Když projektový inženýr u evropského výrobce průmyslových zařízení specifikoval časová relé pro nový ovládací panel, nákupní tým výrobce se ohradil: ”Splňují tato zařízení normu IEC 61812-1?” Bez správné certifikační dokumentace se projekt zastavil. Dodavatel relé tvrdil, že má “shodu CE”, ale označení CE bez testování podle IEC 61812-1 neznamenalo nic pro funkční požadavky časového relé.

Tento scénář se odehrává denně. IEC 61812-1 není jen zaškrtávací políčko shody – je to mezinárodní rámec, který definuje, co znamená “spolehlivé časové relé” v měřitelných, testovatelných termínech. Inženýři specifikující komponenty, manažeři nákupu hodnotící dodavatele a týmy kvality udržující certifikaci čelí stejné otázce: jak víte, že časové relé bude fungovat tak, jak je deklarováno? Norma poskytuje odpověď.

Tři věci činí IEC 61812-1 důležitou: stanovuje globální výkonnostní základní linie pro přesnost a opakovatelnost časování, ověřuje bezpečnost při elektrickém namáhání a environmentálních podmínkách a poskytuje společný jazyk pro porovnávání produktů napříč výrobci. Na evropském trhu je fakticky povinná pro označení CE. Dokonce i v Severní Americe, kde dominují UL a NEMA rámce, certifikace podle IEC 61812-1 signalizuje závazek výrobce k mezinárodním standardům kvality.

Co je IEC 61812-1? Přehled a účel

IEC 61812-1 je mezinárodní norma s názvem “Časová relé a vazební relé pro průmyslové a bytové použití – Část 1: Požadavky a zkoušky”. Publikovaná Mezinárodní elektrotechnickou komisí definuje požadavky na výkon, bezpečnost a elektromagnetickou kompatibilitu pro časová relé používaná v řídicích obvodech, automatizačních systémech a průmyslových zařízeních.

Aktuální verze normy je IEC 61812-1:2023 edice 3.0, publikovaná v červnu 2023. Tato edice nahradila druhou edici z roku 2011 a zavedla významné aktualizace, včetně explicitního pokrytí vazebních relé, požadavků na kybernetickou bezpečnost pro průmyslové automatizační a řídicí systémy (IACS), mandátů pro environmentální informace a rozšířených protokolů rutinního testování.

Představte si IEC 61812-1 jako technickou příručku, která odpovídá na otázku: “Jak vypadá správně navržené časové relé?” Pokrývá elektromechanické i polovodičové reléové technologie, zabývá se zařízeními s montáží na DIN lištu a konfiguracemi zásuvných patic a zahrnuje rozsahy napětí od nízkonapěťových DC obvodů až po průmyslové řídicí aplikace 240 VAC.

Norma slouží současně dvěma skupinám. Pro výrobce poskytuje strukturovaný rámec pro testování a dokumentaci, který po certifikaci otevírá přístup na globální trh – zejména pro EMEA, kde je regionálně přijata jako EN IEC 61812-1:2024 a je fakticky vyžadována pro označení CE. Pro inženýry a odborníky na nákup vytváří společný specifikační jazyk; když datový list tvrdí, že je “v souladu s IEC 61812-1”, přesně víte, pro co bylo toto relé testováno a jaká dokumentace o výkonu by měla existovat.

Rozsah a použitelné produkty: Co norma pokrývá

IEC 61812-1 se vztahuje na časová relé a vazební relé používaná ve dvou širokých aplikačních prostředích: průmyslové aplikace (řízení, automatizace, signál a průmyslové zařízení) a automatické elektrické ovládání pro rezidenční a podobná zařízení. Tento duální rozsah činí normu relevantní, ať už specifikujete relé pro panel tovární automatizace nebo rezidenční systém řízení HVAC.

Co je zahrnuto: Norma pokrývá všechny běžné funkce časového relé – zpoždění při zapnutí (delay-on-energization), zpoždění při vypnutí (delay-on-de-energization), intervalové časování, pulzní výstup, blikání/cyklický provoz, sekvence spouštění motoru hvězda-trojúhelník a multifunkční programovatelné režimy časování. Vztahuje se na elektromechanické reléové výstupy i na polovodičové spínací výstupy. Zařízení používající obvody časování závislé na napětí, časování závislé na proudu, elektronické obvody časování, pneumatické mechanismy časování nebo hybridní technologie spadají do rozsahu.

Co je vyloučeno: Měřicí relé jsou výslovně mimo rozsah normy. IEC 61812-1 se zaměřuje na funkční časová relé, kde je časování primární řídicí funkcí, nikoli na relé, která měří elektrické parametry (napětí, proud, frekvenci) a poskytují časově zpožděné odezvy na základě prahových hodnot měření.

Norma definuje klasifikace zařízení napříč několika dimenzemi: typ spínacího prvku (elektromechanický vs. polovodičový), typ konstrukce a pouzdra, způsob montáže (DIN lišta, zásuvná patice, montáž na PCB, montáž na panel), způsob připojení a vhodnost pro prostředí. Tento klasifikační systém zajišťuje, že se požadavky přizpůsobí různým reléovým technologiím a instalačním scénářům, spíše než aby nutily přístup „jedna velikost pro všechny“.

Pro specifikace nákupu je důležité porozumět rozsahu při čtení datových listů dodavatelů. Pokud datový list relé tvrdí, že je v souladu s IEC 61812-1, můžete očekávat dokumentaci pokrývající typ funkce časování zařízení, kategorii klasifikace, jmenovité provozní parametry a environmentální limity – vše definované v rámci normy.

Vysvětlení klíčových technických požadavků

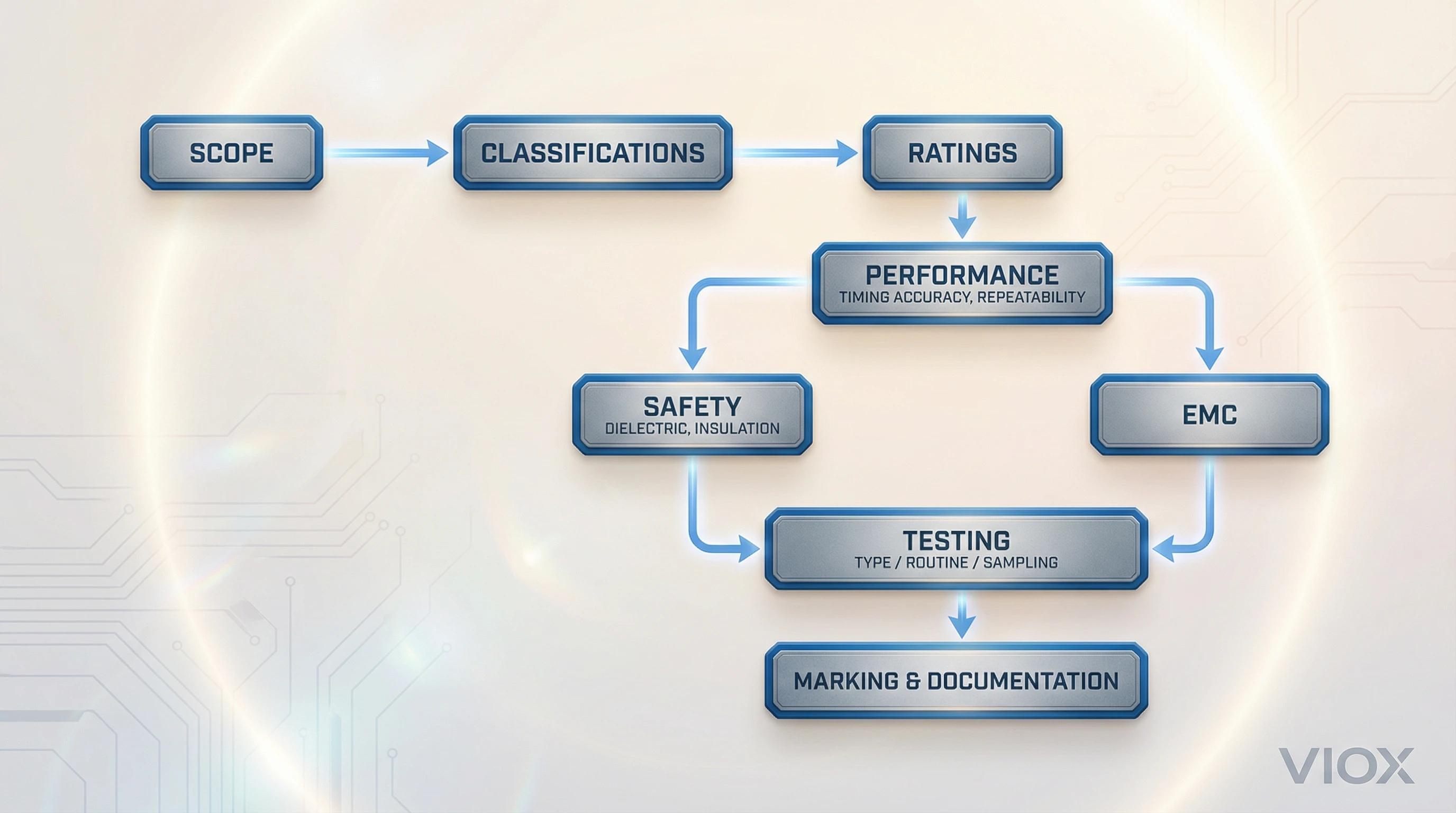

IEC 61812-1 strukturuje své požadavky do odlišných kategorií, z nichž každá se zabývá specifickým aspektem výkonu, bezpečnosti nebo trvanlivosti relé. Tyto požadavky se promítají do testovatelných kritérií, která musí výrobci splnit a inženýři by je měli hledat v datových listech.

Klasifikace a jmenovité hodnoty

Každé relé, které splňuje požadavky, musí deklarovat svou klasifikaci a jmenovité hodnoty, které definují jeho provozní hranice. Jmenovité vstupní napětí a frekvence specifikují rozsah řídicího napětí, při kterém relé pracuje (např. 24 V DC, 120 V AC 50/60 Hz, univerzální vstup 12-240 V AC/DC). Uvolňovací napětí definuje bod, pod kterým se relé odpojí, obvykle 10-20 % jmenovitého napětí. Spotřeba energie udává vstupní výkon odebíraný obvodem časování během provozu.

Jmenovité hodnoty výstupního obvodu se liší podle technologie. Elektromechanické výstupy zahrnují jmenovité hodnoty kontaktů (napětí, proud, typ zátěže) a mechanickou/elektrickou životnost. Polovodičové výstupy specifikují limity spínacího napětí/proudu a svodový proud. Podmíněná jmenovitá hodnota zkratového proudu definuje maximální potenciální zkratový proud, který relé zvládne, když je chráněno specifikovaným nadproudovým zařízením. Environmentální jmenovité hodnoty pokrývají rozsahy provozní/skladovací/přepravní teploty, limity vlhkosti, stupeň znečištění (I-IV podle IEC 60664-1) a jmenovitou nadmořskou výšku.

Specifikace výkonu časování

Zde si IEC 61812-1 zaslouží svou relevanci pro časová relé. Norma definuje, jak musí být přesnost časování měřena a dokumentována:

- Přesnost nastavení: Tolerance mezi nastavenou hodnotou časování a skutečnou naměřenou hodnotou časování za referenčních podmínek (obvykle 23 °C, jmenovité napětí). Příklad: 10sekundový časovač s přesností ±5 % se spustí mezi 9,5-10,5 sekundami.

- OpakovatelnostOpakovatelnost.

- : Jak konzistentně relé dosahuje stejné hodnoty časování napříč více operacemi. Nižší hodnoty opakovatelnosti znamenají konzistentnější výkon.Doba zotavení

- : Minimální interval požadovaný mezi operacemi, než může relé znovu přesně časovatMinimální řídicí impuls

- : Nejkratší doba trvání impulsu potřebná k spolehlivému spuštění časováníVlivné veličiny

: Jak se výkon časování zhoršuje při kolísání napětí (typicky ±15 %) a extrémních teplotách (limity provozního rozsahu).

Příloha A normy poskytuje metody výpočtu pro určení těchto hodnot, které výrobci používají k generování specifikací časování, které vidíte v datových listech.

Bezpečnostní a dielektrické požadavky

- Požadavky na elektrickou bezpečnost zajišťují, že relé nevytvoří nebezpečí úrazu elektrickým proudem nebo katastrofálně selže:Limity ohřevu.

- Dielektrická pevnost: Teploty svorek a přístupných povrchů musí zůstat v definovaných mezích během nepřetržitého provozu a podmínek přetížení. Zkouška tlakem kuličky ověřuje, že se plastové kryty nedeformují pod vlivem tepla.

- Dielektrická pevnost: Relé musí odolat zkouškám napětím o frekvenci sítě (50/60 Hz AC zkušební napětí aplikované mezi izolované obvody) a zkouškám rázovým výdržným napětím (rázové impulsy 1,2/50 μs simulující blesk nebo spínací přechodové jevy) bez průrazu. Zkušební úrovně jsou tabelovány na základě jmenovitého napětí a kategorie izolace.

- Ochrana před úrazem elektrickým proudemVzdušné vzdálenosti a povrchové cesty.

: Fyzické rozestupy mezi vodivými částmi musí splňovat minimální vzdálenosti podle IEC 60664-1, určené pracovním napětím, stupněm znečištění a typem izolace.

Ochrana před úrazem elektrickým proudem

- : Izolační systémy musí zabránit přístupu k nebezpečným živým částem a udržovat integritu za normálních a poruchových podmínek.Požadavky na EMC a prostředí.

- Moderní ovládací panely pracují v elektricky rušivém prostředí. IEC 61812-1 zajišťuje, že časová relé si udrží výkon i přes elektromagnetické rušení:Požadavky na odolnost

- : Relé musí odolat specifikovaným úrovním vedených poruch (poklesy napětí, rázy, rychlé přechodové jevy), vyzařovaným RF polím, elektrostatickému výboji a magnetickým polím bez falešného spuštění nebo chyb časování. Samostatné tabulky definují zkušební úrovně pro průmyslové prostředí vs. rezidenční/lehké průmyslové prostředí.Vyzařované poruchy

Přidána verze 3.0 požadavky na kybernetickou bezpečnost pro relé připojená k průmyslovým automatizačním sítím (prostředí IACS) a environmentální informace mandáty vyžadující od výrobců dokumentaci materiálů, recyklačních dat a environmentálně uvědomělých návrhových procesů.

Mechanická pevnost a výdrž

Svorky, zásuvky a montážní systémy jsou během instalace a provozu vystaveny mechanickému namáhání:

- Zkoušky utahovacího momentu a vytažení svorek: Šroubové svorky musí odolat jmenovitému utahovacímu momentu bez poškození; zkoušky vytažení vodiče ověřují jeho udržení

- Elektrická výdrž: Kontakty (pro elektromechanické výstupy) musí dokončit stanovený počet operací při různých typech zatížení – odporové, indukční (s účiníkem) a nízkoenergetické DC zátěže. Polovodičové výstupy procházejí ekvivalentním testováním spínacích cyklů.

- Zkoušky podmíněného zkratového proudu: Se specifikovaným nadproudovým ochranným zařízením musí relé odolat potenciálním zkratovým podmínkám bez vzniku požáru nebo nebezpečí úrazu elektrickým proudem

Tyto požadavky fungují společně jako systém. Časové relé může mít v laboratorních podmínkách dokonalou přesnost časování, ale selže v terénu, pokud je jeho EMC imunita nedostatečná nebo se jeho svorky uvolní vlivem vibrací. Komplexní rozsah normy IEC 61812-1 řeší plnou provozní realitu.

Zkušební a certifikační postupy

IEC 61812-1 definuje tři kategorie zkoušek, z nichž každá slouží jinému účelu zajištění kvality:

Typové zkoušky ověřují shodu návrhu. Výrobci je provádějí na reprezentativních vzorcích, aby prokázali, že návrh výrobku splňuje všechny standardní požadavky. Typové zkoušky zahrnují celou sadu: zahřívání, základní provoz za referenčních a vlivových podmínek, přesnost a opakovatelnost časování, dielektrická pevnost, izolační odpor, vzdušné vzdálenosti/povrchové cesty, elektrická výdrž, podmíněný zkratový proud, mechanická pevnost, EMC imunita a emise, vibrace, rázy, zkouška žhavou smyčkou a úplnost dokumentace. Typové zkoušky jsou intenzivní – jeden model relé může vyžadovat týdny laboratorního času a desítky vzorků.

Jakmile typové zkoušky projdou, výrobce je neopakuje pro každou výrobní jednotku. Zde přicházejí na řadu ostatní kategorie.

Kusové zkoušky se vztahují na 100 % výroby. Každé jednotlivé relé opouštějící továrnu prochází těmito zkrácenými kontrolami: základní funkční provoz (časuje správně?), dielektrická pevnost při sníženém napětí (pro odhalení vad izolace bez poškození dobrých jednotek) a pro verzi 3.0 rozšířené kusové kontroly včetně určitého ověření časování. Kusové zkoušky odhalí výrobní vady bez nutnosti provádět celý program typových zkoušek.

Náhodné zkoušky se nacházejí mezi typovými a kusovými zkouškami. Výrobci periodicky odebírají výrobní vzorky a provádějí definovanou podmnožinu zkoušek, aby ověřili konzistenci výroby. Tento průběžný dohled zachycuje postupný posun ve výrobních procesech dříve, než způsobí selhání v terénu.

Norma také specifikuje požadavky na značení a dokumentaci v článku 8 a tabulce 7. Relé, která splňují požadavky, musí být trvale označena, včetně identifikace výrobce, označení modelu/typu, jmenovitého vstupního napětí a frekvence, jmenovitých hodnot výstupu, příslušných odkazů na normy (IEC 61812-1) a označení CE, kde je to relevantní. Technická dokumentace musí poskytovat všechny jmenovité hodnoty, specifikace časování (přesnost, opakovatelnost, doba zotavení), environmentální limity, schémata zapojení a pokyny k instalaci.

Pro certifikaci na evropském trhu výrobci obvykle spolupracují s notifikovanými osobami—akreditovanými zkušebními laboratořemi, které jsou oprávněny vydávat EU prohlášení o shodě. Proces zahrnuje předložení technických souborů, poskytnutí vzorků pro typové zkoušky, audity továrny k ověření systémů kvality výroby a průběžný dohled. Po certifikaci může výrobce umístit označení CE a vydat EU prohlášení o shodě pro daný výrobek.

Kupující by si měli uvědomit, že “vyhovuje IEC 61812-1” může znamenat různé věci v závislosti na úrovni ověření. Plná certifikace třetí stranou (s účastí notifikované osoby) má větší váhu než samodeklarovaná shoda bez nezávislých zkušebních protokolů. Při hodnocení dodavatelů se ptejte na zkušební protokoly, nejen na tvrzení.

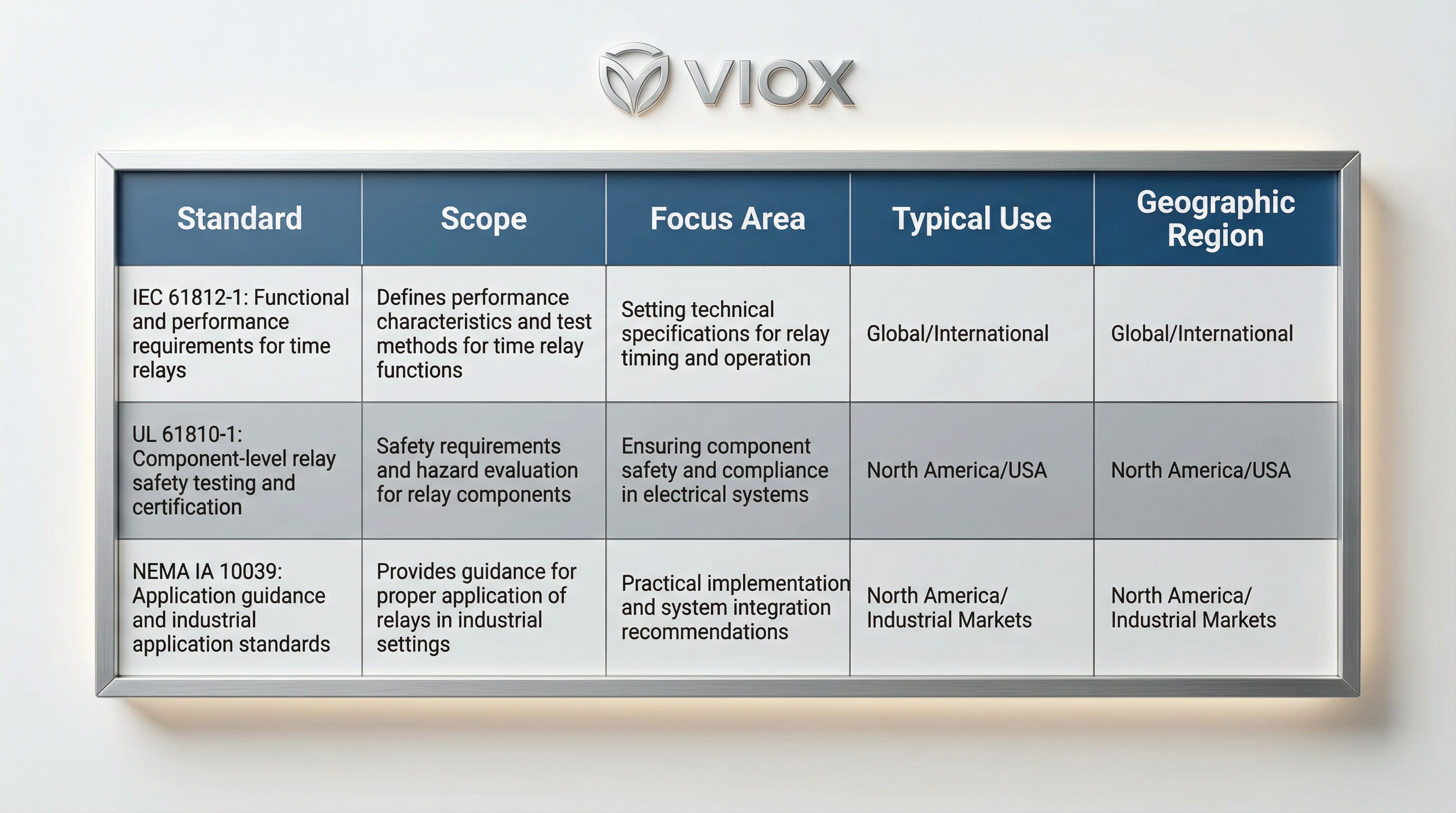

IEC 61812-1 vs severoamerické normy (UL, NEMA)

Inženýři pracující na severoamerických a mezinárodních trzích se často ptají: “Jak souvisí IEC 61812-1 s normami UL 508 nebo NEMA, které znám?” Rámce se doplňují, ale řeší různé úrovně hierarchie produktů.

IEC 61812-1 se zaměřuje konkrétně na funkční požadavky pro časová relé a vazební relé. Definuje výkon časování, klasifikace, environmentální hodnocení, EMC a testování na úrovni aplikace. Představte si ji jako “standard funkční specifikace časového relé”.”

UL 61810-1 (dříve zahrnuta pod UL 508) se zabývá elektromechanickými elementárními relé na úrovni komponent. Ověřuje základní bezpečnost relé – izolační systémy, jmenovité hodnoty kontaktů, nárůst teploty, výdrž – nezávisle na tom, zda má relé funkce časování. Pokud používáte elektromechanická časová relé, jsou relevantní obě normy: UL 61810-1 zajišťuje, že základní kontakty relé a izolace jsou bezpečné, zatímco IEC 61812-1 ověřuje, že obvod časování funguje správně.

UL 508A se zabývá průmyslovými řídicími panely jako kompletními sestavami. Časová relé instalovaná v panelech UL 508A musí splňovat požadavky na úrovni komponent (UL 61810-1 pro elektromechanické typy, UL 508 kapitola 38 pro polovodičová zařízení), ale proces certifikace panelu je oddělen od certifikace relé.

NEMA IA 10039 (dříve NEMA ICS 5) poskytuje aplikační pokyny, postupy instalace a kritéria výběru pro řídicí obvody a pilotní zařízení, včetně časových relé. Není to certifikační standard – je to spíše aplikační příručka. NEMA IA 10039 doplňuje IEC 61812-1 tím, že nabízí praktická doporučení pro výběr, dimenzování a instalaci relé, která jdou nad rámec zkušebních požadavků normy IEC.

Praktické důsledky: Pro projekty v EMEA je certifikace IEC 61812-1 prakticky povinná; označení CE ji vyžaduje. Pro severoamerické projekty je primárním požadavkem uznání UL (obvykle UL 508 nebo UL 61810-1), i když certifikace IEC 61812-1 neškodí a může signalizovat vyšší standardy kvality. Výrobci obsluhující globální trhy často usilují o certifikace IEC i UL na stejné produktové řadě. Pokud specifikujete pro oba trhy, hledejte relé s uznáním IEC 61812-1 i UL – například časová relé VIOX si udržují obě certifikace, aby obsluhovala globální zákazníky bez nutnosti samostatných produktových řad.

Výhody shody s IEC 61812-1

Kromě odškrtávání regulačních políček přináší certifikace IEC 61812-1 hmatatelnou hodnotu pro více zúčastněných stran:

Pro výrobce, je to přístup na trh a konkurenční odlišení. Trhy EMEA účinně vyžadují EN IEC 61812-1:2024 pro označení CE, takže shoda odemyká evropský prodej. Certifikační proces také vynucuje disciplínu návrhu – produkty musí splňovat definované výkonnostní benchmarky, nejen “fungovat dostatečně dobře”. Výrobci s certifikací IEC 61812-1 mohou věrohodně tvrdit, že jejich přesnost časování, opakovatelnost a EMC výkon byly nezávisle ověřeny.

Pro inženýry specifikující komponenty, poskytuje shoda s IEC srovnatelná data o výkonu. Při porovnávání časových relé od různých dodavatelů používají datové listy IEC 61812-1 standardizované specifikace měřené za identických testovacích podmínek. Nastavení přesnosti, opakovatelnosti a výkonu vlivových veličin se stává porovnáním jablek s jablky, nikoli hádáním. Můžete specifikovat “přesnost časování ±5 % podle IEC 61812-1” a přesně vědět, co dostáváte.

Pro týmy nákupu a dodavatelského řetězce, certifikace snižuje zátěž kvalifikace dodavatelů. Dodavatel, který tvrdí, že splňuje IEC 61812-1, by měl mít k dispozici zkušební protokoly, certifikáty typových zkoušek a prohlášení o shodě. Ověření shody se stává kontrolou dokumentace, než aby vyžadovalo váš vlastní testovací program. Snižuje také riziko – komponenty, které selžou v testech IEC, by pravděpodobně způsobily selhání v terénu, záruční reklamace a zpoždění projektu, které by stály mnohem více než jakékoli počáteční úspory z necertifikovaných alternativ.

Pro týmy zajištění kvality a regulace, certifikace IEC 61812-1 zjednodušuje shodu koncového produktu. Pokud stavíte průmyslové řídicí zařízení vyžadující označení CE, použití komponent s certifikací IEC zjednodušuje přípravu vašeho technického souboru. Zkušební data komponent se stávají podpůrným důkazem pro shodu na úrovni vašeho systému.

Pro systémové integrátory a výrobce rozvaděčů, certifikované komponenty znamenají méně překvapení. U časových relé, která splňují požadavky IEC na EMC imunitu, je méně pravděpodobné, že se spustí falešně vlivem šumu VFD nebo blízkých rádiových vysílačů. U relé, která splňují požadavky IEC na výdrž a zkrat, je méně pravděpodobné, že předčasně selžou v náročných aplikacích. Méně zpětných volání z terénu se přímo promítá do nižších nákladů na podporu a lepší pověsti.

Norma také podporuje neustálé zlepšování. Přidání požadavků na kybernetickou bezpečnost a environmentální informace ve verzi 3.0 odráží vyvíjející se potřeby průmyslu. Výrobci, kteří si udržují certifikaci IEC, musí držet krok s těmito aktualizacemi, aby zajistili, že jejich produkty zůstanou relevantní s tím, jak se průmyslové požadavky vyvíjejí.

Jak ověřit tvrzení dodavatele o shodě

Ne všechna tvrzení “vyhovuje IEC 61812-1” jsou si rovna. Zde je návod, jak ověřit tvrzení dodavatele, aniž byste potřebovali vlastní zkušební laboratoř:

Vyžádejte si prohlášení o shodě (DoC). U výrobků s označením CE prodávaných v Evropě musí výrobce poskytnout EU prohlášení o shodě, které uvádí, které směrnice a harmonizované normy výrobek splňuje. IEC 61812-1 (nebo EN IEC 61812-1:2024) by měla být výslovně uvedena. Prohlášení o shodě by mělo obsahovat identifikaci výrobku, údaje o výrobci a jméno/podpis osoby oprávněné jej vydat. Žádné prohlášení o shodě? Varovný signál.

Požádejte o zkušební protokoly nebo certifikáty. Výrobci, kteří skutečně provedli testování podle IEC 61812-1, mají k dispozici zkušební protokoly od akreditovaných laboratoří. Tyto protokoly dokumentují, které testy byly provedeny, testovací podmínky, výsledky a stav vyhověl/nevyhověl. Úplné zkušební protokoly mohou být důvěrné, ale souhrnné certifikáty ukazující rozsah testů a stav vyhověl by měly být k dispozici. Pokud dodavatel nemůže předložit žádnou testovací dokumentaci, jeho tvrzení o shodě je nepodložené.

Zkontrolujte fyzické značení. Článek 8 normy IEC 61812-1 vyžaduje trvalé značení na samotném relé. Hledejte značku výrobce, označení modelu/typu, jmenovité napětí a frekvenci a odkaz na normu IEC 61812-1. Značky CE (pro evropský trh) by měly být viditelné a mít správnou velikost. Chybějící nebo neúplné značení naznačuje nesoulad nebo špatnou kontrolu kvality.

Zkontrolujte úplnost datového listu. Tabulka 7 normy IEC 61812-1 uvádí požadované informace o relé. Vyhovující datový list by měl dokumentovat: typy časových funkcí, rozsahy nastavení, hodnoty přesnosti a opakovatelnosti, jmenovité vstupní napětí/frekvenci, uvolňovací napětí, jmenovité hodnoty výstupního obvodu (typ kontaktu, napětí, proud, životnost), environmentální hodnocení (teplota, vlhkost, stupeň znečištění), vhodnost prostředí EMC a schémata zapojení. Neurčité nebo chybějící specifikace naznačují, že dodavatel buď netestoval, nebo neprošel testováním.

Ověřte zapojení notifikované osoby (pro označení CE). V Evropě vyžadují určité kategorie produktů posouzení shody třetí stranou. Zatímco časová relé obvykle umožňují vlastní certifikaci podle směrnice o nízkém napětí, výrobci používající notifikované osoby pro dobrovolnou certifikaci prokazují vyšší důvěru. Zeptejte se, zda byla zapojena notifikovaná osoba, a vyžádejte si její identifikační číslo.

Zkontrolujte s podobnými produkty. Pokud se specifikace zdají příliš dobré na to, aby byly pravdivé (např. přesnost časování ±1% v rozsahu -40 °C až +85 °C bez vlivu napětí), pravděpodobně tomu tak je. Porovnejte deklarovaný výkon s datovými listy zavedených výrobců pro ověření reality.

Zeptejte se na aktualizace vydání 3.0. Vzhledem k tomu, že IEC 61812-1:2023 Edition 3.0 je aktuální verzí, zeptejte se, zda je certifikace dodavatele podle vydání 2023 nebo staršího vydání 2011. Vydání 3.0 přidalo požadavky na kybernetickou bezpečnost a životní prostředí, takže nedávná certifikace má větší váhu.

Při práci s VIOX zákazníci obdrží kompletní dokumentační balíčky: EU prohlášení o shodě, protokoly o typových zkouškách z akreditovaných laboratoří, úplné specifikace datového listu podle tabulky 7 a značení produktu splňující požadavky článku 8. Naše certifikace jsou udržovány podle aktuální normy Edition 3.0, což zajišťuje, že specifikujete komponenty testované podle nejnovějších požadavků.

Časová relé VIOX: Certifikováno podle IEC 61812-1

Společnost VIOX Electric udržuje certifikaci IEC 61812-1:2023 Edition 3.0 v celé naší produktové řadě časových relé, která zahrnuje funkce zpoždění zapnutí, zpoždění vypnutí, multifunkční a hvězda-trojúhelník. Náš rozsah certifikace zahrnuje konfigurace pro montáž na DIN lištu i zásuvné patice, s rozsahy napětí od 12 V DC do 240 V AC.

Náš certifikační proces zahrnuje akreditované laboratoře třetích stran provádějící úplné typové zkoušky podle požadavků normy: ověření přesnosti a opakovatelnosti časování v rozsahu teplot a napětí, zkoušky dielektrické pevnosti a izolačního odporu, zkoušky odolnosti proti EMC pro průmyslová prostředí (podle úrovní průmyslových zkoušek IEC 61812-1 příloha C), zkoušky elektrické životnosti při odporové a indukční zátěži a ověření mechanické odolnosti včetně zkoušek vibrací a rázů.

Každé časové relé VIOX je dodáváno s trvalým značením podle článku 8, včetně odkazu na IEC 61812-1, označení CE (pro evropský trh), jmenovitého napětí a frekvence, jmenovitých hodnot výstupních kontaktů a úplné identifikace modelu. Technické datové listy dokumentují všechny informace požadované v tabulce 7 a zákazníci na vyžádání obdrží EU prohlášení o shodě.

Pro inženýry specifikující časová relé pro globální projekty mají produkty VIOX jak uznání IEC 61812-1, tak UL, což eliminuje potřebu samostatného získávání komponent pro trhy EMEA a Severní Ameriky. Naše dokumentace o shodě zjednodušuje proces certifikace vašeho koncového produktu, ať už stavíte ovládací panely, automatizační systémy, zařízení HVAC nebo průmyslové stroje.

Navštivte naše stránky produktů, kde najdete podrobné specifikace, aplikační poznámky a dokumentaci o shodě pro konkrétní modely časových relé VIOX.

Závěr: Shoda s normami jako záruka kvality

IEC 61812-1 představuje více než jen regulační formalitu. Je to strukturovaný rámec, který překládá “toto časové relé funguje” do měřitelných, testovatelných kritérií pokrývajících výkon časování, elektrickou bezpečnost, environmentální odolnost a elektromagnetickou kompatibilitu. Pro výrobce je to disciplína návrhu a kvality. Pro specifikátory je to společný jazyk pro porovnávání produktů. Pro nákupní týmy je to nástroj pro ověřování, který snižuje riziko dodavatele.

Vydání 3.0 z roku 2023 udržuje relevanci normy přidáním požadavků na kybernetickou bezpečnost a životní prostředí, které odrážejí současné průmyslové priority. Vzhledem k tomu, že automatizační systémy jsou stále více propojené a tlak na udržitelnost se zvyšuje, tato doplnění zajišťují, že certifikace IEC 61812-1 zůstane smysluplná, spíše než aby se stala zastaralým zaškrtávacím políčkem.

Při hodnocení časových relé se nezastavujte u tvrzení “vyhovuje”. Ověřte prohlášení o shodě, vyžádejte si protokoly o zkouškách, zkontrolujte úplnost datového listu a zkontrolujte fyzické značení. Dokumentační stopa je stejně důležitá jako samotná certifikace – je to váš důkaz, že shoda je skutečná, nikoli jen marketingový jazyk.

Shoda s normami nezabrání každé poruše v terénu, ale zvyšuje vaše šance. Relé testované podle požadavků IEC 61812-1 na přesnost časování má statisticky větší pravděpodobnost spolehlivého fungování než netestovaná alternativa. Relé splňující úrovně odolnosti proti EMC má menší pravděpodobnost falešného spuštění v důsledku elektrického šumu. Relé s dokumentovaným testováním životnosti má menší pravděpodobnost předčasného selhání při zatížení. Shoda je pojištění – platíte předem (v nákladech na komponenty a úsilí o specifikaci), abyste snížili mnohem větší následné náklady z poruch, stažení z trhu a poškození reputace.

Pro váš příští projekt vyžadující časová relé stanovte certifikaci IEC 61812-1 jako požadavek specifikace, nikoli jako volitelnou preferenci. Inženýrská práce již byla provedena, aby se definovalo, co znamená “spolehlivé”. Využijte ji.