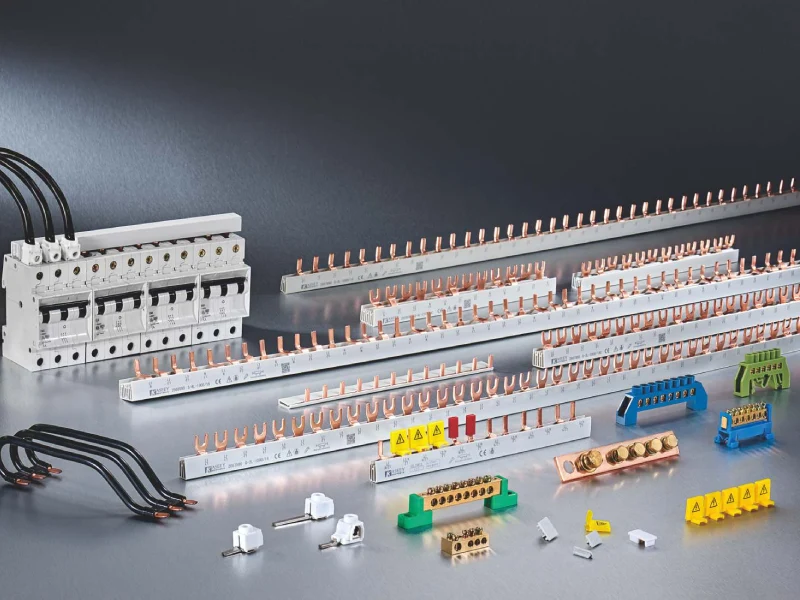

VIOX All Series Electrical Products

New Energy Device

Control Panel Accessories

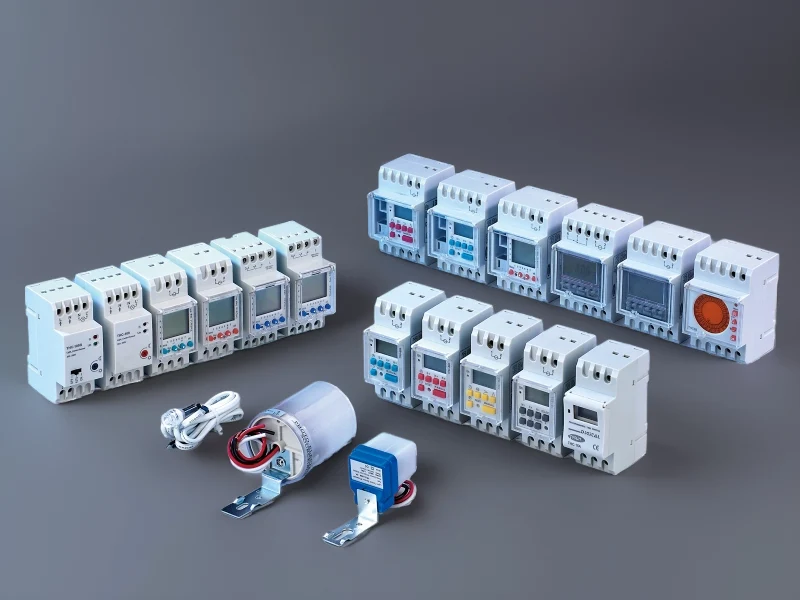

Timer & Photo-Electric Cell

Switch And Socket

Applications

Electrical Solutions for Every Need

As a trusted electrical equipment manufacturer, VIOX delivers high-performance electrical solutions designed for residential, commercial, industrial, and renewable energy applications—providing cost savings, operational efficiency, and reliability across diverse industries worldwide.

Solar & Renewable Energy Systems

The solar sector relies on specialized DC components for safe high-voltage management and surge protection in photovoltaic systems.

Industrial Manufacturing & Automation

Industrial manufacturing requires robust electrical controls for heavy machinery and automation systems.

Commercial & Residential Buildings

Buildings need electrical solutions prioritizing safety and efficiency while meeting codes.

Marine & Offshore Industries

Marine applications require components withstanding saltwater, humidity, and vibration.

Hot Products

Discover Our Best-Selling Electrical Equipment – High Efficiency, Reliable Performance, and Trusted by Electrical Equipment Suppliers Worldwide.

VIOX Manufacturing Facility

VIOX ELECTRIC: Your Direct Source for Electrical Integrity.

Power your world with confidence. VIOX ELECTRIC’s advanced, in-house manufacturing guarantees a reliable supply of high-performance low-voltage components. From critical protection with our AC/DC SPDs, MCBs, and MCCBs, to a complete range of Control Panel Accessories, we are your direct link to quality.

Our factory’s formula is simple: advanced technology, rigorous testing, and streamlined efficiency. This ensures every order meets the highest standards of reliability and safety. Partner with VIOX for stable supply, fast delivery, and manufacturing excellence you can trust.

Why Choose VIOX

At VIOX, we go beyond traditional electrical equipment supply—we deliver comprehensive manufacturing capabilities, stringent quality assurance, and dedicated technical support to help electrical contractors and businesses succeed. From custom electrical solutions to expedited delivery, we ensure seamless experiences for our electrical equipment partners worldwide.

Quality Assurance

VIOX has established a rigorous quality control system to ensure optimal configurations and top-tier service for our customers

15 years’ experience of industry

National high-tech enterprise: VIOX technology has advanced international technology, more than 20 national patents.

Caring After-Sales Support

Our team provides attentive one-on-one support and regular visits for worry-free experiences

Custom Solutions

Tailored solutions designed to match industry-specific demands and meet unique customer needs

R&D Team

Our team comprises 15 in-house R&D experts, supplemented by approximately 10 external units and technical consultants."

Swift Availability

State-of-the-art manufacturing, versatile modular products, and a committed expert team guarantee rapid and efficient deliveries

Trusted By

Contact Now

Let's raise your business to the next level, NOW!

*All your information will be kept strictly confidential and our business staff will ensure that your private information is absolutely safe!