Why Your New VIOX Equipment Arrives With a Generic Warning Label (And Why That’s Actually Correct)

When you unpack a new VIOX switchgear or panelboard, you might notice a bright yellow warning label that reads “Danger – Arc Flash and Shock Hazard.” Some customers ask: “Where’s the specific incident energy data? What PPE category should my electricians wear? Did VIOX skip something?”

The short answer: Absolutely not. If VIOX included detailed arc flash calculations at the factory, we’d be violating fundamental safety principles and potentially exposing your workers to incorrect hazard information. This article clarifies the critical distinction between two types of arc flash labels, explains the legal responsibilities behind each, and shows you exactly what VIOX provides versus what you must determine on-site.

The Two Types of Arc Flash Labels: Understanding the Fundamental Difference

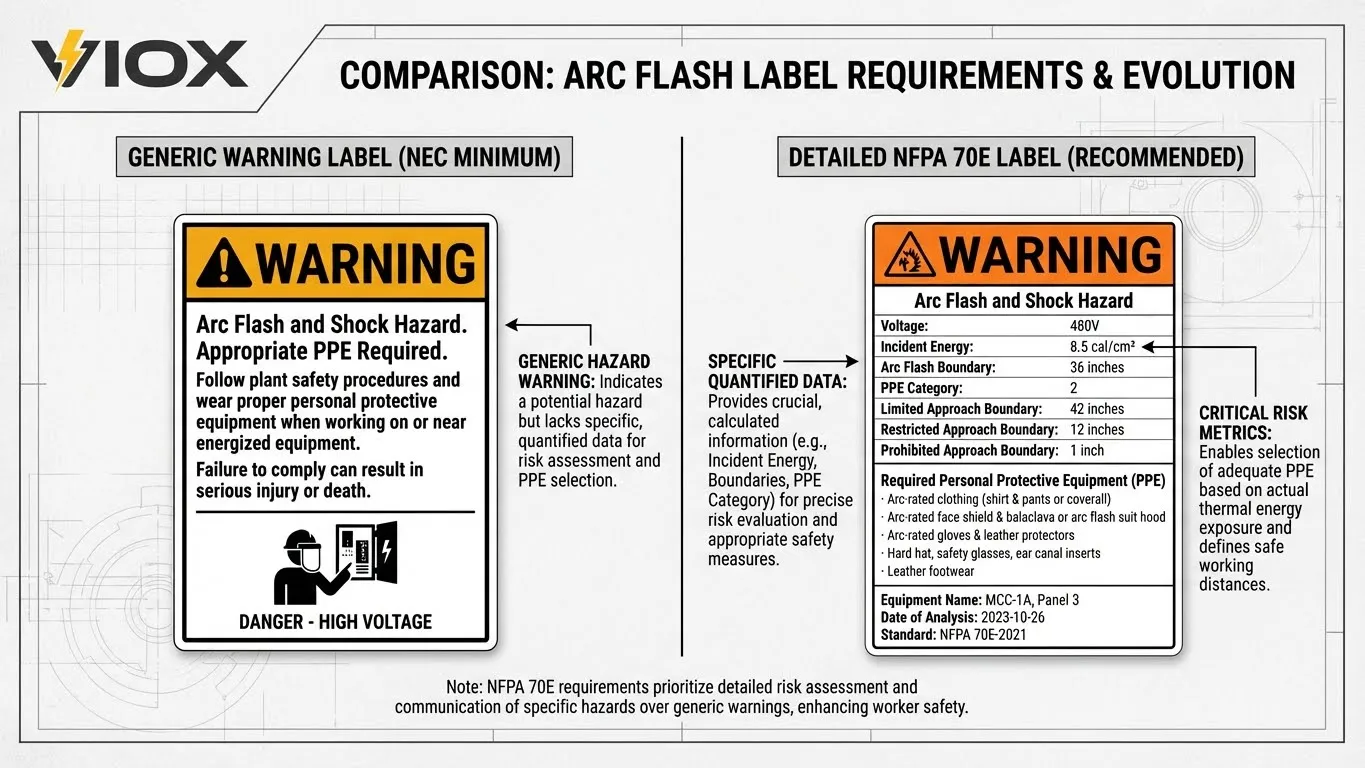

The confusion stems from conflating two entirely separate labeling requirements governed by different standards. Let’s break them down:

Generic Warning Labels (NEC 110.16)

These labels serve as universal hazard alerts required by the National Electrical Code. As of the 2026 NEC, Section 110.16 mandates permanent arc flash hazard markings on electrical equipment in locations other than dwelling units that may require examination, adjustment, servicing, or maintenance while energized.

Key characteristics:

- Purpose: Alert workers that arc flash and shock hazards may exist

- Required information: General warning (no calculations needed)

- Responsibility: Technically the installer’s duty, but reputable manufacturers like VIOX include them as standard

- Compliance standard: NEC 110.16 (now expanded significantly in 2026 edition)

The 2026 NEC represents a major shift—arc flash labels are now mandatory by code, not just recommended practice. This applies to switchboards, switchgear, panelboards, motor control centers, and industrial control panels.

Detailed Arc Flash Labels (NFPA 70E 130.5(H))

These labels provide specific hazard data based on site-specific electrical system analysis. NFPA 70E Section 130.5(H) requires equipment labeling that includes actionable safety information.

Key characteristics:

- Purpose: Provide precise hazard levels and PPE requirements for specific equipment in its installed location

- Required information: Incident energy (cal/cm²), arc flash boundary distance, PPE category or required arc rating, nominal system voltage, and assessment date

- Responsibility: Equipment owner (your facility)

- Compliance standard: NFPA 70E (workplace safety standard)

Comparison Table: Two Labels, Two Purposes

| Aspect | Generic Warning Label (NEC 110.16) | Detailed Arc Flash Label (NFPA 70E 130.5(H)) |

|---|---|---|

| Primary Purpose | Warn of potential hazard existence | Provide specific protective measures |

| Information Content | “Danger/Warning – Arc Flash Hazard” | Incident energy, boundary, PPE category, voltage, date |

| Who Applies It | Manufacturer or installer | Equipment owner (after commissioning) |

| When Applied | At manufacturing or installation | After system energization and arc flash study |

| Calculation Required | No | Yes (IEEE 1584 analysis) |

| Update Frequency | Permanent (unless equipment changed) | Every 5 years or when system changes |

| Code/Standard | NEC 110.16 (installation code) | NFPA 70E 130.5(H) (workplace safety) |

| Legal Responsibility | Manufacturer/contractor | Facility owner/employer |

Why OEM Manufacturers Like VIOX Cannot Provide Detailed Arc Flash Data

This isn’t about cutting corners—it’s about physics and safety. Detailed arc flash labels require calculations that depend entirely on your facility’s electrical infrastructure, which doesn’t exist when equipment leaves our factory.

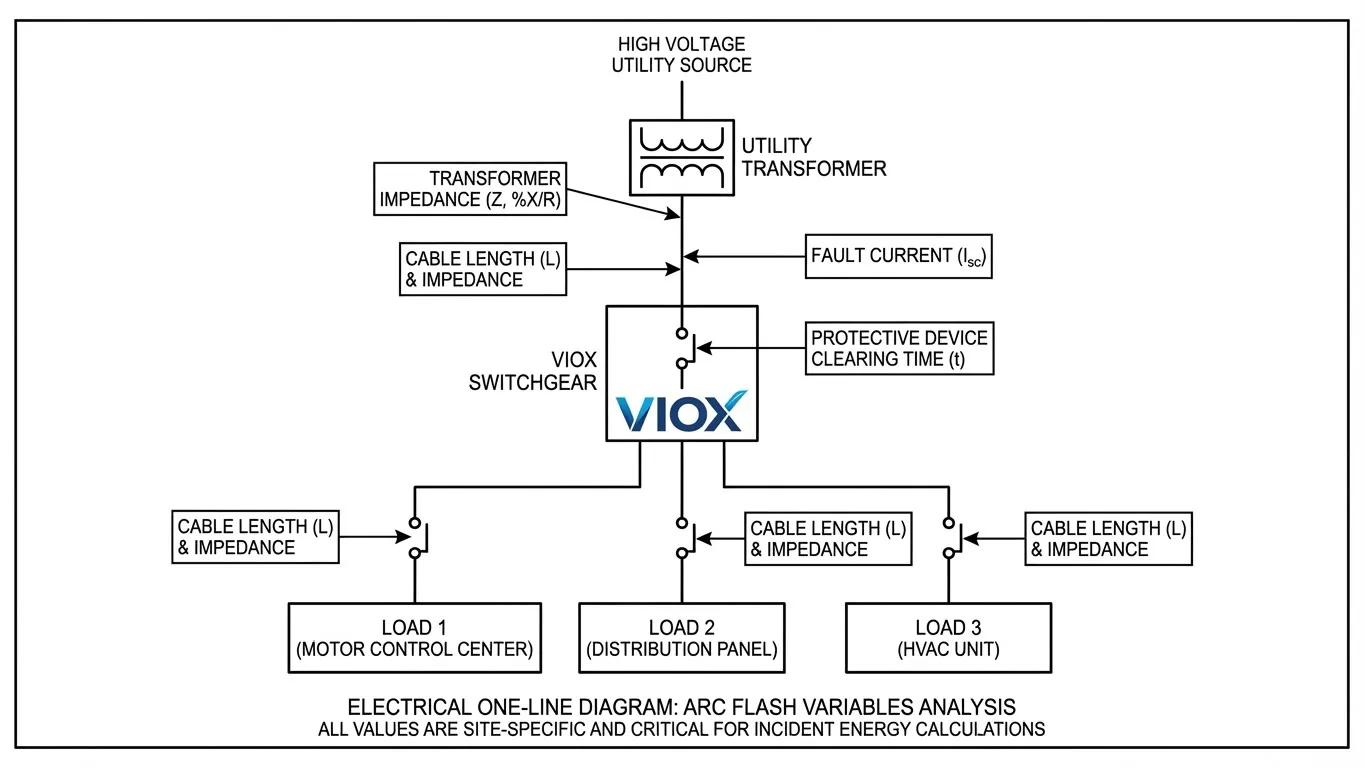

The Variables That Make Factory Labeling Impossible

1. Upstream transformer characteristics

The impedance of your utility or on-site transformer dramatically affects available fault current. A 1500 kVA transformer with 5.75% impedance produces different fault levels than one with 3.5% impedance.

2. Cable length and conductor size

Electrical distance matters. Installing VIOX equipment 50 feet from the transformer yields vastly different incident energy than 500 feet away. Cable impedance reduces available fault current over distance.

3. Utility fault current data

Your utility company’s available fault current at the service point is site-specific. This data doesn’t exist until your facility is connected to the grid.

4. Protective device settings

The clearing time of upstream breakers or fuses directly impacts incident energy calculations. How your system protection is coordinated affects how long an arc fault persists.

5. Working distance

Different equipment configurations and maintenance procedures result in varying working distances, which affect incident energy exposure at the worker’s location.

What IEEE 1584 Calculations Actually Require

Arc flash incident energy calculations follow IEEE 1584 methodology, which requires:

- Three-phase bolted fault current (from short circuit study)

- Equipment type and enclosure dimensions

- Gap between conductors

- Working distance

- Protective device clearing time (from time-current coordination)

None of these parameters exist in a vacuum. They emerge only when your complete electrical system is designed, installed, and energized.

The NEC 2026 Game Changer: Expanded Labeling Requirements

Previous NEC editions only required labels on service equipment rated 1200A or higher. The 2026 NEC Section 110.16 dramatically expands this scope. Now, arc flash hazard markings are required on virtually all electrical equipment that may be serviced while energized in non-dwelling locations.

What Changed in NEC 2026

The new requirements specify that labels must include:

- Nominal system voltage

- Arc flash boundary

- Either available incident energy OR arc flash PPE category (not both)

- Date of assessment

Critically, these labels must be permanent, meeting durability standards in NEC 110.21(B). Handwritten labels no longer comply.

Alignment With NFPA 70E

The 2026 NEC changes align installation requirements more closely with NFPA 70E workplace safety standards. However, the responsibility split remains: NEC governs installation requirements (generic warnings), while NFPA 70E governs workplace safety requirements (detailed hazard data).

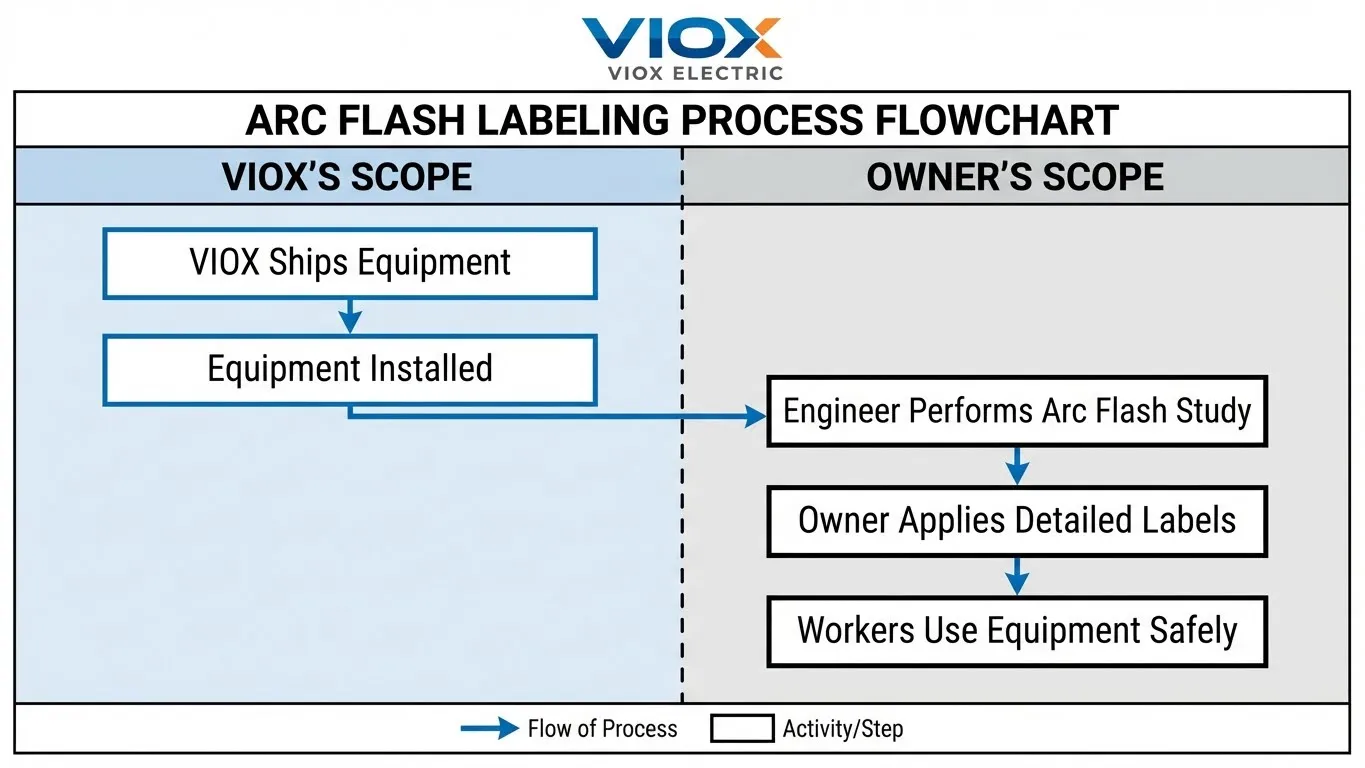

VIOX’s Responsibility vs. Your Responsibility: The Clear Division

Understanding who does what eliminates confusion and ensures compliance.

What VIOX Provides

1. NEC-compliant generic warning labels

Every VIOX switchgear, panelboard, and motor control center ships with factory-installed warning labels meeting NEC 110.16 requirements. These durable labels alert workers to potential arc flash and shock hazards.

2. Equipment specifications

Complete technical documentation including:

- Bus ampacity ratings

- Short circuit ratings (SCCR)

- Protective device specifications

- Equipment dimensions and enclosure type

- One-line diagram showing equipment arrangement

3. Label mounting locations

Strategic placement areas designed for customer-applied detailed arc flash labels. These locations provide visibility, durability, and code compliance.

4. Installation and maintenance documentation

Comprehensive manuals that guide proper installation, which affects system performance and safety.

What Equipment Owners Must Provide

1. Arc flash hazard analysis

Hire a qualified electrical engineer to perform IEEE 1584 calculations for your complete electrical system. This analysis determines:

- Available fault current at each location

- Incident energy levels

- Arc flash boundaries

- Required PPE categories

2. Site-specific arc flash labels

Based on the engineering study, apply durable labels to equipment showing calculated hazard levels. These labels must comply with NFPA 70E 130.5(H).

3. Worker training

Ensure electrical workers understand arc flash hazards, can interpret labels, and know how to select appropriate PPE based on incident energy or PPE category information.

4. Label updates

Review and update arc flash labels every five years or whenever electrical system modifications occur that could affect fault current or protective device settings.

Practical Guidance for VIOX Customers

Step 1: Accept Equipment With Generic Labels

When your VIOX equipment arrives with generic warning labels, verify they’re present and legible. This is baseline NEC compliance that VIOX provides.

Step 2: Commission Your Electrical System

Complete all installation work, energize the system, and verify protective device settings match design specifications.

Step 3: Contract an Arc Flash Study

Engage a qualified electrical engineer (P.E. with arc flash expertise) to:

- Model your complete electrical system

- Calculate incident energy at each equipment location

- Determine arc flash boundaries

- Specify PPE requirements

Step 4: Apply Site-Specific Labels

Use durable, industrial-grade labels that meet NEC 110.21(B) requirements. Labels must withstand the equipment’s operating environment (temperature, humidity, UV exposure, cleaning chemicals).

Step 5: Train Your Workforce

Ensure workers can interpret arc flash labels and understand how to select appropriate PPE based on PPE categories or incident energy ratings.

Step 6: Maintain Label Accuracy

Update labels whenever:

- Electrical system modifications occur

- Equipment is added or replaced

- Protective device settings change

- Five years elapse since last update

How VIOX Supports Your Arc Flash Compliance

While VIOX cannot provide detailed arc flash calculations, we offer value-added services that facilitate your compliance:

Pre-Applied Label Mounting Zones

VIOX equipment includes dedicated areas for customer-applied arc flash labels. These locations ensure:

- Visibility to workers accessing equipment

- Protection from damage during normal operations

- Compliance with OSHA and NFPA 70E placement guidelines

Complete Technical Documentation

Every VIOX product ships with specifications needed for accurate arc flash studies:

- Equipment short-circuit ratings

- Bus and conductor configurations

- Enclosure dimensions

- Protective device coordination data

Engineering Support

VIOX technical support can answer questions about equipment specifications that engineers need for arc flash calculations. We bridge the gap between equipment capabilities and site requirements.

Optional Label Kits

VIOX offers accessory kits containing:

- Blank, durable label stock meeting NEC 110.21(B)

- Label templates showing required data fields

- Mounting instructions

- Protective laminate overlays

These professional-grade materials ensure your site-specific labels match VIOX equipment quality standards.

Frequently Asked Questions

Q: Can VIOX provide “estimated” arc flash data based on typical installations?

A: No. Providing estimated arc flash data without site-specific analysis violates fundamental safety principles and could expose workers to inadequate protection. Arc flash incident energy varies dramatically based on your unique electrical system configuration. Generic estimates are dangerous and non-compliant with NFPA 70E, which requires calculations based on actual system conditions.

Q: How much does an arc flash study typically cost?

A: Arc flash studies typically range from $3,000 to $15,000+ depending on facility size and complexity. Factors affecting cost include: number of equipment locations requiring analysis, electrical system complexity, availability of existing documentation (one-line diagrams, protective device settings), and whether short-circuit studies already exist. This investment protects workers and demonstrates OSHA compliance.

Q: What happens if we operate equipment without detailed arc flash labels?

A: Operating without proper arc flash labels violates NFPA 70E requirements and exposes workers to unknown hazards. OSHA can cite facilities for failing to provide adequate hazard information to employees. More importantly, workers cannot select appropriate PPE without incident energy or PPE category data, creating serious injury risk. In the event of an arc flash incident, lack of proper labeling could result in regulatory penalties and legal liability.

Q: Can we use NFPA 70E table methods instead of detailed calculations?

A: NFPA 70E Table 130.7(C)(15) allows simplified PPE selection for specific tasks and equipment configurations meeting defined parameters. However, this method has strict limitations and may overestimate or underestimate actual hazards. Most facilities benefit from engineered incident energy analysis using IEEE 1584 methodology, which provides accurate, equipment-specific data. The table method should only be used when qualified personnel verify all table parameters match actual conditions.

Q: How often must arc flash labels be updated?

A: NFPA 70E requires arc flash labels be reviewed for accuracy at intervals not exceeding five years. However, updates are mandatory whenever electrical system changes occur that could affect incident energy calculations, including: adding or removing equipment, changing protective device settings, modifying utility service, altering conductor lengths or sizes, or replacing transformers. System modifications typically trigger immediate label updates, not waiting for the five-year cycle.

Q: What PPE is required if there’s no arc flash label on equipment?

A: Without specific arc flash data, workers must assume worst-case hazards and wear maximum available protection or avoid working on energized equipment entirely. NFPA 70E requires employers to ensure workers have hazard information before performing tasks on or near energized equipment. If labels are missing, work should stop until proper arc flash analysis determines actual hazard levels. This protects workers and ensures regulatory compliance.

Q: Does VIOX equipment meet arc flash safety standards?

A: VIOX equipment is designed and tested to meet applicable short-circuit current ratings (SCCR) and includes appropriate protective devices. However, “arc flash safety” depends on how equipment is applied in your specific electrical system. VIOX provides equipment with proper ratings and generic warnings. Achieving workplace arc flash safety requires owners to perform site-specific analysis, apply detailed labels, train workers, and provide appropriate PPE—responsibilities that fall to the equipment owner per NFPA 70E standards.

Conclusion: Partnership in Safety Compliance

Arc flash labeling represents a shared responsibility between equipment manufacturers and owners. VIOX delivers code-compliant equipment with generic warning labels that alert workers to potential hazards—fulfilling our manufacturing obligations under NEC 110.16.

The detailed arc flash analysis and labeling required by NFPA 70E falls to equipment owners because these calculations depend entirely on site-specific electrical system characteristics that don’t exist until equipment is installed and energized. This division of responsibility isn’t bureaucratic red tape—it reflects the fundamental physics of electrical systems and ensures workers receive accurate, actionable safety information.

VIOX partners with customers by providing comprehensive technical documentation, equipment designed for safe maintenance access, dedicated label mounting locations, and engineering support. We understand that arc flash compliance involves complex calculations and significant planning. Our commitment extends beyond delivering quality electrical equipment to supporting your facility’s complete safety program.

When you choose VIOX equipment, you’re selecting a manufacturer that understands the nuances of arc flash safety, respects the boundaries of appropriate labeling responsibility, and provides the technical foundation for your successful NFPA 70E compliance program.

Ready to discuss your next electrical equipment project? Contact VIOX Electric’s technical sales team to learn how our products support your facility’s arc flash safety requirements.