You’re specifying equipment for a solar combiner box, a motor control panel, or a manufacturing facility—and your supplier asks a critical question: “Do you need a fuse holder or a fuse switch disconnector?” Your first instinct is probably cost-driven. A standard fuse holder costs $50–$100. A fused disconnect switch runs $200–$400. The difference feels significant on a multi-circuit installation.

But here’s the tension: your maintenance team might open this device while equipment is running. And if they open the wrong device under load, you’re looking at sustained electrical arcing, potential equipment damage, personnel injury risk, and regulatory violations. The real cost isn’t the initial purchase—it’s the liability.

The answer to whether you can operate them under load depends entirely on how the device is rated by IEC 60947-3. Understanding that difference is what protects your installation and your team.

Understanding Load-Break Operation: The Arc Question

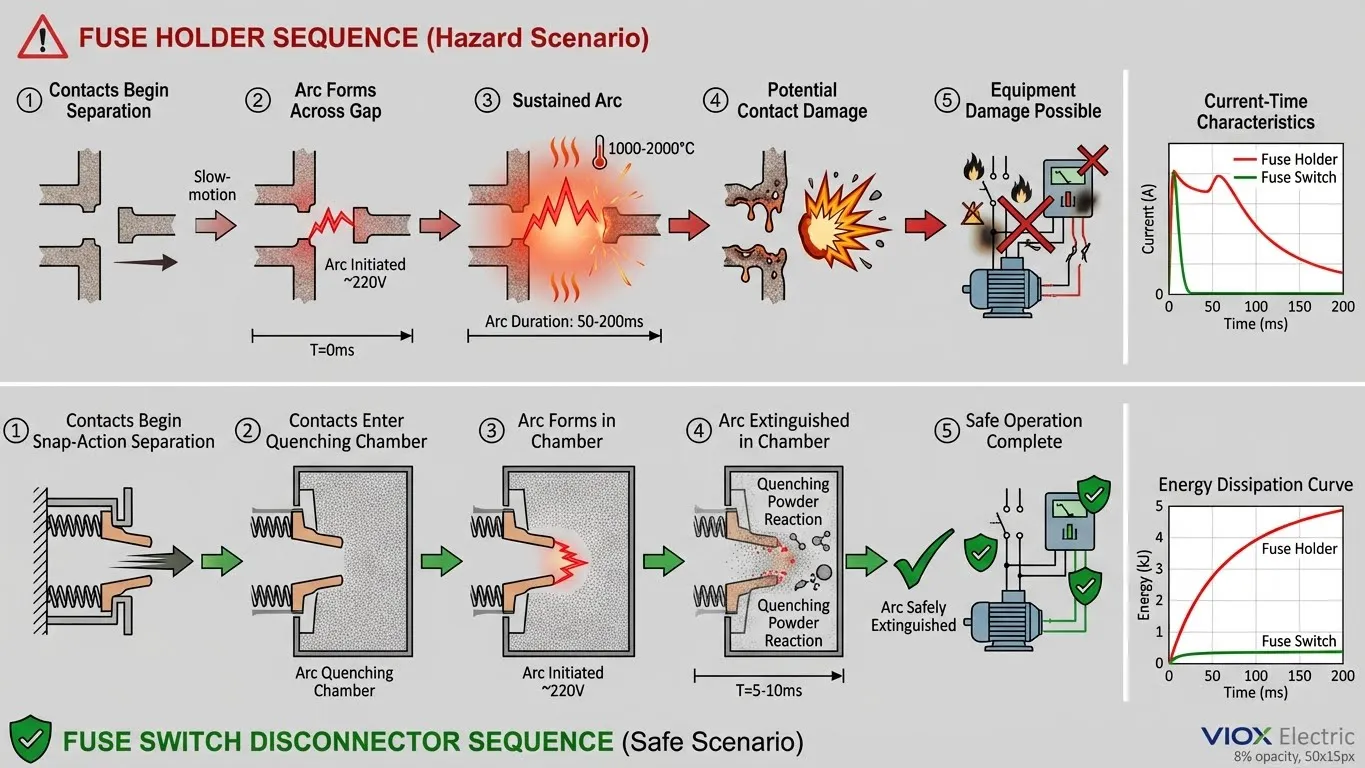

When electrical contacts separate under current flow, something dangerous happens instantly: an arc forms across the gap. This arc creates temperatures exceeding 1000°C—hot enough to melt contacts, damage equipment, and inject enough thermal and electrical energy to injure personnel nearby.

A standard fuse holder cannot safely manage this arc. The contacts separate through simple mechanical action with no internal containment or suppression. The arc sustains for 50–200 milliseconds, potentially causing contact welding, pitting, or internal damage. In worst-case scenarios, the arc can reignite after initial extinction, creating dangerous conditions.

A fuse switch disconnector is specifically engineered to extinguish this arc safely. Through internal arc-quenching chambers filled with specialized insulating materials, rapid snap-action mechanisms, and reinforced contacts, it interrupts the circuit in 5–10 milliseconds—before dangerous energy can accumulate.

This is not a theoretical distinction. IEC 60947-3 standards exist because actual arc flash incidents and equipment failures have established clear safety requirements. Choosing the right device isn’t convenience—it’s compliance and protection.

What is a Fuse Holder? AC-20 Off-Load Only

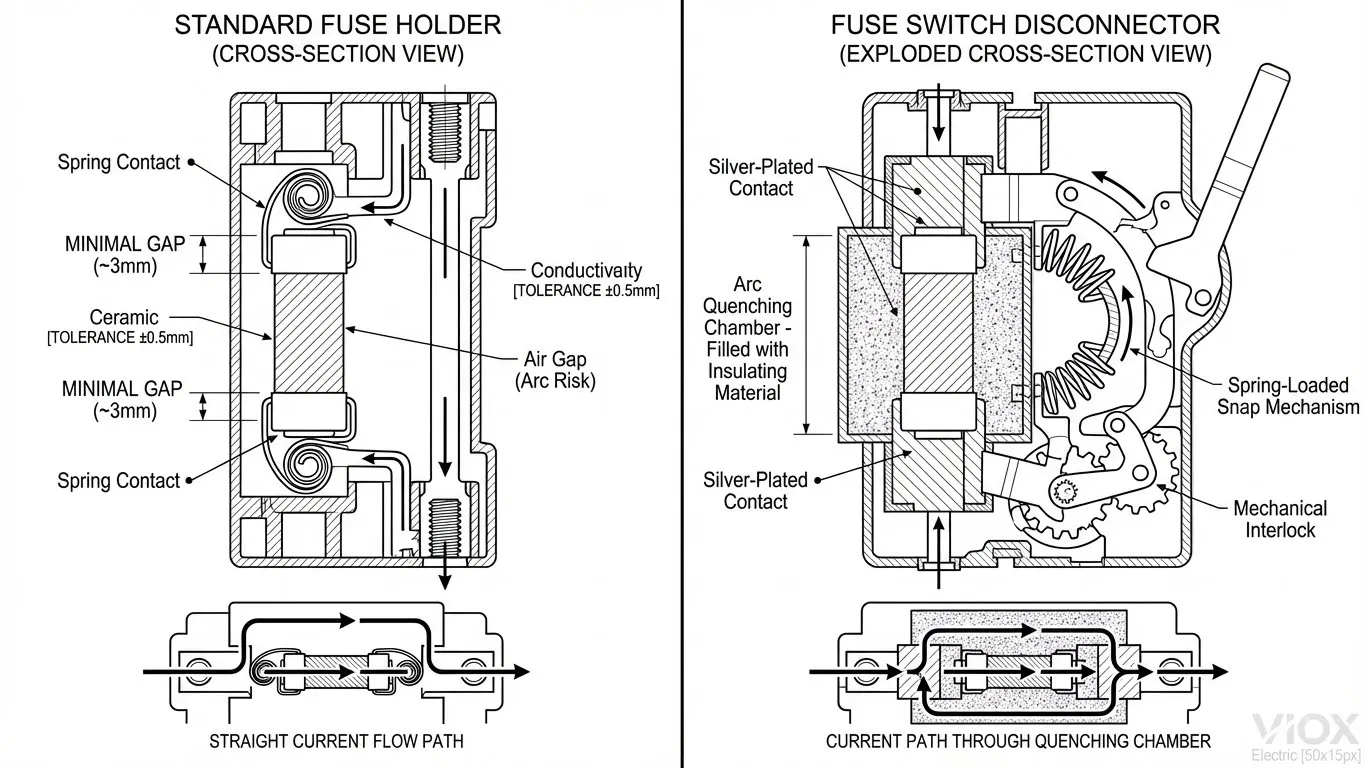

A fuse holder is a mounting component designed to house and connect a fuse within a circuit. It provides secure mechanical mounting, reliable electrical contact, and simplified fuse replacement. Think of it as a connector that positions and holds a fuse in place.

Critical limitation: Most standard fuse holders carry an AC-20 utilization rating. This IEC 60947-3 designation means the device is rated for “switching under no-load conditions only.” In practical terms: you can open it when no current is flowing. You cannot safely open it when the circuit is energized and current is running through it.

Common construction: A ceramic or phenolic body with spring contacts from top and bottom, brass terminal screws, and minimal internal complexity. This simplicity is why they’re inexpensive and why they’re suitable for low-risk applications like backup fuse protection or individual circuit components that are never manually switched under load.

When AC-20 is adequate: You’re using a separate circuit breaker or main switch to de-energize the circuit before opening the fuse holder. Your maintenance procedure always stops the load first, then opens the disconnect device, then accesses the fuse.

When AC-20 is not adequate: Your facility design requires the ability to open the device while the circuit is energized—such as a solar PV combiner box where the incoming DC strings cannot be easily de-energized, or a motor feeder where stopping the motor first might not be practical in all scenarios.

What is a Fuse Switch Disconnector? Load-Break Capability

A fused disconnect switch combines three functions in one enclosure: a manual operating handle for visible isolation, integrated fuses for overcurrent protection, and load-break capability. This means it’s rated to safely open a circuit while current is flowing through it.

AC-22B rating (small inductive loads): The device can safely break small loads—typically resistive loads, small inductive loads like fans or small motors, or mixed loads up to its ampere rating. Break time is typically 10–30 milliseconds, with arc safely confined inside the enclosure.

AC-23A/B rating (heavy motor loads): Advanced designs rate for breaking large inductive loads such as motor starting currents or equipment with high inrush current. These devices have reinforced snap-action mechanisms and larger quenching chambers.

How the design achieves this:

- Arc quenching chamber: Internal space filled with ceramic powder or similar insulating material that rapidly extinguishes forming arcs

- Snap-action mechanism: Spring-loaded contacts that separate rapidly regardless of operator speed, ensuring consistent break time

- Reinforced contacts: Silver-plated copper contacts designed to withstand higher temperatures without welding

- Mechanical interlock: Door cannot open while switch is in ON position, preventing accidental fuse exposure while energized

Result: visible isolation (maintenance personnel can see the gap when the handle is OFF) and safe load-breaking capability, both of which satisfy lockout/tagout requirements and regulatory standards.

Technical Comparison: Fuse Holder vs. Fuse Switch Disconnector

| Feature | Fuse Holder (AC-20) | Fuse Switch Disconnector (AC-22B/AC-23) |

|---|---|---|

| Load-Break Under Current | ❌ Not rated | ✅ Rated (AC-22B small loads, AC-23 heavy loads) |

| Arc Quenching | None; air gap only | ✅ Internal quenching chamber |

| Contact Separation Speed | Manual/variable | ✅ Spring-loaded snap-action (5-10ms) |

| Mechanical Interlock | None | ✅ Door locked in ON position |

| Visible Isolation | No | ✅ Yes (handle OFF = clear gap) |

| Primary Function | Overcurrent protection via fuses | Isolation + Protection + Load-Breaking |

| Arc Duration if Opened Under Load | 50-200ms (dangerous) | 5-10ms (safe) |

| Initial Cost | $50-$150 (30-60A) | $200-$400 (30-60A) |

| Maintenance Complexity | Low | Moderate (fuse replacement) |

| Typical IEC Rating | AC-20 | AC-22B or AC-23A/B |

| Best For | Off-load isolation, backup protection | On-load switching, motor control, solar PV |

| Regulatory Compliance | Manual de-energization required first | Can be opened under load if properly rated |

Practical Example:

- You install a 30A fuse holder for a control circuit. Standard practice requires stopping the load, opening an upstream breaker, verifying de-energization, then accessing the fuses. → AC-20 is appropriate.

- You install a 30A fused disconnect switch for a 3 HP motor feeder. The motor might be running when maintenance needs to isolate the motor for service. An AC-22B switch allows safe opening while the motor runs (though NEC best practice recommends stopping it first). → AC-22B/AC-23 is appropriate.

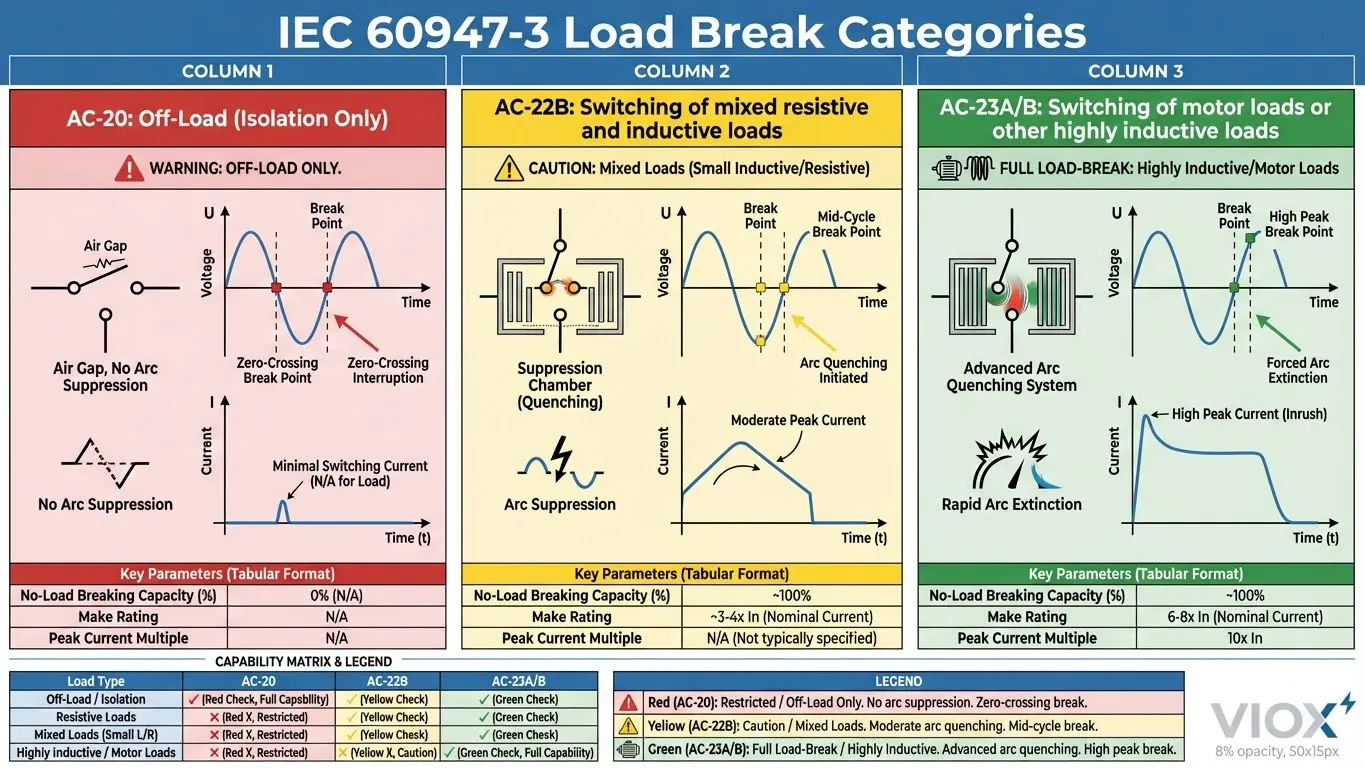

IEC 60947-3 Utilization Categories: Why Standards Matter

AC-20 (Off-Load): Makes and breaks no-load or very small load currents only. Opening under significant load creates sustained arcing. Most standard fuse holders fall into this category.

AC-22B (Small Inductive Loads): Makes and breaks small inductive loads such as small motors, solenoids, or mixed resistive-inductive loads. Peak current on break is typically up to 4× the rated current, but the device contains the arc safely. Suitable for HVAC equipment, small conveyors, or control circuits.

AC-23A/B (Heavy Motor Loads): Makes and breaks motor loads at full voltage and current. Peak current on break can exceed 10× the rated current (for across-the-line starting). These devices have the most robust quenching and are used for main motor feeders. AC-23A is for AC motors; AC-23B is for AC motors started with a softstarter.

Why this matters for your installation: If your specification calls for “AC-20 fuse holders only,” and your facility later requires opening the device under load, you’ve created a safety exposure. If you specify AC-22B fused disconnect switches, you’re planning for operational flexibility while maintaining safety margins.

Safety and Regulatory Requirements: NEC 430.102 & NFPA 70E

The National Electrical Code (NEC) requires disconnect switches for motors to be located “in sight” of the motor—visible and not more than 50 feet away. More importantly, NEC 430.110 requires that motor disconnects have a horsepower rating appropriate to the motor, which typically necessitates load-break capability.

NFPA 70E (Standard for Electrical Safety in the Workplace) emphasizes that opening circuits under load must be done with arc flash hazard awareness. If you’re using a standard fuse holder (AC-20) and opening it under load, you’re creating an uncontrolled arc flash hazard.

Best practice: Always de-energize before opening. But if your installation design allows (or requires) opening the switch while energized, you must use a device rated for that service—AC-22B minimum.

When to Use Each Device

Use a Standard Fuse Holder (AC-20):

- Individual circuit components that are always de-energized before maintenance

- Backup fuse protection where a primary circuit breaker or switch handles load-breaking

- Low-risk applications where no one will be tempted to open under load

- Cost-sensitive installations where compliance requires only off-load isolation

Use a Fused Disconnect Switch (AC-22B/AC-23):

- Motor feeders where NEC 430.110 applies and horsepower ratings are required

- Solar PV combiner boxes where DC strings cannot be easily de-energized

- HVAC equipment serving critical systems where the option to isolate under load is valuable

- Industrial control applications where load-breaking flexibility improves operational safety and uptime

- Any application where maintenance personnel might need to open the device while the circuit is energized

Frequently Asked Questions

Q1: Can I open a standard fuse holder under load in an emergency?

Not safely. While it’s physically possible, you’re creating a sustained arc that can damage contacts, equipment downstream, and potentially injure personnel. Modern installations should always include load-break-rated devices if there’s any possibility of under-load operation. Design your system so load-breaking is done by appropriate devices—circuit breakers or fused disconnect switches—not by default.

Q2: What’s the difference between AC-20, AC-22B, and AC-23?

These are IEC 60947-3 utilization categories that specify what load characteristics a switch can safely handle when breaking (opening) a circuit. AC-20 = no load; AC-22B = small inductive/resistive loads; AC-23A/B = heavy motor loads. Each higher category requires more robust arc-quenching design. Use the category matching your actual application requirement.

Q3: If I use a fused disconnect switch, do I still need an upstream circuit breaker?

For overcurrent protection, the fuses in the disconnect switch provide protection equivalent to a circuit breaker. However, for other functions (like overload protection for motor starters), you might need additional protective devices depending on your system design. Consult NEC Article 430 for motor branch circuit requirements.

Q4: How much more does it cost to use load-break-rated equipment?

Initial hardware cost is typically 2-3× higher ($200-400 vs. $50-150 for 30A devices). However, total cost of ownership includes installation, compliance verification, maintenance, and downtime avoidance. A single unplanned outage or arc flash incident far exceeds the equipment cost difference. Specification and maintenance cost implications are typically recovered in the first incident avoided.

Q5: Does a fused disconnect switch eliminate the need for manual isolation?

No. Even load-break-rated switches should not be opened under load as routine practice. Instead, they provide safe capability for maintenance scenarios where de-energization first isn’t practical or where system design requires flexible isolation. Design your procedures to de-energize first, use load-break switches as a controlled backup capability.

Q6: Are all fuse holders AC-20, or are load-break versions available?

Most modular fuse holders are AC-20. However, some modern modular designs carry AC-22B ratings—check the nameplate. In general, if the device has a simple spring contact design and no internal arc quenching, it’s AC-20. If it includes arc suppression features and snap-action mechanisms, it’s AC-22B or higher. For motor or load-critical applications, always specify and verify the utilization category on the device nameplate.

Key Takeaways

- A standard fuse holder (AC-20) is not rated for opening under load. Opening it while current flows creates sustained arcing, equipment damage risk, and safety hazards.

- A fused disconnect switch (AC-22B/AC-23) is designed for safe load-breaking operation. Internal arc quenching and snap-action mechanisms confine the arc and limit break time to 5–10 milliseconds.

- Your choice depends on how the device will be used. If your procedure always de-energizes first, a fuse holder may be adequate. If operational flexibility or system design requires opening under load, specify AC-22B minimum.

- Specification and training are critical. Ensure your maintenance team understands the difference and follows procedures accordingly. A $300 investment in the right device is cheaper than the regulatory liability of equipment damage or injury.

- Check the IEC 60947-3 utilization category on every switch’s nameplate. Don’t assume—verify that the installed equipment matches your operational requirements.

Need clarification on load-break ratings for your specific application? Contact VIOX Electric’s technical team to discuss your installation requirements and ensure compliance with IEC and NEC standards.

For more information on related topics, explore: