When solar installers discover their “UV-resistant” cable ties crumbling after just 18 months outdoors, the root cause often lies in a misunderstood material science principle: carbon black content. This comprehensive guide explains why truly outdoor-rated cable ties must be black, the chemistry behind UV degradation, and how to specify compliant fasteners that won’t force costly re-visits.

The $12,000 Cable Tie Failure: A Solar EPC’s Wake-Up Call

A mid-sized solar EPC in Arizona learned this lesson the hard way. After using “UV-resistant” white nylon cable ties (purchased at 40% below market rate) across a 2 MW ground-mount array, their maintenance team discovered catastrophic brittleness during a routine 18-month inspection. Over 60% of ties securing junction box wiring and cable trays had surface cracks—some had completely failed, leaving conductors exposed to abrasion.

The financial impact:

- Emergency replacement labor: $8,200

- Expedited shipping of compliant ties: $1,400

- Downtime losses (2 days): $2,600

- Total unplanned cost: $12,200

The culprit? Ties marketed as “UV-resistant” but containing inadequate carbon black—the only proven additive that prevents polymer chain scission under solar radiation.

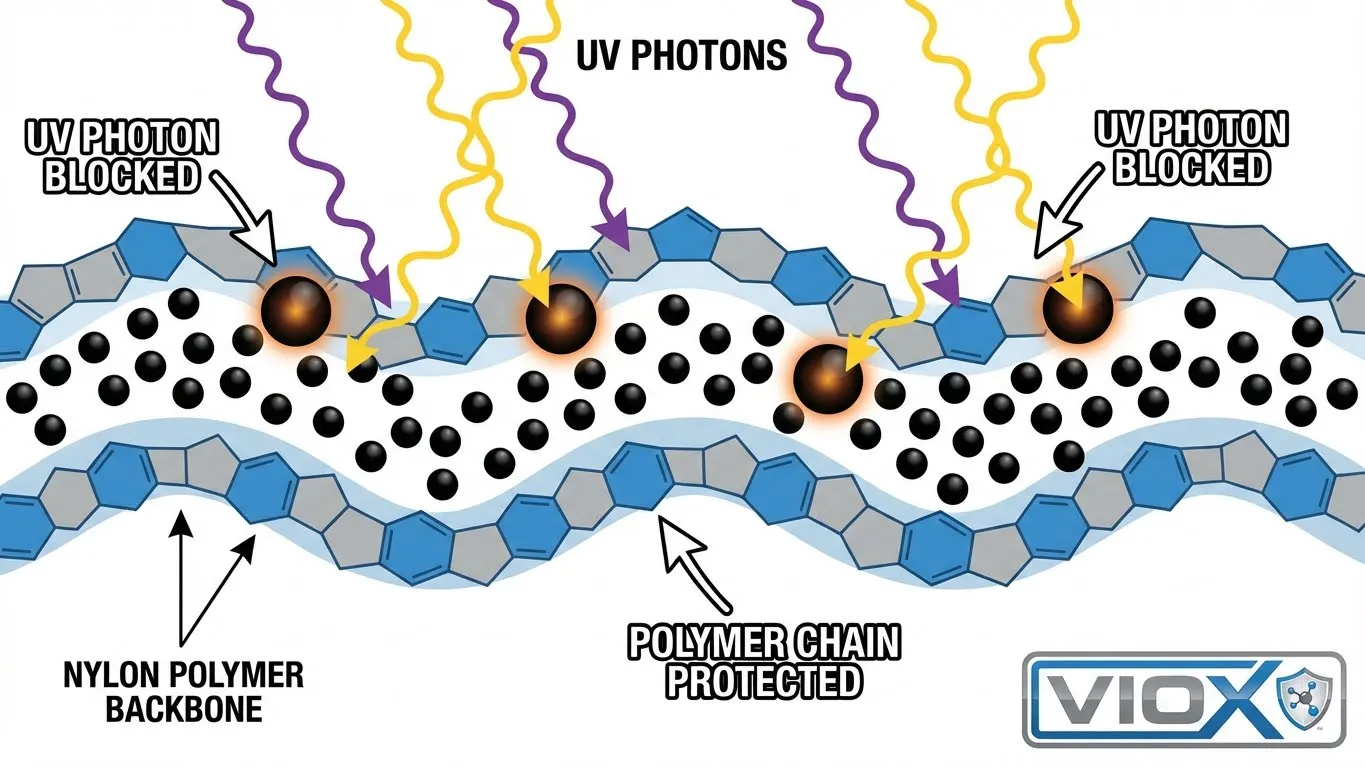

The Chemistry of UV Degradation: Why Polymers Break Down

How Sunlight Destroys Nylon 66

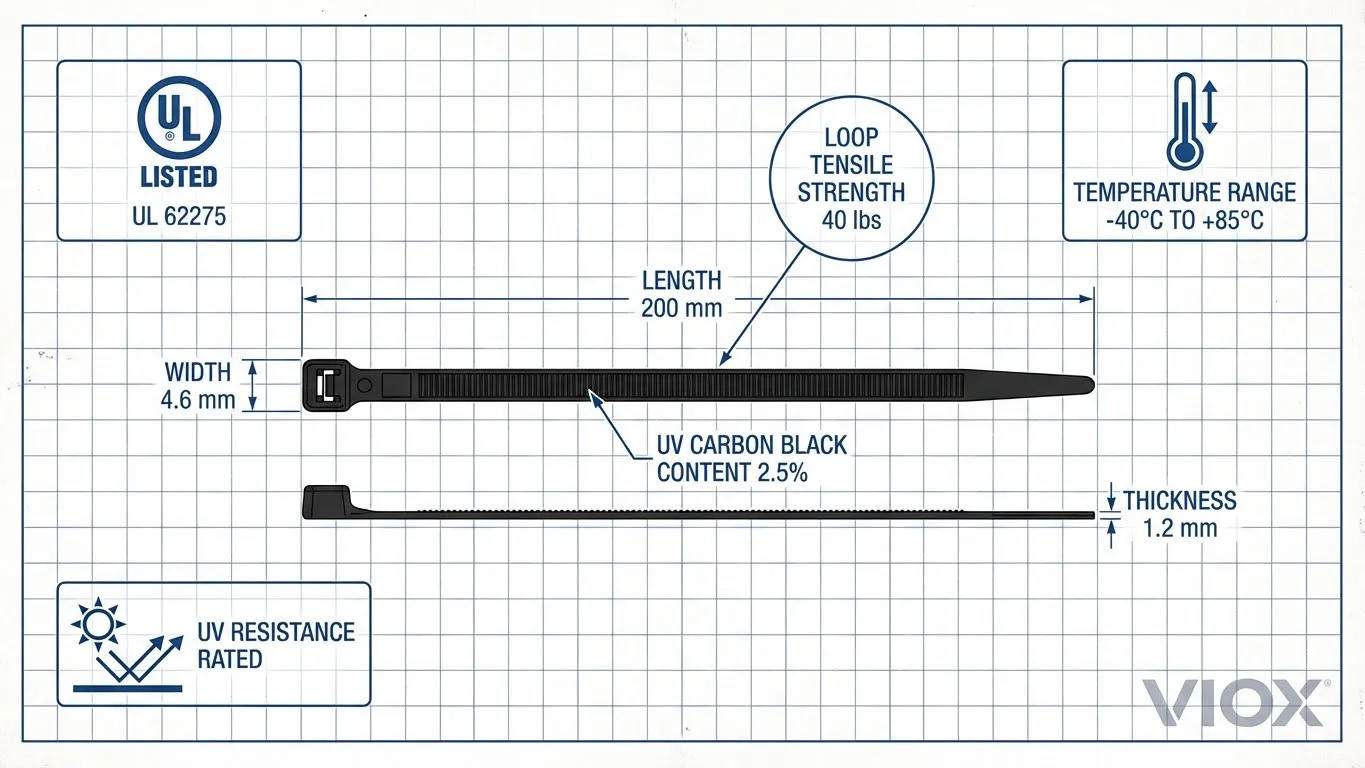

Cable ties are typically manufactured from Nylon 66 (polyamide 6,6), chosen for its excellent tensile strength (85 MPa) and operating temperature range (-40°C to +85°C). However, unprotected nylon is vulnerable to photodegradation:

3-Stage UV Failure Process:

- Photon Absorption (280-400 nm wavelengths): UV-B and UV-A radiation strikes amide bonds in the polymer backbone

- Free Radical Formation: Energy breaks C-N and C-H bonds, creating reactive free radicals

- Chain Scission Cascade: Radicals propagate through the polymer matrix, cleaving long molecular chains into shorter fragments

Visible Symptoms:

- Surface chalking (white powder residue)

- Color fading from translucent white to opaque gray

- Micro-crack formation (visible under 10x magnification)

- Catastrophic embrittlement (50-70% loss of tensile strength)

Carbon Black: The Molecular Shield Against UV

Why Black Ties Outlast White Ties by 10+ Years

Carbon black (not to be confused with carbon fiber or graphite) is a near-pure elemental carbon produced via incomplete combustion of petroleum products. When compounded into nylon at 2-3% by weight, it provides triple-layer protection:

Protective Mechanisms:

| Protection Type | How It Works | Effectiveness |

|---|---|---|

| UV Absorption | Carbon particles absorb 95%+ of incident UV photons before they reach polymer chains | Primary defense |

| Free Radical Scavenging | Unpaired electrons in carbon structure neutralize reactive radicals | Secondary defense |

| Light Scattering | Submicron particles (20-50 nm) diffuse remaining UV energy as harmless heat | Tertiary defense |

Real-World Performance Data:

- White nylon ties (0% carbon black): 12-18 months outdoor life

- “UV-stabilized” white ties (<1% carbon black): 24-36 months

- VIOX black cable ties (2.5% carbon black): 10+ years per UL 62275 accelerated aging

The “UV-Resistant White Tie” Marketing Myth

Why Clear/Natural Ties Can’t Truly Resist UV

Some manufacturers market translucent or white ties as “UV-resistant” by adding:

Ineffective Additives:

- UV Absorbers (Benzotriazoles):

- Migrate to surface over time

- Leach out under temperature cycling

- Provide only 2-3 years protection

- HALS (Hindered Amine Light Stabilizers):

- Effective for indoor polymers

- Degrade rapidly above 60°C (common on rooftops)

- Add 30-50% material cost vs. carbon black

- Titanium Dioxide (White Pigment):

- Reflects visible light but NOT UV

- Can actually accelerate degradation via photocatalytic effect

Critical Specification Point: If a supplier offers “UV-resistant” ties that aren’t jet-black, request third-party test reports per ASTM D4329 (QUV accelerated weathering) showing >5,000 hours exposure without cracking. Most cannot provide this documentation.

Cost Analysis: The True Price of Cheap Cable Ties

Why Paying 15% More Saves 300% Long-Term

Comparative 10-Year Total Cost of Ownership (1,000-tie order for 1 MW solar array):

| Cost Factor | Budget White Ties | VIOX Black UV Ties | Difference |

|---|---|---|---|

| Initial Purchase | $45 | $52 | +$7 |

| Installation Labor (1x) | $180 | $180 | $0 |

| Replacement Events | 3x (years 2, 4, 7) | 0x | -$540 labor |

| Replacement Material | $135 | $0 | -$135 |

| Downtime/Access Costs | $240 | $0 | -$240 |

| Compliance Risk Exposure | Medium | None | Unquantified |

| 10-Year Total | $600 | $232 | -61% cost |

Additional Hidden Costs of Premature Failure:

- Warranty claims processing time

- Reputation damage with end customers

- Emergency call-out logistics

- Potential NEC 110.14(C) temperature rating violations if ties degrade near terminations

.webp)

How to Specify Compliant Cable Ties: The 5-Point Checklist

Engineering Requirements for Outdoor Electrical Installations

When procuring cable ties for solar PV, HVAC outdoor units, or exterior lighting, demand these specifications:

1. Material Composition

- Base resin: Nylon 66 (polyamide 6,6) per ASTM D4066 PA0610 grade

- Carbon black content: 2.0-3.5% by weight (supplier must disclose)

- Reject: Nylon 6, polypropylene, or acetal copolymer for outdoor use

2. UV Resistance Certification

- UL 62275 listing (cable tie standard replacing UL 1565)

- ASTM D4329 QUV test: Minimum 5,000 hours without cracking

- Operating temperature: -40°C to +85°C continuous

3. Tensile Strength

- Minimum loop tensile: 40 lbs (18 kg) for standard ties

- Heavy-duty: 120 lbs (54 kg) for large cable bundles

- Maintain >80% strength after UV exposure

4. Flammability Rating

- UL 94 V-2 minimum (self-extinguishing)

- Preferred: UL 94 V-0 for enclosed spaces

5. Regulatory Compliance

- RoHS compliant (lead-free, REACH-compliant)

- NEC 110.3(B) listed product requirement

- Halogen-free formulation (reduces toxic smoke if fire occurs)

Internal Link Opportunity: For detailed cable sizing requirements that pair with proper cable management, see our guide on Cable Size Types: mm² vs AWG vs BS Conversion.

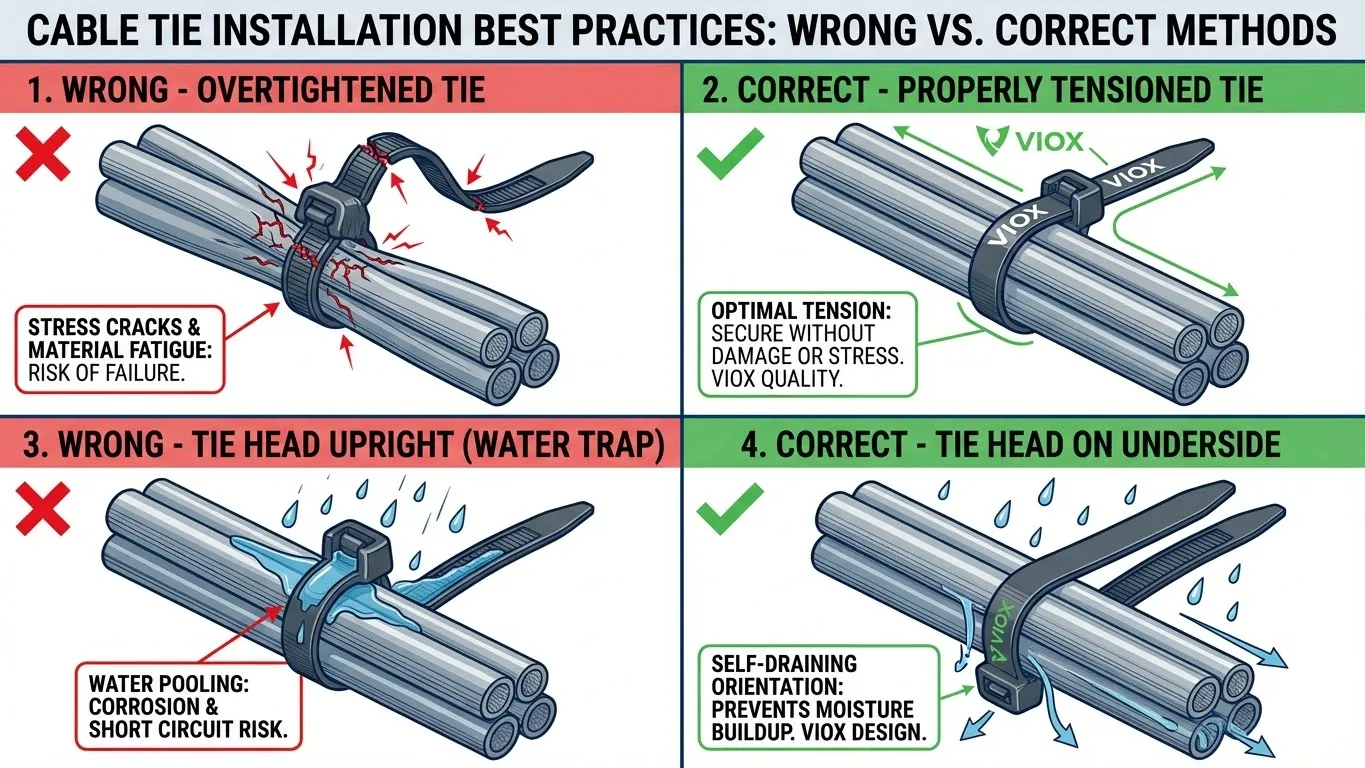

Installation Best Practices: Maximizing Tie Lifespan

Even the best UV-resistant ties can fail prematurely due to installation errors:

Critical Installation Guidelines:

1. Tension Management

- Never overtighten: Proper tension is “snug but slideable”—you should be able to rotate the cable bundle 10-15° within the tie

- Overtightening causes stress concentrations that accelerate failure

- Use tensioning tools calibrated to 45-65 lbs max pull force

2. Orientation Matters

- Position tie head on underside or side of cable run (not top-facing)

- Reduces direct UV exposure to locking mechanism—the weakest point

- Prevents water pooling in ratchet teeth (freeze-thaw damage)

3. Bundling Strategy

- Maximum cables per tie: 75% of tie’s rated bundle diameter

- Group cables by voltage class (separate MV from LV per NEC 300.3(C))

- Leave 2-3mm spacing for thermal expansion

4. Avoid Mixed Materials

- Don’t use metal cable ties near aluminum racking (galvanic corrosion risk)

- Don’t use adhesive-backed mounts unless rated for 85°C+

- For comprehensive grounding practices, review NEC Grounding Requirements.

Beyond Carbon Black: Advanced UV-Resistant Technologies

Emerging Innovations in Cable Tie Manufacturing

While carbon black remains the industry standard, some high-end applications now use:

- Stainless Steel Cable Ties

- When to use: Marine environments, chemical plants, extreme temperatures (-80°C to +538°C)

- Drawback: 8-12x higher cost, requires special installation tools

- VIOX Offering: 316L stainless steel ball-lock ties for corrosive atmospheres

- Fluoropolymer-Coated Ties

- PVDF or FEP coating over nylon core

- Provides chemical resistance + UV protection

- Used in pharmaceutical and semiconductor facilities

- Metal-Detectable Ties

- Contain embedded metal particles for X-ray inspection

- Required in food processing (FDA compliance)

- Still require carbon black for outdoor UV resistance

For related cable management in harsh environments, see Stainless Steel vs Aluminum Junction Box Corrosion Resistance.

Comparison Table: Cable Tie Material Selection Guide

| Application | Recommended Material | UV Rating | Temp Range | Cost Index | Typical Lifespan |

|---|---|---|---|---|---|

| Solar PV arrays | Nylon 66 + 2.5% carbon black | Excellent | -40 to +85°C | 1.0x | 10+ years |

| Indoor control panels | Natural nylon 66 (white) | Not required | -10 to +60°C | 0.8x | 15+ years |

| Marine/offshore | 316L stainless steel | Excellent | -80 to +538°C | 8.5x | 20+ years |

| Chemical plants | PVDF-coated nylon | Excellent | -40 to +150°C | 3.2x | 12+ years |

| Temporary construction | Polypropylene | Poor | 0 to +70°C | 0.5x | 6-12 months |

| HVAC outdoor units | Nylon 66 + carbon black | Excellent | -40 to +85°C | 1.0x | 10+ years |

Note: Cost index normalized to standard black nylon 66 ties (1.0x = $0.05-0.08 per tie in 1,000-piece bulk orders).

Frequently Asked Questions (FAQ)

1. Can I use white cable ties if they’re rated “UV-resistant”?

Short answer: No, not for critical outdoor installations. While some white ties contain UV stabilizers, they cannot match the longevity of carbon black ties. If aesthetic appearance is critical (architectural lighting), use 316 stainless steel ties instead—never compromise on UV protection in exchange for color preference.

2. How do I verify carbon black content in cable ties?

Request the Material Safety Data Sheet (MSDS) and Technical Data Sheet (TDS) from your supplier. Carbon black should be listed at 2-3% by weight. Additionally, UL 62275 certification requires disclosure of UV-resistance additives. If a supplier refuses to provide this documentation, do not purchase.

3. What’s the difference between UL 1565 and UL 62275 ratings?

UL 62275 is the updated international standard (harmonized with IEC 62275) that replaced UL 1565 in 2020. It includes stricter flammability requirements and mandates UV exposure testing. Always specify UL 62275 for new projects—older UL 1565 ties may not meet current NEC requirements. Internal Link: For broader electrical safety standards, see NEC vs IEC Terminology Correspondence.

4. Do cable ties expire if stored indoors?

Properly stored nylon 66 cable ties have a shelf life of 5+ years when kept in sealed bags away from direct sunlight and heat (store below 30°C). However, carbon black content does not degrade during storage—the material is chemically inert. Reject any ties showing discoloration or brittleness out of the package.

5. Can I reuse cable ties during maintenance?

Never reuse cable ties for permanent installations. The ratchet mechanism suffers micro-damage during initial installation, and re-tensioning creates stress points that accelerate failure. For temporary testing, releasable/reusable ties are available, but these cost 3-4x more and have lower tensile ratings (typically 20-30 lbs max).

6. What size cable tie do I need for solar MC4 connectors?

For securing MC4 connector pairs to racking, use 8-inch (200mm) ties with 40 lb tensile rating. This accommodates cable diameter (typically 4-6mm for 10 AWG USE-2 wire) plus connector body. Internal Link: For MC4 connector selection, review How to Select the Right MC4 Solar Connector.

7. Are metal cable ties better than plastic for outdoor use?

It depends on the environment. Stainless steel ties offer superior UV and temperature resistance but cost significantly more and require specialized tools. They’re mandatory for corrosive environments (marine, chemical) but overkill for standard solar installations. Use nylon + carbon black for 95% of outdoor electrical work—reserve metal ties for extreme conditions.

Conclusion: Specifying with Confidence

The $12,000 lesson from our opening case study boils down to a simple material science principle: UV resistance in polymers requires carbon black—period. White or translucent cable ties, regardless of marketing claims, cannot deliver the 10+ year outdoor lifespan that solar PV, HVAC, and exterior electrical installations demand.

Key Takeaways for Procurement Teams:

- Demand disclosure: Require suppliers to specify carbon black content (2.0-3.5% minimum)

- Verify certifications: Accept only UL 62275-listed products with ASTM D4329 test reports

- Calculate TCO, not unit price: A $0.05 tie that fails in 18 months costs 3x more than a $0.08 tie lasting 10 years

- Document compliance: Maintain material certifications for warranty protection and code inspections

VIOX Electric manufactures carbon black cable ties meeting UL 62275 with verified 10+ year outdoor life. Our technical team provides free specification support for EPC and distribution partners—contact us at [technical specifications request] for project-specific guidance.

Related Reading: