When it comes to controlling electric motors and high-power electrical loads, choosing between a contactor and a motor starter can significantly impact equipment safety, operational efficiency, and long-term costs. While these devices may appear similar, they serve distinct purposes in industrial electrical systems.

At VIOX Electric, a leading B2B manufacturer of electrical equipment, we understand that proper component selection is critical for system reliability. This comprehensive guide breaks down the core differences between contactors and motor starters, helping engineers, electricians, and procurement professionals make informed decisions for their applications.

What Is a Contactor? Understanding the Basics

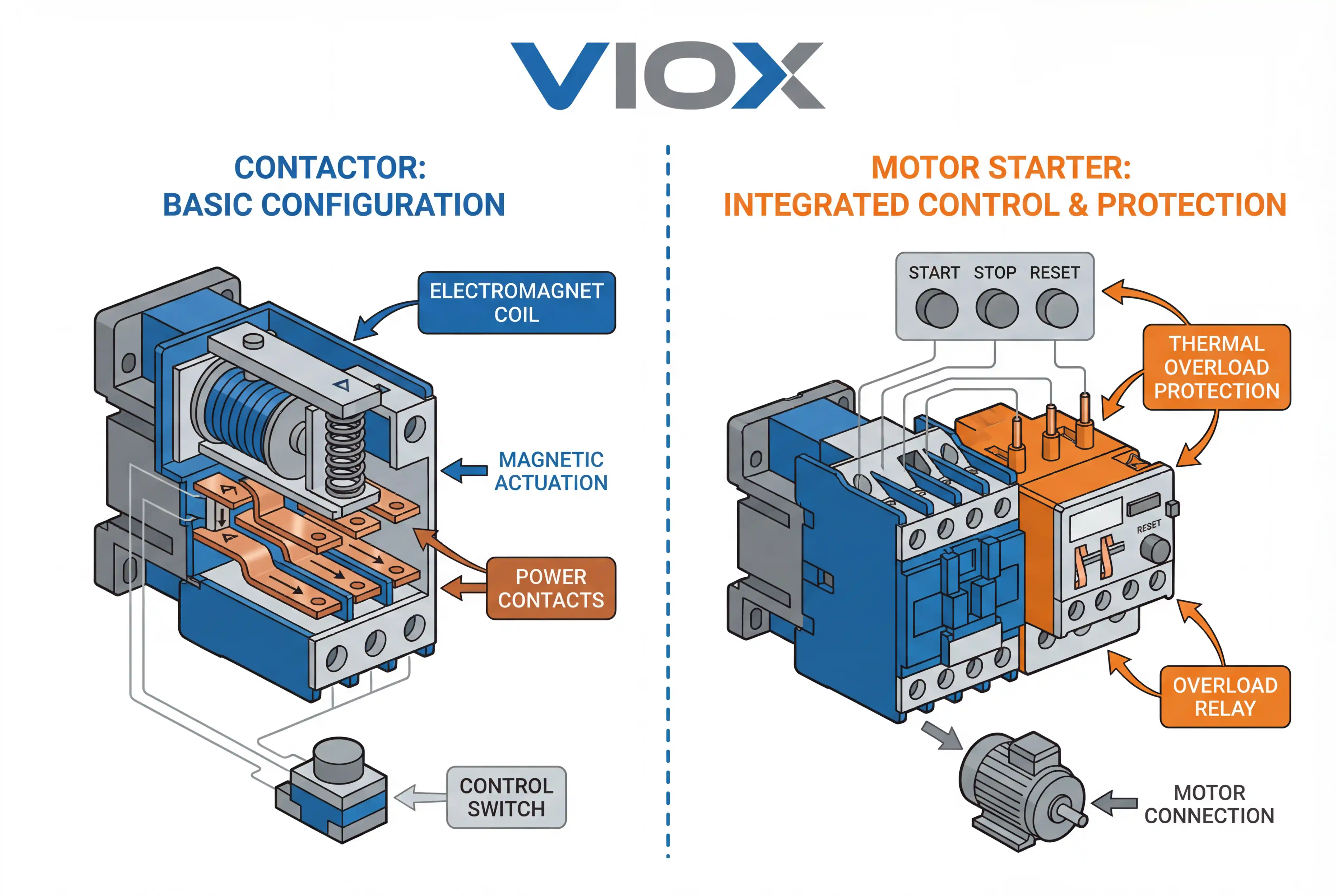

A contactor is an electrically operated switching device designed to make or break high-power electrical circuits. It functions as a heavy-duty relay capable of handling currents typically ranging from 15 amperes to several thousand amperes.

Core Components of a Contactor

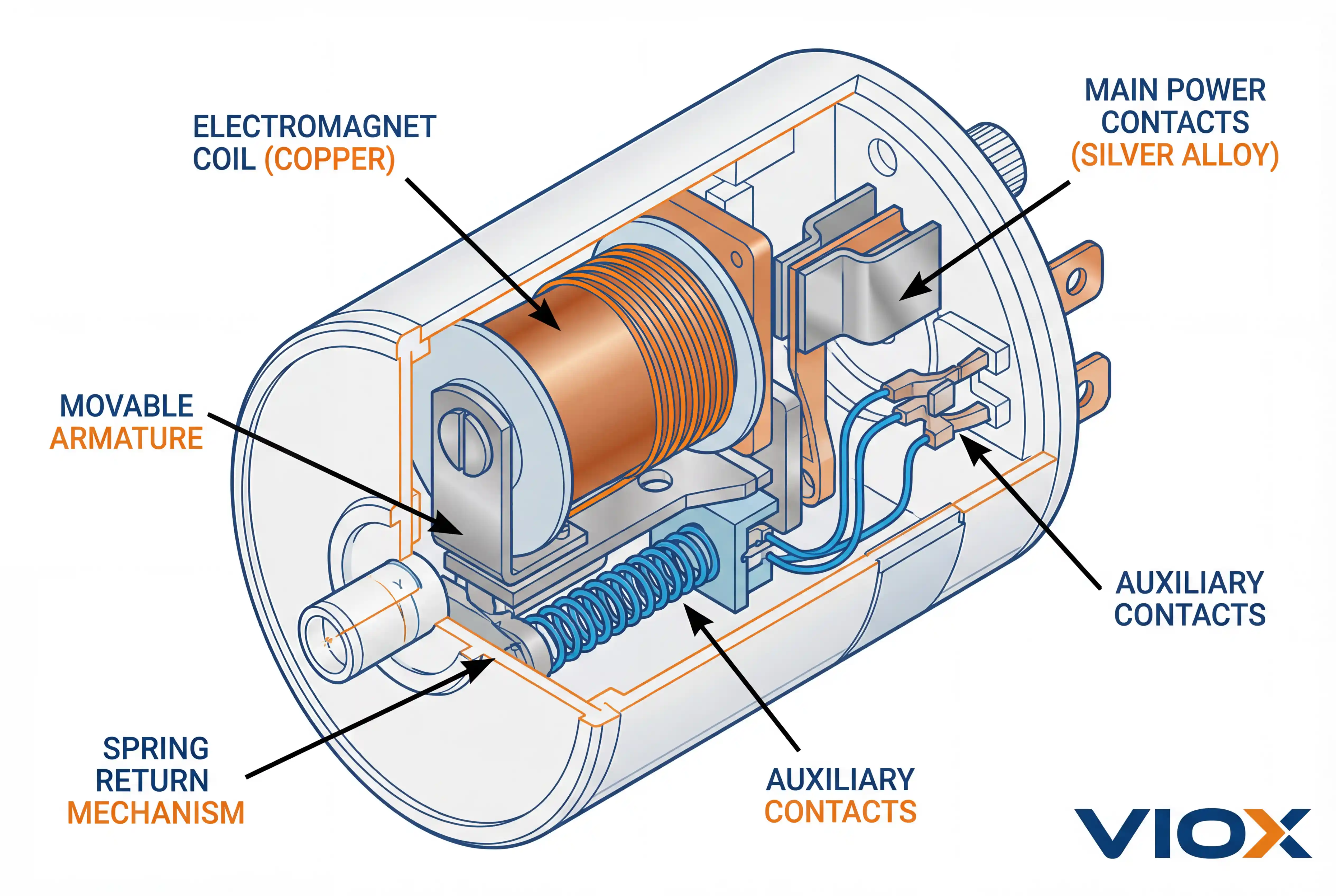

A contactor consists of three primary elements:

- Electromagnet (Coil): A low-power control coil that, when energized, generates a magnetic field. Control voltages typically range from 24V to 600V AC/DC.

- Power Contacts: Current-carrying components made from arc-resistant materials such as silver-cadmium oxide or silver-nickel alloys. These contacts are designed with powerful spring mechanisms to ensure reliable connection.

- Enclosure: Protective housing constructed from insulating materials like thermosetting plastics or Bakelite, providing protection against dust, oil, and accidental contact.

How Contactors Work

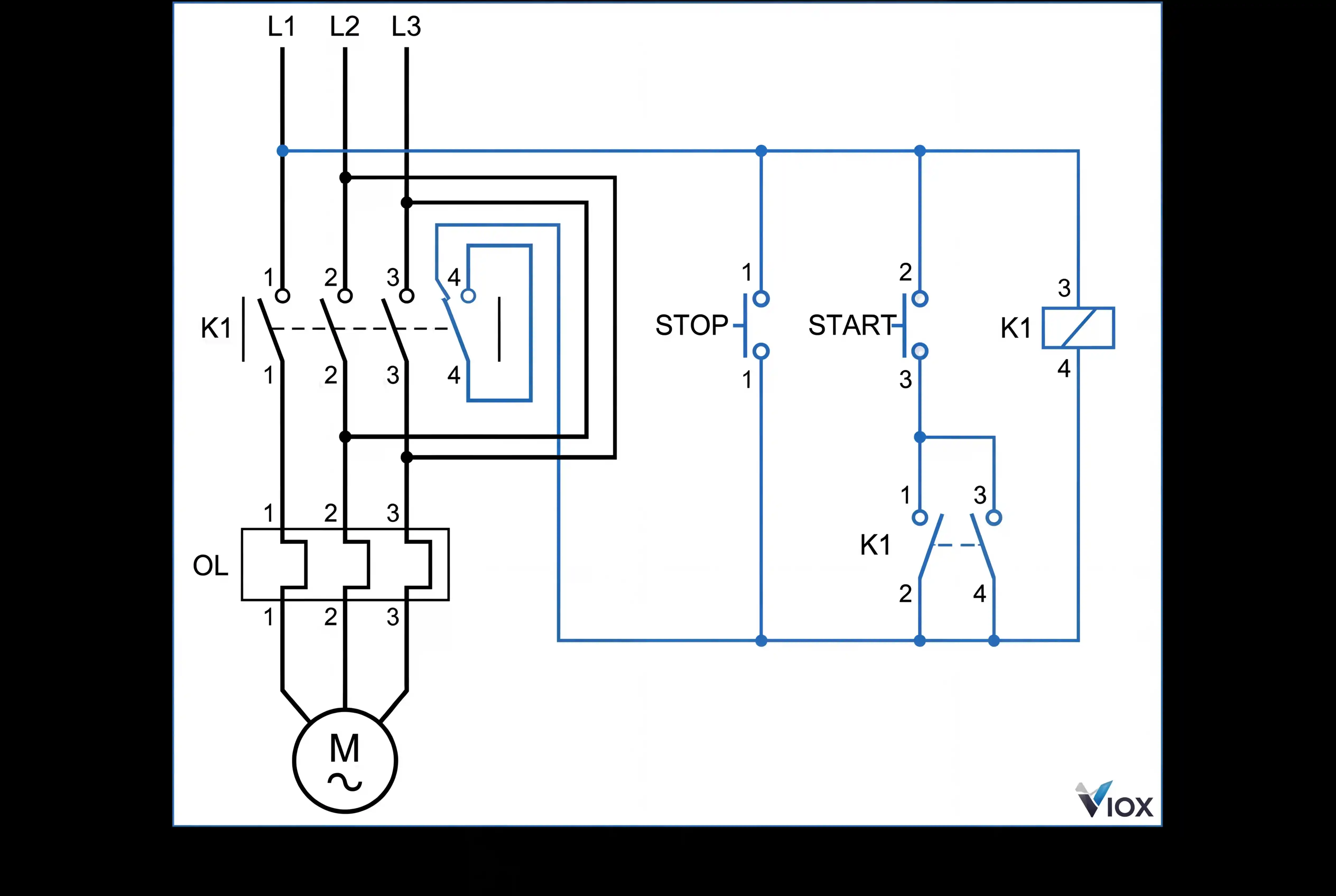

The operation principle is straightforward:

- When control voltage is applied to the electromagnet coil, the resulting magnetic field attracts an armature.

- This action closes the main power contacts with sufficient force to carry high currents.

- When control voltage is removed, the magnetic field collapses, and spring mechanisms open the contacts, interrupting power flow.

- Auxiliary contacts (normally open or normally closed) can be added for control circuit interlocking or status indication.

Key Specifications for Contactors

| Specification | Typical Range | Application Impact |

|---|---|---|

| Rated Current | 9A – 800A+ | Determines load capacity |

| Control Voltage | 24V – 600V AC/DC | Must match control system |

| Number of Poles | 1-4 poles | Matches circuit requirements |

| Utilization Category | AC-1, AC-3, AC-4 | Defines load type compatibility |

| Electrical Life | 100,000 – 1,000,000+ operations | Affects maintenance intervals |

What Is a Motor Starter? Beyond Simple Switching

A motor starter is a comprehensive motor control device that combines switching capability with critical protective functions. It integrates a contactor with an overload relay and often includes additional control components, providing a complete solution for safe motor operation.

Core Components of a Motor Starter

Motor starters include two essential elements:

- Contactor Section: Performs the same switching function as a standalone contactor, controlling power delivery to the motor.

- Overload Relay: The critical protective component that continuously monitors motor current. If current exceeds preset limits for a specified duration (indicating an overload condition), the relay trips, de-energizing the contactor coil and cutting power to prevent motor damage.

Additional components may include:

- Control circuit transformers

- Auxiliary contact blocks

- Indicator lights

- Emergency stop circuits

- Reversing contactors (for reversible motor applications)

How Motor Starters Protect Your Equipment

Motor starters provide three levels of protection:

- Overload Protection: Thermal or electronic relays monitor current and trip if sustained overcurrent occurs (typically 105-125% of rated current).

- Short Circuit Protection: When combined with circuit breakers or fuses, provides instantaneous protection against short circuits.

- Phase Loss Protection: Advanced starters detect and protect against single-phasing conditions that can destroy three-phase motors.

Key Differences: Contactor vs. Motor Starter

Understanding these differences is essential for proper equipment selection:

| Feature | Contactor | Motor Starter |

|---|---|---|

| Primary Function | On/off switching only | Switching + overload protection |

| Core Components | Electromagnet + contacts | Contactor + overload relay + controls |

| Protection Level | None (switching only) | Integrated thermal/electronic overload protection |

| Rating Method | Voltage and current capacity | Motor horsepower (HP) or Full Load Amps (FLA) |

| Typical Applications | Lighting, heating, capacitor banks | Industrial motors, pumps, compressors, fans |

| Cost | Lower (simpler design) | Higher (includes protection features) |

| Standards | IEC 60947-4-1, UL 508 | NEMA ICS 2, IEC 60947-4-1 |

| Maintenance | Contact inspection/replacement | Contacts + overload calibration |

Rating Systems: NEMA vs. IEC

NEMA (North American) Ratings:

- Sized by number designation (Size 00, 0, 1, 2, 3, 4, 5, 6, 7, 8, 9)

- Rated by motor horsepower at specific voltages

- Example: NEMA Size 1 starter = 7.5 HP at 230V, 3-phase

IEC (International) Ratings:

- Designated by letter codes (e.g., AC-3 for normal motor starting)

- Rated by operational current (Ie) and utilization category

- Generally more compact than equivalent NEMA sizes

- Example: 18A contactor with AC-3 category

| NEMA Size | Maximum HP @ 460V | Approximate IEC Equivalent |

|---|---|---|

| 00 | 1.5 HP | 9A contactor |

| 0 | 3 HP | 12A contactor |

| 1 | 7.5 HP | 18A contactor |

| 2 | 15 HP | 32A contactor |

| 3 | 30 HP | 50A contactor |

| 4 | 50 HP | 80A contactor |

Applications: When to Use Each Device

Contactor Applications

Choose a contactor when:

- Load Type: Resistive loads such as lighting arrays, heating elements, or capacitor banks

- Protection: Overload protection is provided by separate devices (PLCs, dedicated motor protection relays)

- Control Requirements: Simple on/off switching without built-in motor protection

- Cost Sensitivity: Budget constraints exist and protection isn’t required

Common contactor applications:

- Commercial and industrial lighting control systems

- Electric heating elements and ovens

- Power factor correction capacitor switching

- Small motors with external protection devices

- Emergency lighting systems

- HVAC damper actuators

Motor Starter Applications

Choose a motor starter when:

- Load Type: Electric motors requiring overload protection

- Safety Requirements: Equipment protection is critical to prevent damage

- Compliance: Local codes require integrated motor protection

- Reliability: Motor downtime has significant cost implications

Common motor starter applications:

- Industrial pumps and compressor systems

- Conveyor belts and material handling equipment

- Machine tools and CNC equipment

- HVAC fans and blowers

- Commercial refrigeration compressors

- Process equipment motors

- Agricultural irrigation pumps

Selection Criteria: Choosing the Right Device

Critical Specifications to Match

For Motor Starters:

- Motor Voltage: Must match motor nameplate voltage (230V, 460V, 575V, etc.)

- Motor Full Load Amps (FLA): Starter must handle motor’s continuous current draw

- Motor Horsepower: Select appropriate NEMA size or IEC rating

- Control Voltage: Match control system voltage (24V, 120V, 240V)

- Starting Method: Direct-on-line (DOL), star-delta, soft start, or VFD

- Duty Cycle: Continuous, intermittent, or jogging service

- Ambient Conditions: Temperature rating, IP/NEMA enclosure rating

For Contactors:

- Load Current: Continuous and inrush current capacity

- Voltage Rating: AC/DC voltage and frequency

- Number of Poles: Match circuit configuration (1, 2, 3, or 4-pole)

- Utilization Category: AC-1 (resistive), AC-3 (motors), AC-4 (heavy starting)

- Auxiliary Contacts: Required number of NO/NC contacts for control

- Coil Voltage: Match control voltage availability

Environmental Considerations

| Factor | Standard Rating | Harsh Environment Rating |

|---|---|---|

| Ambient Temperature | -5°C to +40°C | -25°C to +60°C |

| Enclosure Rating | IP20 / NEMA 1 | IP65 / NEMA 4X |

| Altitude | Up to 1000m | Derating required >1000m |

| Humidity | 50-90% non-condensing | 95% with condensation |

| Vibration | Standard | Enhanced mounting required |

Advanced Starter Types and Technologies

Reduced-Voltage Starters

For larger motors or applications sensitive to starting current:

- Primary Resistor Starters: Use resistors to limit inrush current, providing stepped voltage reduction

- Autotransformer Starters: Employ tapped transformers for smooth acceleration (50-80% line voltage)

- Wye-Delta (Star-Delta) Starters: Start motor in wye configuration, then switch to delta for running

Solid-State Solutions

Soft Starters:

- Use thyristor or SCR technology for gradual voltage ramp-up

- Eliminate mechanical shock and reduce electrical stress

- Programmable acceleration and deceleration profiles

- Lower maintenance (no moving contacts)

- Typical applications: Conveyors, pumps, compressors

Variable Frequency Drives (VFDs):

- Provide speed control throughout operating range

- Soft start/stop capability with energy savings

- Advanced motor protection features

- Higher cost but maximum flexibility

VIOX Electric: Quality Electrical Equipment Manufacturing

At VIOX Electric, we manufacture industrial-grade contactors and motor starters engineered to meet rigorous international standards including IEC, NEMA, UL, and CE certifications. Our products feature:

- High-Quality Materials: Silver alloy contacts for extended electrical life

- Robust Construction: Thermosetting plastic enclosures with excellent arc resistance

- Wide Voltage Range: Control coils from 24V to 600V AC/DC

- Flexible Configuration: Modular auxiliary contact blocks and accessories

- Global Standards: Compliance with IEC 60947-4-1, UL 508, CSA C22.2

- Extended Ratings: Products designed for harsh industrial environments

Our engineering team provides technical support for proper selection, installation, and maintenance of contactors and motor starters for diverse industrial applications.

Installation and Maintenance Best Practices

Installation Guidelines

- Mounting: Install vertically in clean, dry, well-ventilated locations

- Clearances: Maintain minimum clearances per manufacturer specifications (typically 50-100mm)

- Torque: Tighten power terminals to specified torque values (typically 7-12 Nm depending on size)

- Control Wiring: Use appropriate wire gauge for control circuits (typically 14-18 AWG)

- Grounding: Ensure proper equipment grounding per electrical code

Preventive Maintenance Schedule

| Component | Inspection Frequency | Action Items |

|---|---|---|

| Power Contacts | Every 6-12 months | Inspect for pitting, burning, or excessive wear |

| Coil Resistance | Annually | Measure and compare to nameplate values |

| Auxiliary Contacts | Every 12 months | Test continuity and operation |

| Overload Relay | Every 6 months | Verify trip settings and test operation |

| Enclosure | Quarterly | Clean dust/debris, check for damage |

| Connections | Every 6 months | Check for loose terminals, re-torque if needed |

Frequently Asked Questions (FAQ)

Q1: Can I use a contactor instead of a motor starter for my motor?

A: While technically possible, it’s not recommended. Contactors lack overload protection, which is essential for preventing motor damage from sustained overcurrent conditions. Motor starters include integrated overload relays that protect your motor investment and comply with electrical safety codes.

Q2: What’s the difference between NEMA and IEC motor starters?

A: NEMA (North American) starters are typically larger and rated by motor horsepower, while IEC (International) starters are more compact and rated by operational current. IEC starters generally offer more flexibility with modular accessories, while NEMA starters provide standardized ratings with built-in safety margins.

Q3: How do I size a motor starter correctly?

A: Match the starter rating to your motor’s nameplate Full Load Amps (FLA) and horsepower at the operating voltage. Always verify the control voltage matches your control system. For frequent starting applications or harsh environments, consider upsizing by one NEMA size or selecting higher-duty IEC contactors.

Q4: When should I use a soft starter instead of a standard motor starter?

A: Soft starters are ideal when you need to eliminate mechanical shock during startup, reduce electrical inrush current, or provide controlled acceleration/deceleration. They’re particularly beneficial for belt-driven systems, pumps prone to water hammer, or applications with limited electrical service capacity.

Q5: What causes contactor coil failure and how can I prevent it?

A: Common causes include incorrect control voltage, excessive ambient temperature, contamination (dust/moisture), and mechanical wear. Prevention includes: using the correct coil voltage, maintaining proper ventilation, installing in appropriate enclosures (IP54/NEMA 12 minimum for dusty environments), and following recommended maintenance schedules.

Q6: Can contactors and motor starters be used with variable frequency drives (VFDs)?

A: Contactors can be used on the line side (input) of VFDs for isolation purposes, but should NOT be used on the load side (output) while the VFD is operating, as this can damage the drive. Motor starters are similarly used only for isolation, as the VFD provides motor protection. Always install line-side disconnection devices per VFD manufacturer specifications.

Conclusion: Making the Right Choice

The decision between a contactor and a motor starter fundamentally comes down to one critical factor: does your application require motor protection?

- Choose a contactor for simple switching of resistive loads like lighting and heating, or when motor protection is provided separately

- Choose a motor starter for electric motor applications requiring integrated overload protection, ensuring equipment safety and regulatory compliance

At VIOX Electric, we manufacture both contactors and motor starters engineered to deliver reliable performance in demanding industrial environments. Our technical team is available to assist with proper selection, ensuring your electrical control systems operate safely and efficiently.

For technical specifications, product datasheets, or application assistance, contact VIOX Electric – your trusted partner in industrial electrical equipment manufacturing.