Your electrical panel is full. You need to add another circuit for a new bedroom, kitchen outlet, or workshop—but there’s nowhere to fit it. Before you call an electrician to quote a $1,200–$3,000 panel upgrade, consider tandem circuit breakers. These ingenious space-saving devices let you fit two independent 120-volt circuits into a single breaker slot, effectively doubling your panel’s capacity without the expense or disruption of a complete replacement.

But here’s the catch: not every panel can use them. Installing a tandem breaker in the wrong panel type creates serious fire risks, code violations, and failed inspections. The difference between a safe upgrade and a dangerous shortcut often comes down to understanding one critical detail: CTL ratings and panel compatibility.

This guide walks you through what tandem breakers are, how they work, when they’re safe to use, and when alternatives make more sense. Whether you’re a homeowner tackling a renovation or an electrician specifying breakers for a retrofit job, you’ll learn the technical standards that determine compatibility—and the practical steps to ensure your installation stays code-compliant and safe.

1: UNDERSTANDING TANDEM BREAKERS—THE FUNDAMENTALS

What Is a Tandem Circuit Breaker?

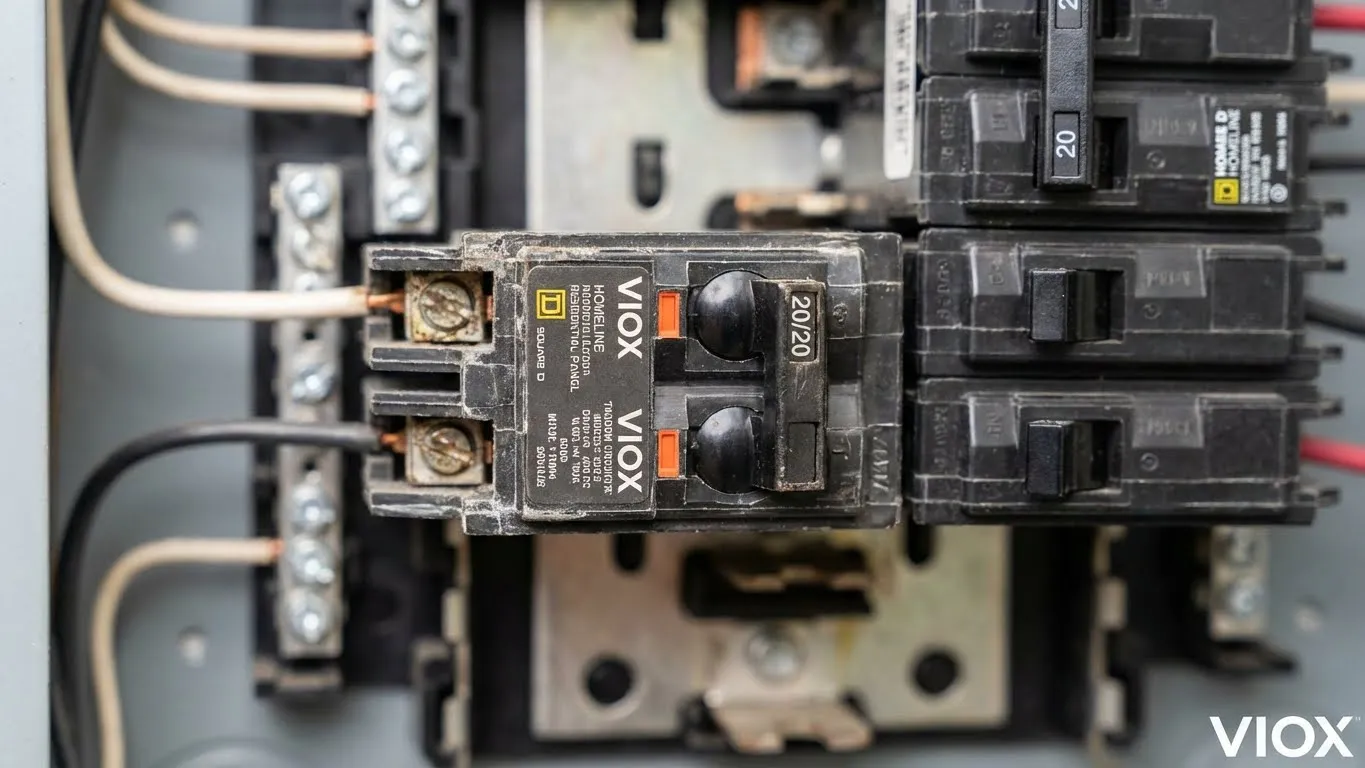

A tandem circuit breaker is a specialized electrical device that houses two independent circuit breakers within a single standard-width breaker housing. Also known as duplex, twin, piggyback, or “double-stuff” breakers, these units occupy just one slot in your electrical panel while providing complete protection for two separate 120-volt circuits.

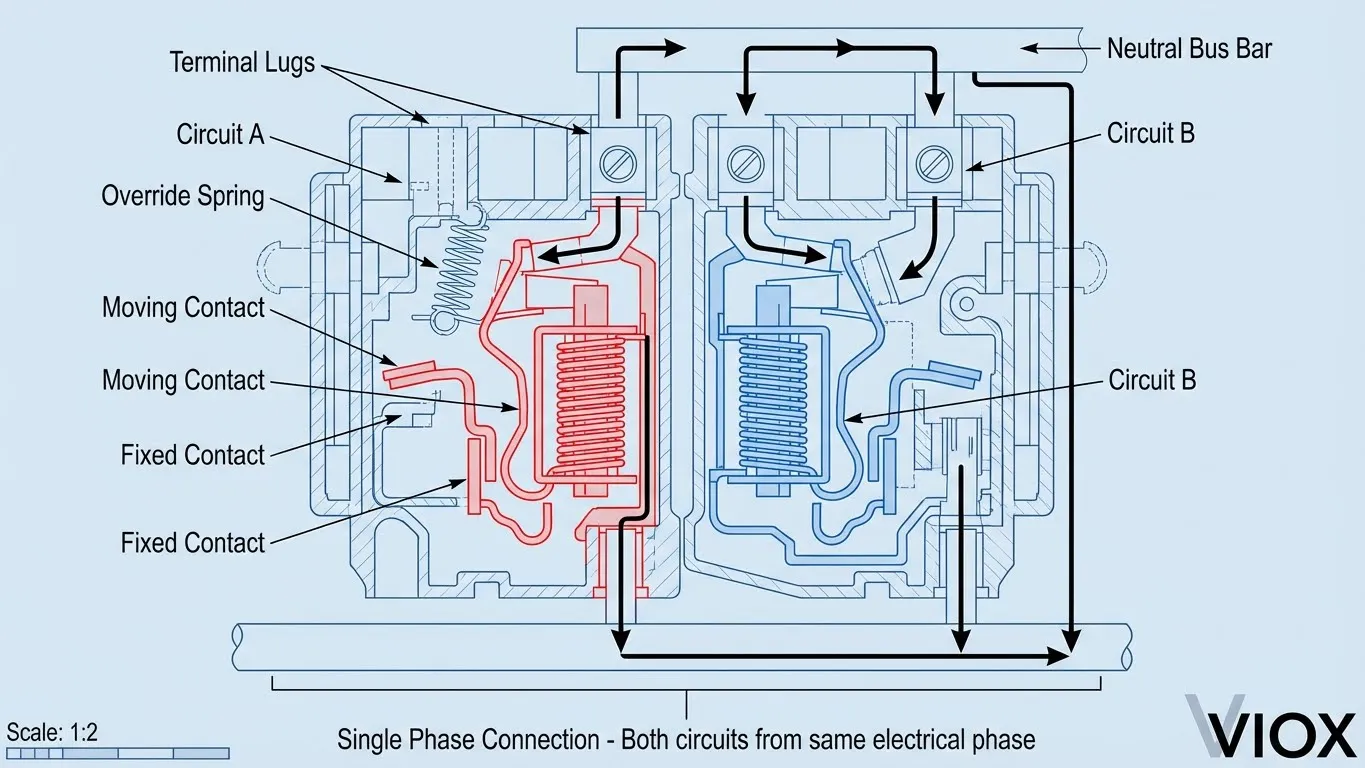

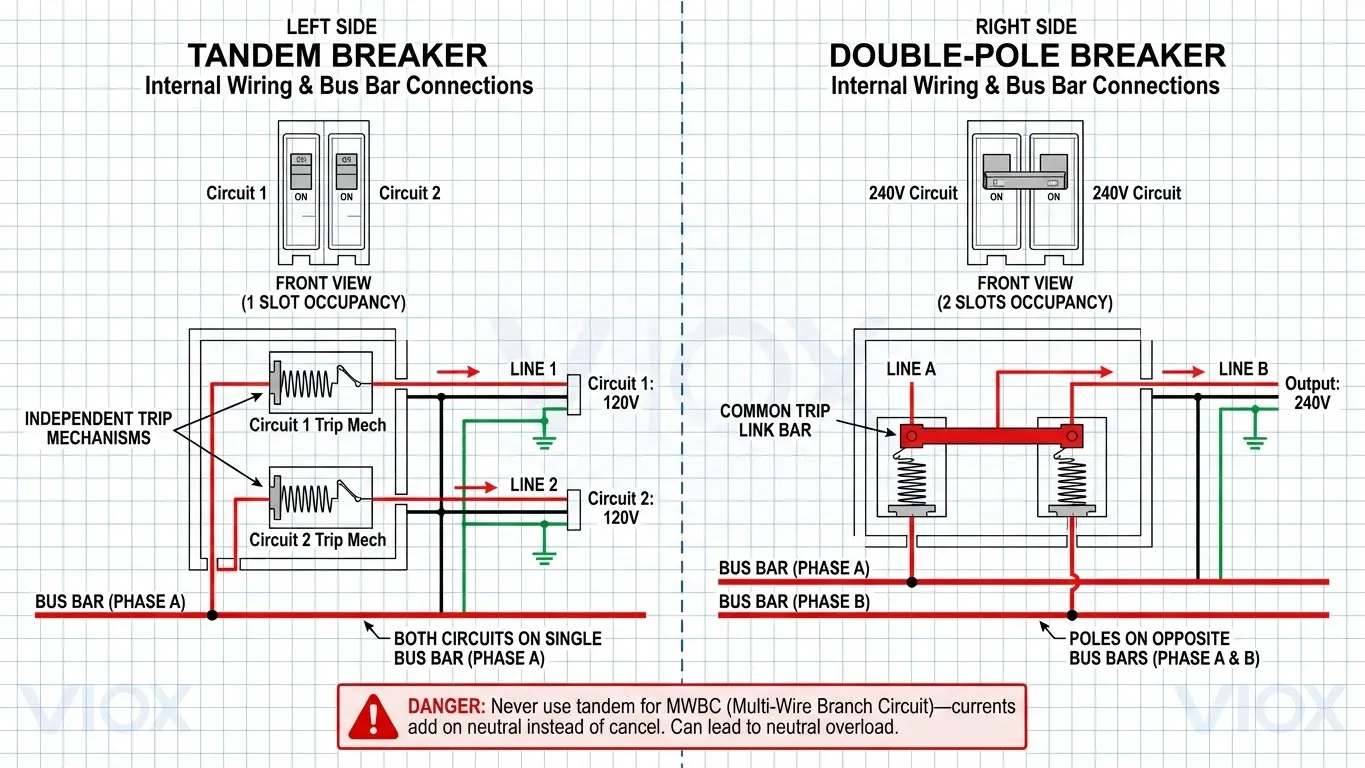

Unlike standard single-pole breakers that protect one circuit, or double-pole breakers that provide 240 volts across two poles, tandem breakers connect to only one pole of your electrical panel’s bus bar. This single-phase connection is crucial—both circuits receive 120 volts independently from the same electrical phase, and each maintains its own trip mechanism. If one circuit experiences an overload or short circuit, only that specific breaker trips while the other continues operating normally.

How Tandem Breakers Work: Internal Architecture

The magic of a tandem breaker lies in its compact internal design. Each unit contains two distinct switching mechanisms housed side-by-side in a single frame. Here’s what makes them function:

Dual Switches & Independent Trip Mechanisms: Each side has its own toggle switch and separate overcurrent-sensing mechanism. These mechanisms operate independently, meaning a fault on one circuit does not affect the other. This is why you can have one breaker in the “tripped” position while the other remains fully operational.

Single Bus Bar Connection: Both circuits connect to one pole of your panel’s alternating current bus bar system. This single-phase connection is why tandem breakers cannot provide 240-volt power—240V circuits require connection to two opposite phases of the electrical system, which only double-pole breakers can deliver.

Neutral Wire Management: Each circuit’s neutral wire connects to the neutral bus bar independently, just like standard breakers. This is critical for safety and distinguishes tandem breakers from multi-wire branch circuit (MWBC) setups, which share a single neutral—a configuration incompatible with tandem breakers.

Amperage Ratings & Configurations

Tandem breakers are available in limited amperage combinations, reflecting their role as light-duty, space-saving solutions:

- 15/15 amp: Common for lighting circuits and standard general-purpose outlets

- 20/20 amp: Popular for kitchen outlets, bathroom circuits, and laundry areas

- 15/20 amp: Mixed configurations where one circuit needs higher capacity than the other

Higher amperage tandems (30 or 50-amp) are not manufactured because heavy-duty loads require either dedicated full-size breakers or double-pole configurations for 240-volt operation.

2: CTL vs. NON-CTL—THE COMPATIBILITY BREAKTHROUGH

Understanding the difference between CTL and Non-CTL breakers is essential for safe tandem breaker installation. This distinction separates code-compliant installations from dangerous shortcuts.

What CTL Means: Circuit Total Limiting Standard

CTL (Circuit Total Limiting) is a UL safety standard established around 1965 to enforce the National Electrical Code’s 42-circuit limit for residential “lighting and appliance” panels. The standard was designed to prevent panel overloading by restricting the total number of circuits that could be installed, regardless of physical slot count.

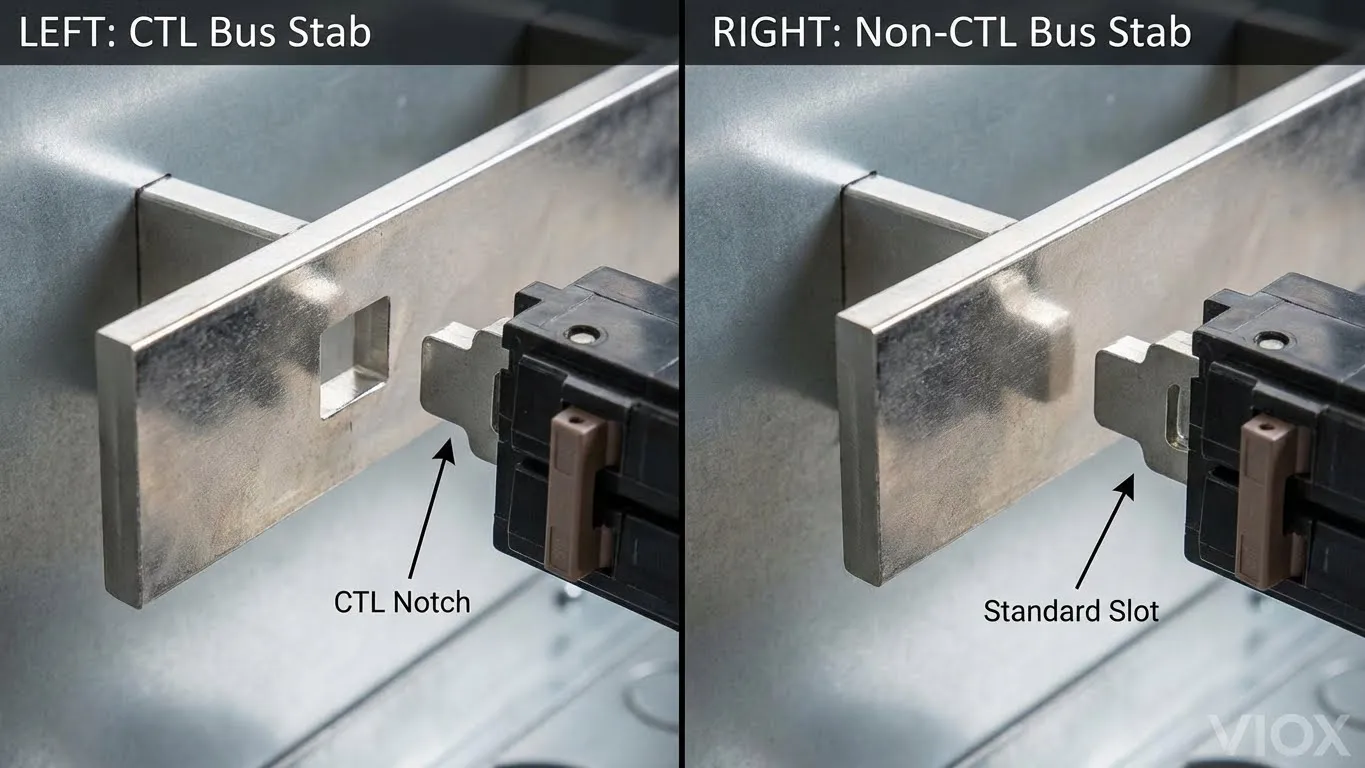

CTL Rejection Features: Modern CTL-rated breakers and panels include physical “rejection” mechanisms that only allow breakers to fit in designated slots. These rejection features take several forms depending on manufacturer:

- Notched bus stabs: A square notch cut into the metal prong where breakers connect

- Modified mounting rails: Different hook depths that only accept compatible breaker types

- Breaker clip design: Tandem breakers have clips shaped to fit only notched slots

These features physically prevent installation in unauthorized locations, making it literally impossible to force a CTL tandem breaker into a standard slot.

Non-CTL Breakers: Replacement-Only Legacy Standard

Non-CTL breakers lack rejection features and are labeled “For replacement use only.” These older breakers were designed for panels manufactured before 1965 that don’t have CTL safety restrictions. Using a Non-CTL breaker in a modern CTL panel is:

- A code violation (NEC 110.3(B))

- A failed inspection

- A potential fire hazard (bypasses engineered safety limits)

Some electricians install Non-CTL breakers by breaking off the rejection clip from a CTL breaker—a practice called using a “cheater” breaker. This is dangerous because it defeats the manufacturer’s engineering controls designed to prevent overloading.

NEC 2008 Update: The 42-Circuit Limit Removed

The National Electrical Code removed the 42-circuit limit in 2008, allowing manufacturers to design panels with 60, 84, or even more circuits. However, this does not eliminate CTL requirements. Modern panels still must be installed according to their specific manufacturer listing (NEC 110.3(B)), and compatibility is determined by each panel model’s design, not by a universal rule.

3: IDENTIFYING PANEL COMPATIBILITY

Before purchasing a tandem breaker, you must verify that your electrical panel is designed to accept it. Here’s how to check:

Check #1: The Panel Model Number

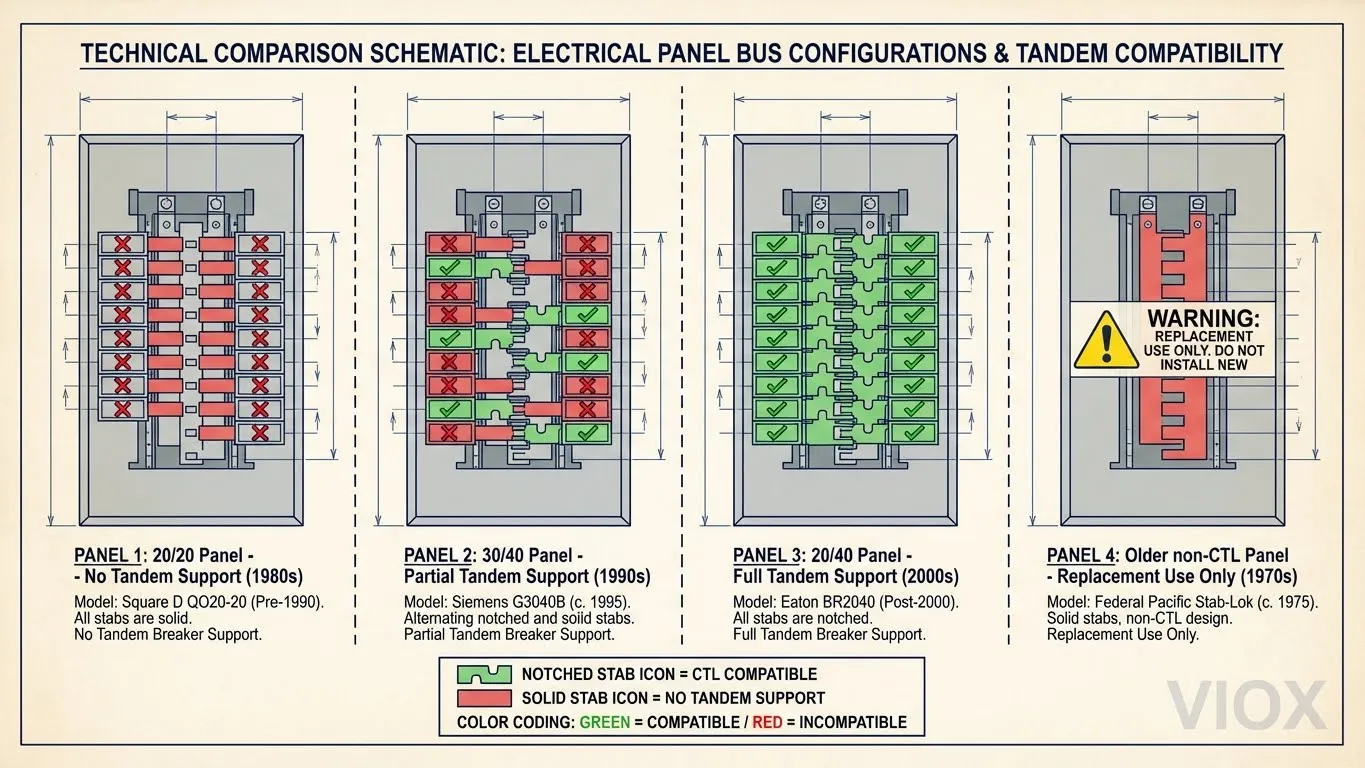

Manufacturers use a “spaces/circuits” naming convention that instantly reveals tandem compatibility:

| Model Number | Meaning | Tandem Breaker Support? |

|---|---|---|

| 20/20 | 20 slots, 20 circuits allowed | ❌ No tandems |

| 30/40 | 30 slots, 40 circuits allowed | ✅ Yes, 10 slots support tandems |

| 20/40 | 20 slots, 40 circuits allowed | ✅ All slots support tandems |

| 40/50 | 40 slots, 50 circuits allowed | ✅ Yes, 10 slots support tandems |

If your panel number is 20/20, 20/30, or 30/30 (where slots equal max circuits), your panel does not support tandem breakers. The “higher second number” indicates tandem-capable slots exist.

Check #2: Inspect the Bus Bar Notches

Open your panel door (safely) and look at the metal tabs where breakers connect.

- Notched bus stabs (square notch cut into the center): Designed for CTL tandem breakers ✅

- Solid rectangular tabs: Standard slots only, no tandem support ❌

Different brands use different rejection designs, but a visual inspection usually confirms compatibility quickly.

Check #3: Review the Panel Diagram

The label inside your panel door includes a wiring diagram. Slots that accept tandem breakers are often marked with a dividing line or highlighted region. This diagram is definitive—if it’s unclear, photograph it and consult the panel manufacturer’s documentation online.

Manufacturer-Specific Compatibility

Common residential panel brands and their tandem support:

- Square D QO/Homeline: Widely compatible with CTL tandems

- Eaton BR/CH: Supports CTL tandems; modern BR panels often support all-tandem configurations

- Siemens QW/Q-Line: Compatible with CTL tandems; also offers Non-CTL (“NC” suffix) for older panels

- GE THQL: Older model with limited tandem slots; check diagram

Always verify against your specific panel’s nameplate and diagram, not just the brand.

4: TANDEM BREAKERS VS. ALTERNATIVES—COMPARISON TABLE

When you need additional circuits, tandem breakers are one of several options. Here’s how they compare:

Option Comparison Matrix

| Feature | Tandem Breaker | Double-Pole Breaker | Subpanel | Panel Upgrade |

|---|---|---|---|---|

| Panel Slots Used | 1 slot | 2 slots | N/A (separate unit) | N/A (replaces existing) |

| Circuits Added | 2 × 120V | 1 × 240V | 8–24+ circuits | 20–40+ circuits |

| Voltage Capacity | Two 120V circuits | One 240V circuit | Flexible | Flexible |

| Installation Cost | $150–$400 | $100–$300 | $500–$1,500 | $1,200–$3,000 |

| Timeframe | 1–2 hours | 1–2 hours | 1–2 days | 1–3 days |

| Future Flexibility | Limited (space-dependent) | Limited (high-amp use only) | Good (expandable) | Excellent (largest capacity) |

| Code Compatibility | Only compatible panels | All modern panels | All codes | All codes |

| AFCI/GFCI Available? | Rarely | Yes | Yes (with proper breakers) | Yes |

| Best For | Adding lights/outlets when panel is full | High-amperage loads (dryer, AC) | Partial capacity expansion | Long-term flexibility |

| Worst Drawback | Only works in compatible panels | Takes 2 slots | Requires subpanel box & conduit | Expensive & invasive |

Key Decision Factors

Use a Tandem Breaker when:

- Your panel is completely full with no remaining standard slots

- You need 1–2 additional 120V circuits for lights or standard outlets

- Your panel is CTL-compatible and has designated tandem slots available

- Budget is a primary concern

- The solution is temporary until a larger upgrade becomes feasible

Use a Double-Pole Breaker when:

- You need to power a 240V appliance (dryer, water heater, air conditioner)

- Your panel has two adjacent empty slots

- The load requires 30–60 amps of capacity

Use a Subpanel when:

- You need 4+ additional circuits

- You want to centralize loads in a specific area (garage, workshop, exterior)

- Future expansion is likely

Upgrade the Main Panel when:

- Your electrical service capacity is insufficient

- You’re adding major new loads (EV charger, heat pump)

- You want future-proof flexibility for 10+ years

5: CRITICAL SAFETY WARNINGS—MWBC & NEUTRAL OVERLOADING

The most dangerous misapplication of tandem breakers involves multi-wire branch circuits (MWBC)—a configuration found in many older homes. Understanding this risk is essential for your safety.

Multi-Wire Branch Circuit (MWBC) Danger

An MWBC is an older wiring method where two separate hot wires share a single neutral wire. Here’s why tandem breakers are incompatible:

Normal MWBC Setup (Wrong with Tandem):

- Hot wire 1 connects to Phase A (say, 15 amps outbound)

- Hot wire 2 connects to Phase B (say, 15 amps outbound)

- The currents are 180° out of phase, so they cancel on the neutral

- Maximum neutral current: ~0–1 amps (safe for a 14 AWG wire)

If You Incorrectly Use a Tandem:

- Both hot wires connect to the same phase (because tandem uses only 1 bus bar connection)

- Both currents flow in the same direction on the neutral

- Current adds together: 15 amps + 15 amps = 30 amps on the neutral

- A 14 AWG neutral wire rated for 15 amps is now carrying 30 amps

- The wire overheats silently—neutral breakers don’t exist, so the breaker never trips

- Result: Electrical fire without any warning

The Solution: Use a Double-Pole Breaker for MWBC

If you have shared-neutral circuits (indicated by breakers on opposite sides of your panel from the same circuit number), always use a double-pole breaker for protection. The common-trip mechanism ensures both hots de-energize together, preventing neutral overloading.

AFCI/GFCI Incompatibility

Modern electrical codes (NEC 2020/2023) require AFCI or GFCI protection for nearly all residential circuits. Tandem breakers are not currently available with these protective features—only full-size breakers offer AFCI/GFCI options. If your area requires AFCI/GFCI protection and your panel cannot fit standard breakers, you may be limited to subpanels or panel upgrades, not tandem solutions.

6: INSTALLATION PROCESS & CODE COMPLIANCE

Professional installation is non-negotiable for electrical panel work. However, understanding the process helps you verify that work is done safely and to code.

Pre-Installation Assessment

Before any work begins:

- Verify Panel Compatibility: Confirm the panel model supports tandem breakers and that designated slots are available

- Load Calculation: Ensure the service entrance (typically 100–200 amps) can safely handle the additional circuits

- Permit Requirements: Check local building codes—most jurisdictions require permits for panel modifications

- Circuit Purpose: Determine the load, wire gauge, and breaker rating needed (typically 15–20 amps, 14–12 AWG wire)

Installation Steps (Professional Only)

- Power Shutdown: The main breaker is switched off; power is verified dead using a multimeter on the bus bars

- Breaker Removal: If replacing an existing breaker, it’s safely removed and the wiring disconnected

- Tandem Installation: The new tandem breaker is clipped into the designated slot (requiring the proper CTL rejection fit)

- Wire Connection: New circuit wiring is connected to the correct terminals—different manufacturers have different terminal positions

- Testing: Power is restored and both circuits are tested for proper voltage and operation

- Inspection: Local inspectors verify the installation meets NEC and local codes

Critical Installation Rules

- Never skip the main breaker off step—electricity can be present even with the main off

- Verify the exact panel model before ordering breakers (QO, BR, and CH breakers are not interchangeable)

- Use proper wire gauge: 15-amp breakers require 14 AWG minimum; 20-amp require 12 AWG

- Test the installation with an approved inspection

7: MAINTENANCE & TROUBLESHOOTING

Once installed, tandem breakers require minimal maintenance, but regular inspection ensures long-term safety.

Regular Inspection Points

- Physical Condition: Check for discoloration, burned plastic, or unusual warmth—signs of overheating

- Switch Operation: Test both switches monthly; they should move smoothly between ON and OFF

- Circuit Behavior: Monitor for frequent nuisance tripping, which may indicate overloading or a faulty breaker

Common Issues & Solutions

| Issue | Likely Cause | Solution |

|---|---|---|

| Frequent tripping | Overloaded circuit or short circuit | Call electrician; may need redistribution or larger breaker |

| Excessive heat | Overloading or poor connection | Professional inspection; possible breaker replacement |

| Difficult switch operation | Internal corrosion or wear | Replace the breaker immediately |

| One side tripped, other OK | Normal operation (independent circuits) | Check the tripped circuit for faults; reset when safe |

KEY TAKEAWAYS

✓ Tandem circuit breakers fit two independent 120V circuits in a single panel slot, doubling available capacity without full panel replacement

✓ CTL compatibility is non-negotiable—only use tandem breakers in panels specifically designed for them; check the model number and bus bar notches

✓ Never use tandem breakers for multi-wire branch circuits (MWBC)—they cause neutral overloading and fire risk

✓ Cost comparison: Tandems ($150–$400) beat subpanels ($500–$1,500) and panel upgrades ($1,200–$3,000) when budget is tight

✓ AFCI/GFCI protection is not available in tandem configurations—use standard breakers if modern codes require these features

✓ Professional installation is essential—working with live electrical panels carries electrocution risk and code compliance requirements

FAQ

Q1: Are tandem circuit breakers safe if properly installed?

Yes, tandem breakers are safe when installed in panels specifically rated for them and connected to appropriate loads. They’re UL-listed and compliant with NEC standards when used correctly.

Q2: Can I use a tandem breaker in any panel?

No. Your panel must be CTL-compatible and have designated tandem-capable slots. Check the model number (e.g., 30/40 means tandem-capable) and inspect the bus bar notches.

Q3: What’s the difference between tandem and double-pole breakers?

Tandem breakers provide two 120V circuits in one slot. Double-pole breakers provide one 240V circuit using two slots. They serve completely different purposes.

Q4: Why can’t I use a tandem for a multi-wire branch circuit (MWBC)?

Tandem breakers connect to only one electrical phase, so both circuits share the same neutral path. This causes currents to add on the neutral instead of canceling, causing overheating and fire risk. Always use a double-pole breaker for MWBC.

Q5: How do I know my panel accepts tandems?

Check three things: (1) Model number format like 30/40 (higher second number = tandem support), (2) Notched bus stabs (not solid), (3) Panel diagram marking tandem-compatible slots.

Q6: Can tandem breakers provide 240-volt power?

No. Tandem breakers connect to only one electrical phase and can only provide 120V per circuit. For 240V, you need a double-pole breaker.

Q7: What happens if I force a tandem into an incompatible slot?

This creates a fire hazard because the breaker won’t make proper electrical contact. It also violates building codes and voids your insurance coverage.

Q8: Do I need a permit to install a tandem breaker?

Most jurisdictions require an electrical permit for any panel modification. Check local building department rules. Professional electricians handle permit logistics and load center vs. panelboard decisions to ensure full compliance.