Key Takeaways

- Global Standard: DIN rail is the universal industry standard (IEC 60715) for mounting electrical components in control panels, ensuring cross-brand compatibility.

- Primary Types: The most common profile is the TS35 (Top Hat) rail, followed by TS15 (Miniature) and TS32 (G-Section) for specific applications.

- Material Matters: Standard rails are zinc-plated steel for strength, while aluminum offers lightweight options and stainless steel provides corrosion resistance.

- Efficiency: DIN rail systems reduce installation time by up to 50% compared to panel mounting, offering high-density organization and modular flexibility.

- Critical Specs: Selection depends on load capacity, environmental conditions, and the specific depth requirements (7.5mm vs. 15mm) of your components.

Introduction

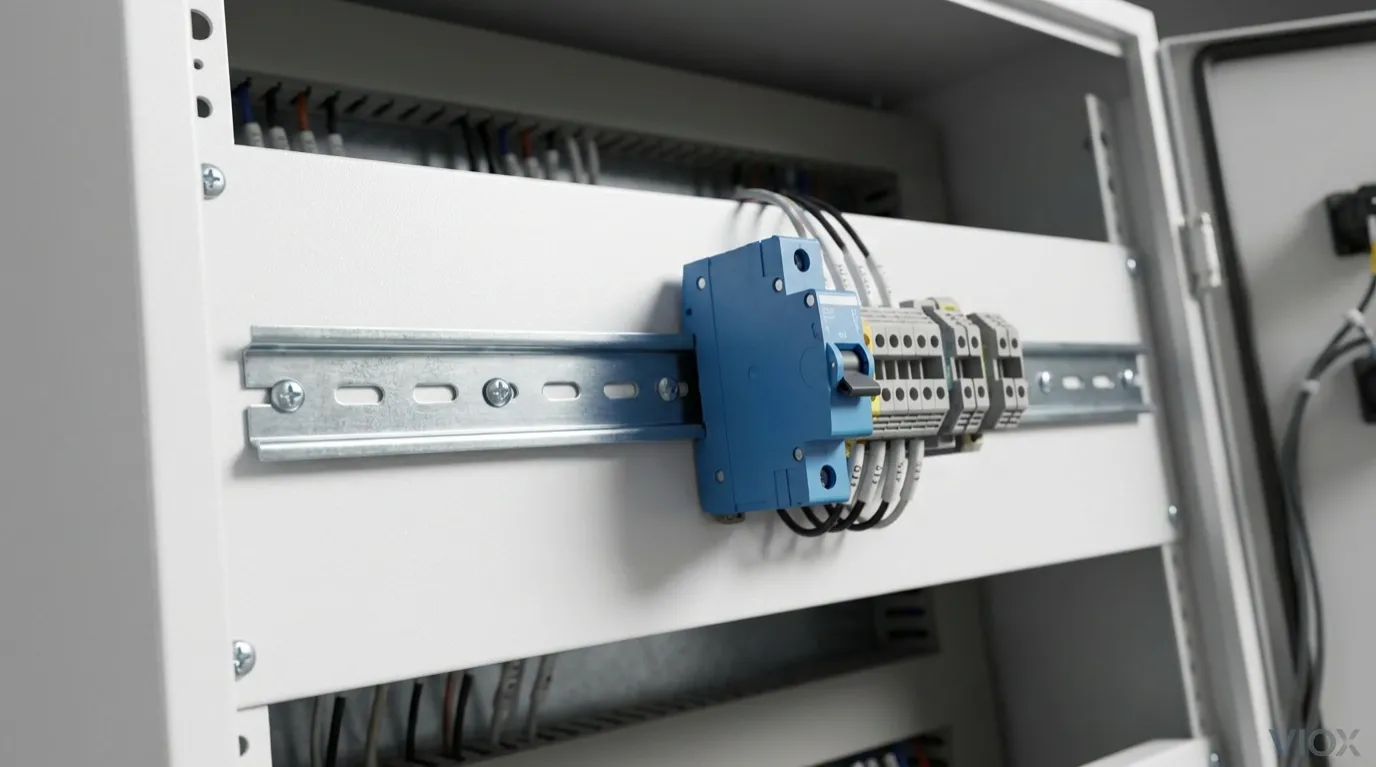

In the world of industrial automation and electrical engineering, few components are as ubiquitous yet critical as the DIN rail. If you open any electrical cabinet, control panel, or distribution box anywhere in the world, you will likely find this standardized metal strip serving as the structural backbone of the system.

But what exactly is a DIN rail, and how did a simple metal strip become the global standard for mounting electrical equipment?

A DIN rail is a standardized metal rail used to mount circuit breakers, terminal blocks, programmable logic controllers (PLCs), and other industrial control equipment inside equipment racks. By providing a universal mounting platform, it allows engineers to mix and match components from different manufacturers—Siemens, ABB, Schneider, or VIOX—without worrying about mechanical compatibility.

This guide explores the technical specifications, types, and best practices for DIN rail systems, helping you select and install the right infrastructure for your electrical projects.

What is DIN Rail? Definition and Origins

The term “DIN” is an acronym for Deutsches Institut für Normung (German Institute for Standardization). While it is now a global standard, the concept originated in Germany in the late 1920s.

Historical Context

The first DIN rail specifications were developed in 1928 by the RWE (Rheinisch-Westfälisches Elektrizitätswerk) to standardize the mounting of electrical components in their facilities. Before this, components were often bolted directly to the panel backplate, a time-consuming process that made maintenance and replacement difficult.

The system was so effective that it was adopted by the German standard DIN 46277. In the 1950s and 60s, as European industrialization surged, the standard spread across the continent (becoming EN 50022) and eventually became the international standard IEC 60715.

The Modern Standard: IEC 60715

Today, the manufacturing and dimensions of DIN rails are governed primarily by IEC 60715 (Dimensions of low-voltage switchgear and controlgear – Standardized mounting on rails). This standard ensures that a 35mm breaker bought in Japan will fit perfectly onto a rail manufactured in Germany or the USA.

Types of DIN Rails and Specifications

While “DIN rail” is often used as a catch-all term, there are several distinct profiles designed for different load capacities and component sizes. Choosing the wrong profile can lead to mechanical failure or fitment issues.

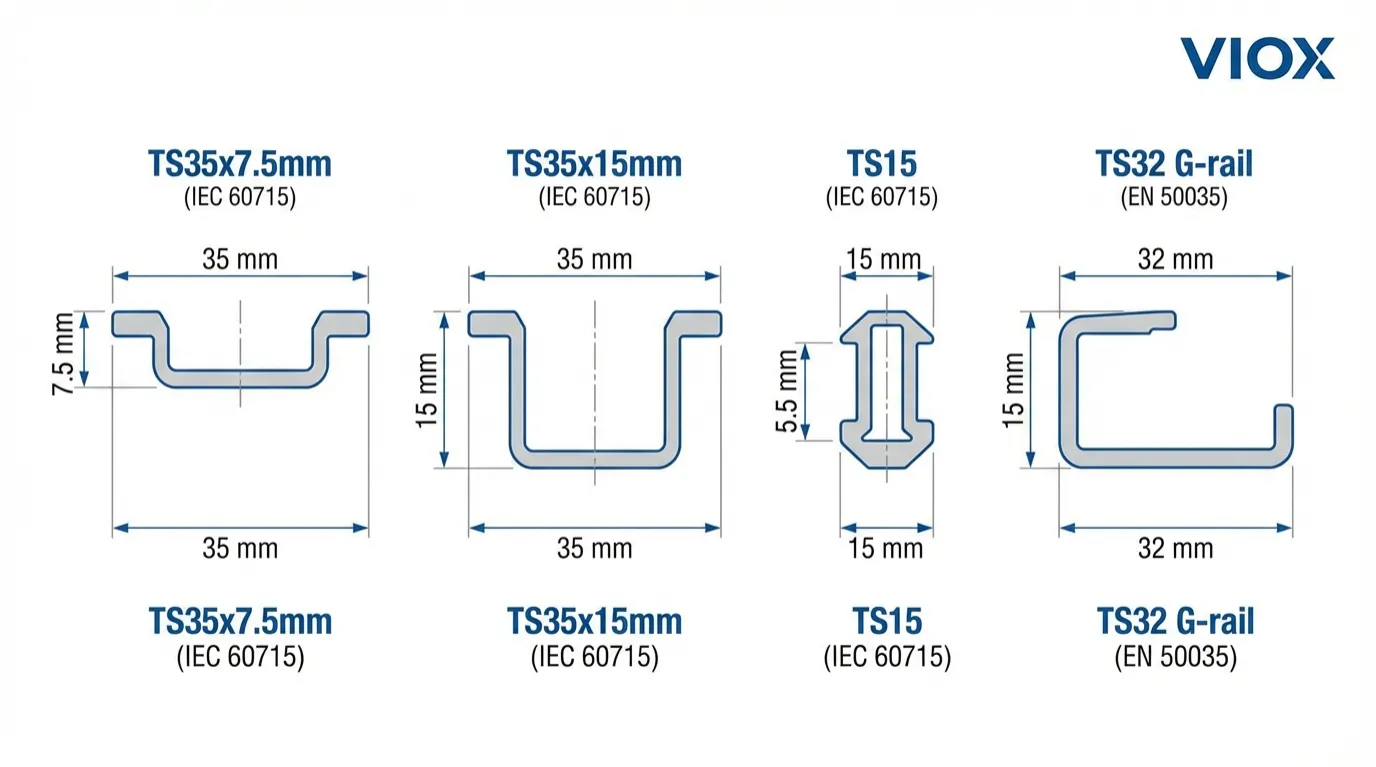

1. Top Hat Rail (TS35)

The TS35 is the industry workhorse, accounting for the vast majority of modern installations. It features a symmetrical, hat-shaped cross-section.

- Standard: IEC 60715 / EN 50022

- Width: 35mm

- Depths:

- 7.5mm (TS35x7.5): The standard depth for general applications (terminal blocks, miniature circuit breakers).

- 15mm (TS35x15): A “deep” version used for heavy components (large PLCs, transformers) requiring extra rigidity.

- Usage: Circuit breakers, PLCs, motor soft starters, relays.

2. Miniature Top Hat Rail (TS15)

The TS15 is a smaller version of the top hat rail, used where space is extremely limited.

- Standard: IEC 60715 / EN 50045

- Width: 15mm

- Depth: 5.5mm

- Usage: Junction boxes, compact terminal blocks, miniature relays.

3. G-Section Rail (TS32)

The TS32 or “G-rail” has an asymmetrical, G-shaped profile. It was the original standard before TS35 took over but is still used for specific heavy-duty applications.

- Standard: EN 50035

- Width: 32mm

- Features: The asymmetrical shape prevents components from being installed in reverse (polarity protection). The curved lip offers high structural strength.

- Usage: Heavy contactors, large transformers, legacy equipment.

4. C-Section Rail

C-section rails are C-shaped and often used for physical support rather than snapping on electronic components, though some terminal blocks are designed for them.

- Widths: 20mm, 30mm, 40mm, 50mm.

- Usage: Cable clamps, physical support structures, specific terminal block types.

DIN Rail Comparison Table

| Type | Designation | Width | Depth | Tolerance (IEC 60715) | Standard | Typical Application |

|---|---|---|---|---|---|---|

| Top Hat | TS35x7.5 | 35mm | 7.5mm | Width ±0.2mm, Depth ±0.15mm | IEC 60715 | MCBs, PLCs, Relays (Standard) |

| Deep Top Hat | TS35x15 | 35mm | 15mm | Width ±0.2mm, Depth ±0.2mm | IEC 60715 | Heavy components, Vibration environments |

| Miniature | TS15 | 15mm | 5.5mm | Width ±0.15mm, Depth ±0.1mm | IEC 60715 | Compact junction boxes, Small terminals |

| G-Section | TS32 | 32mm | 15mm | Width ±0.2mm, Depth ±0.2mm | EN 50035 | Heavy-duty, Polarity-sensitive devices |

For a deeper dive into selecting the right rail for your specific needs, read our guide on How To Choose The Right DIN Rails.

Material Specifications and Manufacturing

The material of the DIN rail dictates its mechanical strength, corrosion resistance, and electrical conductivity (for grounding).

1. Cold Rolled Carbon Steel

- Finish: Zinc-plated with clear or yellow chromate passivation.

- Pros: High strength, low cost, excellent magnetic properties.

- Best For: General industrial panels, dry environments.

2. Aluminum

- Finish: Anodized or plain.

- Pros: Lightweight, easy to cut, non-magnetic.

- Best For: Transport applications (trains, marine), weight-sensitive enclosures.

3. Stainless Steel (AISI 304/316)

- Finish: Polished or natural.

- Pros: Superior corrosion resistance.

- Best For: Chemical plants, offshore oil rigs, food processing facilities.

4. Copper

- Usage: Primarily used as a grounding busbar (PE rail) rather than for mechanical support.

- Pros: High electrical conductivity.

Perforated vs. Unperforated

- Perforated (Slotted): Features pre-punched holes/slots along the length. Easier to install as no drilling is required.

- Unperforated (Solid): Must be drilled by the installer. Offers slightly higher structural rigidity and can be used where the rail acts as a busbar (though this is rare).

Applications Across Industries

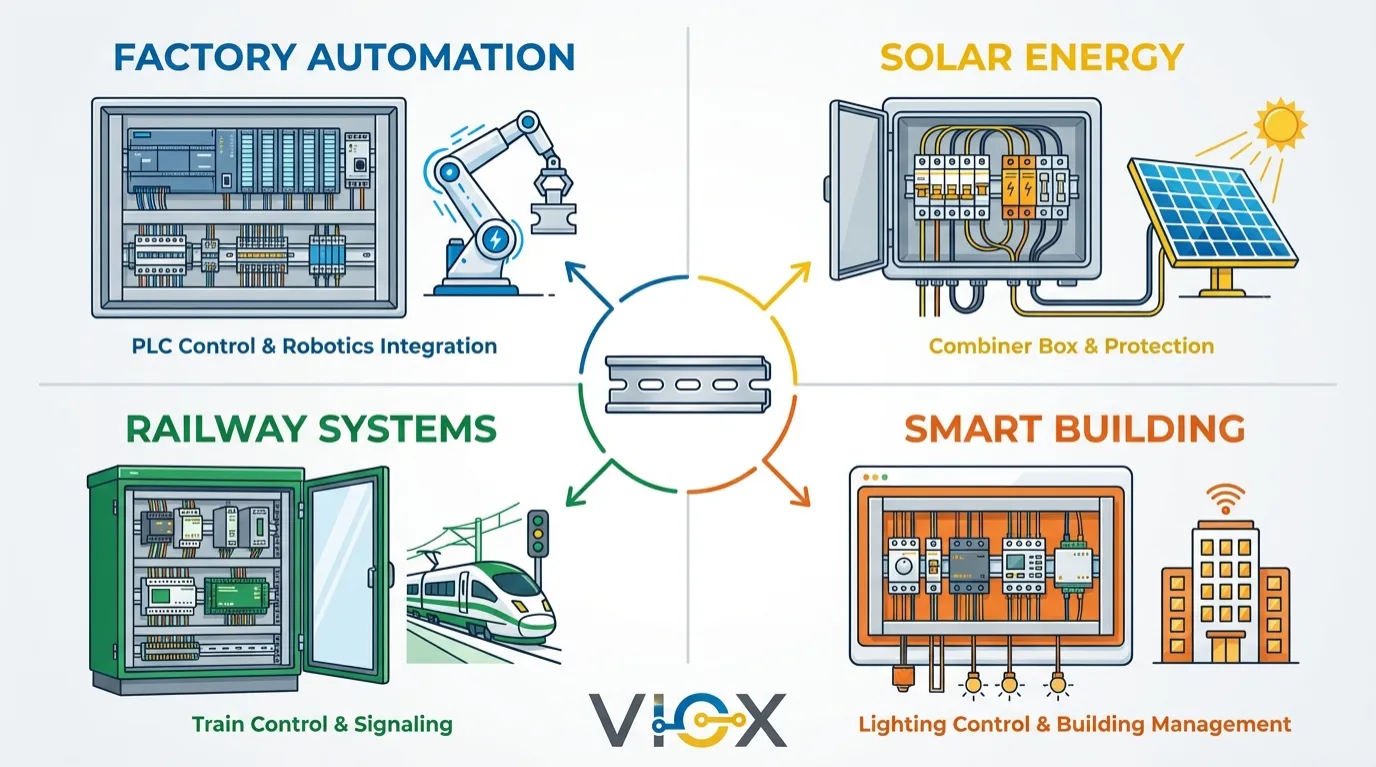

DIN rails have transcended their origins to become essential in virtually every sector that utilizes electricity.

Industrial Automation

In manufacturing plants, DIN rails house the “brains” of the operation. PLCs, I/O modules, and power supplies are snapped onto rails in high-density configurations. The modularity allows for easy replacement of failed components without shutting down the entire panel for extended periods.

Renewable Energy

Solar combiners and wind turbine control boxes rely on DIN rails to mount DC disconnects, fuse holders, and surge protection devices (SPDs). The robust nature of TS35x15 rails is often required here to withstand the vibration in wind turbines.

Building Management Systems (BMS)

Modern smart buildings use DIN rails to mount lighting controllers, HVAC actuators, and energy meters. The compact nature of DIN rail mounting allows these complex systems to fit into standard electrical closets.

Telecommunications

While 19-inch racks are standard for servers, the supporting infrastructure—power distribution units (PDUs), fiber splice boxes, and media converters—often utilizes DIN rail mounting for flexibility within the rack.

Installation Guide: Step-by-Step

Proper installation is crucial for the mechanical stability and safety of the electrical system.

Tools Required

- DIN Rail Cutter (or hacksaw/angle grinder with a deburring tool)

- Tape measure

- Drill and tapping screws (for unperforated rails or panel mounting)

- Spirit level

- PPE (gloves, safety glasses)

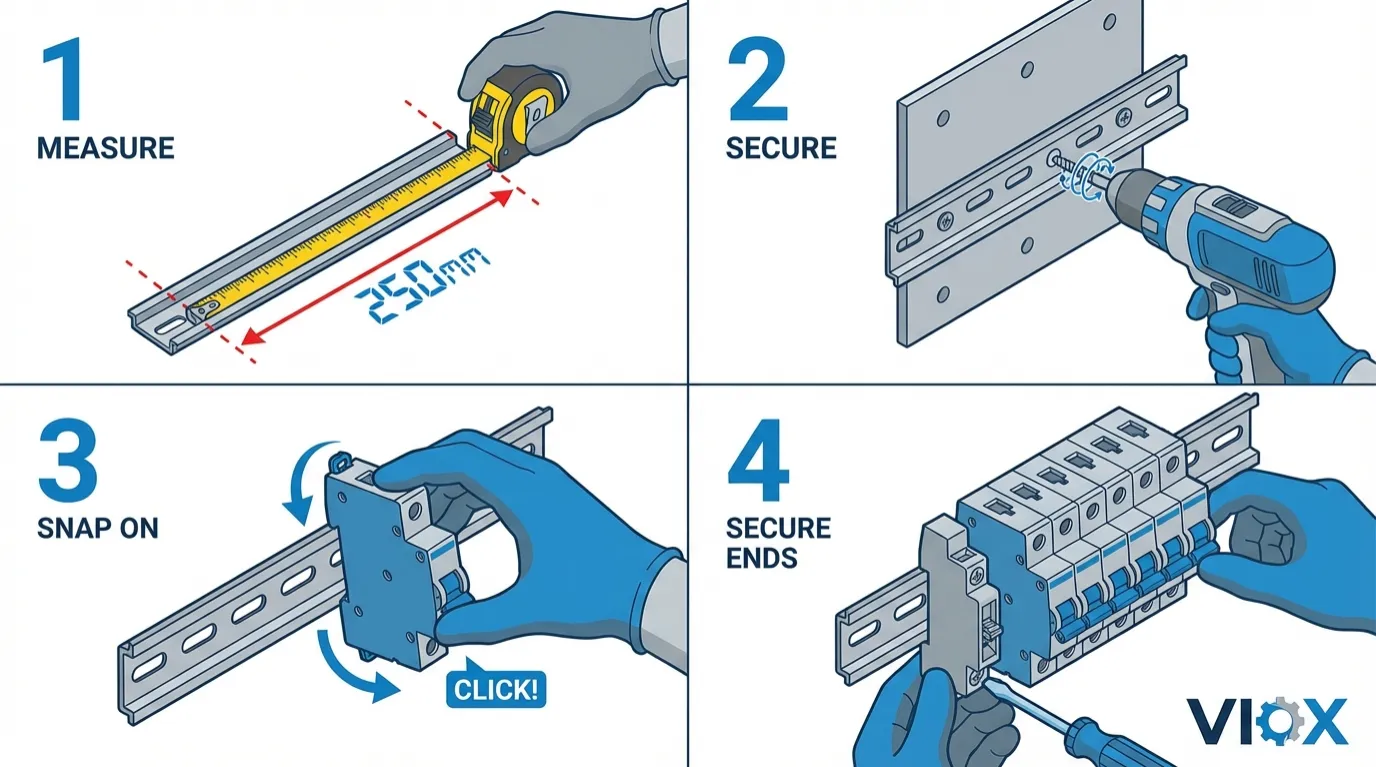

Step 1: Planning and Layout

Determine the layout of your components. Group devices logically (e.g., power input -> protection -> control -> output). Ensure you leave sufficient space between rows for wiring ducts (cable trunking).

Step 2: Measuring and Cutting

Measure the required length. If using a saw, ensure the cut is square. Crucial: Always deburr the cut ends. Sharp edges can damage wire insulation or injure technicians.

Step 3: Mounting the Rail

Secure the rail to the panel backplate.

- Spacing: For standard 35mm rail, mounting screws are typically placed every 200mm to 250mm to prevent flexing under load.

- Leveling: Use a spirit level to ensure the rail is perfectly horizontal.

Step 4: Grounding

If the DIN rail is used as a grounding path (protective earth), ensure the contact between the rail and the backplate is conductive (remove paint if necessary) or use a dedicated grounding terminal block clamped to the rail.

⚠️ CRITICAL SAFETY WARNING: DIN rails are NOT busbars. While they can provide a path to ground (PE – Protective Earth), they are NOT designed to carry load current (Neutral or Phase conductors) unless explicitly specified by the manufacturer. Using a DIN rail as a current-carrying conductor can result in overheating, fire hazard, and electrical shock. Always consult manufacturer specifications and local electrical codes.

Step 5: Installing Components

Snap components onto the rail.

- Top-to-Bottom: Hook the top lip of the component onto the top edge of the rail, then push down and in until the bottom clip snaps into place.

- End Stops: Always install end clamps (end stops) at both ends of a component row. This prevents devices from sliding laterally, which can loosen wire connections.

For a comparison of this method versus older techniques, see DIN Rail vs. Traditional Mounting.

Selection Criteria and Best Practices

To ensure a long-lasting installation, consider these factors:

1. Load Capacity

For heavy components (transformers, large drives), use TS35x15 (15mm deep) rails or G-rails. Standard 7.5mm rails may twist or sag under heavy weight, potentially causing components to pop off.

2. Environmental Conditions

- High Humidity/Outdoor: Use Stainless Steel or Aluminum.

- Vibration (e.g., Railway, Marine): Use deep rails (TS35x15) and heavy-duty end stops. Ensure components are rated for vibration and securely locked.

3. Galvanic Compatibility

Avoid mixing dissimilar metals that can cause galvanic corrosion. For example, mounting an aluminum rail directly onto a bare copper surface in a humid environment can lead to corrosion.

DIN Rail Manufacturing Process

To better understand the precision and quality that goes into DIN rail production, watch this detailed manufacturing overview from VIOX.com:

This video demonstrates the complete manufacturing workflow—from raw material selection and cold rolling to zinc plating and quality inspection—showcasing the industrial processes that ensure DIN rails meet strict IEC 60715 tolerances.

Advantages of DIN Rail Systems

Why has this system dominated the industry for nearly a century?

- Modularity & Flexibility: Components can be added, removed, or rearranged without drilling new holes in the panel.

- Space Efficiency: DIN rail components are designed to be compact and mount vertically, maximizing the use of panel real estate.

- Reduced Labor Costs: “Snap-on” mounting is significantly faster than screw-mounting individual devices.

- Standardization: A single rail type supports thousands of products from hundreds of vendors.

- Wiring Organization: Works seamlessly with cable trunking systems for clean, traceable wiring.

For more on the benefits, read Top 5 Reasons Why DIN Rails Are Essential in Modern Electrical Installations.

FAQ

Can I cut DIN rail to any length?

Yes, DIN rails are typically sold in 1-meter or 2-meter lengths and can be cut to size. It is recommended to use a specialized DIN rail cutter for a clean, burr-free cut, but a hacksaw or angle grinder works if the edges are filed smooth afterwards.

Does the DIN rail carry current?

Generally, no. The rail is for mechanical support. However, it can conduct fault currents if used as a grounding busbar (PE). Never use the rail as a neutral or phase conductor unless using specialized busbar systems designed for that purpose.

⚠️ Safety Warning: DIN rails are NOT designed to carry load current. Using them as current-carrying conductors (Neutral/Phase) can cause overheating, fire hazards, and electrical shock. Only use DIN rails for grounding (PE) or mechanical support unless the manufacturer explicitly specifies current-carrying capability.

What is the weight limit of a DIN rail?

There is no single “weight limit” as it depends on the mounting screw spacing and the rail profile. A standard TS35x7.5 rail mounted every 200mm can typically support control components easily. For loads exceeding 5kg per device or high-vibration areas, upgrade to a TS35x15 rail and reduce mounting screw spacing.

Why are some DIN rails slotted?

Slotted (perforated) rails have pre-cut holes to make installation easier (no drilling required). Solid (unperforated) rails are stronger and preferred for heavy loads or where the rail is used for grounding continuity.

What is the difference between DIN rail and Unistrut?

DIN rail is for mounting small electrical components (breakers, relays). Unistrut (strut channel) is a much larger structural system used to support conduits, pipes, and heavy equipment frames.

Conclusion

The DIN rail is a testament to the power of standardization. From its humble beginnings in 1920s Germany to its status as the IEC 60715 global standard, it has streamlined the electrical industry, making control panels safer, more organized, and easier to maintain.

Whether you are designing a simple junction box or a complex industrial automation system, understanding the nuances of rail types—from the standard TS35 to the heavy-duty G-rail—is essential. By selecting the right material and profile for your application, you ensure a robust foundation for your electrical infrastructure.

For more insights on pricing and procurement, check out our analysis on Key Factors Influencing DIN Rail Prices.