electronics (MLPE), like microinverters or optimizers, are the only path to compliance. This can add thousands of dollars to a project, squeezing margins and making bids less competitive.

But what if there’s a smarter, more robust, and significantly cheaper way?

For a huge category of projects—specifically non-rooftop installations like ground-mounts and solar carports—you don’t need complex, proprietary electronics to meet code. You can achieve full NEC 690.12 compliance using time-tested, rugged, and readily available industrial components.

This is the VIOX Passive Component Strategy. It’s a return to first principles of electrical engineering, using high-quality DC contactors and circuit breaker accessories to build an elegant, fail-safe, and budget-friendly rapid shutdown system. Wondering how much you can save? Check our detailed Rapid Shutdown Compliance Cost Analysis: Centralized vs. Distributed.

Phase 1: Understanding the “Zone” and the Opportunity

The core purpose of NEC 690.12 is to protect first responders. In an emergency, they need to de-energize the high-voltage DC conductors from a solar array to work safely. The rule generally states that within a defined boundary (typically 1 foot around the array), voltage must be reduced to 80V or less within 30 seconds, and for conductors outside that boundary, it must drop to under 30V in the same timeframe.

However, the code has evolved. The primary hazard for firefighters is rooftop operations on enclosed buildings. Recognizing this, the 2023 NEC introduced crucial exceptions.

As stated in NEC 690.12 Exception No. 2, “PV equipment and circuits installed on nonenclosed detached structures including but not limited to parking shade structures, carports, solar trellises, and similar structures shall not be required to comply with 690.12.”

This is a game-changer. For ground-mount and carport systems, where the array is not on a building that firefighters would cut into, the expensive requirement for module-level shutdown is often waived by the Authority Having Jurisdiction (AHJ). Instead, the focus shifts to providing a reliable means of disconnecting the main DC trunk cables running from the solar combiner boxes to the central inverter. This is where our passive component strategy shines.

Phase 2: The Core Components for Your Budget-Friendly RSD

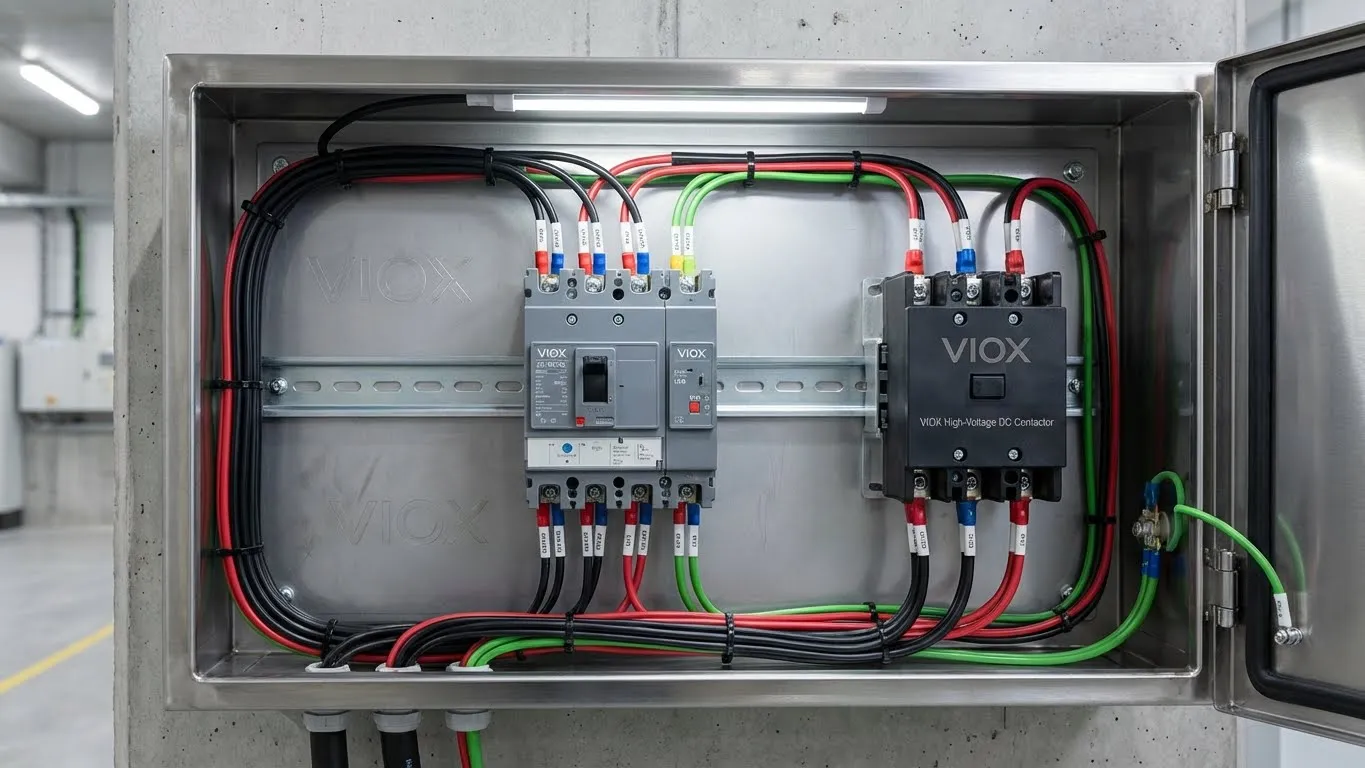

Building this system is about selecting the right tools for the job. VIOX provides a comprehensive suite of industrial-grade components designed for exactly this application.

1. The Executor: Choosing Your Disconnecting Device

This is the component that physically opens the DC circuit. You have two excellent, reliable options.

Option A: High-Voltage DC Contactor (Highly Recommended)

A DC contactor is essentially a heavy-duty relay designed to switch high-power DC loads. It’s the cleanest and most inherently safe method.

- Principle of Operation: A low-voltage control signal energizes an internal coil, which creates a magnetic field to close the main power contacts. When the control signal is lost, internal springs instantly force the contacts apart, breaking the circuit.

- Key Advantage (Fail-Safe): This “normally open” design is naturally fail-safe. If the control power is cut—either intentionally by an E-Stop or unintentionally by a power outage or damaged wire—the contactor defaults to the safe, open state. It requires energy to be on, not to turn off.

- Durability: Unlike circuit breakers, contactors are designed for a high number of switching cycles, making them ideal for systems that may be tested or activated regularly.

While functionally similar, it’s crucial to understand the difference between a control relay and a power contactor. For this application, you need a device rated for the full DC voltage and current of your solar array’s output. Learn more about the differences in our guide: Contactors vs. Relays: Understanding the Key Differences.

Option B: DC Molded Case Circuit Breaker (MCCB) with Accessories

A robust DC circuit breaker can also serve as the executor when equipped with the right accessories. This method integrates overcurrent protection and remote tripping into one device. The key is choosing the right trip accessory.

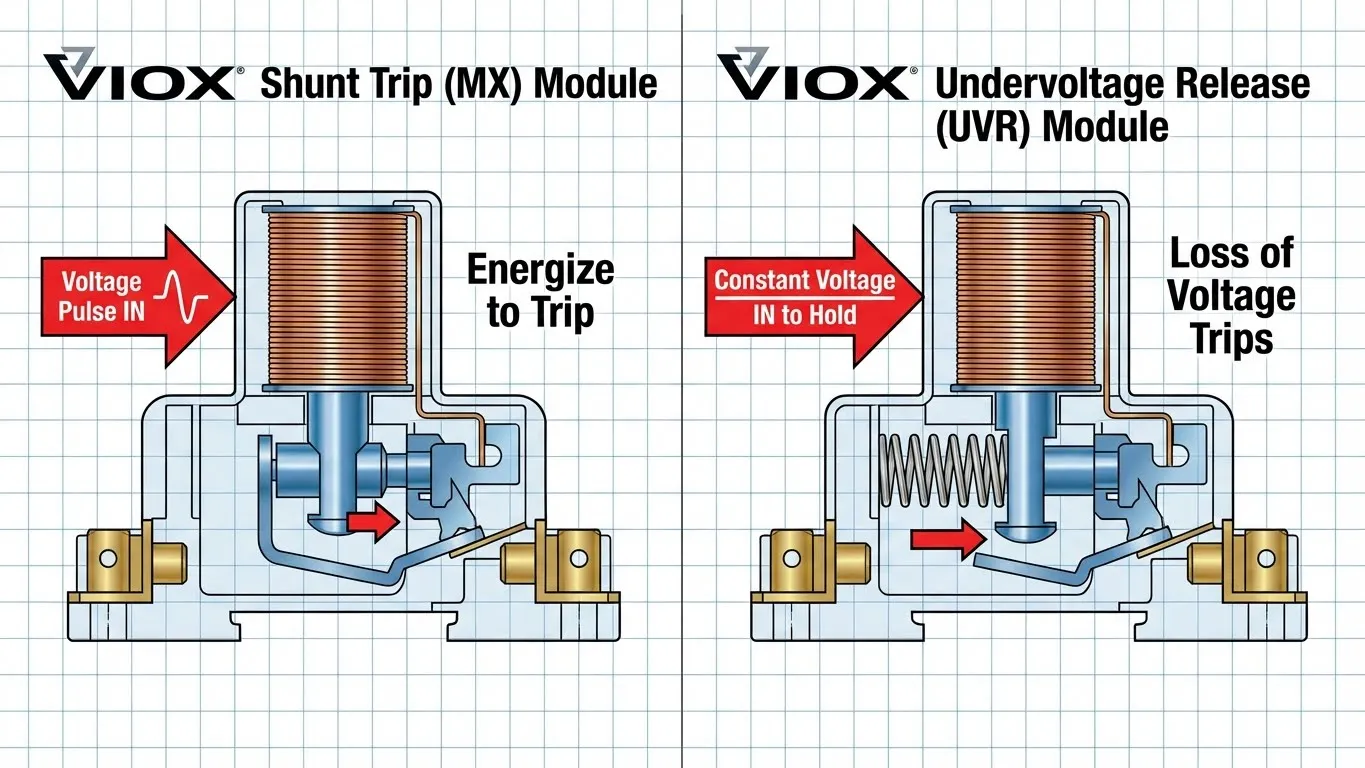

Tech Deep Dive: Shunt Trip (MX) vs. Undervoltage Release (UVR/MN)

This is one of the most critical decisions in your design. While they look similar, their operating principles are opposites.

- Shunt Trip (MX): A shunt trip coil requires a voltage pulse to be applied to trip the breaker. It is an “energize-to-trip” device. This is NOT inherently fail-safe for a rapid shutdown system. If the control power fails, you lose the ability to trip the breaker remotely. A shunt trip is excellent for remote commands but requires a reliable power source (like a UPS) to be considered for safety systems. For a deeper dive, see our guide on When Standard Circuit Breakers Fail: The Engineer’s Complete Guide to Shunt Trip Protection.

- Undervoltage Release (UVR or MN): A UVR coil must be continuously energized to keep the circuit breaker closed. If the control voltage drops below a certain threshold (typically 35-70% of its rating) or is lost completely, the UVR automatically trips the breaker. This “de-energize-to-trip” mechanism is inherently fail-safe, making it a perfect alternative to a contactor.

| Feature | DC Contactor | MCCB with Undervoltage Release (UVR) | MCCB with Shunt Trip (MX) |

|---|---|---|---|

| Operating Principle | Energize to Close | Energize to Hold Closed | Energize to Trip |

| Fail-Safe Nature | Excellent (Naturally Fail-Safe) | Excellent (Naturally Fail-Safe) | Poor (Requires UPS for fail-safe) |

| Reset Method | Automatic (Re-apply control power) | Manual Reset of Breaker | Manual Reset of Breaker |

| Primary Function | High-cycle remote switching | Overcurrent protection + Remote Trip | Overcurrent protection + Remote Trip |

| Complexity | Simple control circuit | Integrated protection and control | Integrated protection and control |

| Best For RSD | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐ (Unless backed by UPS) |

2. The Initiator: Emergency Stop Button

The initiator is the manual trigger for the RSD system. For this, you need a high-reliability industrial Emergency Stop button. The critical specification here is that it must use a Normally Closed (NC) contact block.

When the button is in its normal, ready state, the contact is closed, allowing control current to flow. When you press the button, it breaks the circuit. This ensures that even if the wire to the button is accidentally cut, the system will fail to the safe (shutdown) state. Learn more about contact logic here: Is an Emergency Stop Button Normally Open or Closed?.

3. The Power Source: 24V DC Supply

The brain of this simple system needs a reliable power source. A 24V DC DIN rail power supply is the industry standard for control panels. It provides the low, safe voltage needed to power the contactor or UVR coil through the E-Stop button. Ensure your power supply is properly sized and wired according to best practices, as detailed in our 24V DC Control Panel Wiring Guide.

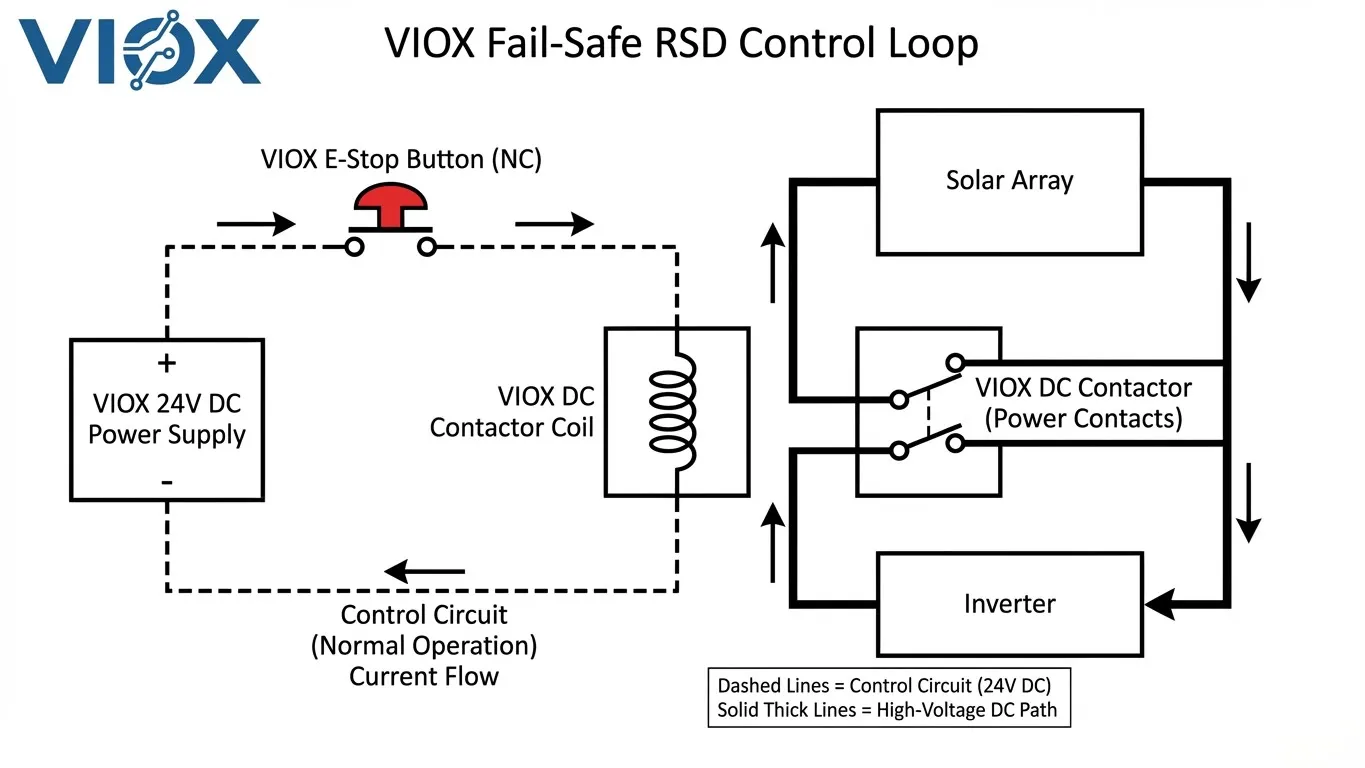

Phase 3: The Wiring Logic – A Beautifully Simple Fail-Safe Loop

The beauty of the passive component strategy is its simplicity. The control wiring creates a “permission-to-run” loop that is inherently fail-safe.

The Logic:

- The 24V DC power supply’s positive (+) terminal is wired to one side of the Emergency Stop button’s NC contact.

- The other side of the E-Stop’s NC contact is wired to the positive (A1) terminal of the DC contactor coil or the UVR coil.

- The negative (A2) terminal of the coil is wired back to the negative (-) terminal of the 24V DC power supply, completing the circuit.

How it Works:

- Normal Operation: The E-Stop is not pressed, so the NC contact is closed. The circuit is complete, the coil is energized, and the main DC contactor/breaker is closed. Your solar array is generating power.

- Emergency Shutdown: A firefighter arrives and presses the E-Stop button. This opens the NC contact, breaking the control circuit. The coil de-energizes, and the contactor springs open (or the UVR trips the breaker) almost instantly. The DC conductors are de-energized.

- Accidental Power Loss: If the control panel loses AC power, the 24V DC supply shuts off. The coil de-energizes. The system fails safe. If a wire in the control loop is severed, the coil de-energizes. The system fails safe.

If you implement this and hear a buzzing sound, it might indicate an issue with the control voltage. Our Common Contactor Troubleshooting Guide can help you diagnose it.

Phase 4: The Cost Analysis – Proof in the Bill of Materials

Let’s quantify the savings. While prices vary, the difference in strategy is stark.

| Cost Comparison: Per-String RSD vs. Centralized Passive RSD | Proprietary RSD Solution (e.g., MLPE-based) | VIOX Passive Component Strategy |

|---|---|---|

| Core Components | Proprietary RSD Box or Module-Level Device | 1x VIOX DC Contactor or MCCB w/ UVR, 1x E-Stop Button, 1x 24V PSU |

| Typical Cost Per String | $150 – $400 | N/A (Centralized solution) |

| Estimated Cost for a 10-String System | $1,500 – $4,000 | ~$400 – $700 (for the entire disconnect system) |

| Complexity | High (Many devices, complex comms) | Low (Simple electromechanical loop) |

| Reliability Points of Failure | Dozens or hundreds of electronic devices | 3-4 robust industrial components |

| Overall Savings | Baseline | Potentially >70% on RSD compliance hardware |

For a commercial ground-mount project with dozens of strings, this translates into tens of thousands of dollars in savings, giving you a massive competitive advantage.

Conclusion: Smart Compliance is Better Than Expensive Compliance

Achieving NEC 690.12 compliance doesn’t have to mean succumbing to expensive, complex electronic ecosystems, especially for ground-mount and carport projects. By leveraging the first principles of electrical safety and using robust, industrial-grade components, you can build a rapid shutdown system that is not only more affordable but arguably more reliable.

The VIOX Passive Component Strategy—using a simple fail-safe loop with a DC contactor or a UVR-equipped breaker—empowers you to design systems that are safe, compliant, and economically intelligent. You’re not just buying a product; you’re implementing a smarter engineering solution.

Ready to design your budget-friendly and robust RSD system? Explore VIOX’s extensive range of DC Contactors, DC Circuit Breakers, and control accessories now.

Safety Disclaimer: The strategy outlined in this article provides a viable and code-compliant path for rapid shutdown in many jurisdictions. However, the final interpretation and approval of any electrical system rest with the local Authority Having Jurisdiction (AHJ). Always consult with your local inspector and gain approval for your design before installation. All work should be performed by qualified electrical professionals.

Short FAQ Section

1. Do all solar installations require NEC 690.12 rapid shutdown?

No. The requirement is primarily for PV systems installed on or in buildings. As of the 2023 NEC, non-enclosed, detached structures like ground-mounts, carports, and solar trellises are often exempt, though the final say belongs to the local AHJ.

2. Can I use a standard AC contactor or breaker for a DC solar application?

Absolutely not. AC and DC arcs behave very differently. DC arcs are much more difficult to extinguish. Using an AC-rated device in a DC circuit is a serious fire and safety hazard. You must use components specifically rated for the DC voltage and current of your system.

3. What’s the main difference between a shunt trip and an undervoltage release?

A shunt trip (MX) requires you to apply power to trip the breaker. An undervoltage release (UVR) loses power to trip the breaker. For a safety system like RSD, the UVR is inherently fail-safe because any interruption in control power (cut wire, power outage) de-energizes the main circuit. You can get more details in our Shunt Trip vs. Undervoltage Release guide.

4. How do I size the DC contactor or breaker for my system?

The device must be rated to handle the system’s maximum DC voltage (Vmp) and current (Imp). You should also factor in a safety margin, typically 125% of the maximum continuous current, and consider derating for ambient temperature as per NEC guidelines.

5. So, to be clear, ground-mounted systems don’t need rapid shutdown?

While the 2023 NEC provides a clear exception, the AHJ has the final authority. Some jurisdictions may still require a string-level disconnect for ground-mounts, especially if the DC conductors enter a building for any reason. The strategy in this article is the perfect, low-cost solution for meeting that string-level requirement.

6. What maintenance is required for a contactor-based RSD system?

It’s minimal but important. We recommend an annual inspection as part of your regular system check. This involves visually inspecting for any signs of overheating or corrosion and functionally testing the E-Stop button to ensure the contactor opens crisply and reliably. Refer to our Industrial Contactor Maintenance Checklist for more details.