Key Takeaways

- Fundamental Distinction: Terminal boxes utilize structured terminal blocks for organized, accessible connections and frequent maintenance, whereas junction boxes protect permanent wire splices and are rarely accessed after installation.

- Code Compliance: Both enclosures must adhere to NEC Article 314, but terminal boxes often require stricter accessibility and working space clearances due to their role in active maintenance and testing.

- Application Specificity: Specify terminal boxes for industrial control panels, automation systems, and instrumentation. Use junction boxes for general building wiring, power distribution branching, and splice protection.

- ROI Consideration: While terminal boxes have a higher initial material cost, they significantly reduce troubleshooting time and operational downtime (OPEX), offering superior long-term value in complex industrial environments.

Quick Answer: Terminal Box vs. Junction Box

A terminal box is an electrical enclosure equipped with organized terminal blocks designed for frequent access, testing, and modification of connections. It serves as a control interface or distribution point in industrial systems. Conversely, a junction box is a protective enclosure used primarily to house permanent wire splices (typically joined by wire nuts or crimps) and protect them from environmental factors; it is not intended for regular operational access.

Introduction

In the precise world of industrial electrical engineering, the terms “terminal box” and “junction box” are often used interchangeably, yet they represent distinct components with vastly different functions, design philosophies, and code requirements. For procurement engineers and system designers, confusing these enclosures can lead to code violations, maintenance nightmares, and compromised system reliability.

The choice between a terminal box and a junction box is not merely about housing wires—it is a strategic decision about accessibility, maintainability, and system lifecycle management. A junction box serves as a static shield for permanent connections, while a terminal box acts as a dynamic interface for active systems.

This guide provides a definitive technical comparison for 2025, analyzing the specifications, NEC/NEMA requirements, and application criteria to ensure you specify the correct enclosure for your electrical installations.

What Is a Terminal Box?

A terminal box (often called a terminal enclosure or connection box) is a purpose-built enclosure designed to house electrical junction boxes with terminals. Its primary function is to provide a structured, organized, and accessible interface for connecting field wiring to control systems, machinery, or power distribution networks.

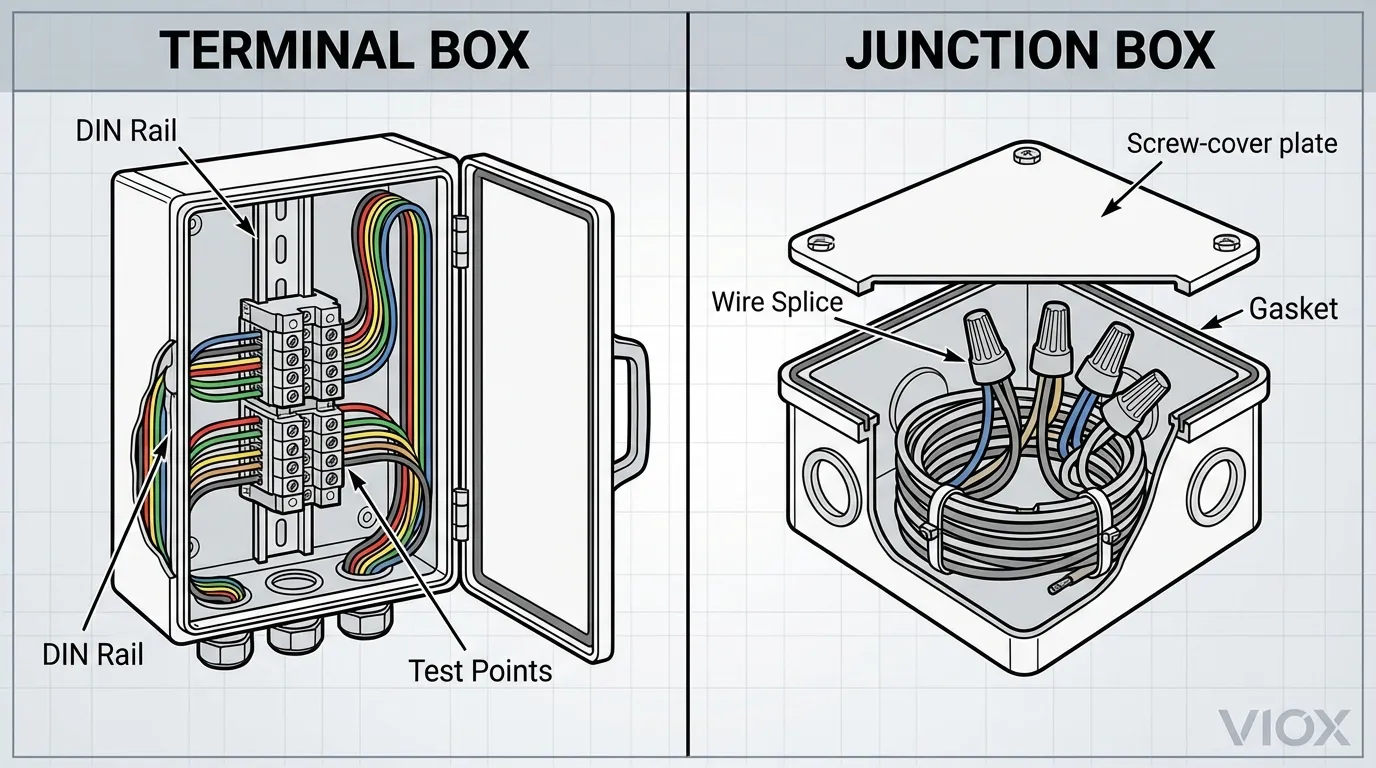

Key Characteristics

- Internal Components: Features DIN rails, terminal blocks (screw, spring-clamp, or push-in), and marking tags.

- Accessibility: Designed with hinged doors, quick-release latches, or removable covers to facilitate frequent access.

- Organization: Wires are terminated individually, labeled, and arranged logically for easy identification.

- Maintenance: Allows for individual circuit isolation, testing, and modification without disturbing adjacent connections.

Terminal boxes are the backbone of industrial automation, serving as the critical handover point between field sensors/actuators and the central control cabinet.

What Is a Junction Box?

A junction box (J-box) is a protective enclosure used to interconnect wires, typically to split a power circuit to multiple outlets or to extend a run. Its primary role is containment and protection. Once installed, a junction box is rarely opened unless a fault occurs or a renovation is required.

Key Characteristics

- Internal Components: Contains wire splices joined by twist-on wire connectors (wire nuts), crimp caps, or simple busbars. Lacks organized terminal strips.

- Accessibility: Often secured with screw-down covers; accessible but not designed for rapid entry.

- Permanence: Connections are intended to be permanent. Modifying a circuit often requires cutting and re-splicing wires.

- Simplicity: Focuses on protecting conductors from physical damage, dust, and moisture.

For a deeper dive into the specific varieties, refer to our guide on understanding electrical junction box types.

Terminal Box vs. Junction Box: The Core Differences

To the untrained eye, both appear to be simple boxes. However, the engineering distinctions determine their suitability for specific environments.

1. Connection Architecture

The most significant difference lies in the connection method. Terminal boxes utilize terminal blocks, which provide a secure, vibration-resistant mechanical connection for each wire. This setup allows for AC junction box applications where circuit integrity is paramount. Junction boxes rely on free-floating splices, which can become disorganized and difficult to trace in complex circuits.

2. Maintenance and Troubleshooting

In an industrial fault scenario, time is money. A terminal box allows a technician to insert a multimeter probe directly into a terminal test point to verify voltage or continuity. In a junction box, the technician must unscrew the cover, untwist wire nuts, and physically separate wires to test a circuit—a process that is slow, invasive, and risks damaging the copper conductors.

3. Space and Sizing

Terminal boxes are typically larger relative to the wire count because they must accommodate the DIN rail, terminal blocks, and wire bending radii. Junction boxes are sized based on the volume of the conductors and splice devices, often resulting in a more compact footprint. Correct sizing is critical; consult our junction box sizing guide to ensure compliance.

Comprehensive Comparison Guide

Table 1: Technical Specifications & Features

| Feature | Terminal Box | Junction Box |

|---|---|---|

| Primary Function | Organized connection, testing, & maintenance | Wire protection & branching |

| Connection Method | DIN-rail mounted terminal blocks | Wire nuts, crimps, or splice blocks |

| Access Frequency | High (Regular maintenance/testing) | Low (Permanent installation) |

| Wire Organization | High (Labeled, individual terminations) | Low (Bundled splices) |

| Troubleshooting | Fast (Test points available) | Slow (Requires undoing splices) |

| Vibration Resistance | Excellent (Secure clamping) | Moderate (Depends on connector quality) |

| Space Requirement | Larger (Requires rail & bending space) | Compact (Volume-based sizing) |

| Cost | Higher initial cost | Lower initial cost |

| Typical Voltage | Low to High (24V – 1000V+) | Low to Medium (120V – 600V) |

| Current Capacity | High (Up to 600A+ with blocks) | Limited by wire nut/connector rating |

Table 2: Application Suitability Matrix

| Application Scenario | Recommended Enclosure | Rationale |

|---|---|---|

| Industrial Control Panel | Terminal Box | Requires frequent testing, labeled circuits, and organized wiring. |

| Residential Lighting Circuit | Junction Box | Simple branching, rarely accessed, cost-sensitive. |

| Motor Termination | Terminal Box | High vibration environment; needs secure lugs/blocks. |

| Outdoor Sensor Wiring | Terminal Box | Needs moisture protection and easy sensor replacement. |

| Building Power Distribution | Junction Box | Permanent splices for long cable runs. |

| Instrumentation Signals | Terminal Box | Shield grounding and signal integrity are critical. |

For a detailed breakdown of how these compare to distribution boxes, see our analysis on junction vs. distribution vs. terminal box.

Table 3: Cost Analysis & ROI

| Cost Factor | Terminal Box | Junction Box |

|---|---|---|

| Material Cost | $$$ (Enclosure + DIN Rail + Blocks) | $ (Enclosure + Wire Nuts) |

| Installation Labor | $$ (Requires mounting blocks & ferrule termination) | $ (Fast twisting/splicing) |

| Maintenance Labor | $ (Rapid testing & modification) | $$$ (Time-consuming troubleshooting) |

| Downtime Risk | Low (Quick fault isolation) | High (Complex fault finding) |

| Long-term ROI | High for industrial/critical systems | High for simple/static systems |

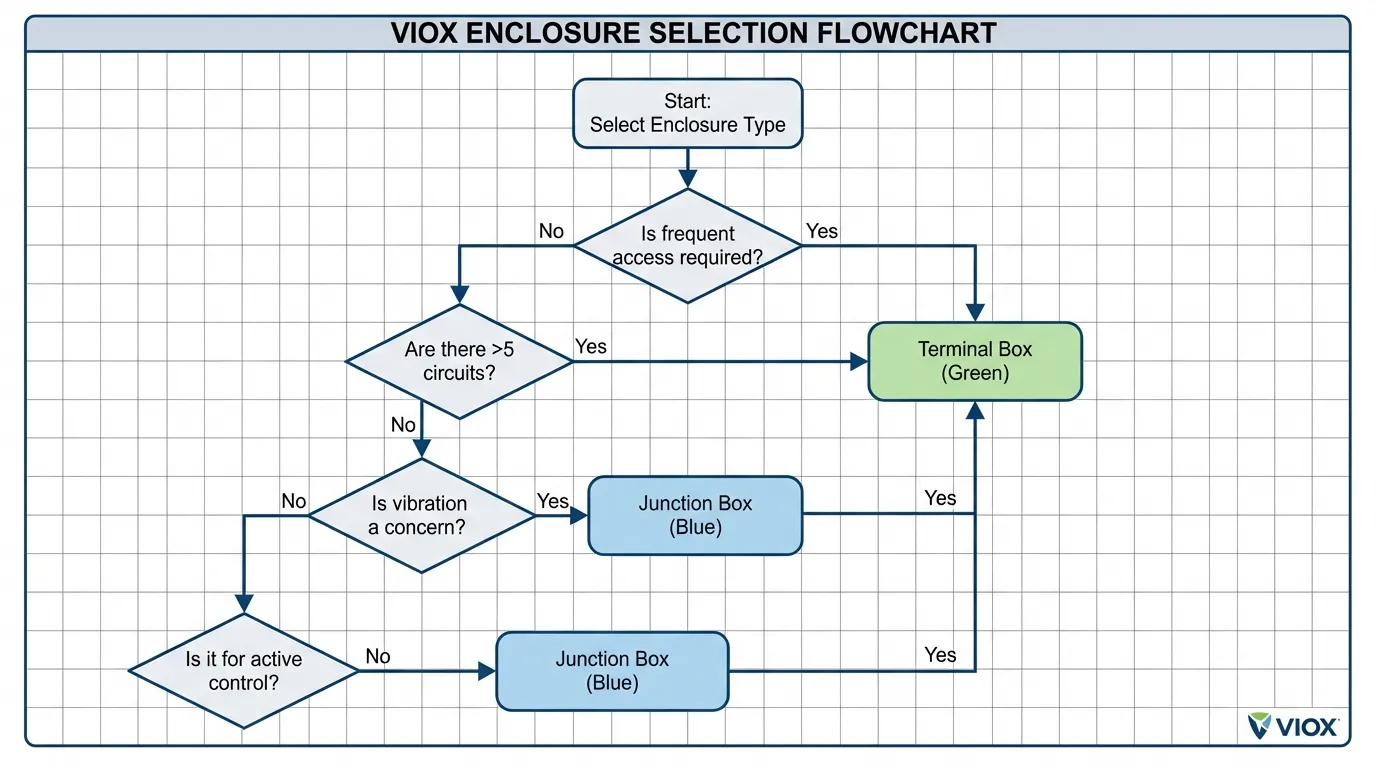

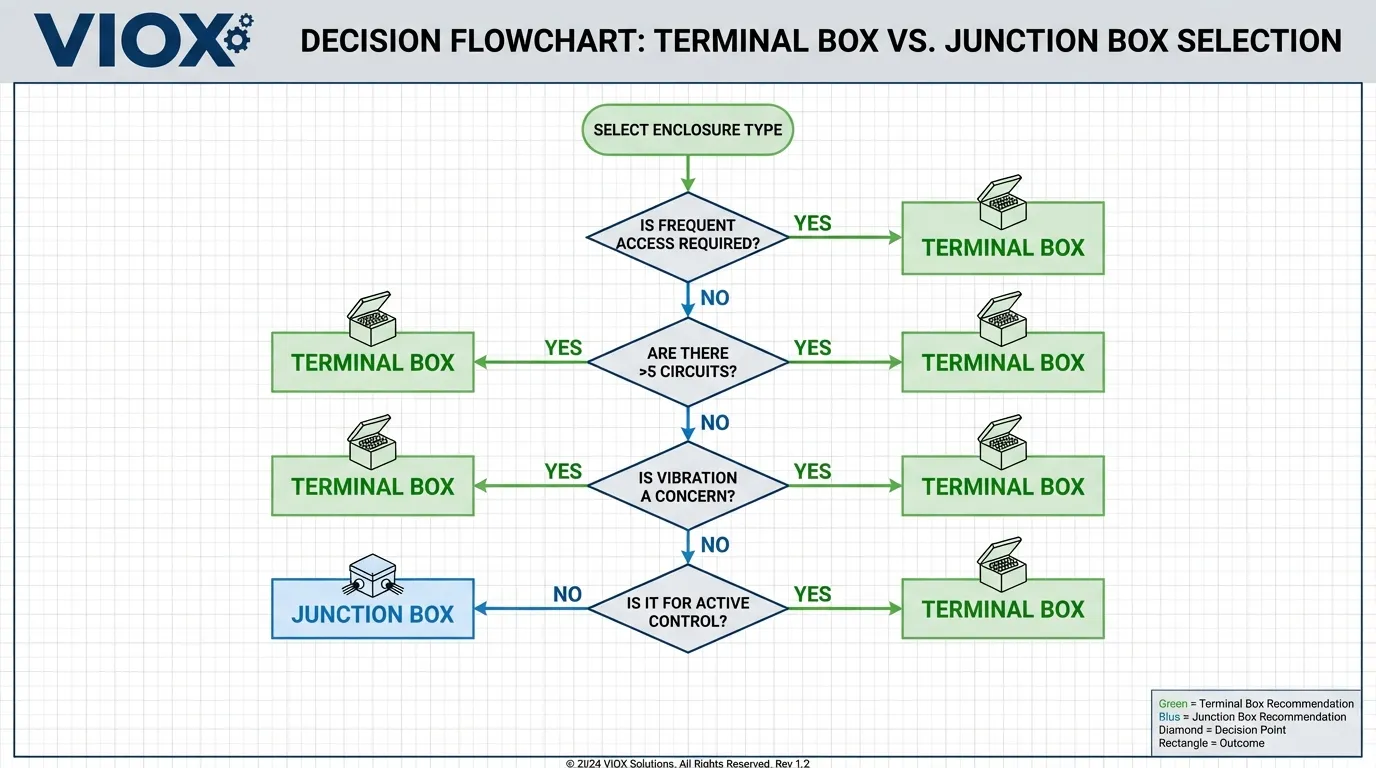

Detailed Selection Criteria

Choosing the right box involves more than just price. Use this decision framework to select the optimal solution for your project.

When to Choose a Terminal Box

- Complex Wiring: If you have more than 4-5 circuits entering a single enclosure.

- Future Expansion: If you anticipate adding sensors or modifying control logic.

- Critical Systems: Where downtime must be minimized, and fault-finding speed is essential.

- Signal Integrity: When managing sensitive 4-20mA signals or data cables that require shield termination.

When to Choose a Junction Box

- Static Installations: Lighting, receptacle power, or simple feeder splices that will not change.

- Space Constraints: When fitting into tight ceiling voids or wall cavities.

- Budget Constraints: For non-critical general purpose wiring where component cost is a primary driver.

Technical Standards and Code Compliance (NEC & NEMA)

Compliance is non-negotiable. Both enclosure types must meet specific standards to ensure safety and legality.

NEC Article 314 Requirements

The National Electrical Code (NEC) Article 314 governs the installation of outlet, device, pull, and junction boxes.

- Accessibility (314.29): All boxes must be accessible without removing part of the building structure. Terminal boxes, due to their maintenance nature, often require working space clearances similar to switchboards (NEC 110.26) if they contain energized components that may be serviced while live.

- Box Fill (314.16): Junction boxes are strictly limited by conductor volume. Terminal boxes must be sized to accommodate the terminal blocks and adequate wire bending space (NEC 312.6).

- Labeling: Terminal boxes require detailed circuit identification.

For a comprehensive review of code specifics, read our guide on NEC code for junction boxes.

NEMA Ratings for Environments

Selecting the correct NEMA rating is critical for both types:

- NEMA 1: Indoor, general purpose (Office/Warehouse).

- NEMA 12: Indoor, dust-tight (Factory floor).

- NEMA 4/4X: Outdoor/Washdown, watertight & corrosion-resistant (Food processing, Marine).

- NEMA 7/9: Hazardous locations (Explosion-proof).

When deciding between materials, consider the environment. Metal vs. plastic junction boxes offer different benefits regarding grounding, durability, and corrosion resistance.

Installation and Troubleshooting Best Practices

Installation Tips

- Labeling: In terminal boxes, label every wire and every terminal point. In junction boxes, label the wire bundles with circuit numbers.

- Spare Capacity: Always size terminal boxes with 20% spare DIN rail space for future expansion.

- Cable Entry: Use rated cable glands (strain relief) to maintain the NEMA rating of the enclosure.

- Grounding: Ensure the enclosure door of a terminal box is bonded to the ground, especially if it carries pilot lights or switches.

Troubleshooting Common Issues

- Loose Connections: Thermal cycling can loosen screws. Terminal boxes with spring-cage terminals mitigate this. Junction box wire nuts can loosen if not properly twisted.

- Moisture Infiltration: Often caused by improper gasket seating or unsealed conduit entries.

- Overcrowding: A common violation in junction boxes (box fill) leading to overheating. Terminal boxes prevent this by design through fixed spacing.

Frequently Asked Questions (FAQ)

Q1: Can I use a junction box as a terminal box?

Technically, yes, if you install a DIN rail and terminal blocks inside. However, standard junction boxes may lack the depth or mounting bosses required for proper terminal block installation. It is better to purchase a purpose-built terminal enclosure.

Q2: Do terminal boxes require more space than junction boxes?

Yes. Terminal boxes require internal clearance for the terminal blocks and organized wire routing. A junction box can be more compact because wires are bundled together, but this sacrifices organization.

Q3: Are terminal boxes required by code for industrial machinery?

While not explicitly “required” to be a specific type, NFPA 79 (Electrical Standard for Industrial Machinery) strongly favors the use of terminal blocks for all field wiring connections to ensure safety, identification, and maintainability.

Q4: Which is more expensive: a terminal box or a junction box?

A terminal box has a higher BOM (Bill of Materials) cost due to the enclosure, rails, blocks, end plates, and markers. However, the labor savings during commissioning and troubleshooting often make it cheaper over the system’s life.

Q5: Can I splice wires inside a terminal box?

It is poor practice. If a wire is too short, use a feed-through terminal block to extend it. Avoid using wire nuts inside a terminal box as it defeats the purpose of an organized enclosure.

Q6: How do I size a terminal box?

Calculate the total width of all terminal blocks, end stops, and accessories. Add 20% for spares. Ensure there is sufficient depth for the blocks plus wire bending radius (typically 2-3 inches clearance from block to wall).

Q7: Do I need a metal or plastic terminal box?

Use metal (stainless or carbon steel) for high-impact areas, EMI shielding, or extreme heat. Use plastic (polycarbonate/fiberglass) for corrosive environments, Wi-Fi/RF transparency, and electrical insulation.

Q8: What is the difference between a distribution box and a terminal box?

A distribution box typically contains protective devices (fuses, breakers) to split power into subsidiary circuits. A terminal box is primarily for connecting/passing through wires without overcurrent protection, though some terminal blocks can include fuses.

Conclusion

The distinction between a terminal box and a junction box defines the operational philosophy of your electrical system. A junction box is a “set it and forget it” protective measure, ideal for static infrastructure. A terminal box is an active management tool, essential for the dynamic, high-reliability demands of modern industry.

For industrial panels, automation, and critical power distribution, the terminal box is the superior choice, offering unparalleled organization, safety, and maintenance speed. While the upfront investment is higher, the return on investment through reduced downtime and enhanced safety is undeniable.

Ready to upgrade your electrical infrastructure? VIOX Electric manufactures premium NEMA-rated terminal boxes and junction boxes tailored for the most demanding industrial applications. From custom-configured terminal enclosures to rugged explosion-proof junction boxes, our engineering team ensures your project meets every code and performance standard.

Explore VIOX Terminal Box Solutions or Contact Our Engineers today for a free consultation on your next project.