နိဒါန်း

လျှပ်စစ်ဘေးကင်းရေးစံနှုန်းများ တင်းကျပ်လာပြီး ယုံကြည်စိတ်ချရသော ဆားကစ်အကာအကွယ်အတွက် စျေးကွက်တောင်းဆိုမှုများ ကြီးထွားလာသည်နှင့်အမျှ MCB ထုတ်လုပ်မှု အရည်အသွေး အာမခံချက်သည် အရေးကြီးလာပါသည်။ ထုတ်လုပ်မှုတွင် အရည်အသွေးအာမခံချက်သည် ထုတ်ကုန်များသည် သတ်မှတ်ထားသော စံချိန်စံညွှန်းများနှင့် ဖောက်သည်များ၏ မျှော်လင့်ချက်များ ပြည့်မီကြောင်း သေချာစေမည့် စနစ်ကျသော လုပ်ငန်းစဉ်တစ်ခုဖြစ်ပြီး၊ လျှပ်စစ်စနစ်များတွင် ၎င်းတို့၏ ဘေးကင်းရေး-အရေးပါသော အခန်းကဏ္ဍကို ပေးထားသည့် အသေးစား circuit breakers များအတွက် ဤမူအရ အထူးအရေးကြီးပါသည်။

ခေတ်မီလျှပ်စစ်တပ်ဆင်မှုများသည် ဝန်ပိုခြင်းနှင့် တိုတောင်းခြင်းတို့ကို အကာအကွယ်ပေးရန်အတွက် MCB များပေါ်တွင် မူတည်သည်။ MCB များသည် အလိုအလျောက်လည်ပတ်နေသော လျှပ်စစ်ခလုတ်များအဖြစ် လျှပ်စစ်ချို့ယွင်းမှုနှင့် စက်ချို့ယွင်းမှုမှ ကာကွယ်ရန် ဝန်ပို သို့မဟုတ် ရှော့လျှပ်စီးပတ်လမ်းအတွင်း လည်ပတ်ရန် ဒီဇိုင်းထုတ်ထားသည်။ ဤစက်ပစ္စည်းများ ပျက်ကွက်သောအခါ၊ နောက်ဆက်တွဲဆိုးကျိုးများမှာ စက်ပစ္စည်းများ ပျက်စီးခြင်းမှ မီးဘေး အန္တရာယ်နှင့် ပုဂ္ဂိုလ်ရေး ထိခိုက်ဒဏ်ရာရခြင်းအထိ ဖြစ်နိုင်သည်။

ဤပြည့်စုံသောလမ်းညွှန်ချက်သည် MCB ထုတ်လုပ်မှုတွင် မရှိမဖြစ်လိုအပ်သော အရည်အသွေးအာမခံအလေ့အကျင့်များကို ဆန်းစစ်သည်၊ လျှပ်စစ်ကျွမ်းကျင်ပညာရှင်များ၊ ဝယ်ယူရေးမန်နေဂျာများနှင့် အရည်အသွေးထိန်းချုပ်ရေးကျွမ်းကျင်သူများက အသေးစား circuit breaker အရည်အသွေးနှင့် ထုတ်လုပ်မှုစံနှုန်းများကို အကဲဖြတ်ရာတွင် ရှာဖွေရမည့်အရာများကို ရှာဖွေဖော်ထုတ်ပေးပါသည်။

MCB ထုတ်လုပ်မှု အရည်အသွေး စံနှုန်းများကို နားလည်ခြင်း။

နိုင်ငံတကာစံနှုန်းများဘောင်

IEC 60898 နှင့် IEC 60947-2 သည် ကမ္ဘာတစ်ဝှမ်း MCB အရည်အသွေးစံနှုန်းများ၏ ကျောရိုးဖြစ်သည်။ IEC 60898-1 သည် နည်းပညာမဟုတ်သောအသုံးပြုသူများအတွက် လိုက်လျောညီထွေဖြစ်စေမည့် လိုအပ်ချက်များနှင့် သက်ဆိုင်ပြီး IEC 60947-2 သည် စက်မှုအသုံးချပရိုဂရမ်များအတွက် circuit breakers များကို အုပ်ချုပ်သည်။ ဤစံချိန်စံညွှန်းများကို နားလည်ခြင်းသည် ထိရောက်သော အရည်အသွေးအာမခံချက်အတွက် အရေးကြီးပါသည်။

အဓိက စံသတ်မှတ်ချက်များ-

- IEC 60898-1- 125A အထိ လူနေအိမ်နှင့် စီးပွားရေးဆိုင်ရာ အသုံးချပရိုဂရမ်များအတွက် ဒီဇိုင်းထုတ်ထားသည်။

- IEC 60947-2- စက်မှုအသုံးချပရိုဂရမ်များကို ပိုမိုကျယ်ပြန့်သော နယ်ပယ်နှင့် ချိန်ညှိနိုင်သော ဝိသေသလက္ခဏာများဖြင့် လွှမ်းခြုံထားသည်။

- ညစ်ညမ်းမှု ဒီဂရီ အမျိုးအစား ခွဲခြားခြင်း- မတူညီသော ပတ်ဝန်းကျင် ခံနိုင်ရည် လိုအပ်ချက်များ

- စွမ်းဆောင်ရည် စံနှုန်းများကို ချိုးဖောက်ခြင်း- တိကျသော ချို့ယွင်းချက် လက်ရှိ အနှောင့်အယှက်ပေးနိုင်စွမ်းများ

ဒေသဆိုင်ရာ လိုက်နာမှု လိုအပ်ချက်များ

ထုတ်ကုန်များသည် ပစ်မှတ်စျေးကွက်အပေါ် မူတည်၍ IEC၊ UL နှင့် CSA အပါအဝင် ကမ္ဘာတစ်ဝှမ်းရှိ ထုတ်ကုန်စံနှုန်းများနှင့် ကိုက်ညီရပါမည်။ ဤစံနှုန်းများစွာကို လိုက်နာခြင်းသည် ရှုပ်ထွေးမှုကို တိုးစေသော်လည်း ပိုမိုကျယ်ပြန့်သော စျေးကွက်လက်ခံမှုကို သေချာစေသည်။

ဒေသဆိုင်ရာစံနှုန်းများ ပါဝင်သည်-

- မြောက်အမေရိက: UL 489, CSA C22.2 နံပါတ် 5

- ဥရောပ- EN 60898-1၊ EN 60947-2

- အာရှ-ပစိဖိတ်- IEC စံနှုန်းများကို နိုင်ငံအသီးသီးမှ လက်ခံကျင့်သုံးခြင်း။

- ထွန်းသစ်စစျေးကွက်များ- မကြာခဏဆိုသလို IEC ကို ပြည်တွင်းမွမ်းမံမှုများဖြင့် လိုက်နာပါ။

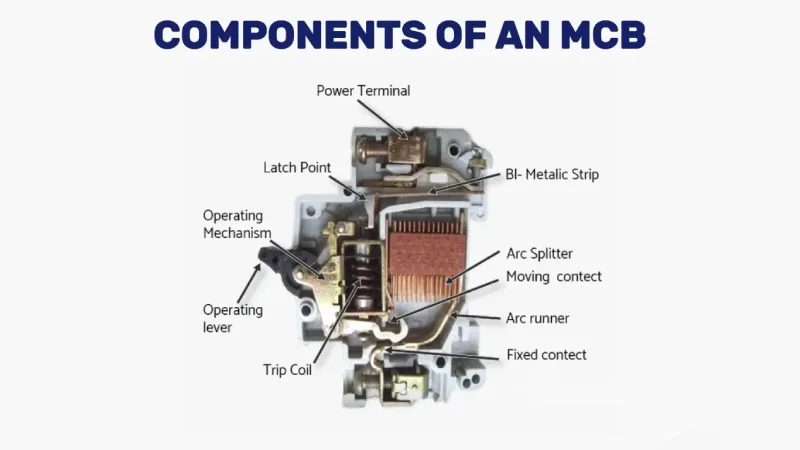

အရေးပါသော အစိတ်အပိုင်းများနှင့် အရည်အသွေးစစ်ဆေးရေးဂိတ်များ

အပူကာကွယ်ရေးစနစ်

အပူကာကွယ်ရေးစနစ်သည် ဝန်ပိုနေခြင်းကိုသိရှိရန်အတွက် bimetallic strip ကိုအသုံးပြုသည်။ ဝန်ပိုသွားသောအခါ၊ တိုးလာသော လျှပ်စီးကြောင်းသည် bimetal ကို အပူပေးပြီး ဘရိတ်ကာကို ကွေးသွားစေပြီး ခေါက်လိုက်သည့်အချိန်သည် လက်ရှိပြင်းအားနှင့် ပြောင်းပြန်ကွဲလွဲပါသည်။

အရည်အသွေးစစ်ဆေးရေးဂိတ်များ-

- Bimetal ဖွဲ့စည်းမှု- သင့်လျော်သော အလွိုင်းရွေးချယ်မှုနှင့် အပူကုသမှုကို စစ်ဆေးပါ။

- Calibration တိကျမှု- ခရီးစဉ်မျဉ်းကွေးများသည် IEC သတ်မှတ်ချက်များနှင့် ကိုက်ညီကြောင်း သေချာပါစေ။

- အပူချိန်တည်ငြိမ်မှု- လည်ပတ်မှုအပူချိန်အပိုင်းအခြားတစ်လျှောက် စွမ်းဆောင်ရည်ကို စမ်းသပ်ပါ။

- အသက်ကြီးခြင်း လက္ခဏာများ- အပူတုံ့ပြန်မှု၏ ရေရှည်တည်ငြိမ်မှုကို မှန်ကန်ကြောင်း သက်သေပြပါ။

သံလိုက်ကာကွယ်ရေးစနစ်

သံလိုက်ခရီးစဉ်ယူနစ်သည် မြင့်မားသောလျှပ်စီးကြောင်းဖြင့် ရွေ့လျားနိုင်သော သံလိုက်စက်ကို ဆွဲဆောင်ကာ အဆက်အသွယ်များကို 0.5 မီလီစက္ကန့်အတွင်း ဖွင့်ပေးခြင်းဖြင့် သံလိုက်ခရီးစဉ်ယူနစ်သည် တိုတောင်းသောဆားကစ်များကို ကာကွယ်ပေးသည်။

အရေးပါသော အရည်အသွေးအချက်များ-

- Coil ဒီဇိုင်း- သံလိုက်စက်ကွင်းအား ခိုင်ခံ့မှုအတွက် သင့်လျော်သော ဝါယာကြိုးနှင့် အလှည့်အရေအတွက်

- Armature တိကျမှု- တသမတ်တည်း ခရီးသွင်ပြင်လက္ခဏာများအတွက် တိကျသော ကွာဟချက်အကွာအဝေး

- တုံ့ပြန်မှုအချိန်- မှားယွင်းနေသော ရေစီးကြောင်းများအတွက် မီလီစက္ကန့်ခွဲခွဲ တုံ့ပြန်မှုကို အတည်ပြုခြင်း။

- Calibration Tolerance- ±10% အတွင်း သံလိုက်ခရီးစဉ်အမှတ် တိကျမှု

Arc Extinguishing စနစ်

ဗို့အားနည်းပါးသော MCB များသည် arc chutes - အဆစ်များကို ပိုင်းခြားပြီး အေးစေသော အပြန်အလှန် လျှပ်ကာအပြိုင် သတ္တုပြားများ အစုအဝေးများကို အသုံးပြုကာ ပြားအရေအတွက်သည် တိုတောင်းသော circuit အဆင့်သတ်မှတ်ချက်နှင့် nominal ဗို့အားပေါ်မူတည်ပါသည်။

အရည်အသွေး အကဲဖြတ်ခြင်း အမှတ်များ-

- Arc Chute ဒီဇိုင်း- သင့်လျော်သောပန်းကန်အကွာအဝေးနှင့် လျှပ်ကာပစ္စည်းများ

- ဆက်သွယ်ရန်ပစ္စည်းများ- ကြေးနီ သို့မဟုတ် ကြေးနီသတ္တုစပ်ဖြင့်ပြုလုပ်ထားသည့် အဆက်အသွယ်များ၊ ငွေသတ္တုစပ်များနှင့် အခြားလျှပ်ကူးပစ္စည်းများ၊

- Arc Runner Configuration- extinguishing chamber သို့ ထိရောက်သော arc လမ်းညွှန်မှု

- Insulation Integrity- arc chamber ပစ္စည်းများ၏ Dielectric strength ကို စမ်းသပ်ခြင်း။

Mechanical Operating Mechanism ၊

စက်ပိုင်းဆိုင်ရာစနစ်သည် တိကျသောအဆက်အသွယ်ဖိအားနှင့် ချိန်ညှိမှုကို ထိန်းသိမ်းထားစဉ် အခြေအနေအားလုံးတွင် စိတ်ချယုံကြည်စွာလည်ပတ်နိုင်ရမည်။

စစ်ဆေးရေး သတ်မှတ်ချက်-

- ဆက်သွယ်ရန်ဖိအား- ခုခံမှုနည်းသောချိတ်ဆက်မှုအတွက် လုံလောက်သောအင်အား

- လည်ပတ်ရေးတပ်ဖွဲ့- သတ်မှတ်ထားသော ကန့်သတ်ချက်များအတွင်း ကိုယ်တိုင်လုပ်ဆောင်မှု

- ခံနိုင်ရည်စမ်းသပ်ခြင်း- အဖွင့်အပိတ်ကြားရှိ စက်ဘီးစီးခြင်းလုပ်ငန်း 5 ခုသည် လိုက်လျောညီထွေဖြစ်ပြီး ချော်လဲခြင်းဖြစ်စဉ်မရှိဘဲ လိုက်လျောညီထွေရှိပြီး ယုံကြည်စိတ်ချရသောဖြစ်သင့်သည်။

- ပစ္စည်းအရည်အသွေး- နွေဦးသံမဏိဂုဏ်သတ္တိများနှင့် ပလပ်စတစ်အစိတ်အပိုင်း တာရှည်ခံမှု

မရှိမဖြစ်စမ်းသပ်မှုလိုအပ်ချက်များ

အပူစမ်းသပ်ခြင်း ပရိုတိုကောများ

စမ်းသပ်ခြင်းတွင် 1.13In၊ 1.45In နှင့် 2.55In လက်ရှိအဆင့်များတွင် နှောင့်နှေးမှုစမ်းသပ်မှုများ ပါဝင်ပြီး IEC 60898 စံနှုန်းများအရ သတ်မှတ်ထားသော အချိန်ပြတင်းပေါက်များအတွင်း breaker ခရီးစဉ်များ ရှိမရှိ စစ်ဆေးခြင်း။

Standard Test Sequence-

- 1.13 စမ်းသပ်မှု- 1 နာရီအတွင်း ခရီးမထွက်ကြောင်း အတည်ပြုပါ။

- 1.45 စမ်းသပ်မှုတွင်- အချိန်-လက်ရှိမျဉ်းကွေးကန့်သတ်ချက်များအတွင်း ခရီးစဉ်ကို အတည်ပြုပါ။

- 2.55 စမ်းသပ်မှုတွင်- ပိုမိုမြင့်မားသောဝန်ပိုတွင်ပိုမိုမြန်ဆန်သောတုံ့ပြန်မှုကိုအတည်ပြုပါ။

- အပူချိန်မြင့်တက်ခြင်း စမ်းသပ်ခြင်း- ဝန်အောက်ရှိ အစိတ်အပိုင်း အပူချိန်ကို စောင့်ကြည့်ပါ။

သံလိုက်စမ်းသပ်ခြင်း လိုအပ်ချက်များ

စမ်းသပ်ခြင်းတွင် သမားရိုးကျမဟုတ်သော လျှပ်စီးကြောင်း (Int) နှင့် နောက် 5 စက္ကန့်အတွင်း သမားရိုးကျ tripping current (It) ပါဝင်သည်။

စမ်းသပ်မှု ကန့်သတ်ချက်များ-

- ချက်ခြင်းခရီး- သံလိုက်ကာကွယ်ရေးသည် သတ်မှတ်ချက်များအတွင်း လုပ်ဆောင်နေကြောင်း အတည်ပြုပါ။

- Short-Circuit Performance- အမြင့်ဆုံး ချို့ယွင်းမှုအခြေအနေများအောက်တွင် စမ်းသပ်ဖောက်ထွင်းနိုင်မှု

- ရွေးချယ်မှုစမ်းသပ်ခြင်း- အထက်ရေစီးကြောင်းစက်များနှင့် သင့်လျော်သော ညှိနှိုင်းဆောင်ရွက်မှုကို သေချာပါစေ။

- Arc နှောင့်ယှက်ခြင်း- သတ်မှတ်ထားသောအချိန်အတွင်း ပြီးပြည့်စုံသော arc မျိုးသုဉ်းခြင်းကို အတည်ပြုပါ။

လျှပ်စစ်စွမ်းဆောင်ရည်စမ်းသပ်ခြင်း။

ပါဝါကြိမ်နှုန်းခံနိုင်ရည်ရှိဗို့အားစမ်းသပ်ခြင်း- စွမ်းဆောင်ရည်စစ်ဆေးခြင်းတွင် စံချိန်စံညွှန်း GB10963 နှင့် IEC60898 တို့ကို ရည်ညွှန်းသည့် စမ်းသပ်မှုများအားလုံးတွင် ပါဝါ-ကြိမ်နှုန်းခံနိုင်ရည်ရှိသော ဗို့အားစမ်းသပ်မှု ပါဝင်ပါသည်။

ပြည့်စုံသောစမ်းသပ်မှုအစုံ-

- လျှပ်ကာခံနိုင်ရည်- တိုင်များနှင့် မြေပြင်ကြား အနိမ့်ဆုံး 5MΩ

- Dielectric Strength- ပြိုကွဲခြင်းမရှိဘဲ သတ်မှတ်ထားသော စမ်းသပ်ဗို့အားများကို ခံနိုင်ရည်ရှိသည်။

- အဆက်အသွယ် ခုခံမှု- အဆက်အသွယ် အင်တာဖေ့စ်တစ်လျှောက် အနိမ့်နှင့် တည်ငြိမ်သော ခုခံမှု

- အပူချိန်မြင့်တက်ခြင်း- အစိတ်အပိုင်းများသည် အပူချိန်ကန့်သတ်ချက်များအတွင်း ရှိနေပါသည်။

အရည်အသွေးစစ်ဆေးရေးစာရင်း

Visual and Dimensional စစ်ဆေးခြင်း။

ပုံပန်းသဏ္ဍာန် စာမေးပွဲသည် အရည်အသွေး အကဲဖြတ်ခြင်း၏ ပထမတန်းကို ပုံဖော်သည်။ စစ်ဆေးခြင်းတွင် ပုံပန်းသဏ္ဍာန်စစ်ဆေးခြင်း၊ ပြင်ပနှင့် အတွင်းပိုင်း အဓိကပစ္စည်းစစ်ဆေးခြင်း၊ စက်လည်ပတ်မှုနှင့် စွမ်းဆောင်ရည်စစ်ဆေးခြင်းတို့ ပါဝင်ပါသည်။

အမြင်အာရုံစစ်ဆေးရေးအမှတ်များ-

- အိမ်ရာခိုင်မာမှု- အက်ကွဲခြင်း၊ ပုံပျက်ခြင်း သို့မဟုတ် ပစ္စည်းချွတ်ယွင်းချက်မရှိပါ။

- အမှတ်အသားပြုခြင်း မှန်ကန်မှု- အဆင့်သတ်မှတ်ခြင်းနှင့် အသိအမှတ်ပြု အမှတ်အသားများကို ရှင်းလင်းပါ။

- Terminal အခြေအနေ- သင့်လျော်သောဝက်အူကြိုးချည်ခြင်းနှင့် အဆက်အသွယ်မျက်နှာပြင်များ

- အတွင်းပိုင်းစည်းဝေးပွဲ- အစိတ်အပိုင်းများကို နေရာချထားခြင်းနှင့် လုံခြုံစေခြင်းတို့ကို မှန်ကန်စေသည်။

ပစ္စည်းအရည်အသွေး အကဲဖြတ်ခြင်း။

အတွင်းပိုင်း အဓိကပစ္စည်းစစ်ဆေးခြင်းသည် အစိတ်အပိုင်းအရည်အသွေးသတ်မှတ်ချက်များနှင့် ကိုက်ညီကြောင်း သေချာစေသည်။

ပစ္စည်းအတည်ပြုခြင်း-

- ဆက်သွယ်ရန်ပစ္စည်းများ- ငွေသတ္တုစပ်ဖွဲ့စည်းမှုနှင့် အထူကို စစ်ဆေးပါ။

- Arc Chute Materials- သင့်လျော်သော လျှပ်ကာပစ္စည်းဂုဏ်သတ္တိများကို အတည်ပြုပါ။

- အိမ်သုံးပစ္စည်းများ- မီးမလောင်နိုင်သော နှင့် စက်ပိုင်းဆိုင်ရာ ဂုဏ်သတ္တိများကို အတည်ပြုပါ။

- အတွင်းသတ္တုများ- ကြေးနီပါဝင်မှုနှင့် သတ္တုစပ် သတ်မှတ်ချက်များကို စစ်ဆေးပါ။

Functional Testing Checklist

စွမ်းဆောင်ရည်စမ်းသပ်ခြင်း Matrix-

| စမ်းသပ်မှုအမျိုးအစား | ဇာတိ | စံ | သတ်မှတ်ချက် |

|---|---|---|---|

| ပူခရီး | 1.13 In | IEC 60898 | ၁ နာရီအတွင်း ခရီးမထွက်ပါ။ |

| ပူခရီး | 1.45 In | IEC 60898 | မျဉ်းကွေးအတွင်း ခရီး |

| ပူခရီး | 2.55 In | IEC 60898 | မျဉ်းကွေးအတွင်း ခရီး |

| သံလိုက်ခရီးစဉ် | ချက်ခြင်း | IEC 60898 | ခရီးစဉ် < 0.1 စက္ကန့် |

| ဗို့အားကိုခံနိုင်ရည်ရှိသည်။ | 2.5kV | IEC 60898 | ပြိုကွဲခြင်းမရှိ |

| စက်လည်ပတ်မှု | ၁၀၊၀၀၀ သံသရာ | IEC 60898 | ယုံကြည်စိတ်ချရသောလည်ပတ်မှု |

ပတ်ဝန်းကျင် စမ်းသပ်ခြင်း

လည်ပတ်မှုအခြေအနေ အတည်ပြုခြင်း-

- အပူချိန်အတိုင်းအတာ- -25°C မှ +55°C လုပ်ဆောင်ချက်

- စိုထိုင်းဆ ခုခံမှု- 95% RH မဟုတ်သော condensing

- တုန်ခါမှုဒဏ်ခံနိုင်မှု- သယ်ယူပို့ဆောင်ရေးနှင့် တပ်ဆင်မှုဆိုင်ရာ ဖိစီးမှုများ

- ညစ်ညမ်းမှုဒီဂရီ- တပ်ဆင်ပတ်ဝန်းကျင်အတွက် သင့်လျော်သည်။

အဖြစ်များသော ထုတ်လုပ်မှု ချို့ယွင်းချက်များ

အရေးကြီးသော ချို့ယွင်းချက်များ (Safety Impact)

Arc Chute ချို့ယွင်းချက်များ- အန္တရာယ်များ သို့မဟုတ် MCB ပျက်စီးမှုများကို ကာကွယ်ရန် လက်ရှိပြတ်တောက်နေချိန်တွင် ထုတ်လုပ်သော သံမှိုနှင့် အကာအရံများသည် စွမ်းအင်ကို ခံနိုင်ရည်ရှိရပါမည်။

စောင့်ကြည့်ရန် အရေးကြီးသော ပြဿနာများ-

- မလုံလောက်သော Arc ပြတ်တောက်မှု- မလုံလောက်သော arc chute ဒီဇိုင်း

- ဆက်သွယ်ရန် ဂဟေဆော်ခြင်း- ညံ့ဖျင်းသော အဆက်အသွယ်ပစ္စည်းများကို ဖွင့်ရန် ပျက်ကွက်စေသည်။

- လျှပ်ကာပြိုကွဲခြင်း- ကျိုးပဲ့သော dielectric ခွန်အား

- စက်ပိုင်းဆိုင်ရာ စည်းနှောင်ခြင်း- လည်ပတ်မှု ယန္တရား ချို့ယွင်းမှု

အဓိကချို့ယွင်းချက်များ (စွမ်းဆောင်ရည်သက်ရောက်မှု)

ချိန်ညှိခြင်းဆိုင်ရာ ပြဿနာများ- အရည်အသွေးမြင့် bimetal စာရွက်ကို အရည်အသွေးကောင်း MCB များတွင် အသုံးပြုပြီး အရည်အသွေးကောင်း MCB သည် ဝန်ပိုသွားပါက ချက်ခြင်း ခရီးရောက်ပါမည်။

အဓိက အရည်အသွေး စိုးရိမ်စရာများ-

- Trip Curve Deviation- လက်ခံနိုင်သော ခံနိုင်ရည်ကြိုးများ အပြင်ဘက်

- ဆက်သွယ်ရန်ခုခံမှု- သတ်မှတ်ချက်ကန့်သတ်ချက်များထက် ပိုများသည်။

- လည်ပတ်မှုအင်အားစု- အလွန်အကျွံ လက်စွဲစစ်ဆင်ရေး အင်အား လိုအပ်သည်။

- အပူချိန် မတည်ငြိမ်မှု- အပူချိန်ဖြင့် ဝိသေသလက္ခဏာများ ပျံ့လွင့်ခြင်း။

အသေးစားချို့ယွင်းချက်များ (အလှကုန်/စာရွက်စာတမ်းများ)

ပုံပန်းသဏ္ဍာန်နှင့် အမှတ်အသားပြဿနာများ-

- မျက်နှာပြင် ပြီးမြောက်ခြင်း- ခြစ်ရာများ သို့မဟုတ် အရောင်ပြောင်းခြင်း (အလုပ်မလုပ်သော)

- အမှတ်အသားအရည်အသွေး- မှိန်ဖျော့သွားခြင်း သို့မဟုတ် မှားယွင်းနေသော အဆင့်သတ်မှတ်ချက် တံဆိပ်များ

- ထုပ်ပိုးမှု- ထုတ်ကုန်ကို မထိခိုက်စေဘဲ အသေးစား ထုပ်ပိုးမှု ပျက်စီးခြင်း။

- စာရွက်စာတမ်း- နည်းပညာဆိုင်ရာ အချက်အလက်စာရွက်များ ပျောက်ဆုံးနေ သို့မဟုတ် မမှန်ပါ။

ပေးသွင်းသူ အကဲဖြတ်မှု မူဘောင်

ထုတ်လုပ်မှုစွမ်းရည် အကဲဖြတ်ခြင်း။

အရည်အသွေးစီမံခန့်ခွဲမှုစနစ်- ISO 9001 ကဲ့သို့သော ကောင်းမွန်သောဖွဲ့စည်းပုံကျသော QMS ကို အကောင်အထည်ဖော်ခြင်းသည် အရည်အသွေးကို ထိန်းသိမ်းရန်နှင့် မြှင့်တင်ရန်၊ လုပ်ငန်းစဉ်များ၊ တာဝန်များကို သတ်မှတ်ခြင်းနှင့် စစ်ဆေးမှုများအတွက် မူဘောင်တစ်ခုဖြစ်သည်။

အကဲဖြတ်မှု သတ်မှတ်ချက်-

- ISO 9001 အသိအမှတ်ပြုလက်မှတ်- လက်ရှိနှင့် အတိုင်းအတာ-သင့်လျော်သော လက်မှတ်

- IEC 17025 စမ်းသပ်ခြင်း- အသိအမှတ်ပြုထားသော အိမ်တွင်းစမ်းသပ်မှုစွမ်းရည်

- ထုတ်လုပ်မှုထိန်းချုပ်ရေး- စာရင်းအင်းဆိုင်ရာ လုပ်ငန်းစဉ် ထိန်းချုပ်အကောင်အထည်ဖော်မှု

- ခြေရာခံနိုင်မှုစနစ်များ- အစိတ်အပိုင်းနှင့် လုပ်ငန်းစဉ် ခြေရာခံနိုင်မှု

နည်းပညာဆိုင်ရာ ကျွမ်းကျင်မှု စိစစ်ခြင်း။

ဒီဇိုင်းနှင့် ဖွံ့ဖြိုးတိုးတက်မှု စွမ်းရည်-

- အင်ဂျင်နီယာအရင်းအမြစ်များ- ဝန်ထမ်းများတွင် အရည်အချင်းပြည့်မီသော လျှပ်စစ်အင်ဂျင်နီယာများ

- စမ်းသပ်ကိရိယာ- MCB အပူနှင့် သံလိုက်တုံ့ပြန်မှု၏ လုပ်ရိုးလုပ်စဉ်နှင့် အရည်အသွေးထိန်းချုပ်မှု စမ်းသပ်ခြင်းအတွက် နိုင်ငံတကာစံချိန်စံညွှန်းများနှင့်ပြည့်မီရန် ဒီဇိုင်းထုတ်ထားသော စမ်းသပ်မှုစနစ်များ

- လိုက်နာမှု အသိပညာ- သက်ဆိုင်သော စံနှုန်းများကို နားလည်ခြင်း။

- စဉ်ဆက်မပြတ် တိုးတက်မှု- လက်ရှိ အရည်အသွေးမြှင့်တင်မှု အထောက်အထား

ထောက်ပံ့ရေးဆိုင်ခွဲစီမံအုပ်ချုပ်မှု

အစိတ်အပိုင်း အရည်အသွေး ထိန်းချုပ်မှု-

- ပေးသွင်းသူအရည်အချင်း- ခွင့်ပြုထားသော ရောင်းချသူစာရင်းများနှင့် စာရင်းစစ်ခြင်း။

- အဝင်စစ်ဆေးခြင်း- ကုန်ကြမ်းနှင့် အစိတ်အပိုင်းများကို စစ်ဆေးခြင်း။

- ပစ္စည်းအထောက်အထားများ- ပစ္စည်းဂုဏ်သတ္တိများ၏ မှန်ကန်သောစာရွက်စာတမ်းများ

- ထိန်းချုပ်မှု ပြောင်းလဲခြင်း- ဒီဇိုင်း သို့မဟုတ် ပေးသွင်းသူ အပြောင်းအလဲများအတွက် တရားဝင် လုပ်ငန်းစဉ်များ

အကောင် အထည်ဖော်ရန် အကောင်းဆုံး အလေ့အကျင့်များ

ဝင်လာသော အရည်အသွေးထိန်းချုပ်မှု

စစ်ဆေးခြင်းနမူနာနည်းဗျူဟာ- စက်မှု-စံ AQL နမူနာကောက်ယူခြင်းတွင် ကိန်းဂဏန်းလမ်းညွှန်ချက်များအပေါ်အခြေခံ၍ နမူနာအရွယ်အစားများကို ရွေးချယ်ခြင်း၊ အမျိုးအစားသုံးမျိုးတွင် ခွင့်ပြုနိုင်သော ချို့ယွင်းချက်အရေအတွက်များကို စစ်ဆေးခြင်း ပါဝင်သည်။

အကောင်းဆုံး အလေ့အကျင့် အကောင်အထည်ဖော်ခြင်း-

- AQL Sampling Plans- အများအပြားအရွယ်အစားအတွက် သင့်လျော်သောနမူနာ

- ပထမအပိုဒ်စစ်ဆေးခြင်း- ကနဦးထုတ်လုပ်မှုကို စေ့စေ့စပ်စပ် အကဲဖြတ်ခြင်း။

- Batch Testing- ထုတ်လုပ်မှုလုပ်ငန်းတစ်ခုစီ၏ ကိုယ်စားပြုနမူနာ

- ပေးသွင်းသူ အမှတ်စာရင်းများ- လက်ရှိ စွမ်းဆောင်ရည် ခြေရာခံခြင်း။

လုပ်ငန်းစဉ် အရည်အသွေး စောင့်ကြည့်စစ်ဆေးခြင်း။

လုပ်ငန်းစဉ်အတွင်း ထိန်းချုပ်မှုများ-

- Statistical Process Control- အဓိက ကန့်သတ်ဘောင်များကို အချိန်နှင့်တပြေးညီ စောင့်ကြည့်ခြင်း။

- First-Pass Yield- ထုတ်လုပ်မှု ထိရောက်မှု မက်ထရစ်များကို ခြေရာခံခြင်း။

- ချို့ယွင်းမှုနှုန်း ခွဲခြမ်းစိတ်ဖြာခြင်း- ထပ်တလဲလဲ ပြဿနာများကို ဖော်ထုတ်ခြင်း။

- မှန်ကန်သောလုပ်ဆောင်မှုစနစ်များ- စနစ်တကျ ပြဿနာဖြေရှင်းခြင်း။

စာရွက်စာတမ်းနှင့် ခြေရာခံနိုင်မှု

အရည်အသွေးမှတ်တမ်းများ စီမံခန့်ခွဲမှု-

- စမ်းသပ်မှုလက်မှတ်များ- စစ်ဆေးမှုအားလုံး၏ စာရွက်စာတမ်းအပြည့်အစုံ

- Calibration မှတ်တမ်းများ- စက်ပစ္စည်း တိုင်းတာမှု အခြေအနေနှင့် မှတ်တမ်း

- ကိုက်ညီမှုမရှိသော အစီရင်ခံစာများ- အရည်အသွေးဆိုင်ရာ ပြဿနာများကို စနစ်တကျ ကိုင်တွယ်ခြင်း။

- ဖောက်သည်တုံ့ပြန်ချက်- နယ်ပယ်စွမ်းဆောင်ရည်ဒေတာကို ပေါင်းစပ်ခြင်း။

စဉ်ဆက်မပြတ် တိုးတက်မှု

အရည်အသွေးမြှင့်တင်ရေး အစီအစဉ်-

- ချို့ယွင်းချက် ခွဲခြမ်းစိတ်ဖြာခြင်း- နယ်ပယ် ချို့ယွင်းမှုများကို စုံစမ်းစစ်ဆေးခြင်း၏ အရင်းခံအကြောင်းရင်း

- ဒီဇိုင်းသုံးသပ်ချက်များ- ထုတ်ကုန်စွမ်းဆောင်ရည်ကို ပုံမှန်အကဲဖြတ်ခြင်း။

- နည်းပညာ အပ်ဒိတ်များ- တိုးတက်ကောင်းမွန်သော ပစ္စည်းများနှင့် လုပ်ငန်းစဉ်များ ပေါင်းစပ်ခြင်း။

- လေ့ကျင့်ရေးအစီအစဥ်များ- အရည်အသွေးရှိသော ဝန်ထမ်းများအတွက် စဉ်ဆက်မပြတ်ပညာရေး

နိဂုံး

MCB ထုတ်လုပ်မှုတွင် အရည်အသွေးအာမခံချက်သည် စံချိန်စံညွှန်းများလိုက်နာမှု၊ အစိတ်အပိုင်းအရည်အသွေး၊ စမ်းသပ်မှုခိုင်မာမှုနှင့် စနစ်တကျစစ်ဆေးရေးလုပ်ငန်းစဉ်များပါ၀င်သည့် ပြည့်စုံသောချဉ်းကပ်မှုတစ်ခု လိုအပ်ပါသည်။ အသေးစား circuit breaker များ၏ ဘေးကင်းရေး-အရေးပါသည့် သဘောသဘာဝသည် ထုတ်လုပ်သူနှင့် ဝယ်သူများကဲ့သို့ အရည်အသွေးအမြင့်ဆုံး စံချိန်စံညွှန်းများကို ထိန်းသိမ်းရန် တောင်းဆိုသည်။

အဓိက ထုတ်ယူမှုများ-

ထုတ်လုပ်သူများအတွက်-

- ISO 9001 နှင့် IEC စံနှုန်းများနှင့်အညီ ခိုင်မာသော QMS ကို အကောင်အထည်ဖော်ပါ။

- သင့်လျော်သော စမ်းသပ်ကိရိယာများနှင့် ချိန်ညှိခြင်းအစီအစဉ်များတွင် ရင်းနှီးမြှုပ်နှံပါ။

- ပြည့်စုံသော ပေးသွင်းသူ အရည်အချင်းနှင့် စောင့်ကြည့်ခြင်းကို ထူထောင်ပါ။

- အသေးစိတ်စာရွက်စာတမ်းများနှင့် ခြေရာခံနိုင်မှုစနစ်များကို ထိန်းသိမ်းပါ။

ဝယ်ယူသူများအတွက်-

- IEC စံနှုန်းများကို အခြေခံ၍ အသေးစိတ် အရည်အသွေး သတ်မှတ်ချက်များကို ပြုစုပါ။

- သင့်လျော်သော AQL နမူနာနှင့် စစ်ဆေးရေး ပရိုတိုကောများကို အကောင်အထည်ဖော်ပါ။

- ပေးသွင်းသူ၏ ထုတ်လုပ်မှုစွမ်းရည်နှင့် အသိအမှတ်ပြုလက်မှတ်များကို အကဲဖြတ်ပါ။

- လက်ရှိ အရည်အသွေး စောင့်ကြည့်ခြင်းနှင့် တုံ့ပြန်မှုစနစ်များ ထူထောင်ပါ။

အရည်အသွေးကျွမ်းကျင်သူများအတွက်

- တိုးတက်ပြောင်းလဲနေသော IEC စံနှုန်းများနှင့် ဒေသဆိုင်ရာလိုအပ်ချက်များဖြင့် လက်ရှိနေပါ။

- အလုံးစုံ အရည်အသွေး ကုန်ကျစရိတ်များကို စီမံခန့်ခွဲရာတွင် အရေးကြီးသော ဘေးကင်းရေးကဏ္ဍများကို အာရုံစိုက်ပါ။

- အရည်အသွေးစောင့်ကြည့်ခြင်းနှင့် မြှင့်တင်ခြင်းအတွက် ဒေတာမောင်းနှင်သည့် နည်းလမ်းများကို အကောင်အထည်ဖော်ပါ။

- အပြန်အလှန် အရည်အသွေး ကတိကဝတ်များကို အခြေခံ၍ ခိုင်မာသော ပေးသွင်းသူ မိတ်ဖက်များ တည်ဆောက်ပါ။

ပြည့်စုံသော MCB ထုတ်လုပ်မှု အရည်အသွေး အာမခံချက်တွင် ရင်းနှီးမြှုပ်နှံမှုသည် နယ်ပယ်တွင် ချို့ယွင်းမှုများ လျော့နည်းခြင်း၊ ဘေးကင်းမှု စွမ်းဆောင်ရည် မြှင့်တင်ပေးခြင်းနှင့် ဖောက်သည်ယုံကြည်မှု ပိုမိုခိုင်မာခြင်းတို့မှတစ်ဆင့် အမြတ်ဝေစုများကို ပေးဆောင်သည်။ လျှပ်စစ်စနစ်များ ပိုမိုရှုပ်ထွေးလာပြီး ဘေးကင်းရေးလိုအပ်ချက်များ ပိုမိုတင်းကြပ်လာသည်နှင့်အမျှ MCB ထုတ်လုပ်မှုတွင် တိကျသောအရည်အသွေးအာမခံချက်၏ အရေးပါမှုသည် ဆက်လက်ကြီးထွားလာမည်ဖြစ်သည်။

ဆက်စပ်

2025 ခုနှစ်တွင် ကမ္ဘာ့စျေးကွက်ကို လွှမ်းမိုးမည့် ထိပ်တန်း MCB ထုတ်လုပ်သူ ၁၀ ဦး

MCB အတွက် မှန်ကန်သော Busbar ကိုရွေးချယ်နည်း

RCD နှင့် MCB- လျှပ်စစ်ကာကွယ်ရေးကိရိယာများတွင် အဓိကကွာခြားချက်များကို နားလည်ခြင်း။

MCB Busbars ကို ထည့်သွင်းသည့်အခါ ရှောင်ရှားရန် ထိပ်တန်း 5 အမှားများ