As the global transition to electric mobility accelerates, the focus shifts from individual home chargers to large-scale commercial EV charging infrastructure. Deploying chargers for fleets, public parking garages, and shopping malls is far more complex than a simple residential installation. These environments demand an electrical system that is not only powerful but exceptionally safe, reliable, and intelligent.

The challenges are significant: continuous high-current loads running for hours, potential for harmonic distortion, exposure to harsh outdoor conditions, and, most critically, an uncompromising requirement for public and operator safety. A piecemeal approach to protection is a recipe for downtime, equipment failure, and unacceptable safety risks.

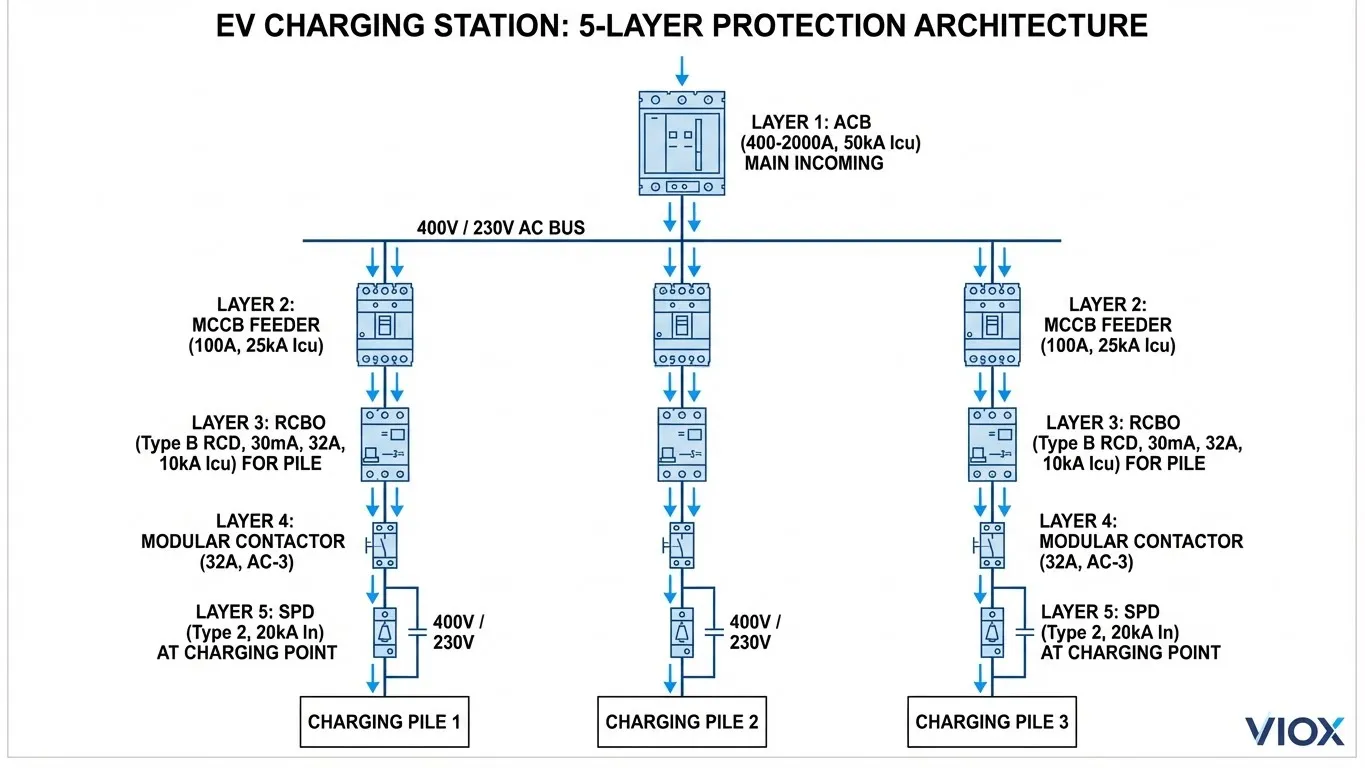

At VIOX, we advocate for a systematic, multi-layered protection architecture. This approach ensures that every point in the electrical chain—from the grid connection down to the individual charging port—is fortified with the correct protective device. This guide details our five-layer strategy, integrating Air Circuit Breakers (ACBs), Molded Case Circuit Breakers (MCCBs), and Residual Current Breakers with Overcurrent protection (RCBOs) to build a truly robust EV charging ecosystem.

Layer 1: The Grid Connection (Main Incoming Feeder)

The foundation of any commercial charging station is the main incoming feeder, typically on the low-voltage side of a dedicated transformer. This is the single point of supply for the entire site, handling substantial currents from 400A to over 2000A. Protecting this critical entry point is non-negotiable.

Core Component: Air Circuit Breaker (ACB)

The role of the main circuit breaker is to provide primary overcurrent protection and high-level fault interruption for the entire installation. For this task, the Air Circuit Breaker (ACB) is the industry standard. Its primary function is to safely disconnect the entire station in the event of a major short circuit or a sustained overload, preventing catastrophic failure and protecting the utility grid.

ACBs are specified for their high rated current (In) and, crucially, their ultimate breaking capacity (Icu), which for large-scale EV infrastructure should be in the 65kA to 100kA range to handle the potential short-circuit current from the supply transformer.

VIOX Insight: Why Draw-out Type ACBs are Essential for Charging Stations

For a commercial operation where uptime is directly tied to revenue, maintenance can be a major challenge. This is where the choice between a fixed and a draw-out ACB becomes critical. While a fixed ACB is bolted directly to the busbars, a draw-out ACB is mounted on a sliding chassis.

This design allows an operator to safely rack out, inspect, test, or replace the entire breaker without de-energizing the main panelboard. In a 24/7 charging plaza, this means a faulty ACB can be swapped in minutes, not hours, dramatically improving system availability. For more details on this, see our complete guide on fixed-type vs. draw-out type ACBs.

| Feature | Fixed Type ACB | Draw-out Type ACB | VIOX Recommendation for EV Stations |

|---|---|---|---|

| Maintenance | Requires full panel shutdown. | Can be replaced while panel is live. | Draw-out Type |

| Downtime | High (hours). | Minimal (minutes). | Draw-out Type |

| Initial Cost | Lower. | Higher. | Investment in uptime justifies cost. |

| Safety | Higher risk during maintenance. | Enhanced safety via isolation. | Draw-out Type |

| Footprint | Smaller. | Larger due to chassis. | A necessary trade-off for reliability. |

Layer 2: Power Distribution (The Sub-Distribution Panel)

Once power enters the facility through the ACB, it must be divided and sent to various charging zones or “islands.” A sub-distribution panel serves this purpose, feeding groups of 4 to 8 chargers. The protection at this layer is crucial for selectivity—ensuring a fault on a single charger group doesn’t cause the main ACB to trip and black out the entire station.

Core Component: Molded Case Circuit Breaker (MCCB)

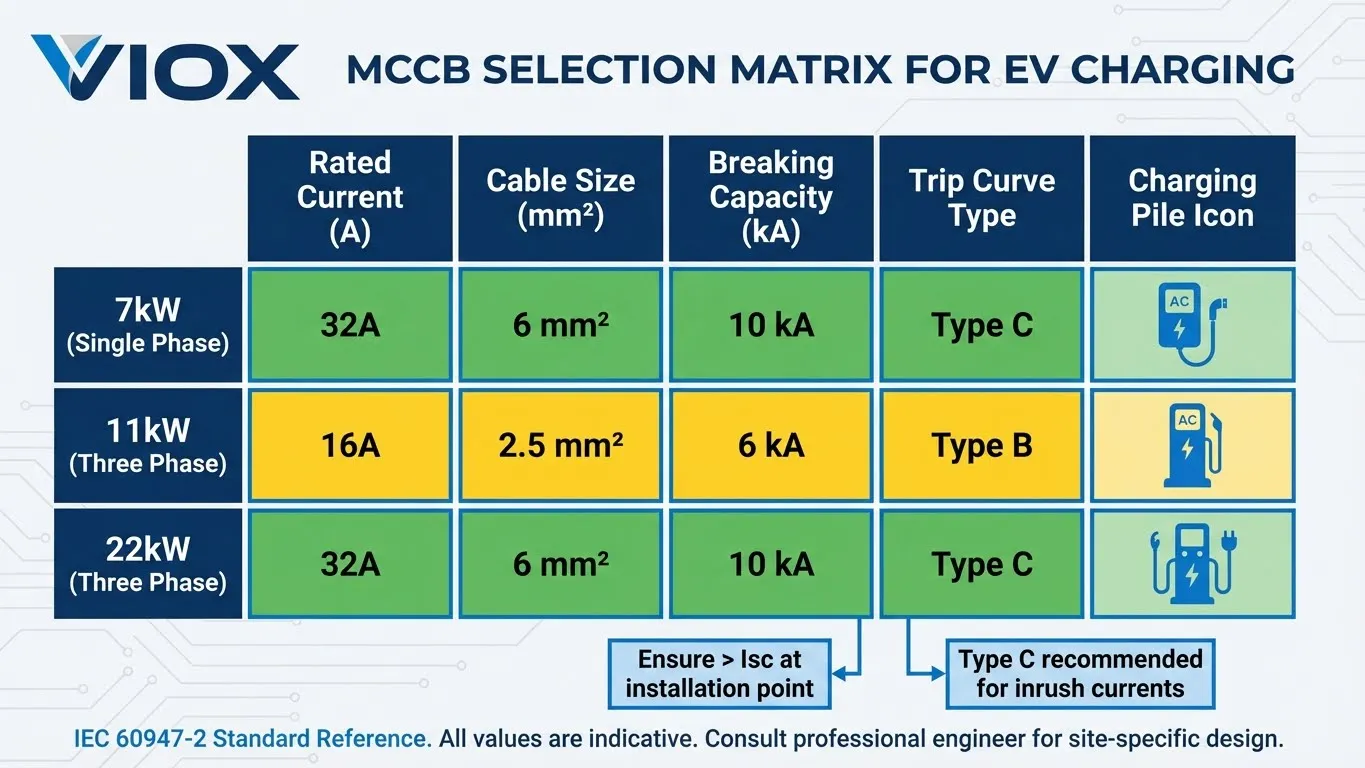

MCCBs are the workhorses of commercial power distribution. In an EV charging context, they serve as the feeder protection for each group of chargers. Compliant with IEC 60947-2, they provide robust protection against overloads and short circuits within a more compact frame than an ACB.

VIOX Insight: The Critical Role of Electronic Trip Units (ETUs)

While basic thermal-magnetic MCCBs are available, commercial EV charging loads demand more intelligence. EV chargers are not simple resistive loads; they are sophisticated power electronic devices that can have complex startup sequences and load profiles.

This is why VIOX strongly recommends MCCBs with Electronic Trip Units (ETUs). An ETU uses a microprocessor to offer highly adjustable and precise protection settings (Long-time, Short-time, Instantaneous). This allows engineers to:

- Fine-tune overload protection to match the continuous load of the chargers without nuisance tripping.

- Set short-time delays to achieve proper coordination (selectivity) with the upstream ACB and downstream final circuit breakers.

- Monitor power quality and log fault events for easier diagnostics.

Properly connecting these breakers to the power distribution system is also paramount for safety and reliability. For more information, explore our guides on MCCB selection and busbar connection protection.

| Charger Power (per pile) | No. of Chargers per Group | Total Group Load (Amps) | Recommended VIOX MCCB Rating (Amps) |

|---|---|---|---|

| 7.4 kW (1-ph) | 6 | ~192A | 250A Frame, set to 200A |

| 11 kW (3-ph) | 4 | ~64A | 100A Frame, set to 80A |

| 22 kW (3-ph) | 4 | ~128A | 160A Frame, set to 140A |

| 22 kW (3-ph) | 8 | ~256A | 300A Frame, set to 275A |

Note: Sizing must account for continuous load factors (e.g., 125% per NEC) and local code requirements.

Layer 3: The Charging Pile Input (Final Circuit Protection)

This is the most critical layer for personnel safety. The final circuit directly feeds a single EV charging port, and it must provide flawless protection against both overcurrent and, most importantly, life-threatening electrical leakage.

Core Component: RCBO (Residual Current Breaker with Overcurrent)

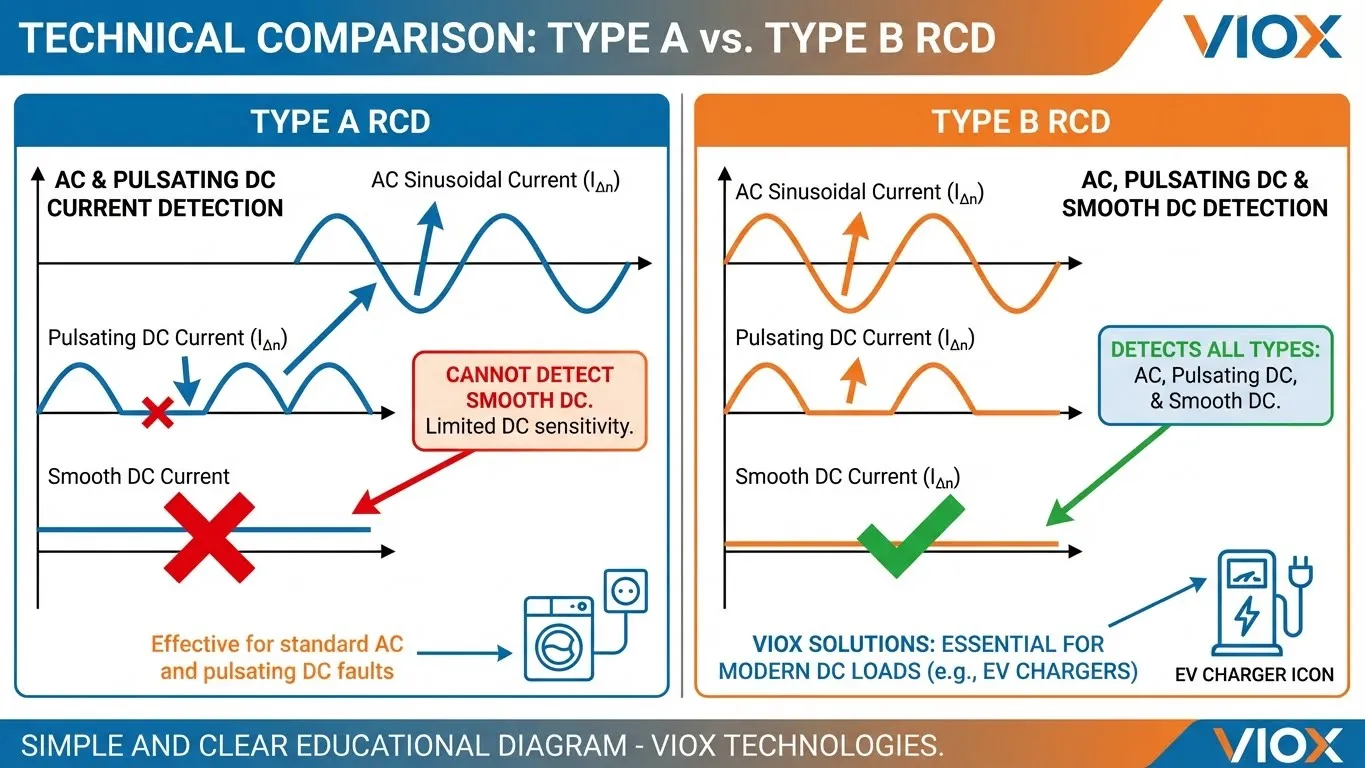

An RCBO is the ideal device for this layer, as it combines the overload and short-circuit protection of a Miniature Circuit Breaker (MCB) with the earth leakage protection of a Residual Current Device (RCD) in a single, compact unit. However, not all RCDs are created equal, and for EV charging, the type of RCD is paramount.

VIOX Insight: The Non-Negotiable Need for Type B RCD Protection

An electric vehicle’s onboard charger converts AC power from the wall into DC power to charge the battery. Under certain fault conditions within the vehicle, this process can cause smooth DC leakage current to flow back into the AC circuit.

This is a risk unique to power electronics like EV chargers and solar inverters. A standard Type A RCD, commonly found in residential settings, is designed to detect AC and pulsating DC leakage only. It is completely blind to smooth DC leakage current. Worse, the presence of more than 6mA of DC leakage can saturate the magnetic core of a Type A RCD, rendering it unable to trip even for the AC faults it’s designed to protect against.

This is why IEC 61851-1 and other global standards mandate protection against DC residual currents. This is achieved using a Type B RCD (or an equivalent system with a Type A RCD plus a separate 6mA DC detection device). A Type B RCD is specifically designed to detect sinusoidal AC, pulsating DC, and smooth DC leakage currents, providing comprehensive protection.

Using anything less than Type B protection in a commercial EV charging station is a serious compliance and safety failure. For a deep dive into this crucial topic, read our essential guide on RCCB types for EV charging. For specific sizing calculations for the final circuit, refer to our 7kW-22kW charger breaker sizing guide.

| RCD Type | Sinusoidal AC Fault | Pulsating DC Fault | Smooth DC Fault | Suitable for EV Charging? |

|---|---|---|---|---|

| Type AC | ✅ | ❌ | ❌ | No. Unsafe. |

| Type A | ✅ | ✅ | ❌ | Only if charger has integrated 6mA DC protection. |

| Type F | ✅ | ✅ | ❌ | No. Offers high-frequency protection but not smooth DC. |

| Type B | ✅ | ✅ | ✅ | Yes. The safest and most compliant choice. |

Layer 4: Control & Switching (Inside the Charger)

Deep inside the charging station is the component that does the daily work: the contactor. This device acts as the heavy-duty switch, energizing and de-energizing the output to the vehicle on command from the station’s controller (which communicates via protocols like OCPP).

Core Component: AC Contactor (Modular or Industrial)

Unlike a circuit breaker, which is a safety device, a contactor is designed for frequent, operational switching. In a busy public charging station, a single contactor might operate dozens or even hundreds of times per day.

VIOX Insight: Prioritizing Electrical Life and Silent Operation

For AC Level 2 charging stations, which are often installed in noise-sensitive areas like residential parking garages or office buildings, modular contactors are the superior choice. They are designed for DIN-rail mounting, are extremely compact, and are engineered for silent, “hum-free” operation. If you’ve ever dealt with a buzzing or chattering contactor, you understand the value of a silent design.

Most importantly, for this application, you must specify a contactor with a high electrical life. A contactor’s mechanical life (how many times it can open and close with no load) is always much higher than its electrical life (how many times it can switch its rated load). For the relentless duty cycle of an EV charger, a contactor with a high AC-1 utilization category rating and a proven electrical endurance of hundreds of thousands of cycles is essential for long-term reliability. Compare the benefits of modular vs. traditional contactors to make the right choice for your design.

Layer 5: Transient Safety (Surge Protection)

The sophisticated electronics inside both the EV charger and the vehicle itself are highly vulnerable to voltage surges. These transients can be caused by lightning strikes near the facility or by switching operations on the utility grid. A single powerful surge can destroy control boards and the car’s On-Board Charger (OBC), leading to expensive repairs and unhappy customers.

Core Component: Surge Protection Device (SPD)

An SPD’s job is to detect a transient overvoltage and divert the harmful surge current safely to the ground before it reaches sensitive equipment. A layered approach to surge protection is most effective.

VIOX Insight: A Coordinated SPD Strategy (Type 1+2 and Type 2)

- Main Panel (Layer 1): A Type 1+2 SPD should be installed at the main switchboard, right after the main ACB. A Type 1 device is robust enough to handle partial lightning currents, providing the first and most powerful line of defense.

- Sub-Distribution (Layer 2): A Type 2 SPD should be installed in the sub-distribution panels that feed the charger groups. This secondary SPD clamps any residual voltage let through by the primary SPD and protects against internally generated surges.

This coordinated approach ensures that voltage is clamped to progressively lower, safer levels as it moves toward the final load. This is a crucial element for both AC charging and even more so for high-power DC fast charger protection. For a complete overview of sourcing these critical components, consult our ultimate SPD buying guide.

The Big Picture: Commercial vs. Residential Protection

The electrical demands and safety requirements of a commercial charging hub are an order of magnitude greater than a single home charger. This table summarizes the key differences in the protection philosophy. For a more detailed comparison, see our commercial vs. residential protection guide.

| Protection Aspect | Residential EV Charger | Commercial EV Charging Station |

|---|---|---|

| Main Breaker | 100-200A Main Panel Breaker | 400A – 2000A+ Air Circuit Breaker (ACB) |

| Feeder Protection | N/A (direct circuit) | Molded Case Circuit Breakers (MCCB) for groups |

| Final Circuit | 32A-40A MCB or RCBO | 32A-63A RCBO per port |

| Leakage Protection | Type A (if charger has 6mA DC sense) or Type B | Type B RCBO (Mandatory) |

| Surge Protection | Type 2 (Whole Home) recommended | Type 1+2 (Main Incomer) + Type 2 (Sub-panels) |

| Uptime Focus | Convenience | Mission-Critical (Revenue Generating) |

| Maintenance | Reactive (trip/failure) | Proactive (Draw-out breakers, monitoring) |

Frequently Asked Questions (FAQ)

1. Why can’t I just use standard MCBs for commercial EV charging?

Standard Miniature Circuit Breakers (MCBs) lack the adjustable trip settings of MCCBs, making coordination and selectivity in a large system difficult. More importantly, an MCB provides no protection against earth leakage, which is a critical safety requirement for EV charging. An RCBO is the minimum for the final circuit.

2. What’s the real difference between a Type A and Type B RCD for an EV charger?

A Type A RCD cannot detect smooth DC leakage current, a specific risk posed by EV chargers. This can lead to the device failing to trip when a dangerous fault occurs. A Type B RCD is designed to detect AC, pulsating DC, and smooth DC leakage, providing complete protection as mandated by safety standards like IEC 61851-1.

3. How do I size an ACB for a 20-charger commercial station?

Sizing the main ACB involves calculating the total maximum demand, applying a diversity factor (which may be 1.0 for commercial stations, assuming all chargers could be used simultaneously), and considering future expansion. For a station with twenty 22kW (32A) chargers, the total load is 640A. A diversity factor of 0.8 might yield 512A. You would select the next standard ACB size up, such as an 800A frame ACB, and set the electronic trip unit accordingly. Always consult a qualified engineer.

4. Do I need SPDs on every single charging pile?

The most effective strategy is layered. A main Type 1+2 SPD at the incoming service entrance provides the primary protection. Secondary Type 2 SPDs should be placed in the distribution panels feeding groups of chargers. Placing an SPD in every single pile is generally not necessary if the distance from the sub-panel is short (e.g., <10 meters) and may not be cost-effective.

5. What is a typical breaking capacity (kA rating) for MCCBs in EV charging?

This depends on the Prospective Short Circuit Current (PSCC) at the point of installation. For sub-distribution panels fed from a large transformer, the PSCC can be significant. Typical breaking capacities for MCCBs in this application range from 25kA to 50kA to ensure they can safely interrupt a fault without failing.

Conclusion: Building the Electrical Backbone for E-Mobility

A successful commercial EV charging station is more than an assembly of chargers. It is a cohesive electrical ecosystem where safety and reliability are designed in from the very first connection to the grid. A robust electrical “nervous system”—built on a layered architecture of correctly specified ACBs, MCCBs with intelligent trip units, mandatory Type B RCBOs, and coordinated surge protection—is the true foundation of a high-uptime, profitable, and, above all, safe charging network.

By implementing this five-layer protection strategy, developers and operators can move beyond simply providing power and deliver the confidence and dependability the future of e-mobility demands.

Are you designing your next commercial charging station? Contact the VIOX engineering team for a comprehensive Bill of Materials (BOM) review and selection advice tailored to your project’s specific needs.