検査官があなたの ジャンクションボックス. を開けます。電線の数を数え、ボックスの刻印を確認し、再度数えます。そして赤いタグ。「NEC 314.16違反—ボックスの占有率超過。サインオフする前に完全にやり直す必要があります。」“

その不合格検査は、わずか2立方インチ小さすぎる$4の接続箱が原因で、1週間の遅延と数千ドルの手直し費用が発生しました。電気工事士が “「ボリュームトラップ」”

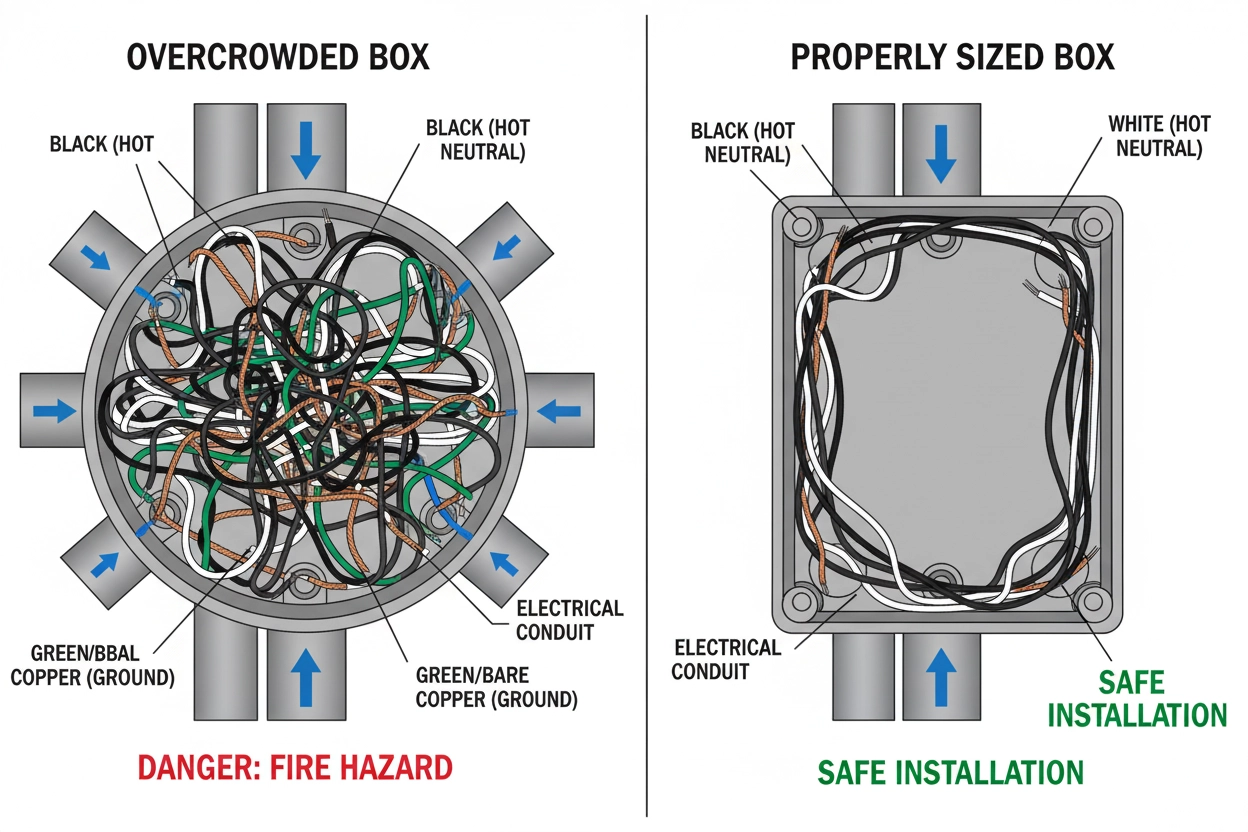

と呼ぶものへようこそ。接続箱は配線接続を収容し、損傷から保護し、火災を防ぐために火花を封じ込めます。しかし、正しいサイズにすることは単なる最良の慣行ではなく、米国電気工事規程(NEC)で義務付けられている重要な安全要件です。小さすぎるボックスは電線を過密状態にし、絶縁体の損傷、過熱を引き起こし、重大な火災の危険性を生み出します。 .

NECは、電線のサイズに応じて、接続箱のサイズを決定するための2つの異なる方法を提供しています。

- NEC 314.16(ボックス占有率): より細い導体(6 AWG以下)の場合、サイズは必要な総体積に基づいています。 “「充填率」”と考えてください—ボックス内のすべてのコンポーネントが投票権を持ち、それらすべてを数える必要があります。.

- NEC 314.28(プルボックス): より太い導体(4 AWG以上)の場合、サイズは太いケーブルを安全に引っ張って曲げるために必要な物理的寸法に基づいています。これは “「8倍ルール」” が適用される場所です。.

このガイドでは、設置が安全で法規に準拠していることを確認するために、両方の計算方法について説明します。.

パート1:細い導体(6 AWG以下)のサイジング– NEC 314.16ボックス占有率計算

14 AWG、12 AWG、または10 AWGのような一般的な家庭用配線サイズを使用する場合は、「ボックス占有率」計算を使用する必要があります。この方法は、ボックスに必要な最小立方インチ(cu in)の体積を決定します。この計算を間違えると、ボリュームトラップに直接遭遇することになります—通常は、日常的だと思っていた検査中に。.

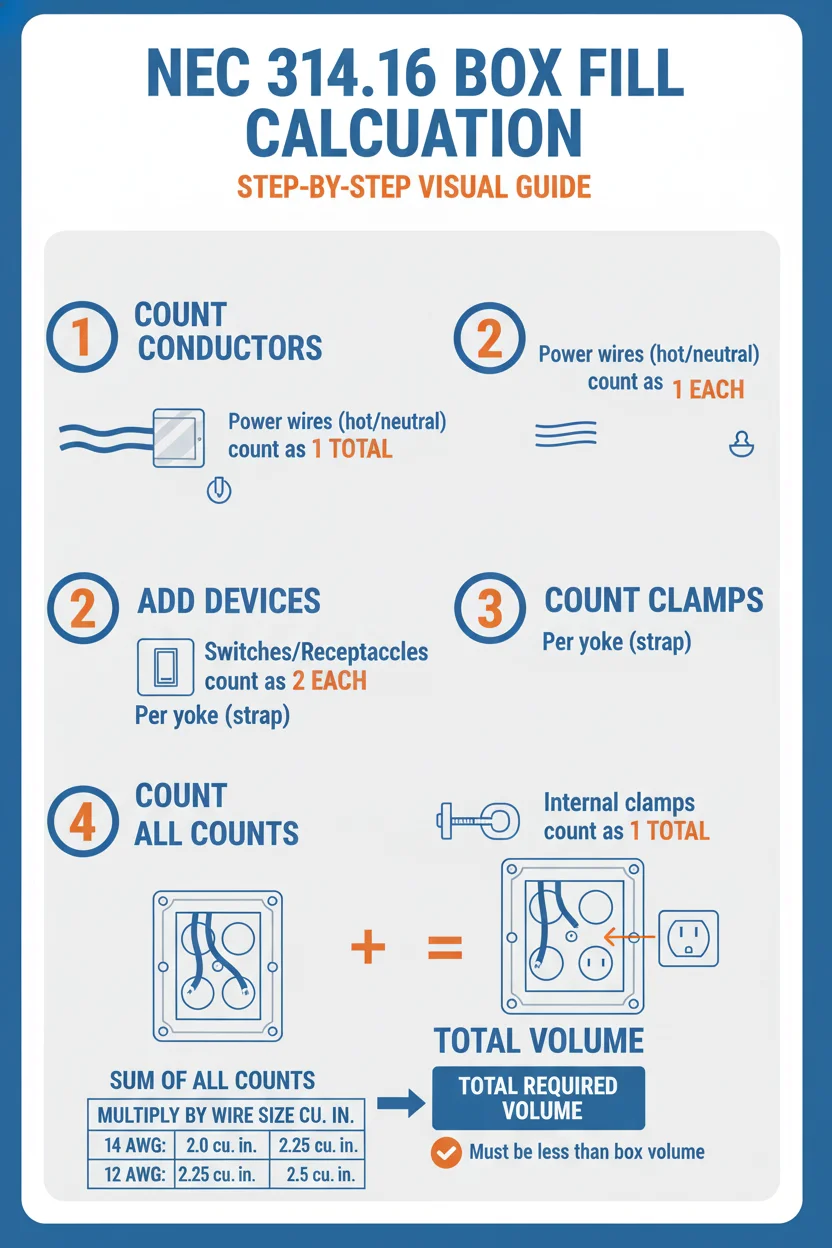

ボックス占有率の計算方法

必要な総体積を決定するには、次の手順に従ってください。ボックス内の各コンポーネントには、接続されている最大の電線サイズに基づいて「導体相当量」の値が割り当てられます。これは電線の民主主義と考えることができます—すべての要素が投票権を持ちますが、一部は他の要素よりも重要です。.

- 導体: ボックスの外から来て、ボックス内で終端またはスプライスされる各電線を と呼ばれます。 導体として数えます。.

- デバイス: 各デバイス(例:スイッチまたはコンセント)を 二つの 導体として数えます。デバイスはこの選挙で二重投票者です。.

- クランプ: すべての内部ケーブルクランプをまとめて と呼ばれます。 導体として数えます—それらはブロックとして投票します。.

- 接地線: すべての裸銅線または緑色の接地線をまとめて と呼ばれます。 導体として数えます。接地線はパックで移動します。それらはすべて1つとして数えられます。.

- 照明器具スタッド/ヒッキー: 各照明器具スタッドまたはヒッキーを と呼ばれます。 導体として数えます。 .

導体相当量の合計がわかったら、その数に、以下の表にあるその電線サイズの体積許容値を掛けます。.

表1:電線体積許容値(NEC 314.16(B)に基づく)

| ワイヤーサイズ | 導体あたりの体積(cu in) |

|---|---|

| 14AWG | 2.00 cu in |

| 12AWG | 2.25 cu in |

| 10AWG | 2.50 cu in |

| 8AWG | 3.00 cu in |

| 6AWG | 5.00 cu in |

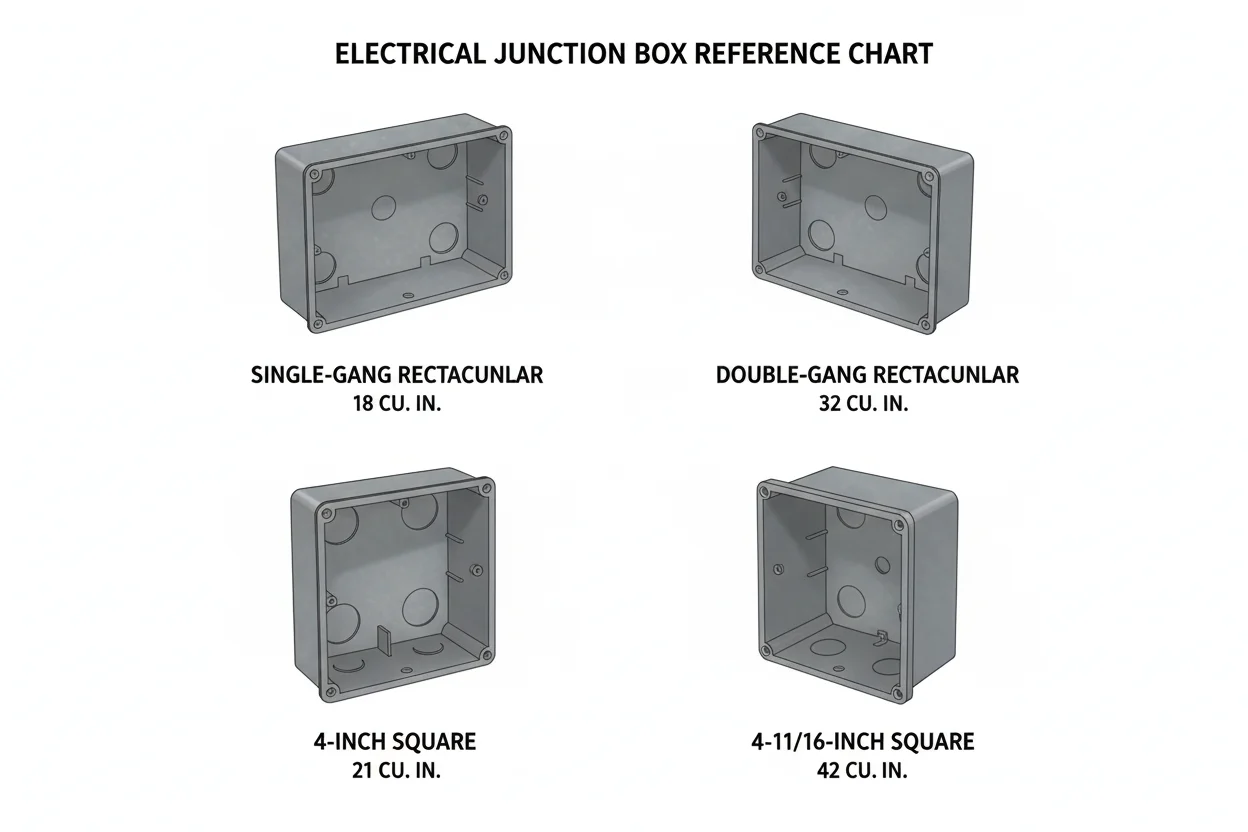

表2:標準ボックス体積(NEC 314.16(A)に基づく)

| ボックスタイプ | 最小体積 |

|---|---|

| シングルギャング | 18 cu in |

| 2ギャング | 36 cu in |

| 4インチスクエア | 30.3 cu in |

| 4-11/16インチスクエア | 42 cu in |

ボックス占有率の例

シナリオ 単一のコンセントをボックスに取り付けています。2本の12/2非金属シースケーブル(それぞれホット、ニュートラル、およびアース付き)がボックスに入り、内部クランプがあります。投票の内訳は次のとおりです。

- 導体: 2ホット+ 2ニュートラル= 4

- 接地線: 2本の接地線は 1 (パックとして移動)

- クランプ: 内部クランプは 1 (ブロックとして投票)

- デバイス: コンセントは 2 (二重投票者)

合計導体相当量: 4 + 1 + 1 + 2 = 8

体積計算: 電線サイズが12 AWGの場合、導体あたり2.25立方インチが必要です。.

8導体 × 2.25立方インチ/導体 = 18.0立方インチ

少なくとも18.0立方インチの容積を持つボックスを選択する必要があります。標準的なシングルギャングボックス(18立方インチ)は、この最小要件を正確に満たしています。つまり、容量が100%ということです。電気工事では、「容量が正確に100%」というのは、「検査承認を重視するなら、ワンサイズ上げる」という意味になります。“

パート2:太い導体(4 AWG以上)のサイジング – NEC 314.28 プルボックスの計算

太い導体(4 AWG以上)の場合、焦点は容積から物理的な寸法に移ります。電線が太くなるためです。規則はよりシンプルになります。ボックスは、導体の絶縁を損傷することなく、導体を引き込み、曲げることができるように十分に大きくする必要があります。規則は引き込みの種類によって異なります。.

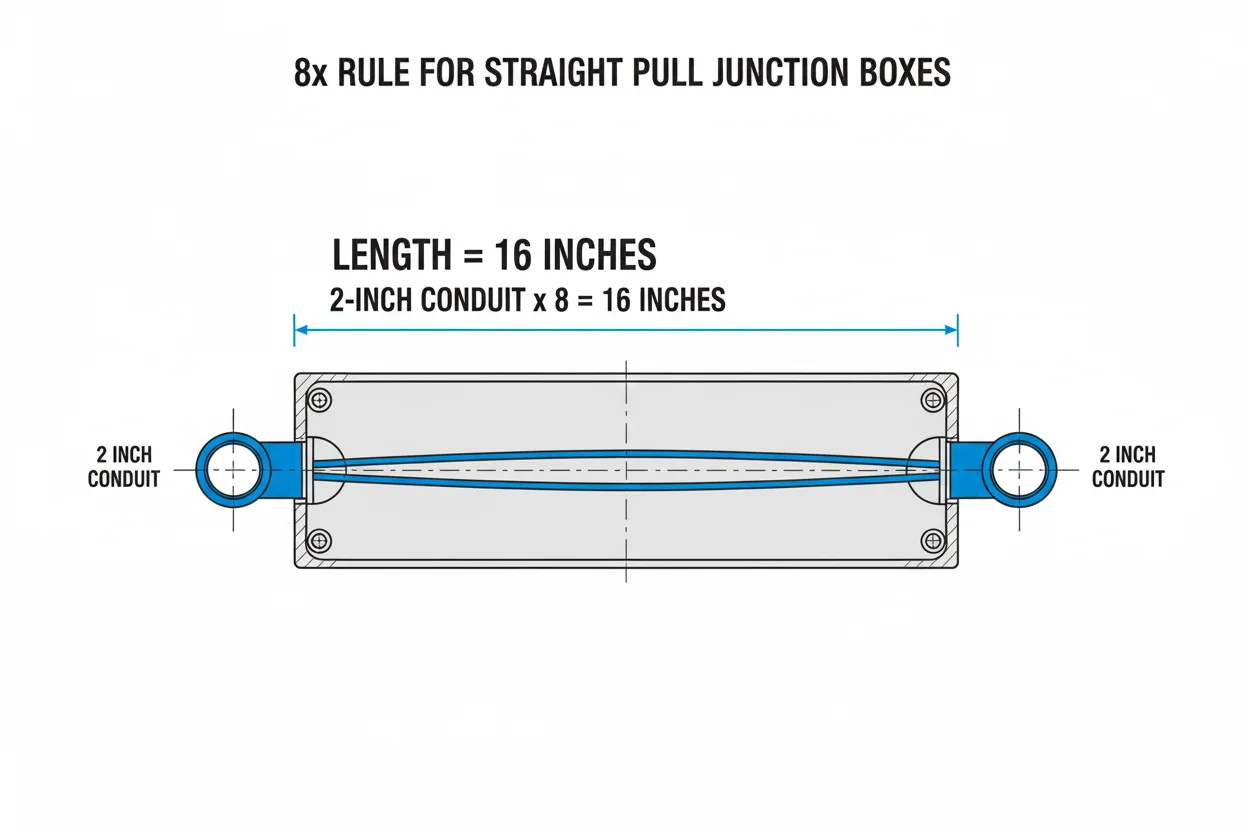

ストレートプル

ストレートプルでは、導体はボックスの一方の側から入り、反対側の壁から出ます。ここで 8倍ルール は、そのエレガントなシンプルさで定評があります。.

- 規則: ボックスの長さは、少なくとも 8倍(8x) 最大の電線管(コンジット)の呼びサイズである必要があります。 .

2インチの電線管が反対側の壁に出入りする場合、ボックスの長さは少なくとも16インチ(2″ × 8 = 16″)必要です。それだけです。.

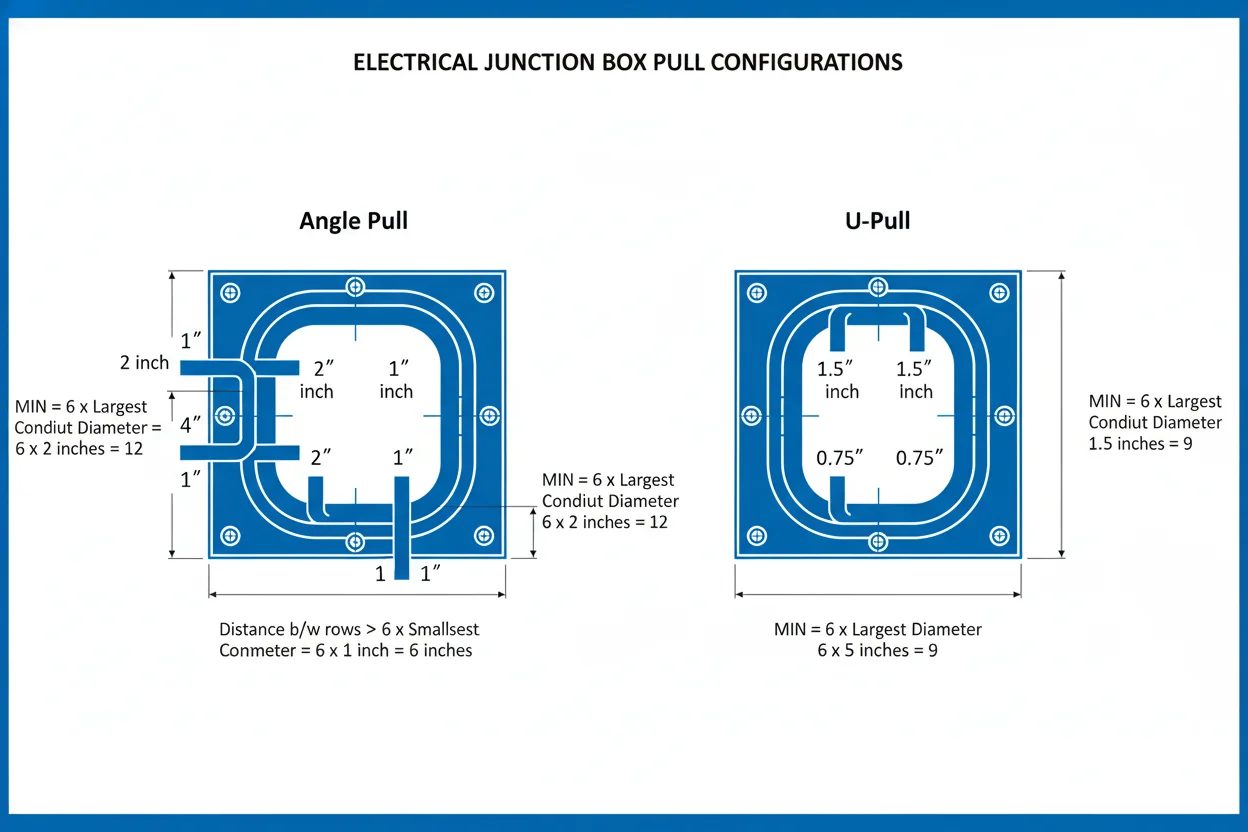

アングルプル、Uプル、またはスプライス

これは、導体が一方の壁から入り、隣接する壁(アングルプル)、同じ壁(Uプル)から出る場合、またはボックス内でスプライスされる場合に適用されます。.

- 規則: 電線管の入口から反対側の壁までの距離は、少なくとも 6倍(6x) 最大の電線管の呼びサイズ、, プラス直径の合計 同じ壁の同じ列にある他のすべての電線管の。これを “「6倍の安全ネット」と呼びます。”

電線管間の距離

- 規則: 同じ導体ランを囲む電線管間の距離は、少なくとも 6倍(6x) 最大の電線管の呼びサイズである必要があります。.

プルボックスの例(複合プル)

ボックスにストレートプルとアングルプルの両方が含まれている場合は、両方を計算し、各方向(水平および垂直)で最大の寸法を使用する必要があります。.

シナリオ プルボックスには、次の電線管があります。

- 左側の壁: 3インチと2インチの電線管が1つずつ。.

- 右側の壁: 2インチの電線管が1つ。.

- 上の壁: 3インチの電線管が1つ。.

- 2インチの電線管は、ストレートプル(左から右)用です。.

- 3インチの電線管は、アングルプル(左から上)用です。.

1. 水平方向の寸法(長さ)の計算:

- ストレートプル(左から右): このプルで最大の電線管は2インチです。.

- 8 × 2″ = 16″

- アングルプル(左側の壁から): 最大の電線管は3インチです。その壁にあるもう一方の電線管は2インチです。.

- (6 × 3″) + 2″ = 18″ + 2″ = 20″

- 結果: 最大の寸法を選択します。 20インチ.

2. 垂直方向の寸法(高さ)の計算:

- アングルプル(上の壁から): 最大の(そして唯一の)電線管は3インチです。.

- 6 × 3″ = 18″

- 結果: 垂直方向の寸法は 18インチ.

最終的なボックスサイズ: ボックスは少なくとも 長さ20インチ、高さ18インチである必要があります。.

安全への配慮

電気工事を開始する前に、常に安全を優先してください。.

- 電源を切る: 回路の電源を メインブレーカー パネルで切ります。.

- 電源がオフになっていることを確認する: ボルトメーターまたは非接触回路テスターを使用して、取り扱う電線に電圧がないことを確認します。 .

- 絶縁工具を使用する: 電気工事用に設計された工具を使用してください。.

- PPEを着用する: 安全メガネと絶縁手袋の使用を推奨します。.

- 明るく整理された場所で作業する: 作業場所が明るく、障害物がないことを確認してください。.

共通の間違いを避ける

- ボックス内の過密状態: 計算されたボックスの容量を超えないでください。これは、過熱や電気火災の最も一般的な原因であり、検査不合格の最大の理由の一つです。容量不足は新たな問題を引き起こします。.

- 不適切なボックスタイプの選択: 屋外や湿気の多い場所には耐候性ボックスを、金属被覆(MC)ケーブルまたは電線管には金属ボックスを使用してください。.

- 不適切な配置: ボックスはアクセス可能な場所に設置してください。完成した壁の中に埋めて、修理できないようにしないでください。検査官は、見つけられないボックスをいつまでも覚えています。.

- 不十分な接地: 感電の危険を防ぐため、すべての接地線を互いに、そして金属ボックスに確実に接続してください。.

- 地域の規定の無視: NECは国の基準ですが、お住まいの地域には追加の要件がある場合があります。必ず地域の規制を確認してください。フェニックスで合格しても、シカゴでは不合格になる可能性があります。.

結論

ジャンクションボックスの適切なサイズ選定は、安全で信頼性の高い電気工事のための基本的なスキルです。理解し、正しく適用することで 充填率 (小径電線の場合、NEC 314.16)および 8倍ルール (大径電線の場合、NEC 314.28)により、設置が規格に準拠し、機能的で、そして最も重要なこととして安全であることを保証できます。.

そして、検査官があなたのジャンクションボックスを開けたとき?赤いタグではなく、緑のタグがもらえるでしょう。.

免責事項: このガイドは情報提供のみを目的としています。電気工事は危険を伴う可能性があります。常に最新版の米国電気工事規程(National Electrical Code)を参照し、地域の修正条項を確認し、自分で行うことに不安がある場合は、資格のある電気技師に依頼することを検討してください。.