Modular Contactor Manufacturer

As a leading modular contactor manufacturer and supplier in China, VIOX ELECTRIC delivers high-quality solutions engineered for reliability and performance. Our BCH8 and BMC7 series modular contactors showcase our commitment to engineering excellence, combining innovative design and robust construction. Choose VIOX Electric to meet the demanding needs of modern electrical systems with our superior modular contactor offerings.

Certified By

AC/DC Modular Contactor - BMC7 Series

AC/DC Modular Contactor - BCH8 Series

BCH8 Manual Modular Contactor

A Brief Self-Nomination: Why Choose VIOX Electric?

With over a decade of experience, VIOX Electric has established itself as a trusted partner in the electrical components industry. The company’s modular contactors adhere to global standards IEC/EN61095 and IEC 60947-4-1, ensuring compatibility and reliability across diverse applications1. VIOX offers customizable solutions, including DC coil configurations and specialized pole arrangements, to meet specific customer needs. Their products feature UL94 V-0 flame-retardant materials and IP40 protection, demonstrating a commitment to safety and sustainability

Custom Solutions: We focus on providing solutions that solve your unique electrical challenges. Whether you need specific configurations, sizes, or capabilities for your modular contactors, we can create a custom solution just for you.

Expert Guidance: Our customer support team comprises industry experts. They will work closely with you to understand your requirements and provide informed, practical solutions to meet your needs.

Advanced Production Techniques: To ensure you receive superior modular contactors, we employ state-of-the-art equipment, materials, and production processes. This guarantees that our solutions are both efficient and durable.

VIOX Excellent material selection, standard Design

Super Energy-Saving

In the working state, the contactor needs to be powered for a long time to keep the coil energized. During this process, a large amount of electrical energy is consumed. The B series contactor, with its optimized electromagnetic system, greatly reduces the holding power of the contactor.

Reduced size by 20%

The width of the B series contactor is much smaller than that of traditional contactors, saving installation space for users, and it can be conveniently installed in standard distribution boxes.

Premium Material Selection

The foundation of product quality lies in the choice of raw materials. The B series contactors are made from carefully selected raw material suppliers, both domestic and international, to achieve reliable quality through premium materials.

MODULAR CONTACTOR DIMENSIONS AND SIZE CHART

1-POLE CONFIGURATIONS (1P, 1 MODULE)

| MODEL | IE RATING AC-1 | IE RATING AC-3 | IE RATING AC-7A | IE RATING AC-7B | AVAILABLE COIL VOLTAGES |

|---|---|---|---|---|---|

| BMC7-16/10 | 16A | 6A | 16A | 7A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-20/10 | 20A | 7A | 20A | 9A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-25/10 | 25A | 9A | 25A | 9A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-32/10 | 32A | 12A | 32A | 12A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-16/01 | 16A | 6A | 16A | 7A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-20/01 | 20A | 7A | 20A | 9A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-25/01 | 25A | 9A | 25A | 9A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-32/01 | 32A | 12A | 32A | 12A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

1-POLE CONFIGURATIONS (1P, 2 MODULES)

| MODEL | IE RATING AC-1 | IE RATING AC-3 | IE RATING AC-7A | IE RATING AC-7B | AVAILABLE COIL VOLTAGES |

|---|---|---|---|---|---|

| BMC7-40/10 | 40A | 18A | 40A | 18A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-63/10 | 63A | 25A | 63A | 25A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-40/01 | 40A | 18A | 40A | 18A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-63/01 | 63A | 25A | 63A | 25A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

2-POLE CONFIGURATIONS (2P, 1 MODULE)

| MODEL | IE RATING AC-1 | IE RATING AC-3 | IE RATING AC-7A | IE RATING AC-7B | AVAILABLE COIL VOLTAGES |

|---|---|---|---|---|---|

| BMC7-16/20 | 16A | 6A | 16A | 7A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-20/20 | 20A | 7A | 20A | 9A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-25/20 | 25A | 9A | 25A | 9A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-32/20 | 32A | 12A | 32A | 12A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-16/11 | 16A | 6A | 16A | 7A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-20/11 | 20A | 7A | 20A | 9A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-25/11 | 25A | 9A | 25A | 9A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-32/11 | 32A | 12A | 32A | 12A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-16/02 | 16A | 6A | 16A | 7A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-20/02 | 20A | 7A | 20A | 9A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-25/02 | 25A | 9A | 25A | 9A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-32/02 | 32A | 12A | 32A | 12A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

2-POLE CONFIGURATIONS (2P, 2 MODULES)

| MODEL | IE RATING AC-1 | IE RATING AC-3 | IE RATING AC-7A | IE RATING AC-7B | AVAILABLE COIL VOLTAGES |

|---|---|---|---|---|---|

| BMC7-40/20 | 40A | 18A | 40A | 18A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-63/20 | 63A | 25A | 63A | 25A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-40/11 | 40A | 18A | 40A | 18A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-63/11 | 63A | 25A | 63A | 25A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-40/02 | 40A | 18A | 40A | 18A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-63/02 | 63A | 25A | 63A | 25A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

3-POLE CONFIGURATIONS (3P, 2 MODULES)

| MODEL | IE RATING AC-1 | IE RATING AC-3 | IE RATING AC-7A | IE RATING AC-7B | AVAILABLE COIL VOLTAGES |

|---|---|---|---|---|---|

| BMC7-16/30 | 16A | 6A | 16A | 7A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-20/30 | 20A | 7A | 20A | 9A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-25/30 | 25A | 9A | 25A | 9A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-32/30 | 32A | 12A | 32A | 12A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-16/03 | 16A | 6A | 16A | 7A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-20/03 | 20A | 7A | 20A | 9A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-25/03 | 25A | 9A | 25A | 9A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-32/03 | 32A | 12A | 32A | 12A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

3-POLE CONFIGURATIONS (3P, 3 MODULES)

| MODEL | IE RATING AC-1 | IE RATING AC-3 | IE RATING AC-7A | IE RATING AC-7B | AVAILABLE COIL VOLTAGES |

|---|---|---|---|---|---|

| BMC7-40/30 | 40A | 18A | 40A | 18A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-63/30 | 63A | 25A | 63A | 25A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-40/03 | 40A | 18A | 40A | 18A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-63/03 | 63A | 25A | 63A | 25A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

4-POLE CONFIGURATIONS (4P, 2 MODULES)

| MODEL | IE RATING AC-1 | IE RATING AC-3 | IE RATING AC-7A | IE RATING AC-7B | AVAILABLE COIL VOLTAGES |

|---|---|---|---|---|---|

| BMC7-16/40 | 16A | 6A | 16A | 7A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-20/40 | 20A | 7A | 20A | 9A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-25/40 | 25A | 9A | 25A | 9A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-32/40 | 32A | 12A | 32A | 12A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-16/04 | 16A | 6A | 16A | 7A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-20/04 | 20A | 7A | 20A | 9A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-25/04 | 25A | 9A | 25A | 9A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-32/04 | 32A | 12A | 32A | 12A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-16/22 | 16A | 6A | 16A | 7A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-20/22 | 20A | 7A | 20A | 9A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-25/22 | 25A | 9A | 25A | 9A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-32/22 | 32A | 12A | 32A | 12A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-16/31 | 16A | 6A | 16A | 7A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-20/31 | 20A | 7A | 20A | 9A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-25/31 | 25A | 9A | 25A | 9A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-32/31 | 32A | 12A | 32A | 12A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

4-POLE CONFIGURATIONS (4P, 3 MODULES)

| MODEL | IE RATING AC-1 | IE RATING AC-3 | IE RATING AC-7A | IE RATING AC-7B | AVAILABLE COIL VOLTAGES |

|---|---|---|---|---|---|

| BMC7-40/40 | 40A | 18A | 40A | 18A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-63/40 | 63A | 25A | 63A | 25A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-40/04 | 40A | 18A | 40A | 18A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-63/04 | 63A | 25A | 63A | 25A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-40/22 | 40A | 18A | 40A | 18A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-63/22 | 63A | 25A | 63A | 25A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-40/31 | 40A | 18A | 40A | 18A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

| BMC7-63/31 | 63A | 25A | 63A | 25A | 12V, 24V AC/DC, 48V AC/DC, 110V AC/DC, 230V AC/DC |

BCH8-1P (Single Pole) Contactors

| Rating (In) | AC-7a | AC-7b | Control Voltage | Contact | Width (18mm modules) |

|---|---|---|---|---|---|

| 16A | 16A | 6A | 230V | 1NO | 1 |

| 16A | 16A | 6A | 230V | 1NC | 1 |

| 20A | 20A | 7A | 230V | 1NO | 1 |

| 20A | 20A | 7A | 230V | 1NC | 1 |

| 25A | 25A | 9A | 230V | 1NO | 1 |

| 25A | 25A | 9A | 230V | 1NC | 1 |

BCH8-2P (Two Pole) Contactors

| Rating (In) | AC-7a | AC-7b | Control Voltage | Contact | Width (18mm modules) |

|---|---|---|---|---|---|

| 16A | 16A | 6A | 230V | 2NO | 1 |

| 16A | 16A | 6A | 230V | 2NC | 1 |

| 16A | 16A | 6A | 230V | 1NO+1NC | 1 |

| 20A | 20A | 7A | 230V | 2NO | 1 |

| 20A | 20A | 7A | 230V | 2NC | 1 |

| 20A | 20A | 7A | 230V | 1NO+1NC | 1 |

| 25A | 25A | 9A | 230V | 2NO | 1 |

| 25A | 25A | 9A | 230V | 2NC | 1 |

| 25A | 25A | 9A | 230V | 1NO+1NC | 1 |

| 40A | 40A | 18A | 230V | 2NO | 2 |

| 40A | 40A | 18A | 230V | 2NC | 2 |

| 40A | 40A | 18A | 230V | 1NO+1NC | 2 |

| 63A | 63A | 25A | 230V | 2NO | 2 |

| 63A | 63A | 25A | 230V | 2NC | 2 |

| 63A | 63A | 25A | 230V | 1NO+1NC | 2 |

| 100A | 100A | – | 230V | 2NO | 3 |

| 100A | 100A | – | 230V | 2NC | 3 |

| 100A | 100A | – | 230V | 1NO+1NC | 3 |

BCH8-3P (Three Pole) Contactors

| Rating (In) | AC-7a | AC-7b | Control Voltage | Contact | Width (18mm modules) |

|---|---|---|---|---|---|

| 16A | 16A | 6A | 230V | 3NO | 2 |

| 25A | 25A | 9A | 230V | 3NO | 2 |

| 40A | 40A | 18A | 230V | 3NO | 3 |

| 63A | 63A | 25A | 230V | 3NO | 3 |

| 100A | 100A | – | 230V | 3NO | 6 |

BCH8-4P (Four Pole) Contactors

| Rating (In) | AC-7a | AC-7b | Control Voltage | Contact | Width (18mm modules) |

|---|---|---|---|---|---|

| 16A | 16A | 6A | 230V | 4NO | 2 |

| 16A | 16A | 6A | 230V | 2NO+2NC | 2 |

| 16A | 16A | 6A | 230V | 3NO+1NC | 2 |

| 20A | 20A | 7A | 230V | 4NO | 2 |

| 20A | 20A | 7A | 230V | 4NC | 2 |

| 25A | 25A | 9A | 230V | 4NO | 2 |

| 25A | 25A | 9A | 230V | 2NO+2NC | 2 |

| 25A | 25A | 9A | 230V | 3NO+1NC | 2 |

| 40A | 40A | 18A | 230V | 4NO | 3 |

| 40A | 40A | 18A | 230V | 4NC | 3 |

| 40A | 40A | 18A | 230V | 2NO+2NC | 3 |

| 63A | 63A | 25A | 230V | 4NO | 3 |

| 63A | 63A | 25A | 230V | 4NC | 3 |

| 63A | 63A | 25A | 230V | 2NO+2NC | 3 |

| 100A | 100A | – | 230V | 4NO | 6 |

| 100A | 100A | – | 230V | 2NO+2NC | 6 |

| 100A | 100A | – | 230V | 3NO+1NC | 6 |

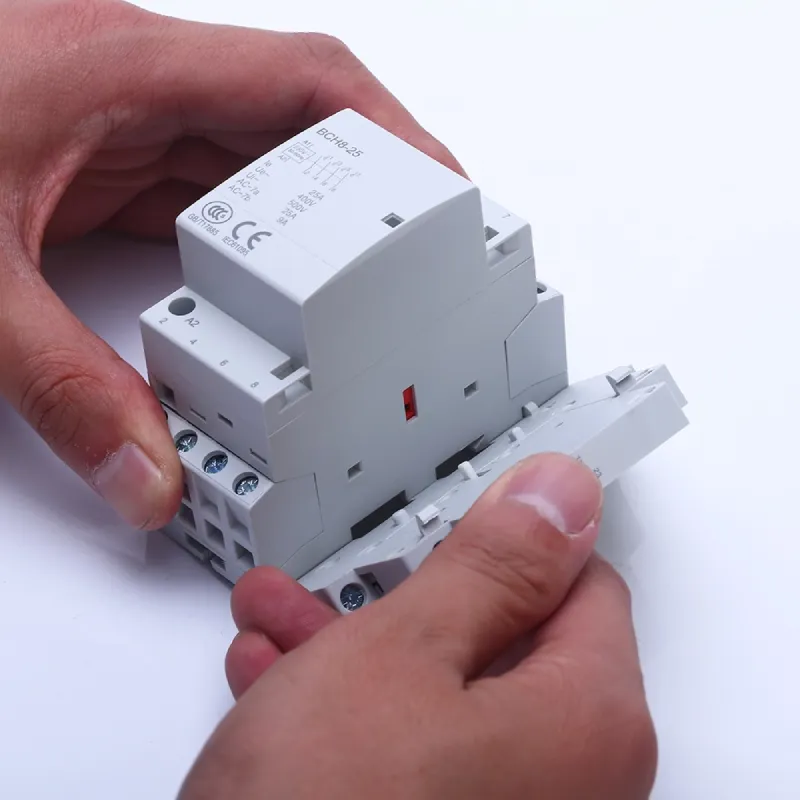

VIOX Modular Contactor Installation Guide

Installation of VIOX modular contactors is straightforward, requiring only a DIN rail (35mm), screwdriver, and appropriate copper cables. The process involves three key steps:

01

02

03

For optimal performance, ensure proper torque application and use the recommended cable sizes. This simple installation process, combined with VIOX's precision engineering, guarantees reliable operation in various electrical control applications.

Get Your Free Sample!

We provide samples for free, you just need to tell us what you need

More Than Just a modular contactor Manufacturer

At VIOX, we go beyond manufacturing modular contactors by offering a suite of value-added services tailored to meet your project needs. Our commitment to excellence ensures that every customer receives personalized attention, expert guidance, and seamless support throughout their journey with us.

Service Consultation

Whether your modular contactor requirements are straightforward or complex, our team provides expert advice and technical consultation. For more intricate projects, we offer in-depth engineering support to ensure optimal product selection and application.

Product Recommendations

Unsure which modular contactor suits your system? Our specialists provide free, customized recommendations based on your specific operational and environmental requirements, ensuring you get the perfect fit.

Logistics Support

If you lack a reliable freight forwarder, we can arrange transportation from our factory to your project site at no extra cost. Our logistics team ensures timely and secure delivery to keep your project on schedule.

Installation Support

Need help with installation? Our technical team is available to answer your questions or provide hands-on support. For larger projects, we can even dispatch an engineer to your site for on-the-ground assistance.

Frequently Asked Questions

We have compiled some common questions from our clients. If your question isn’t included here, our customer service is always available to help. We’d love to talk with you.

How Can I Get a Quote for the Modular Contactor?

To get a quote for our Modular Contactor, contact our customer service team. We are available 24/7. Just provide the specifics of your order like the type, size, and quantity. We’ll guide you through the entire ordering process.

What is Your MOQ for the Order?

We have a low MOQ or minimum order quantity. You can order as little as one unit, and we will deliver according to your specifications.

What Is the Turnaround Time for My Order?

The standard turnaround time for our Modular Contactor is 7 to 10 business days. Delivery time may extend by up to 15 business days due to transit. For custom or bulk orders, we can discuss the turnaround time before finalizing your order.

Can I Get a Sample Before Placing the Order?

Yes, we provide samples for evaluation and approval. Creating samples typically takes 3 to 7 business days.

Can You Make Customized Modular Contactor?

Yes, we offer customized Modular Contactor. Let us know your requirements, and our expert customer service team will work with you through the design process.

What is Your Warranty for the Modular Contactor?

We offer a 3-year warranty on all Modular Contactor we produce. This ensures we deliver high-quality products. Every product is thoroughly tested before delivery.

KNOWLEDGE About Modular Contactor

What is a Modular Contactor?

A modular contactor is an electromechanical switching device designed for DIN rail mounting in distribution boards. It’s used for remote control of lighting, heating, ventilation, and other electrical loads in residential, commercial, and industrial applications.

Key Contactor Components of Modular Contactor

Modular contactors consist of three primary components that work together to control electrical circuits:

Coil: The electromagnetic core of the contactor, responsible for generating the magnetic field that operates the device. When energized, it creates the force to move the contacts.

Contacts: These are the physical connection points that make or break the electrical circuit. Modular contactors typically feature main contacts for power switching and auxiliary contacts for control and signaling purposes.

Enclosure: A compact, modular housing designed to fit on DIN rails, providing protection and easy installation. The enclosure often includes terminal connections for wiring and may feature a manual override switch for testing or emergency operation.

Modern modular contactors may also incorporate additional elements such as arc suppression technology, electronic control modules for enhanced functionality, and built-in surge protection to improve performance and safety in various applications

Modular Contactor Operation Principles

Modular contactors operate through a straightforward electromagnetic mechanism designed for efficient and reliable circuit control. At their core, they consist of three main components: a coil, contacts, and an enclosure. When the coil is energized by a control voltage, it generates a magnetic field that pulls the movable contacts toward fixed contacts, completing the circuit and allowing current to flow to the connected load. Upon de-energizing the coil, the magnetic field collapses, and a spring mechanism pushes the contacts apart, breaking the circuit.

This mechanism enables modular contactors to handle high-power circuits using low-power control signals. They are available in Normally Open (NO) or Normally Closed (NC) configurations, providing flexibility for different applications. Their rapid open-and-close action ensures precise switching, making them ideal for managing lighting systems, HVAC units, and motor loads in residential, commercial, and industrial settings.

Types of Modular Contactors

Four main families of modular contactors cater to specific applications:

Domestic contactors for peak/off-peak hours and heating circuit switching

Motor control contactors with extended contact life for frequent operations

Reversing contactors combining standard units with mechanical interlocks for power supply reversal

Safety contactors utilizing mirrored contacts to indicate position, often in emergency shutdowns

These specialized types enable precise control in various scenarios, from residential energy management to industrial motor control and safety systems.

Compact and Modular Design of Modular Contactor

Modular contactors are characterized by their compact, standardized design optimized for efficient installation and space utilization. Typically measuring 18-54mm in width for 2-4 pole configurations, these devices are significantly smaller than traditional contactors, allowing for higher density in electrical panels. Their construction features a durable plastic or metal enclosure with integrated DIN rail mounting clips for easy installation.

Key physical attributes include:

Standardized dimensions compatible with DIN rail systems

Modular expansion capabilities for auxiliary contacts and timer modules

Touch-safe terminal designs to reduce accidental contact risks

Advanced terminal configurations like cage clamp technology for secure wire retention

Integrated arc suppression chambers to extend operational lifespan

Optional manual override switches for direct control

These physical characteristics enable modular contactors to offer superior flexibility and safety in a wide range of electrical control applications, from residential lighting systems to industrial motor controls.

Modular vs Traditional Contactors

Modular contactors and traditional contactors differ significantly in size, efficiency, and application. Modular contactors are up to 70% smaller than their traditional counterparts, with some models as narrow as 18mm for 2-pole configurations. This compact design allows for efficient space utilization in electrical panels, making them ideal for residential and small commercial settings where panel space is limited.

In terms of energy efficiency, modular contactors employ energy-saving coils that consume only 0.5-2W of holding power, compared to the 5-10W required by traditional contactors. This reduced energy consumption makes modular contactors more cost-effective for residential use. Additionally, modular contactors offer greater versatility, capable of handling both AC and DC circuits, while traditional contactors are typically designed for specific circuit types. The ease of installation and integration with modern electrical systems further distinguishes modular contactors, making them a preferred choice for applications requiring frequent updates or modifications.

Selecting the Right Contactor

When selecting the right modular contactor for your application, consider these key factors:

Load requirements: Determine the electrical load type (resistive, inductive, or capacitive) and rating. For motors or transformers, factor in inrush current, which can be 5-10 times the normal operating current.

Voltage ratings: Ensure the contactor’s voltage rating matches or exceeds your system’s operating voltage for both the main circuit and control circuit.

Contact configuration: Choose the appropriate number of poles (typically 1-4) based on your system requirements (e.g., single-phase, three-phase).

Operating environment: Consider factors like temperature, dust, moisture, and vibration that may affect the contactor’s performance or require special protection ratings.

Switching frequency: For applications with frequent cycling, solid-state contactors may offer longer lifespans.

Additionally, evaluate the contactor’s electrical and mechanical durability, and consider any specific certifications or standards compliance required for your application. By carefully assessing these factors, you can select a modular contactor that ensures optimal performance and efficiency in your electrical system.

Troubleshooting Common Issues with Modular Contactors

When troubleshooting modular contactors, several common issues may arise. One frequent problem is the contactor failing to close or open, often due to low control voltage or coil failure. Ensure the power supply matches the contactor’s coil voltage requirements, as using the wrong voltage can cause malfunction or overheating. Contact wear is another issue to watch for, indicated by pitting, arcing, or carbon deposits on the contact surfaces. These signs suggest it’s time for maintenance or replacement.

Intermittent operation or excessive noise during switching can indicate mechanical problems or contamination. Regular cleaning and inspection can prevent many issues. For persistent problems, consult the manufacturer’s fault analysis guide and consider professional diagnosis. Remember, safety is paramount when working with electrical components – always disconnect power before inspecting or servicing contactors.

Key Industries Using Modular Contactors

Modular contactors find widespread use across various industries due to their versatility and compact design. Key sectors leveraging these devices include:

Building Automation: In smart buildings, modular contactors control lighting, HVAC, and security systems, enhancing energy efficiency and occupant comfort.

Renewable Energy: Solar power installations utilize modular contactors for inverter control and grid connection management.

Manufacturing: Industrial automation systems employ modular contactors to control motors, conveyor belts, and production line equipment.

E-mobility: Electric vehicle charging stations incorporate modular contactors for safe and efficient power distribution.

Data Centers: These facilities use modular contactors to manage power distribution and backup systems, ensuring uninterrupted operation.

The adaptability of modular contactors makes them invaluable in these industries, offering reliable control solutions while optimizing space and energy consumption.

Maintenance and Longevity Considerations

Modular contactors find widespread use across various industries due to their versatility and compact design. Key sectors leveraging these devices include:

Building Automation: In smart buildings, modular contactors control lighting, HVAC, and security systems, enhancing energy efficiency and occupant comfort.

Renewable Energy: Solar power installations utilize modular contactors for inverter control and grid connection management.

Manufacturing: Industrial automation systems employ modular contactors to control motors, conveyor belts, and production line equipment.

E-mobility: Electric vehicle charging stations incorporate modular contactors for safe and efficient power distribution.

Data Centers: These facilities use modular contactors to manage power distribution and backup systems, ensuring uninterrupted operation.

The adaptability of modular contactors makes them invaluable in these industries, offering reliable control solutions while optimizing space and energy consumption

Installation Best Practices for Modular Contactors

When installing modular contactors, proper mounting and wiring are crucial for optimal performance and safety. Mount the contactor on a 35mm DIN rail in a well-ventilated location away from heat sources and moisture. Ensure correct wiring by connecting control wires to the A1 and A2 coil terminals, and load wires to the main contact terminals (L1, L2, L3) as specified in the manufacturer’s instructions. Use appropriately sized wires and tighten all connections to the specified torque values.

Verify contactor compatibility with your system’s voltage and current requirements

Provide adequate clearance around the contactor for ventilation

Use wire strippers, crimping tools, and insulated screwdrivers for safe installation

Conduct a continuity test with a multimeter after installation to verify proper operation5

Regular maintenance, including visual inspections for signs of wear or overheating, is essential for prolonging the contactor’s lifespan and ensuring continued safe operation.

Manufacturing Process Overview

The manufacturing process of modular contactors involves several precise stages, combining advanced engineering with stringent quality control:

Design and Prototyping: Engineers use CAD software to create 3D models, allowing for virtual testing before physical prototyping begins.

Component Production: Key parts are manufactured, including silver alloy or copper-tungsten composite contact points, precision-molded polymer housings, and electromagnetic coils.

Assembly: A hybrid approach combines automated precision with skilled manual oversight. Robotics ensure consistent component placement, while technicians handle quality verification.

Testing: Comprehensive testing includes dielectric strength, contact resistance, mechanical endurance, and thermal performance evaluations.

Certification: Products meeting industry standards receive appropriate certifications like CE, NF, Semko, ISI, UKCA, and SAA.

Leading manufacturers implement flexible production methodologies, balancing efficiency with customization capabilities. This includes automated production lines with high-precision robotics and just-in-time manufacturing practices to optimize production flow and reduce inventory costs.

Yueqing Contactor Market Share

Yueqing, a county-level city in China’s Zhejiang province, has emerged as a significant player in the global modular contactor market. Known as “China’s Electrical Town,” Yueqing has become a hub for electrical equipment manufacturing, including modular contactors.

The city’s market share in the modular contactor industry has been steadily growing, driven by factors such as:

A concentration of specialized manufacturers, with over 600 marketing organizations established domestically

Strong government support for the electrical industry, including policy incentives and infrastructure development

A focus on innovation and high-tech development, with companies like CHINT Group leading the way in smart grid technologies

Competitive pricing and production capabilities, allowing Yueqing-based companies to capture significant portions of both domestic and international markets

While exact market share figures for Yueqing are not readily available, industry forecasts suggest that modular contactors will capture 60% of the global market by 2030, driven by smart building demand and energy efficiency regulations. Yueqing’s manufacturers are well-positioned to capitalize on this growth, leveraging their expertise in electrical equipment production and their established presence in key markets across Asia, the Middle East, and beyond.

Request an OEM Modular Contactor Quote

VIOX Electric is ready to assist you with your OEM Modular Contactor needs. We offer high-quality and cost-effective solutions.