Key Takeaways

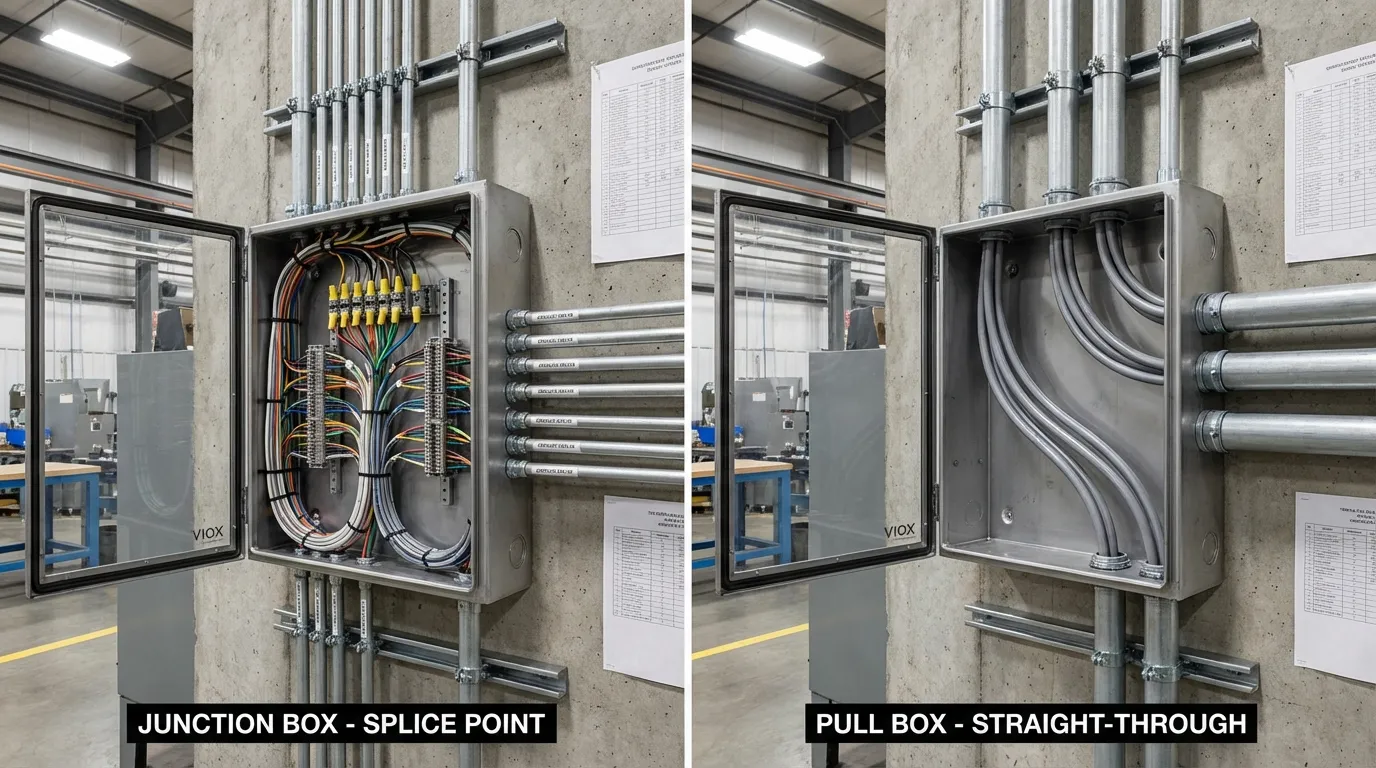

- Primary Function Difference: Junction boxes house and protect wire splices and connections, while pull boxes facilitate wire installation through conduit systems without containing permanent connections.

- NEC Code Distinction: Junction boxes follow NEC 314.16 (box fill calculations), while pull boxes are governed by NEC 314.28 (sizing based on raceway dimensions for conductors 4 AWG and larger).

- Sizing Requirements: Pull boxes require minimum dimensions of 8× the largest raceway for straight pulls and 6× for angle pulls, while junction boxes are sized based on conductor count and volume.

- Cost Impact: Junction boxes typically cost $5-$50 for standard applications, while pull boxes range from $50-$500+ depending on size and complexity, with installation time differing by 2-3 hours.

- Critical Selection Factor: Use junction boxes where wire connections are needed; use pull boxes for long conduit runs (>100 feet), multiple bends, or heavy conductor installations to prevent cable damage.

Introduction

In electrical installations, understanding the difference between pull box vs junction box is fundamental to ensuring code compliance, system safety, and installation efficiency. While these electrical enclosures may appear similar, confusing their purposes can lead to NEC violations, installation failures, and potential safety hazards.

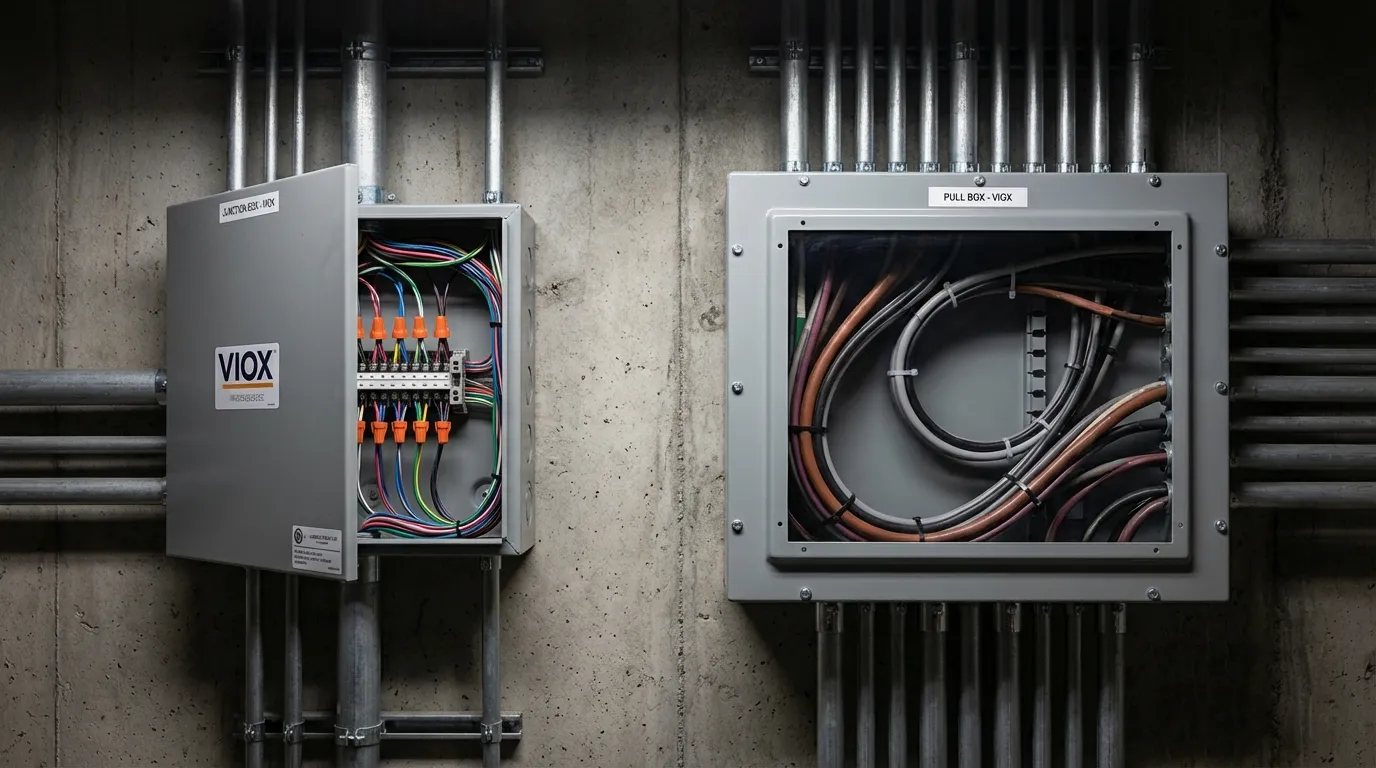

A junction box serves as a protective housing for wire splices and terminations—the connection point where circuits branch to outlets, switches, and equipment. Conversely, a pull box functions as an access point in conduit systems, facilitating wire installation without containing permanent connections. This distinction impacts everything from box sizing calculations to material selection and installation methods.

For electrical contractors, panel builders, and facility managers, selecting the wrong box type can result in failed inspections, costly rework, and compromised system integrity. This comprehensive guide clarifies the pull box vs junction box debate, covering NEC requirements, sizing calculations, selection criteria, and installation best practices to ensure your electrical systems meet code and perform reliably.

What is a Junction Box?

A junction box is an electrical enclosure designed to house and protect wire splices, terminations, and connections where multiple circuits converge. Governed primarily by NEC Article 314.16, junction boxes serve as the central hub for distributing electrical power to various loads throughout a building or facility.

Primary Functions

Junction boxes perform several critical roles in electrical systems:

- Connection Protection: Encloses wire splices using wire nuts, terminal blocks, or other approved connectors, preventing exposure to environmental factors (moisture, dust, physical damage).

- Circuit Distribution: Provides a central point where incoming circuits branch to multiple outlets, switches, or equipment.

- Maintenance Access: Offers accessible points for troubleshooting, repairs, and system modifications without requiring wall or ceiling demolition.

- Code Compliance: Meets NEC 314.29 requirements that all splices must be enclosed in approved boxes with removable covers.

- Fire Prevention: Contains potential arcing or overheating within a non-combustible enclosure, preventing fire spread.

Technical Specifications

Junction boxes must meet specific NEC requirements:

- Box Fill Calculation (NEC 314.16): Volume must accommodate all conductors, devices, clamps, and fittings based on cubic inch requirements per conductor size.

- Accessibility (NEC 314.29): Must remain accessible without removing building structure or finishes.

- Grounding (NEC 314.4): Metal boxes require proper grounding; plastic boxes must have grounding provisions for metal conduits.

- Environmental Rating: Indoor boxes (NEMA 1), outdoor/wet locations (NEMA 3R, 4, 4X), hazardous locations (NEMA 7, 9).

For detailed guidance on selecting appropriate junction boxes, see our comprehensive junction box sizing guide and understanding electrical junction box types.

What is a Pull Box?

A pull box is an electrical enclosure strategically placed in conduit systems to facilitate wire installation, reduce cable stress, and provide access points for future modifications. Unlike junction boxes, pull boxes typically do not contain permanent wire splices or connections—they serve purely as “rest stops” for conductors traveling through complex or lengthy conduit runs.

Primary Functions

Pull boxes address specific installation challenges:

- Wire Installation Aid: Provides intermediate access points where electricians can pull cables in stages, preventing excessive tension that could damage insulation.

- Bend Radius Management: Allows proper cable bending at conduit direction changes, maintaining manufacturer-specified minimum bend radius requirements.

- Conduit System Access: Facilitates future wire additions, replacements, or system upgrades without requiring conduit replacement.

- Tension Reduction: Breaks long conduit runs into manageable segments, especially critical for large conductors (4 AWG and larger) or high-conductor-count installations.

- Code Compliance: Mandatory where conduit bends exceed NEC limits (maximum 360° total bends between pull points).

Technical Specifications

Pull boxes are governed by NEC Article 314.28 with specific sizing requirements:

- Straight Pull Sizing (NEC 314.28(A)(1)): Minimum length = 8× trade size of largest raceway entering the box.

- Angle/U-Pull Sizing (NEC 314.28(A)(2)): Distance from raceway entry to opposite wall = 6× largest raceway + sum of other raceways on same wall.

- Conductor Spacing: Distance between raceways containing same conductors ≥ 6× trade size of larger raceway.

- No Box Fill Calculation: Unlike junction boxes, pull boxes don’t require cubic inch calculations since they contain no splices.

For applications requiring both functions, consult our guide on junction box vs pull box to understand when hybrid solutions are appropriate.

Pull Box vs Junction Box: Key Differences

Understanding the pull box vs junction box distinction is critical for code-compliant installations. While both are electrical enclosures, their functions, sizing methods, and applications differ significantly.

| Feature | Junction Box | Pull Box |

|---|---|---|

| Primary Function | Houses wire splices and connections | Facilitates wire pulling through conduits |

| Contains Splices/Connections | Yes—permanent splices required | No—typically no connections (through-pulls only) |

| NEC Code Requirements | NEC 314.16 (box fill calculations) | NEC 314.28 (raceway-based sizing) |

| Sizing Method | Based on conductor count and volume (cubic inches) | Based on raceway size (8× or 6× multiplier) |

| Typical Size Range | 4″×4″ to 12″×12″ (residential/light commercial) | 12″×12″ to 36″×36″+ (industrial/heavy conductors) |

| Installation Location | At connection points (outlets, switches, equipment) | Along conduit runs (every 100 ft or at bends) |

| Access Requirements | Must remain accessible (NEC 314.29) | Must remain accessible for wire pulling |

| Material Options | Plastic, steel, aluminum, fiberglass, cast iron | Typically steel or fiberglass for durability |

| Cost Range | $5-$50 (standard applications) | $50-$500+ (size-dependent) |

| Installation Time | 30-60 minutes | 2-4 hours (larger size, more complex mounting) |

| Maintenance Needs | Periodic inspection of connections | Minimal—primarily access verification |

| Typical Applications | Residential wiring, lighting circuits, equipment connections | Industrial conduit systems, long cable runs, heavy conductors |

| Grounding Requirements | Metal boxes must be grounded (NEC 314.4) | Metal boxes must be grounded if used as equipment grounding path |

| Cover Requirements | Must have removable cover (NEC 314.28(C)) | Must have removable cover for access |

| Environmental Protection | NEMA 1 (indoor) to NEMA 4X (outdoor/corrosive) | NEMA 3R to NEMA 4X (often outdoor installations) |

Key Distinction for Professionals

The fundamental difference: Junction boxes are for connections; pull boxes are for access. If you’re splicing wires, you need a junction box sized per NEC 314.16. If you’re routing conductors through a complex conduit system, you need a pull box sized per NEC 314.28.

For detailed material selection guidance, see our metal vs plastic junction boxes comparison and weatherproof junction box guide for outdoor applications.

NEC Code Requirements

Proper pull box vs junction box selection requires understanding distinct NEC requirements for each enclosure type. Non-compliance results in failed inspections, safety hazards, and costly rework.

Junction Box Requirements (NEC 314.16)

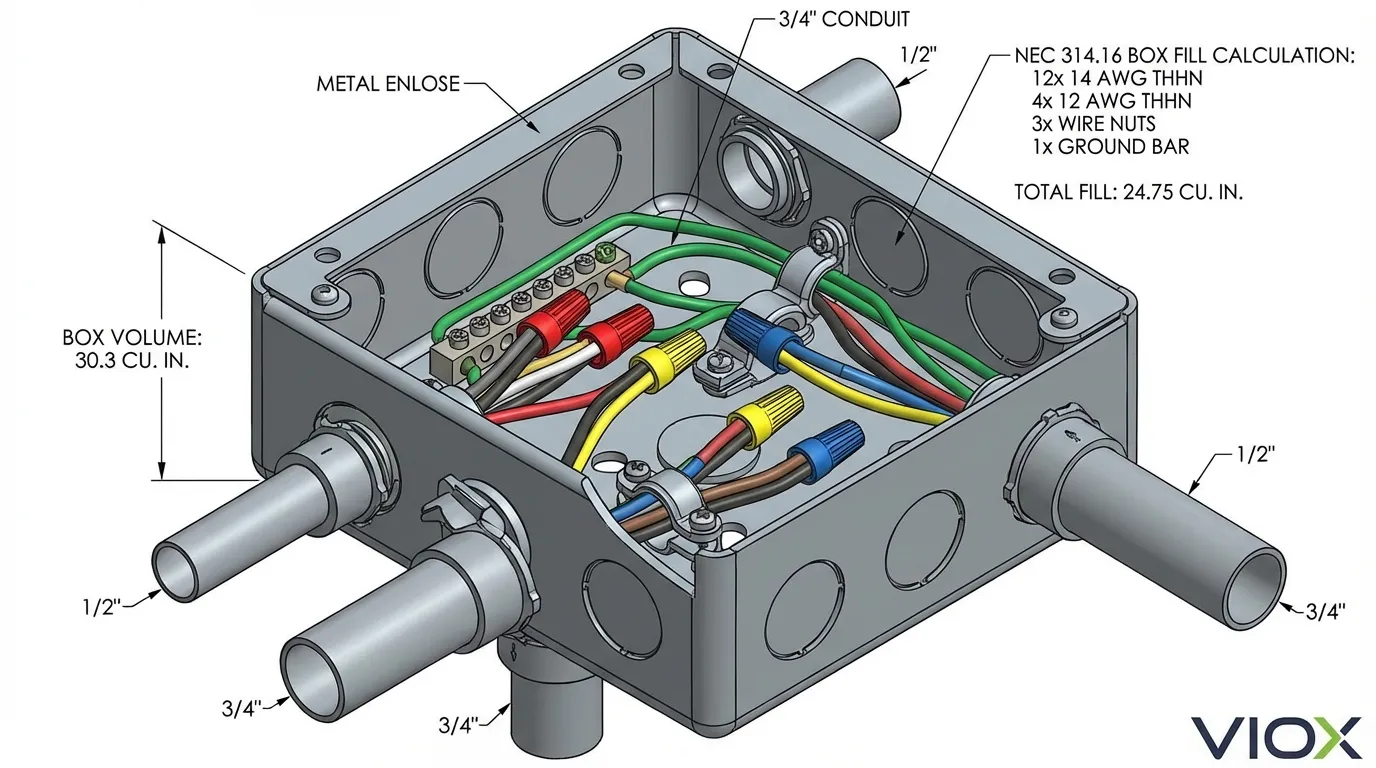

Junction boxes containing conductors 18 AWG through 6 AWG must meet box fill calculations:

Box Fill Formula:

- Each conductor: Volume per Table 314.16(B)

- Each device (receptacle, switch): 2× conductor volume

- Each cable clamp: 1× conductor volume

- Each equipment grounding conductor: 1× conductor volume (count once regardless of number)

- Each fixture stud/hickey: 1× conductor volume

Example Calculation:

A junction box contains:

- 6× #12 AWG conductors (6 × 2.25 cu.in. = 13.5 cu.in.)

- 1× device (2 × 2.25 cu.in. = 4.5 cu.in.)

- 1× cable clamp (1 × 2.25 cu.in. = 2.25 cu.in.)

- 1× equipment ground (1 × 2.25 cu.in. = 2.25 cu.in.)

- Total Required: 22.5 cubic inches

- Minimum Box: 4″×4″×2⅛” (30.3 cu.in.) ✓ Compliant

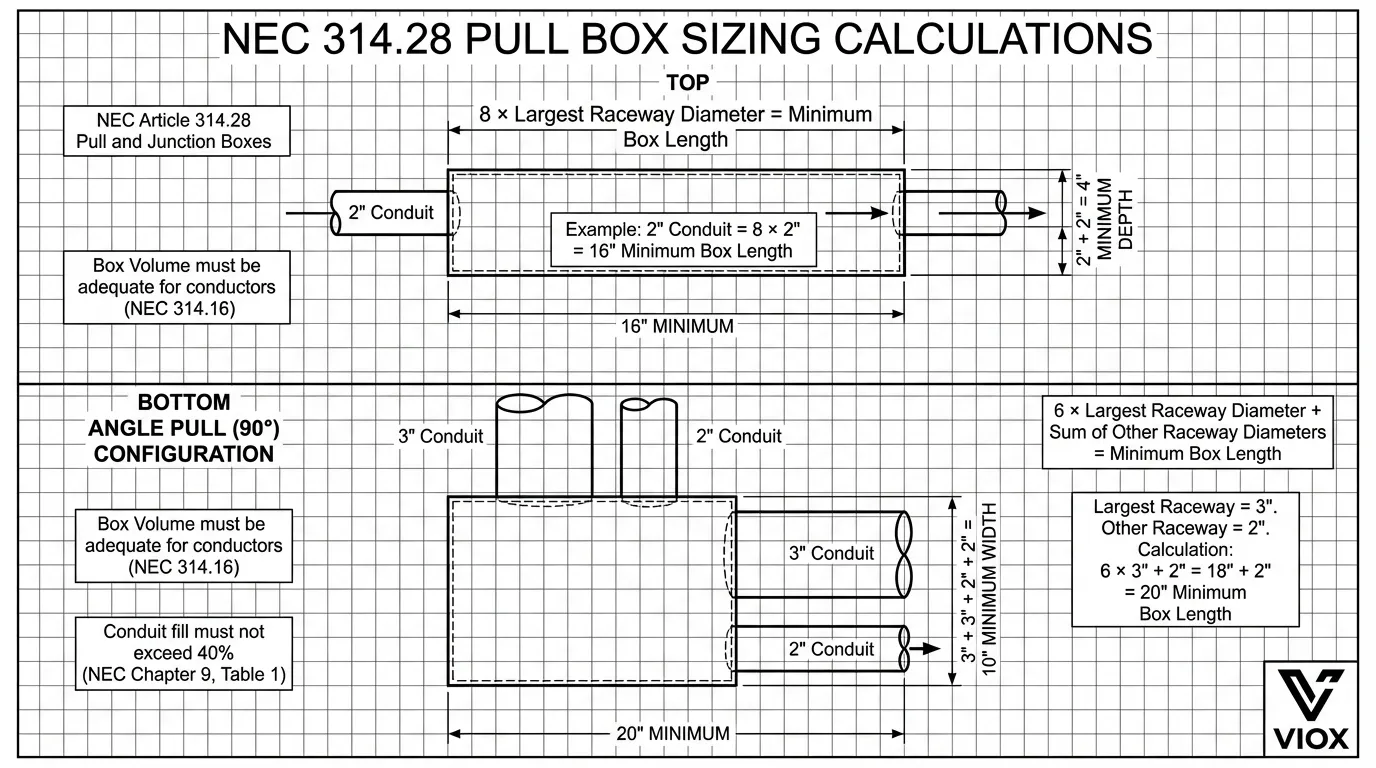

Pull Box Requirements (NEC 314.28)

Pull boxes containing conductors 4 AWG and larger follow raceway-based sizing:

Straight Pull Sizing (NEC 314.28(A)(1)):

- Minimum length = 8× trade size of largest raceway

- Example: 2″ conduit requires minimum 16″ box length (2″ × 8 = 16″)

Angle/U-Pull Sizing (NEC 314.28(A)(2)):

- Distance from raceway entry to opposite wall = 6× largest raceway + sum of other raceways on same wall

- Example: One 2″ conduit + two 1″ conduits on same wall:

(6 × 2″) + (1″ + 1″) = 12″ + 2″ = 14″ minimum

Conductor Spacing:

- Distance between raceways containing same conductors ≥ 6× trade size of larger raceway

- Example: Two 2″ conduits with same conductors require minimum 12″ spacing (2″ × 6 = 12″)

Accessibility Requirements (NEC 314.29)

Both junction boxes and pull boxes must:

- Remain accessible without removing building structure or finishes

- Have removable covers for maintenance access

- Be properly labeled for identification

- Not be concealed by building materials (drywall, ceiling tiles, etc.)

For comprehensive NEC compliance guidance, see our NEC code for junction boxes article.

When to Use a Junction Box

Select a junction box when your installation requires wire splices, terminations, or circuit distribution:

Residential Applications

- Branch Circuit Distribution: Where main circuit splits to multiple outlets or switches

- Lighting Circuits: Connecting multiple light fixtures to a single circuit

- Appliance Connections: Hardwired appliance terminations (dishwashers, disposals, HVAC)

- Service Panel Extensions: Adding circuits in finished spaces without panel access

Commercial/Industrial Applications

- Equipment Terminations: Motor control circuits, VFD connections, control panel interfaces

- Instrumentation Wiring: Sensor connections, control system integration points

- Emergency Systems: Fire alarm, emergency lighting, exit sign circuits

- Data/Communications: Low-voltage system integration with power circuits

Code-Mandated Scenarios

- All Wire Splices (NEC 300.15): Every splice must be enclosed in approved box

- Device Installations: Receptacles, switches, and devices require proper boxes

- Fixture Connections: Ceiling/wall-mounted fixtures need junction box support

- Accessible Connections: Where future modifications are anticipated

For specific junction box selection criteria, consult our junction box selection guide and terminal box vs junction box comparison.

When to Use a Pull Box

Select a pull box when your conduit system requires wire installation access without permanent connections:

Long Conduit Runs

- Distance Threshold: Runs exceeding 100 feet require intermediate pull points

- Heavy Conductors: 4 AWG and larger cables need tension relief every 75-100 feet

- High Conductor Count: Multiple cables in single conduit increase pulling tension

Multiple Conduit Bends

- NEC 360° Rule: Maximum 360° total bends between pull points (typically 4× 90° bends)

- Bend Radius Protection: Ensures cables maintain manufacturer minimum bend radius

- Complex Routing: Where conduit path changes direction multiple times

Industrial/Heavy-Duty Applications

- Feeder Circuits: Large conductor installations (250 MCM, 500 MCM, 750 MCM)

- Underground Conduit Systems: Transitioning between underground and above-ground installations

- Cable Tray Transitions: Where cables transfer from tray to conduit systems

- Future Expansion: Anticipating additional circuits in existing conduit infrastructure

Specific Installation Scenarios

- Vertical Risers: Multi-story buildings requiring intermediate access points

- Outdoor Conduit Runs: Weather-exposed installations needing periodic access

- Hazardous Locations: Where conduit sealing requires accessible junction points

- High-Voltage Systems: Over 600V installations requiring specialized access (NEC 314.71)

For outdoor applications, review our weatherproof junction box and explosion proof vs standard junction box guides.

Sizing Requirements and Calculations

Proper sizing is critical for pull box vs junction box installations. Incorrect sizing leads to NEC violations, conductor damage, and installation failures.

Junction Box Sizing Example

Scenario: Installing a junction box for lighting circuit with the following:

- 4× #14 AWG hot conductors

- 4× #14 AWG neutral conductors

- 2× #14 AWG equipment grounds

- 2× cable clamps

- 1× fixture stud

Calculation:

- Conducters: 8× #14 AWG = 8 × 2.0 cu.in. = 16.0 cu.in.

- Equipment grounds: 1× 2.0 cu.in. = 2.0 cu.in. (count once)

- Cable clamps: 2× 2.0 cu.in. = 4.0 cu.in.

- Fixture stud: 1× 2.0 cu.in. = 2.0 cu.in.

- Total: 24.0 cubic inches

Box Selection: 4″×4″×2⅛” octagon box (30.3 cu.in.) ✓ Compliant

Pull Box Sizing Example (Straight Pull)

Scenario: Installing pull box for straight conduit run with:

- One 3″ rigid metal conduit

- Conductors: 500 MCM THHN (4 AWG equivalent)

Calculation:

- Minimum length = 8× largest raceway

- 8 × 3″ = 24″

- Minimum box dimension: 24″ length

Box Selection: 24″×12″×8″ pull box ✓ Compliant

Pull Box Sizing Example (Angle Pull)

Scenario: Installing pull box with 90° angle pull:

- One 2″ conduit entering left side

- Two 1″ conduits entering left side

- One 2″ conduit exiting bottom

Calculation (Left Wall to Right Wall):

- 6× largest raceway = 6 × 2″ = 12″

- Sum of other raceways = 1″ + 1″ = 2″

- Minimum dimension: 12″ + 2″ = 14″

Calculation (Top Wall to Bottom Wall):

- 6× largest raceway = 6 × 2″ = 12″

- Minimum dimension: 12″

Box Selection: 16″×14″×8″ pull box ✓ Compliant (rounded up to standard size)

For complex installations, use our junction box sizing calculator for automated calculations.

Installation Best Practices

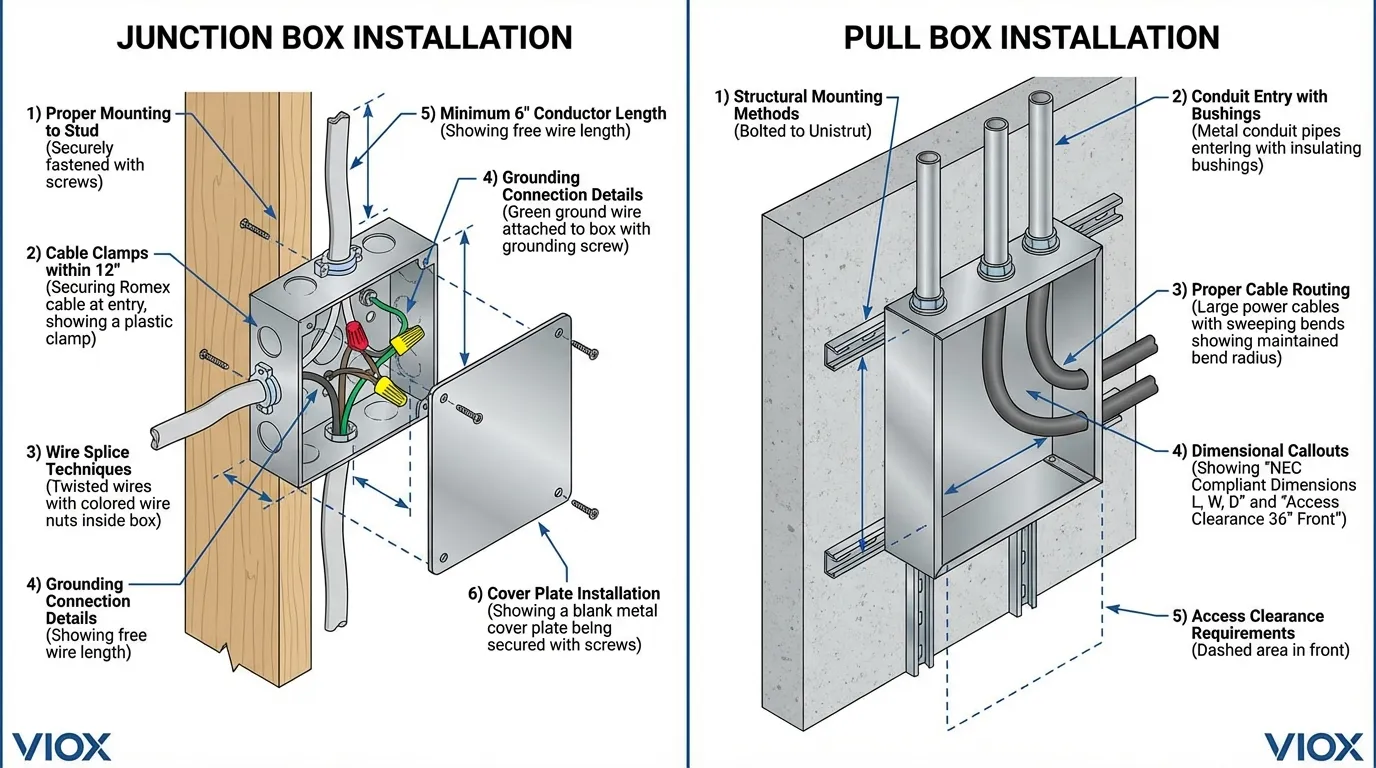

Junction Box Installation

Mounting Requirements:

- Secure to structural members (studs, joists, ceiling supports)

- Use appropriate fasteners for box weight and conductor load

- Maintain proper depth: box face flush with finished wall surface

- Support independently—do not rely on conduit for support

Wiring Practices:

- Strip conductors to minimum length (⅝” for wire nuts)

- Use appropriately sized wire connectors (follow manufacturer ratings)

- Maintain color coding: black/red (hot), white (neutral), green/bare (ground)

- Secure cables within 12″ of box entry (NEC 314.17(C))

- Leave 6″ minimum conductor length inside box for connections

Grounding:

- Bond metal boxes to equipment grounding system

- Use grounding screws (10-32 thread) or grounding clips

- Ensure continuous grounding path through all connections

Pull Box Installation

Location Planning:

- Install before conduit bends exceed 360° total

- Position at accessible locations (not above ceilings, behind walls)

- Consider future access requirements

- Mount at comfortable working height (48″-60″ center for wall-mounted boxes)

Mounting Requirements:

- Use heavy-duty supports for large boxes (24″+ dimensions)

- Anchor to structural members capable of supporting box weight + conductor load

- Provide adequate clearance for cover removal and wire pulling

- Ensure level installation for proper conduit alignment

Conduit Entry:

- Use proper conduit fittings (locknuts, bushings, hubs)

- Maintain conduit alignment to prevent conductor binding

- Install bushings on all conduit entries to protect conductor insulation

- Seal outdoor boxes with appropriate gaskets (NEMA 3R, 4, 4X)

For detailed installation procedures, see our how to install junction box guide and junction box vs joint box comparison.

Common Mistakes to Avoid

Junction Box Errors

Undersizing Boxes:

- Problem: Insufficient cubic inch capacity for conductor count

- Consequence: Overheating, conductor damage, NEC violation

- Solution: Always calculate box fill per NEC 314.16 before installation

Improper Grounding:

- Problem: Metal boxes not bonded to equipment grounding system

- Consequence: Shock hazard, code violation

- Solution: Use grounding screws or clips on all metal boxes

Concealed Boxes:

- Problem: Boxes hidden behind drywall, ceiling tiles, or finishes

- Consequence: NEC 314.29 violation, maintenance access issues

- Solution: Ensure all boxes remain accessible with removable covers

Inadequate Support:

- Problem: Boxes supported only by conduit or cable

- Consequence: Physical damage, connection failure

- Solution: Mount boxes independently to structural members

Pull Box Errors

Incorrect Sizing Calculations:

- Problem: Using junction box (314.16) calculations for pull boxes

- Consequence: Undersized boxes, conductor damage during pulling

- Solution: Apply NEC 314.28 raceway-based sizing (8× or 6× multipliers)

Insufficient Access Clearance:

- Problem: Boxes installed in tight spaces without pulling room

- Consequence: Difficult installations, conductor damage

- Solution: Provide minimum 36″ clearance in front of box for wire pulling operations

Missing Conductor Spacing:

- Problem: Raceways with same conductors too close together

- Consequence: NEC 314.28(A)(2) violation, difficult wire routing

- Solution: Maintain 6× raceway spacing between entries with same conductors

Improper Sealing:

- Problem: Outdoor boxes without proper gaskets or sealing

- Consequence: Water intrusion, corrosion, system failure

- Solution: Use NEMA-rated boxes with appropriate gaskets for environment

Material Selection Guide

Choosing appropriate materials for pull box vs junction box applications depends on environmental conditions, conductor types, and installation requirements.

| Material | Advantages | Disadvantages | Best Applications | Cost Range |

|---|---|---|---|---|

| PVC/Plastic | Lightweight, corrosion-resistant, non-conductive, low cost | Lower impact resistance, temperature limitations (60°C max), UV degradation | Indoor residential, light commercial, non-metallic conduit systems | $5-$25 |

| Steel (Painted) | High strength, impact-resistant, economical, readily available | Corrosion in wet environments, requires grounding | Indoor commercial/industrial, dry locations, standard applications | $15-$75 |

| Galvanized Steel | Corrosion-resistant, high strength, durable | Heavier weight, higher cost than painted steel | Outdoor installations, wet locations, corrosive environments | $25-$150 |

| Stainless Steel (304/316) | Superior corrosion resistance, chemical resistance, long lifespan | High cost, specialized fabrication | Marine environments, chemical plants, food processing, coastal installations | $100-$500+ |

| Aluminum | Lightweight, corrosion-resistant, non-magnetic, easy fabrication | Lower strength than steel, galvanic corrosion with dissimilar metals | Weight-sensitive applications, non-magnetic requirements, outdoor use | $50-$200 |

| Fiberglass (FRP) | Excellent corrosion resistance, lightweight, non-conductive, UV-resistant | Higher cost, limited impact resistance, specialized mounting | Chemical plants, wastewater treatment, extreme corrosive environments | $75-$300 |

| Cast Iron | Extreme durability, impact-resistant, fire-resistant, long lifespan | Very heavy, difficult installation, high cost | Hazardous locations, explosion-proof requirements, heavy industrial | $150-$600+ |

Environmental Rating Selection (NEMA)

- NEMA 1: Indoor, dry locations (standard junction boxes)

- NEMA 3R: Outdoor, rain-resistant (most outdoor pull boxes)

- NEMA 4/4X: Outdoor, watertight, corrosion-resistant (marine, chemical)

- NEMA 12: Indoor, dust-tight, drip-tight (industrial environments)

- NEMA 7/9: Hazardous locations, explosion-proof (Class I, II, III)

For detailed material comparisons, see our stainless steel vs aluminum junction box guide and electrical enclosure material selection.

Cost Comparison and ROI Analysis

Understanding the total cost of ownership for pull box vs junction box installations helps optimize project budgets while maintaining code compliance.

Initial Cost Breakdown

Junction Boxes:

- Standard plastic (4″×4″): $5-$10

- Metal octagon (4″×4″): $8-$15

- Large metal (12″×12″): $25-$50

- Weatherproof (NEMA 3R): $15-$40

- Explosion-proof (NEMA 7): $150-$400

Pull Boxes:

- Small (12″×12″×6″): $50-$100

- Medium (18″×18″×8″): $100-$200

- Large (24″×24″×10″): $200-$400

- Extra-large (36″×36″×12″): $400-$800

- Custom sizes: $500-$2,000+

Installation Labor Costs

Junction Box Installation:

- Residential: 0.5-1.0 hours ($50-$100 labor)

- Commercial: 1.0-2.0 hours ($100-$200 labor)

- Industrial: 2.0-3.0 hours ($200-$300 labor)

Pull Box Installation:

- Standard: 2-4 hours ($200-$400 labor)

- Large/complex: 4-8 hours ($400-$800 labor)

- Heavy-duty mounting: 6-10 hours ($600-$1,000 labor)

Long-Term ROI Considerations

Proper Sizing Benefits:

- Avoids rework costs (typically 3-5× initial installation cost)

- Prevents conductor replacement ($50-$200 per conductor)

- Eliminates failed inspection delays (1-2 weeks project delay)

- Reduces maintenance costs (easier access = faster repairs)

Material Selection Impact:

- Stainless steel: 20-30 year lifespan (marine/corrosive environments)

- Galvanized steel: 15-20 year lifespan (outdoor installations)

- Plastic: 10-15 year lifespan (indoor, dry locations)

- Replacement cost: 2-3× initial installation (labor + materials + downtime)

Code Compliance Value:

- Avoids citation fines ($500-$5,000 per violation)

- Prevents insurance claim denials (non-compliant installations)

- Maintains facility safety certifications (OSHA, insurance requirements)

- Protects against liability in electrical incidents

For project planning, see our distribution box vs junction box cost comparison.

FAQ

What is the main difference between a pull box and a junction box?

The primary difference is function: junction boxes house wire splices and connections, while pull boxes facilitate wire installation through conduit systems without containing permanent connections. Junction boxes are sized using NEC 314.16 box fill calculations based on conductor count, whereas pull boxes follow NEC 314.28 raceway-based sizing (8× largest raceway for straight pulls, 6× for angle pulls). This fundamental distinction determines which box type is code-compliant for specific applications.

Can a pull box be used as a junction box?

Yes, a pull box can function as a junction box if it meets NEC 314.16 box fill requirements for the conductors and connections it will contain. However, this is typically inefficient as pull boxes are sized much larger than necessary for junction box applications, resulting in higher material and installation costs. The reverse is not true—a junction box cannot serve as a pull box for large conductors (4 AWG+) unless it meets NEC 314.28 sizing requirements, which standard junction boxes rarely do.

How do I calculate the minimum size for a pull box?

For straight pulls (NEC 314.28(A)(1)): Minimum box length = 8× trade size of largest raceway entering the box. Example: 2″ conduit requires 16″ minimum length (2″ × 8 = 16″). For angle or U-pulls (NEC 314.28(A)(2)): Distance from raceway entry to opposite wall = 6× largest raceway + sum of other raceways on same wall. Example: One 2″ conduit + two 1″ conduits = (6 × 2″) + (1″ + 1″) = 14″ minimum. Always round up to nearest standard box size.

Do pull boxes need to be grounded?

Yes, metal pull boxes must be grounded per NEC 314.4 if they are part of the equipment grounding path or contain metal raceways. This requires bonding the box to the equipment grounding conductor system using grounding screws, bonding jumpers, or listed grounding devices. Non-metallic (PVC, fiberglass) pull boxes do not require grounding but must provide grounding continuity for metal conduits entering the box. Proper grounding prevents shock hazards and ensures fault current paths for overcurrent device operation.

Can junction boxes be installed in walls or ceilings?

Yes, junction boxes can be installed in walls and ceilings, but they must remain accessible per NEC 314.29 without removing building structure or finishes. This means boxes cannot be buried behind drywall, plaster, or ceiling tiles without access panels. Acceptable installations include: boxes behind removable cover plates, boxes in accessible attics/crawl spaces, and boxes above suspended ceilings with removable tiles. Concealed junction boxes are NEC violations and create safety hazards by preventing inspection and maintenance.

What NEMA rating do I need for outdoor pull boxes?

For outdoor installations, specify NEMA 3R minimum (rain-resistant, sleet-resistant) for general weather protection. Upgrade to NEMA 4 or 4X (watertight, corrosion-resistant) for direct water exposure, washdown areas, or corrosive environments (coastal, chemical). NEMA 4X provides superior corrosion resistance using stainless steel or fiberglass construction. For hazardous locations, specify NEMA 7 or 9 (explosion-proof) per NEC Article 500. Always verify local code requirements and environmental conditions before final selection.

How often should pull boxes be installed in long conduit runs?

Install pull boxes at intervals not exceeding 100 feet for straight runs or when conduit bends total 360° (typically four 90° bends) per NEC requirements. For heavy conductors (250 MCM+) or high-conductor-count installations, reduce intervals to 75 feet to minimize pulling tension. Additional pull boxes are required at: significant direction changes, transitions between conduit types (rigid to EMT), vertical-to-horizontal transitions, and locations where future circuit additions are anticipated. Proper pull box spacing prevents conductor insulation damage during installation.

What happens if I use an undersized junction box?

Using an undersized junction box violates NEC 314.16 and creates multiple hazards: 1) Conductor damage from tight bending and compression, leading to insulation failure and short circuits; 2) Overheating from inadequate heat dissipation in crowded boxes, potentially causing fires; 3) Difficult maintenance making future repairs dangerous and time-consuming; 4) Failed inspections requiring complete reinstallation (3-5× initial cost); 5) Liability exposure in electrical incidents due to non-compliant installations. Always calculate box fill before installation and round up to next standard size for safety margin.

Conclusion

Understanding the pull box vs junction box distinction is fundamental to code-compliant, safe electrical installations. Junction boxes serve as connection points where circuits branch and terminate, requiring precise box fill calculations per NEC 314.16. Pull boxes function as access points in conduit systems, facilitating wire installation without permanent connections, and are sized using NEC 314.28 raceway-based calculations.

Key selection criteria include: Use junction boxes where wire splices or terminations are needed—at outlets, switches, equipment connections, and circuit distribution points. Use pull boxes for long conduit runs (>100 feet), multiple bends (>360° total), large conductors (4 AWG+), or complex routing requiring installation access without permanent connections.

Proper sizing is critical: undersized boxes lead to NEC violations, conductor damage, and safety hazards. Junction boxes require cubic inch calculations based on conductor count, while pull boxes need raceway-based calculations (8× for straight pulls, 6× for angle pulls). Material selection depends on environmental conditions—plastic for indoor/dry locations, galvanized steel for outdoor use, stainless steel or fiberglass for corrosive environments.

For professional electrical contractors, panel builders, and facility managers, investing time in proper pull box vs junction box selection prevents costly rework, ensures code compliance, and maintains system safety. When in doubt, consult NEC Article 314, local electrical codes, and experienced electrical engineers to verify your installation meets all requirements.

For additional guidance, explore our comprehensive resources: junction box sizing guide, NEC code for junction boxes, electrical enclosures guide, and junction box types.

VIOX Electric manufactures a complete range of junction boxes and pull boxes meeting NEC, UL, and IEC standards for residential, commercial, and industrial applications. Contact our technical team for application-specific recommendations and custom enclosure solutions.