When specifying switching solutions for industrial control panels, motor control applications, or power distribution systems, electrical engineers and procurement managers face a critical decision: should you choose a rotary cam switch or a toggle switch? While both serve the fundamental purpose of controlling electrical circuits, the differences between these two switching technologies can significantly impact system performance, safety, and long-term operational costs.

The rotary cam switch has become the preferred solution for complex industrial applications requiring multi-position control, high current capacity, and robust durability. Unlike simple toggle switches that offer basic on-off functionality, rotary cam switches provide sophisticated switching sequences that can control multiple circuits simultaneously through a single operator interface. This capability makes them indispensable in applications ranging from motor reversing and star-delta starting to generator changeover and multi-speed control systems.

Understanding the technical differences, application requirements, and selection criteria between these two switch types is essential for making informed decisions that optimize both performance and cost-effectiveness. This comprehensive guide examines the specifications, operating mechanisms, and real-world applications of rotary cam switches and toggle switches, providing you with the technical knowledge needed to specify the right solution for your specific requirements.

Understanding Rotary Cam Switches

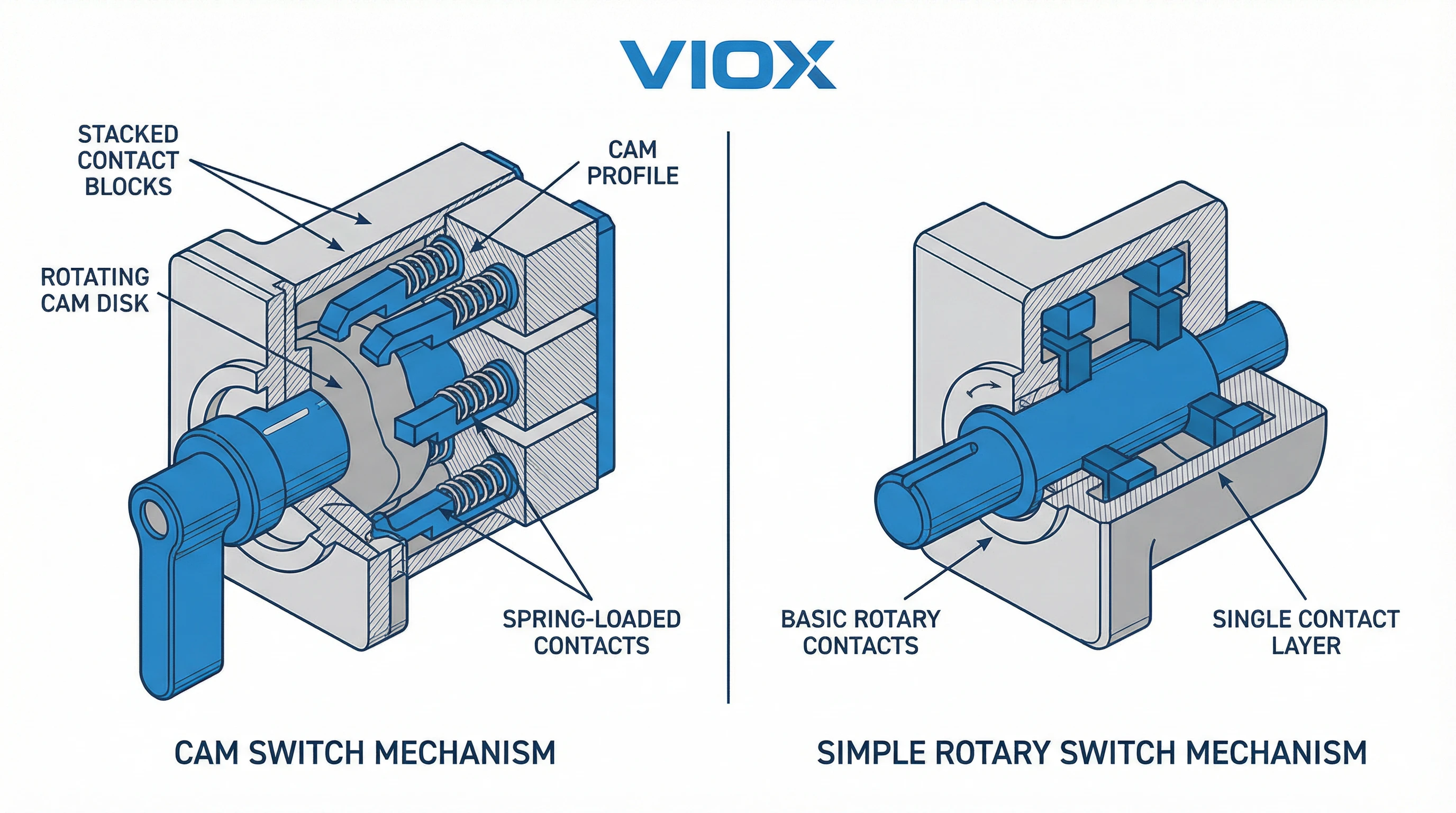

A rotary cam switch is a manually operated switching device that uses a rotating shaft and cam mechanism to control multiple electrical circuits through precise, pre-programmed switching sequences. When the operator rotates the handle to different positions, internal cam profiles engage and disengage spring-loaded contacts in a predetermined pattern, allowing a single switch to manage complex control functions.

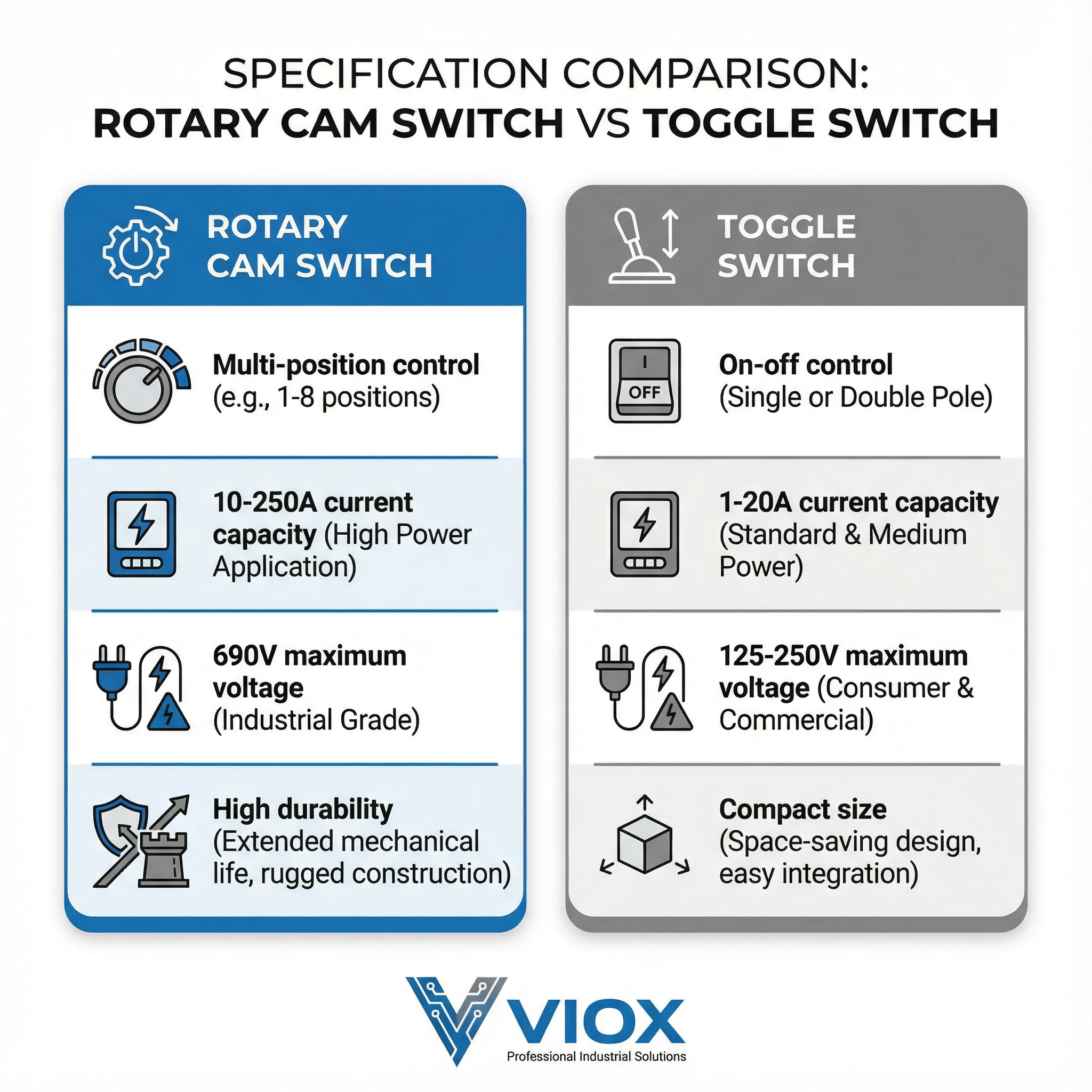

The defining characteristic of a rotary cam switch is its ability to handle multiple poles and positions simultaneously. Modern rotary cam switches are available in configurations ranging from 2 to 12 positions, with pole counts extending from single-pole up to 12 poles or more. This versatility enables them to control numerous independent circuits from a single control point—a capability essential for sophisticated industrial applications.

Current ratings for rotary cam switches span a broad spectrum to accommodate diverse applications. Standard industrial models typically range from 10A to 125A, with heavy-duty variants capable of handling 160A to 250A or even higher. Voltage capacities are equally impressive, with most rotary cam switches rated for operation up to 690V AC, while specialized DC versions for photovoltaic applications can handle up to 1000V DC.

The construction of a rotary cam switch emphasizes durability and reliability. These switches feature robust housings—often die-cast metal or high-grade thermoplastic—designed to withstand harsh industrial environments. Contact materials typically consist of copper or silver alloys engineered for high conductivity and resistance to arcing. The modular design of many rotary cam switches allows for customization by stacking contact blocks to create application-specific switching programs.

Mechanical endurance is a critical specification, with industrial-grade rotary cam switches rated for 500,000 to over 1 million no-load operations. Electrical life varies by utilization category but typically ranges from 3,000 to 20,000 on-load switching cycles, depending on the load type and current level. This exceptional durability makes rotary cam switches a cost-effective long-term solution despite their higher initial cost compared to simpler switching devices.

Understanding Toggle Switches

Toggle switches represent one of the most recognizable and widely used switching mechanisms in electrical systems. Operating through a simple lever action, these switches provide straightforward on-off or changeover control through a mechanical flipping motion. The lever connects to an internal armature that makes or breaks electrical connections as the switch is actuated.

The simplicity of toggle switches is both their primary advantage and their limitation. The most basic configuration, a single-pole, single-throw (SPST) switch, controls a single circuit with two states: open or closed. More complex variants include single-pole, double-throw (SPDT) for three-position control and double-pole, double-throw (DPDT) switches that can control two separate circuits simultaneously. However, even the most sophisticated toggle switch configurations fall short of the multi-circuit control capabilities offered by rotary cam switches.

Toggle switches typically handle lower voltage and current ratings compared to industrial rotary cam switches. Standard toggle switches are commonly rated for 125V to 250V AC, with current ratings ranging from under 1A for logic-level applications to 15A or 20A for power switching. While heavy-duty industrial toggle switches are available with higher ratings, they generally cannot match the current-handling capacity of comparably sized rotary cam switches.

The construction of toggle switches varies from compact sub-miniature designs for electronics applications to larger industrial models with protective boots and sealing for harsh environments. However, the exposed lever mechanism inherently presents vulnerability to environmental contaminants unless specifically designed with sealed enclosures. Toggle switches offer decent mechanical life, though typically less than industrial-grade rotary cam switches, making them more suitable for applications with moderate switching frequency.

Technical Comparison: Rotary Cam Switch vs Toggle Switch

To make informed switching decisions, it’s essential to understand how rotary cam switches and toggle switches compare across critical technical specifications. The following comparison highlights the key differences that influence application suitability:

| Specification | Rotary Cam Switch | Toggle Switch |

|---|---|---|

| Control Complexity | Multi-position (2-12+ positions), multi-pole (up to 12+ poles), custom switching sequences | Simple 2-3 position control, SPST to DPDT configurations |

| Voltage Rating | Up to 690V AC standard, 1000V DC for specialized applications | Typically 125V-250V AC |

| Current Rating | 10A to 250A+ (industrial applications) | Under 1A to 20A (standard models) |

| Number of Circuits | Can control multiple independent circuits simultaneously | Usually 1-2 circuits |

| Mechanical Life | 500,000 to 1,000,000+ operations | Varies, generally lower than rotary cam switches |

| Electrical Life | 3,000 to 20,000 on-load cycles (utilization category dependent) | Moderate, application dependent |

| Switching Mechanism | Rotational cam-actuated contacts | Linear flip-action lever |

| Enclosure Protection | IP ratings available (IP65, IP67, IP69K) | Limited environmental protection unless sealed |

| Contact Material | Copper/silver alloys for high-load applications | Brass, copper, or silver with various platings |

| Mounting | Panel mount, front/rear installation, various shaft lengths | Panel mount, multiple sizes available |

| Customization | Highly modular, stackable contact blocks | Limited customization |

| Cost | Higher initial investment | Lower cost |

| Ideal Use Case | Complex industrial control, motor management, multi-circuit control | Simple on-off control, space-constrained applications |

This technical comparison reveals why rotary cam switches dominate in industrial motor control, power distribution, and complex automation systems, while toggle switches remain the practical choice for straightforward control functions where simplicity and cost-effectiveness are priorities.

Operating Mechanisms Explained

Understanding the internal operating mechanisms of these switches clarifies why each excels in different applications.

How Rotary Cam Switches Work

The rotary cam switch mechanism centers on a rotating shaft that drives multiple pre-shaped cam discs. When an operator turns the handle to select a position, these cams rotate against spring-loaded contact assemblies. The profiled edges of each cam are precisely engineered to push contact arms open or allow them to close at specific rotational angles, creating predetermined switching sequences.

This cam-and-follower design enables remarkable versatility. Different cam profiles can create make-before-break connections (where new contacts close before old ones open) or break-before-make sequences (where contacts open before new ones close), depending on application requirements. The rotary action provides clear visual indication of the selected position, and detent mechanisms create tactile feedback at each position, preventing accidental positioning between states.

The mechanical advantage of rotational motion allows rotary cam switches to switch high currents reliably. The cam profiles can be designed to provide rapid contact separation with sufficient force to extinguish arcs, contributing to both safety and contact longevity. Multiple contact blocks can be stacked on a common shaft, allowing a single handle movement to execute complex switching programs across numerous circuits.

How Toggle Switches Work

Toggle switches employ a fundamentally simpler mechanism. A lever handle connects to a spring-loaded armature inside the switch body. When the lever is flipped, it moves past a mechanical “over-center” point where the internal spring snaps the contacts rapidly into their new position. This snap action ensures quick contact movement, minimizing arcing during switching.

In a basic SPST configuration, moving the toggle lever rotates the internal armature, which either presses two contact points together (closed position) or separates them (open position). More complex DPDT toggle switches contain multiple contact sets that switch simultaneously, but the fundamental mechanism remains a simple lever-driven snap action. The exposed lever provides quick, decisive operation but also means the internal mechanism experiences more direct exposure to environmental factors compared to the enclosed shaft of a rotary cam switch.

Applications and Use Cases

The technical differences between rotary cam switches and toggle switches naturally lead to distinct application profiles where each technology excels.

Where Rotary Cam Switches Excel

Motor Control Applications: Rotary cam switches are the industry standard for three-phase motor control. They manage forward-reverse operations, star-delta starting sequences, and multi-speed control with reliability that simple switches cannot match. In conveyor systems, packaging machinery, and production lines, a single rotary cam switch provides precise control over motor operations including start, stop, reverse, and speed selection.

Power Transfer and Changeover: Generator transfer applications rely on rotary cam switches to safely switch between mains power and backup generators. The make-before-break or break-before-make contact sequences ensure smooth transitions without interruption in critical facilities like hospitals, data centers, and manufacturing plants. The ability to handle high voltages and currents makes rotary cam switches essential for these demanding applications.

HVAC and Compressor Control: Industrial heating, ventilation, and air conditioning systems use rotary cam switches for fan speed control, damper positioning, and multi-stage heating or cooling control. The multi-position capability allows operators to select from numerous operating modes without requiring multiple individual switches.

Industrial Control Panels: Panel builders specify rotary cam switches for complex machinery where multiple circuits must be controlled in coordinated sequences. The rotary format provides clear visual indication of operating mode, while the robust construction withstands the frequent operation typical in industrial settings.

Where Toggle Switches Are Preferred

Simple On-Off Control: For straightforward power control of lights, single-speed motors, or basic equipment, toggle switches provide an economical and reliable solution. Their quick flip action offers decisive control without the complexity of multi-position selection.

Space-Constrained Installations: In control panels where real estate is limited, compact toggle switches occupy minimal space while providing effective circuit control. Their small footprint makes them ideal for dense panel layouts or portable equipment.

Low-Voltage Control Circuits: Toggle switches excel in control signal applications, mode selection between manual and automatic operation, and other low-current switching tasks where the sophisticated capabilities of a rotary cam switch would be unnecessary and cost-ineffective.

Emergency Stop and Safety Functions: Guarded toggle switches with protective covers find use in safety applications where accidental actuation must be prevented but immediate manual override capability is required.

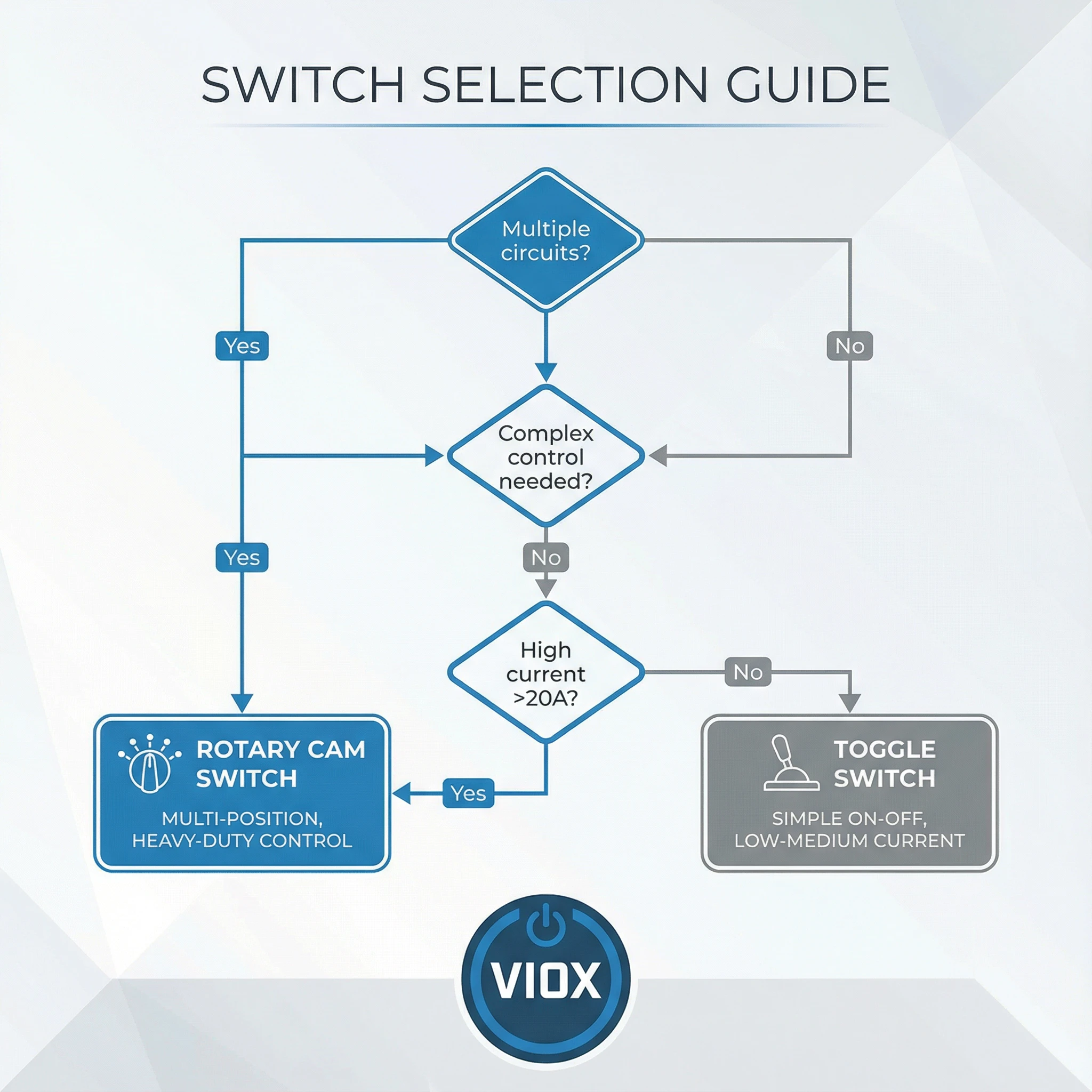

Selection Guide: Which Switch to Choose?

Choosing between a rotary cam switch and a toggle switch requires evaluating several critical factors against your specific application requirements.

Choose a Rotary Cam Switch When:

- You need to control multiple independent circuits from a single operator interface

- Complex switching sequences are required (motor reversing, star-delta starting, multi-speed control)

- The application involves high voltage (above 250V) or high current (above 20A) switching

- Multiple operating positions (more than 3) are necessary

- Long mechanical and electrical life is critical to minimize maintenance

- Clear visual indication of operating mode is important for safety or operational efficiency

- The application environment is harsh, requiring robust construction and environmental sealing (IP65-IP69K)

- Initial cost can be justified by long-term reliability and reduced downtime

Choose a Toggle Switch When:

- Simple on-off or three-position control is sufficient

- Controlling only one or two circuits

- Voltage and current requirements are moderate (under 250V, under 20A)

- Panel space is extremely limited

- Quick, decisive manual actuation is preferred

- Cost minimization is a primary concern

- The application involves infrequent switching operations

- Control signal or logic-level switching rather than power switching

Key Decision Factors:

Complexity Requirements: If your application requires coordinated control of multiple circuits or sequential switching operations, the rotary cam switch is almost certainly the correct choice. Toggle switches simply cannot replicate this functionality without using multiple switches and additional control logic.

Load Requirements: For high-power industrial applications, rotary cam switches provide the current-handling capacity, arc suppression, and contact durability necessary for reliable operation. Toggle switches work well for lower-power applications where their limitations don’t compromise performance.

Total Cost of Ownership: While rotary cam switches have higher upfront costs, their superior mechanical endurance and electrical life often result in lower total cost of ownership for industrial applications. Calculate the cost impact of potential failures, downtime, and replacement frequency when making your decision.

Safety and Compliance: Applications subject to IEC 60947-3 or similar standards often require the capabilities and certifications that rotary cam switches provide. Verify that your chosen switch meets all applicable standards for your application and geographic market.

IEC 60947-3 Standards and Compliance

For industrial switching applications, compliance with IEC 60947-3 is often mandatory. This international standard governs low-voltage switchgear and controlgear, specifically covering switches, disconnectors, switch-disconnectors, and fuse-combination units for circuits up to 1000V AC or 1500V DC. Rotary cam switches used in industrial motor control and power distribution typically fall under this standard’s requirements.

IEC 60947-3 defines critical parameters including utilization categories that classify switches based on their intended load types. Common categories include AC-20 (no-load switching), AC-21 (resistive loads), AC-22 (mixed resistive and inductive loads), and AC-23 (motor loads). These classifications determine the required making and breaking capacity, ensuring the switch can safely handle the electrical stresses of its intended application.

The standard specifies rigorous testing requirements including making and breaking capacity tests, temperature rise tests, dielectric strength verification, and short-circuit withstand capability. Mechanical durability requirements typically mandate 10,000 to 20,000 no-load operations for disconnectors and higher cycles for load-break switches. Electrical life specifications vary by utilization category, with AC-23 motor switching applications requiring 1,000 to 3,000 on-load cycles.

When specifying rotary cam switches for industrial applications, verify that the manufacturer provides documentation of IEC 60947-3 compliance, including the specific utilization categories for which the switch is rated. This ensures your switching solution meets international safety standards and provides the performance characteristics required for reliable operation.

Conclusion

The choice between a rotary cam switch and a toggle switch fundamentally depends on your application’s complexity, load requirements, and operational environment. Rotary cam switches excel in demanding industrial applications where multi-circuit control, high current capacity, and long-term reliability justify their higher initial investment. Their ability to manage complex switching sequences from a single control point makes them indispensable in motor control, power transfer, and sophisticated automation systems.

Toggle switches remain the practical choice for simpler applications where straightforward on-off control, compact size, and cost-effectiveness are primary considerations. Their reliability in basic switching tasks and minimal space requirements ensure they continue to serve essential roles in countless electrical systems.

At VIOX Electric, we manufacture both rotary cam switches and toggle switches engineered to meet the demanding requirements of industrial and commercial applications. Our rotary cam switch product line offers configurations from 10A to 250A, voltage ratings up to 690V AC, and full IEC 60947-3 compliance across multiple utilization categories. Whether you’re designing a complex motor control system or a simple power distribution panel, selecting the appropriate switch technology ensures optimal performance, safety, and long-term value.

For technical specifications, custom configurations, or application engineering support, contact our technical sales team to discuss your specific switching requirements and discover how VIOX switching solutions can enhance your electrical systems’ performance and reliability.