The $80,000 Wake-Up Call: When Silent SPD Failures Cost More Than Equipment

A 5MW solar farm in Arizona discovered a harsh reality during a routine quarterly inspection: the surge protective device (SPD) in their main combiner box had failed six months earlier. The visual indicator showed red, but no one had noticed—the site was unmanned, and the inspection schedule had gaps. During those six months, three lightning events passed through the system unprotected, progressively damaging inverter MPPT circuits. The total replacement cost: $82,000, plus two weeks of lost generation revenue.

This scenario plays out across solar and industrial facilities worldwide. SPDs are designed to fail in a “safe” mode—they remain electrically connected in parallel, so your system keeps running. But this silent failure leaves your expensive equipment completely vulnerable to the next surge event. By the time damage occurs, it’s too late.

SPD remote signaling eliminates this blind spot. It’s not optional monitoring for large-scale solar farms and industrial sites—it’s essential infrastructure that protects your capital investment. This guide explains the technology, ROI calculations, and implementation strategies that every facility manager and solar EPC needs to understand.

What is SPD Remote Signaling?

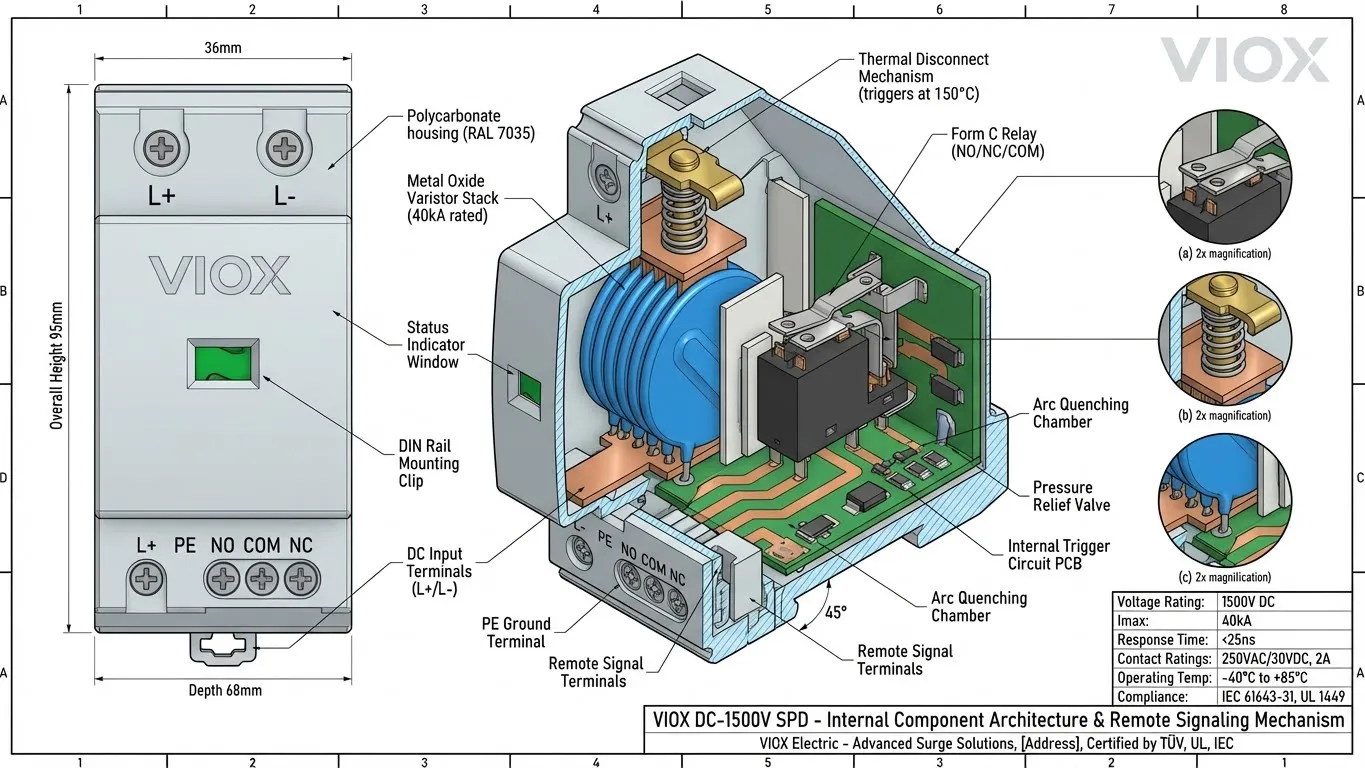

SPD remote signaling is a built-in alarm system that communicates the operational status of surge protective devices to monitoring platforms in real-time. At its core, it uses a dry contact relay (Form C configuration) that automatically switches state when the SPD’s protection modules fail or reach end-of-life.

Technical Fundamentals

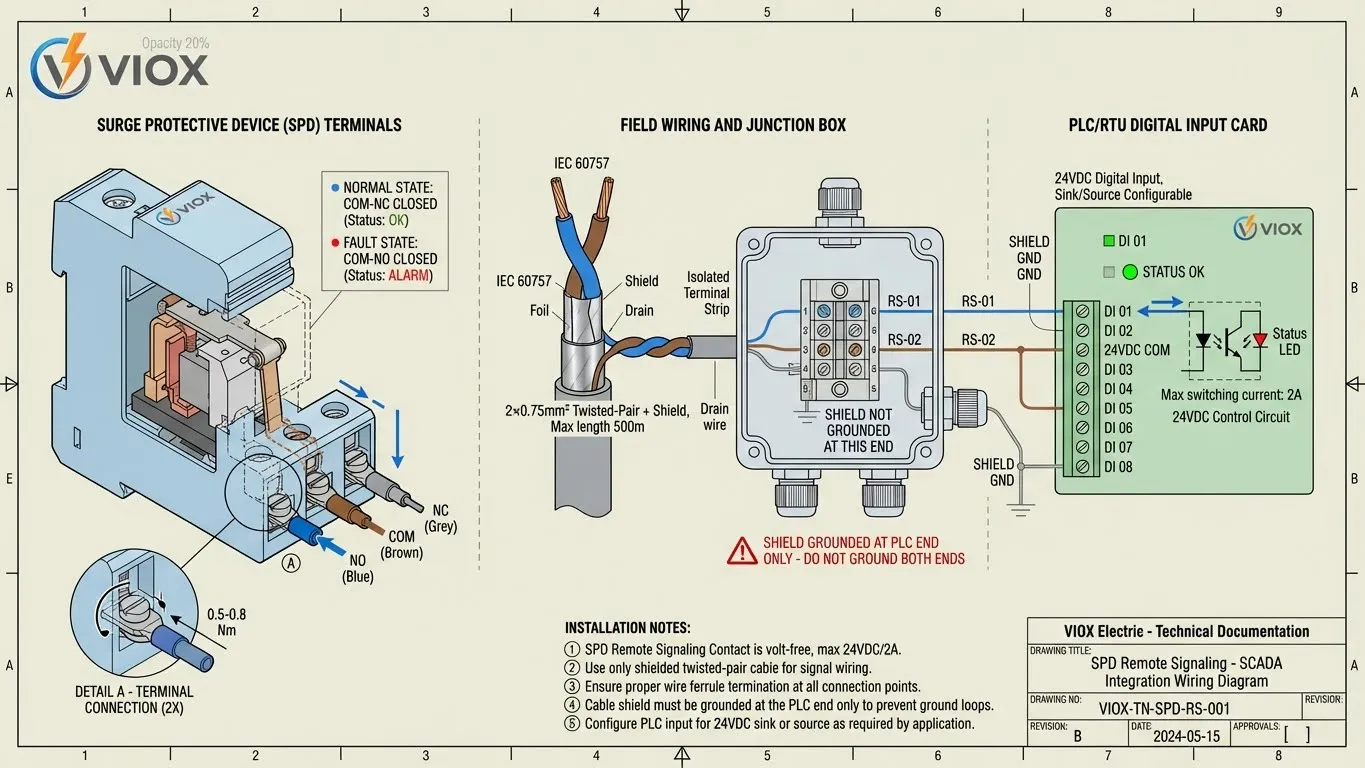

A remote signaling contact consists of three terminals:

- NO (Normally Open): Open circuit during normal SPD operation; closes when SPD fails

- COM (Common): Shared reference terminal for both NO and NC circuits

- NC (Normally Closed): Closed circuit during normal operation; opens when SPD fails

Normal Operation State:

- NO-COM terminals: Open (no continuity)

- NC-COM terminals: Closed (continuity present)

Failure State:

- NO-COM terminals: Closed (alarm signal active)

- NC-COM terminals: Open (supervisory circuit broken)

When the SPD’s internal thermal disconnect triggers or varistor elements degrade beyond operational limits, an internal mechanical or electronic switch reverses these contact states. This status change feeds directly into SCADA systems, building management systems (BMS), or programmable logic controllers (PLCs), triggering immediate alerts to maintenance teams.

Both IEC 61643-11 (AC surge protection standards) and IEC 61643-31 (DC surge protection for photovoltaic systems) reference remote indication capabilities as recommended features for critical infrastructure applications. While not mandatory in all jurisdictions, remote signaling is increasingly specified in utility-scale solar projects and industrial facilities where downtime costs justify the investment.

How Remote Signaling Works: The Technical Architecture

Understanding the complete signal path from SPD to control room ensures reliable implementation and troubleshooting capability.

Contact Types & Wiring

Engineers must choose between NO and NC configurations based on fail-safe logic requirements:

Normally Open (NO) Configuration:

- Use case: Alarm-on-failure systems where closed contact = problem detected

- Advantages: No continuous current draw; suitable for battery-powered alarm panels

- Wiring: NO and COM terminals connect to PLC digital input or alarm panel input

- Typical voltage: 24VDC control circuit (some systems support up to 250VAC/DC)

Normally Closed (NC) Configuration:

- Use case: Supervisory circuits requiring continuous signal integrity verification

- Advantages: Detects both SPD failure AND wiring/connection failures (broken wire = alarm)

- Wiring: NC and COM terminals in series with supervised circuit

- Applications: Critical facilities (data centers, hospitals) where wire integrity matters

Most SCADA integrations use NO contacts because they align with standard alarm logic: closed contact = fault condition. However, high-reliability facilities often implement NC supervisory circuits that continuously verify both the SPD status and the integrity of all wiring between the field device and control system.

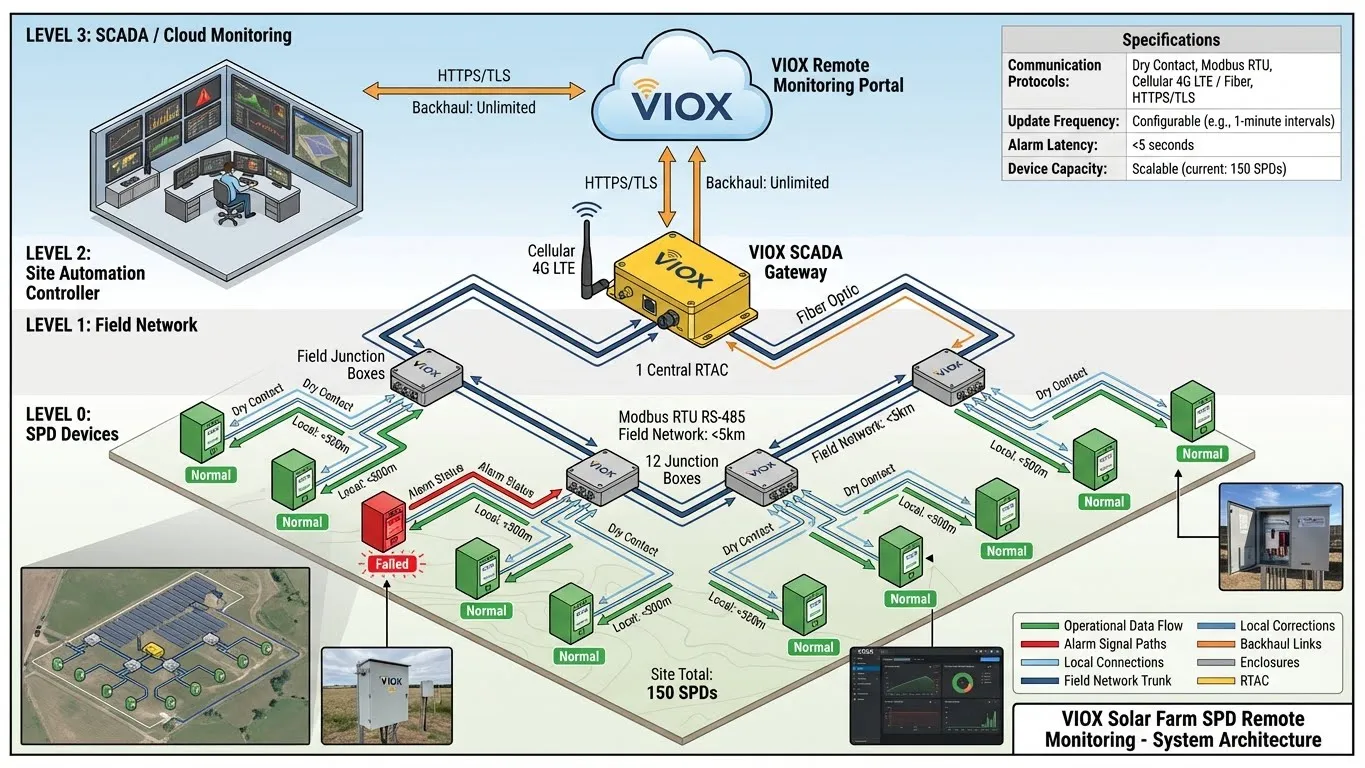

Common Integration Methods:

- Direct connection to PLC digital inputs (24VDC sink/source logic)

- Relay modules for voltage/logic level conversion

- Remote terminal units (RTUs) for multi-point aggregation

- Discrete alarm panels with individual LED indicators per SPD

Integration Points

Modern SPD remote signaling integrates across multiple industrial control platforms:

SCADA Systems:

- Schneider Electric EcoStruxure: Modbus RTU/TCP integration via RTU gateways

- Siemens SICAM / DIGSI: IEC 61850 GOOSE messaging for substation environments

- SEL Real-Time Automation Controllers (RTACs): Direct digital I/O mapping for solar farms

- Open-protocol platforms: DNP3, OPC-UA for vendor-agnostic integration

Building Management Systems (BMS):

- BACnet integration for commercial buildings and large rooftop solar installations

- Alarm prioritization within existing HVAC/lighting control hierarchies

- Integration with work order management for automated maintenance dispatch

Standalone Alarm Solutions:

- Annunciator panels with visual/audible indicators for smaller sites (50kW–500kW)

- SMS/email gateways with cellular connectivity for remote unmanned locations

- Cloud-based IoT platforms with mobile app notifications

A typical utility-scale solar farm might have 50-200+ SPDs distributed across combiner boxes, each with remote signaling wired back to a central RTAC. The RTAC aggregates all alarm states, timestamps failure events, and sends consolidated alerts to the operations center via fiber optic or cellular backhaul. This architecture enables a single O&M technician to monitor thousands of protection points across multiple sites from one control room.

Why Remote Monitoring is Critical for Solar & Industrial Sites

The value proposition for SPD remote signaling becomes obvious when you analyze failure modes, inspection logistics, and downtime economics.

The “Silent Killer” Problem

Surge protective devices are designed with a critical safety feature: when they fail, they disconnect themselves from the circuit through thermal or mechanical means, but they remain physically installed and electrically isolated. This parallel connection architecture means your solar inverter, PLC, or industrial control system continues operating normally—you won’t notice any immediate performance change.

What happens next is the dangerous part:

- The failed SPD provides zero surge protection

- System operates normally until the next transient event

- Lightning strike or switching surge enters unprotected

- Voltage spike reaches sensitive electronics (inverters, PLCs, MPPT controllers)

- Equipment damage ranges from minor circuit board failures to complete inverter replacement

Real-world case data from solar O&M providers shows that unmonitored SPD failures lead to secondary equipment damage in approximately 40-60% of cases where significant surge events occur within 6 months of SPD end-of-life. A $150 SPD failure becomes a $75,000 inverter replacement because no one knew the protection was gone.

This problem is particularly acute in solar applications because DC surge protection differs fundamentally from AC systems—DC arcs are harder to extinguish, and photovoltaic arrays generate continuous energy even during fault conditions, making unprotected surges more destructive.

Challenges of Manual Inspection

For utility-scale solar farms spanning 50-500+ acres with 100-200 combiner boxes, manual SPD inspection faces insurmountable logistics:

Scale challenges:

- A 100MW solar farm might have 150+ individual SPDs across the site

- Walking inspection time: 4-6 hours per technician for visual checks only

- Many combiner boxes located in difficult terrain or requiring lift equipment access

- Quarterly inspection schedule means 48-72 hours of labor annually per site

Industrial facilities face different but equally severe challenges:

- SPDs often mounted in electrical rooms, rooftops, or hazardous classified areas requiring safety protocols

- 24/7 production schedules limit maintenance windows

- Visual inspection requires panel de-energization in many jurisdictions (downtime cost)

- False sense of security: visual indicator might be obscured by dust, condensation, or label deterioration

Labor economics:

- Electrician labor cost: $75-$150/hour including benefits and vehicle costs

- Annual inspection cost for 100MW solar farm: $15,000-$25,000

- Opportunity cost: inspector hours could be spent on revenue-generating activities

- Insurance implications: inadequate inspection frequency may void equipment warranties

ROI of Remote Monitoring

The financial justification for SPD remote signaling becomes compelling when you model failure probability against equipment replacement costs:

Cost-benefit calculation example (100MW solar farm):

| Item | Without Remote Signaling | With Remote Signaling |

|---|---|---|

| SPD initial cost (150 units) | $22,500 ($150/unit) | $30,000 ($200/unit) |

| Annual inspection labor | $20,000 (quarterly visits) | $3,000 (annual validation only) |

| MTBF secondary damage event | 1 inverter every 2-3 years | Near zero (immediate replacement) |

| Average inverter replacement cost | $85,000 per event | $0 (protection maintained) |

| Annual risk-adjusted cost | $28,000-$42,000 | $3,000 |

| 5-year total cost | $140,000-$210,000 | $45,000 |

Additional benefits not captured in direct cost calculations:

- Reduced downtime: Inverter failures often require 2-4 weeks lead time for replacement parts; preventing one failure saves 200-400 MWh of lost generation ($20,000-$40,000 revenue at $0.10/kWh)

- Warranty protection: Many inverter manufacturers void warranties if facility can’t prove adequate surge protection was maintained

- Insurance premiums: Some insurers offer reduced premiums for sites with comprehensive monitoring

- Predictive maintenance: Remote signaling provides failure timestamp data enabling analysis of surge event patterns and equipment degradation trends

For industrial facilities where a single production line shutdown costs $50,000-$500,000 per day, the ROI becomes even more dramatic. A pharmaceutical manufacturing plant or semiconductor fab can justify SPD remote monitoring on a single prevented outage event.

The critical insight: SPD remote signaling reduces site visit frequency by 60-80% while simultaneously eliminating 90%+ of secondary equipment damage risk from undetected SPD failures. The $50-$200 incremental cost per SPD pays for itself within 6-18 months in most commercial and industrial applications.

Applications Where Remote Signaling is Essential

While any facility with surge protection benefits from status monitoring, certain applications make remote signaling not just valuable but operationally mandatory:

Utility-Scale Solar Farms (500kW+)

Why it’s critical:

- Site spans hundreds of acres with equipment distributed across difficult terrain

- Unmanned operation is standard (single O&M team covers 5-10 sites)

- Each central inverter protects $150K-$500K of equipment

- Production loss from unplanned downtime: $2,000-$10,000 per day per MW

Typical implementation:

- DC SPDs in each string combiner box (50-200 units per site)

- AC SPDs at inverter outputs and medium-voltage transformer secondaries

- Remote contacts wired to RTAC or PLC concentrator via twisted-pair field cable

- Fiber optic or cellular backhaul to remote operations center

- Integration with existing SCADA monitoring inverter performance and meteorological data

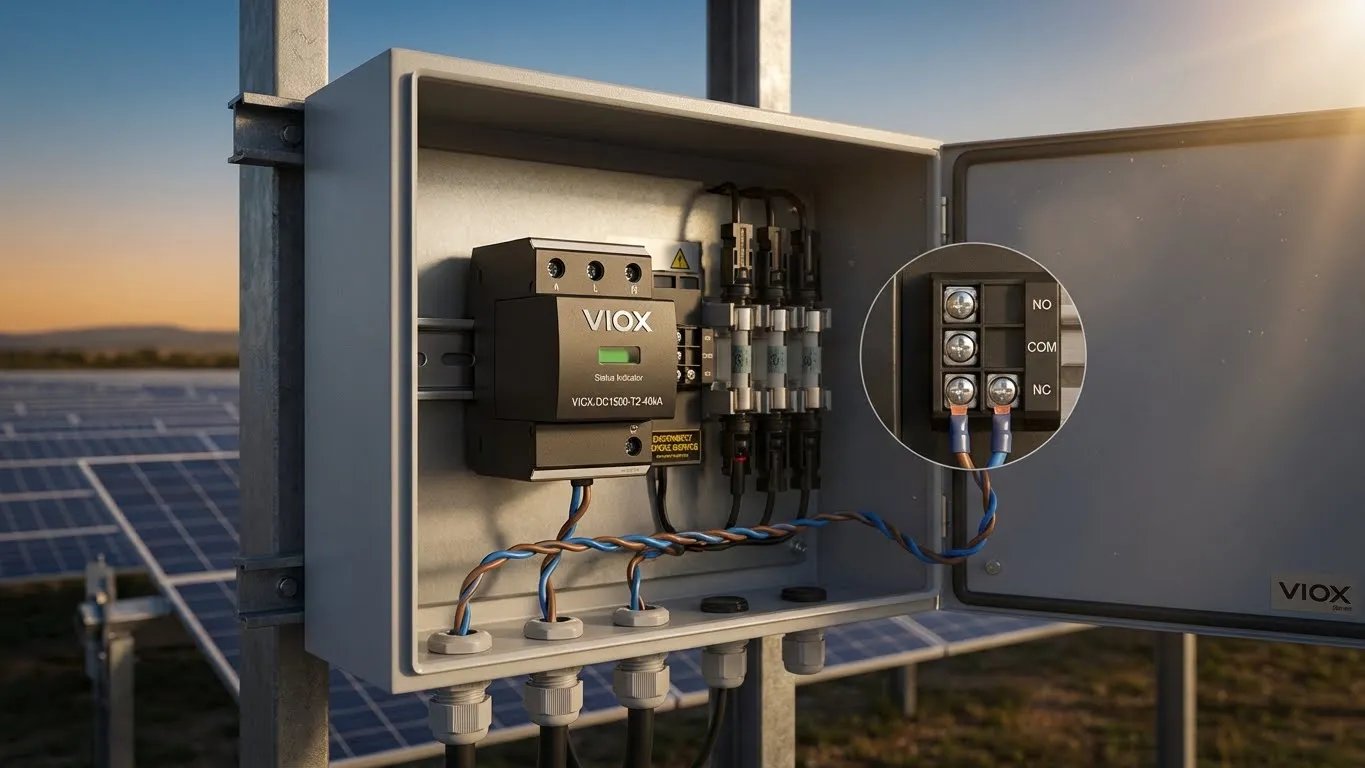

VIOX 1500V DC SPDs designed for utility-scale applications include hot-swappable modules and remote signaling as standard features, enabling maintenance teams to respond immediately when alarms trigger.

Rooftop Commercial Solar (50kW-500kW)

Why it’s critical:

- Rooftop access requires lift equipment or confined space procedures

- Visual inspection frequency limited by building access policies

- Tenants/building owners rarely have technical staff to check status indicators

- Rapid shutdown requirements mean more distributed protection points

Typical implementation:

- Compact AC/DC SPDs near rooftop inverters

- Remote signaling integrated into building BMS via BACnet protocol

- Email/SMS alerts to solar maintenance provider when failures occur

- Reduced insurance liability through documented protection monitoring

For commercial installations where solar combiner boxes sit on rooftops 50-200 feet above ground, remote signaling eliminates the need for monthly crane rentals just to verify SPD status.

Industrial Manufacturing Facilities

Why it’s critical:

- 24/7 production schedules with downtime costs of $10K-$500K per hour

- Critical process control PLCs require continuous protection

- Electrical rooms often in classified hazardous areas requiring special access procedures

- Quality systems demand documented evidence of protection equipment status

Typical implementation:

- AC Type 1+2 SPDs at service entrance and distribution panels

- Type 2 SPDs protecting motor control centers and sensitive instrumentation

- Hard-wired integration into plant-wide PLC/SCADA infrastructure

- Maintenance work orders automatically generated when alarms trigger

- Monthly status reports for ISO 9001 / IATF 16949 compliance documentation

Facilities using centralized inverter systems for on-site solar generation integrate SPD monitoring into existing plant automation architecture.

Telecom Towers & Remote Base Stations

Why it’s critical:

- Sites located in remote high-lightning-incidence areas

- Unmanned operation with limited maintenance visits (monthly or quarterly)

- Single surge event can disable communications serving thousands of customers

- Service level agreements (SLAs) with severe penalties for extended outages

Typical implementation:

- DC SPDs on -48VDC power distribution to radio equipment

- AC SPDs at utility service entrance

- Remote monitoring via cellular M2M data connection

- Integration with network operations center (NOC) alarm management systems

Water Treatment Plants & Pump Stations

Why it’s critical:

- Facilities often located in remote areas prone to lightning activity

- VFD-controlled pump systems highly susceptible to surge damage

- Environmental regulations require continuous operation (untreated discharge prohibited)

- SCADA systems monitor remote sites—SPD status naturally integrates

Typical implementation:

- Type 1 SPDs at service entrance with remote signaling

- Type 2 SPDs protecting VFDs, PLCs, and instrumentation

- Integration with water/wastewater SCADA platforms (typically DNP3 or Modbus)

- Alarm escalation to on-call maintenance staff via automated phone calls

Data Centers (Tier III/IV Facilities)

Why it’s critical:

- Uptime requirements of 99.99% or higher demand comprehensive monitoring

- Power infrastructure represents millions in capital investment

- Surge events can compromise battery backup systems (VRLA/Li-ion)

- Regulatory compliance (PCI-DSS, HIPAA) requires documented protection measures

Typical implementation:

- Multi-stage SPD protection with remote monitoring at every level

- Integration with DCIM (Data Center Infrastructure Management) platforms

- Real-time dashboard showing protection status for all critical circuits

- Automated ticketing systems generate maintenance work orders immediately upon failure detection

VIOX SPD Remote Signaling Solutions

VIOX Electric manufactures comprehensive surge protection solutions with integrated remote monitoring capabilities designed specifically for solar and industrial applications. Our product line addresses the full spectrum of installation requirements from residential retrofits to utility-scale solar farms.

DC SPD Series (Solar Applications)

VIOX DC-1000V Type 2 SPD:

- Voltage rating: 1000VDC continuous operating voltage

- Discharge capacity: 40kA (8/20μs) per pole

- Applications: Residential and commercial rooftop solar (string inverters up to 500kW)

- Remote signaling: Optional Form C contact, 24-250VAC/DC rating

VIOX DC-1500V Type 1+2 SPD:

- Voltage rating: 1500VDC continuous operating voltage (utility-scale systems)

- Discharge capacity: 60kA (8/20μs) per pole

- Hot-swappable modular design for zero-downtime cartridge replacement

- Remote signaling: Standard feature with pre-wired terminal block

- Compliance: IEC 61643-31, UL 1449 4th Edition, TÜV certified

AC SPD Series (Grid Connection & Industrial)

VIOX AC Type 1+2 Combined Arrester:

- Voltage ratings: 230/400VAC (single and three-phase configurations)

- Discharge capacity: 50kA/pole (Type 1), 40kA/pole (Type 2)

- Applications: Service entrance protection, distribution panels, motor control centers

- Remote signaling: Form C contact rated 5A@250VAC resistive

Key Technological Features

Dual Verification System:

Every VIOX SPD combines visual status indication (green/red window) with remote signaling contacts. This redundancy ensures operators can verify protection status both on-site during commissioning and continuously via SCADA during operation. The visual indicator provides instant verification during maintenance procedures, while remote contacts deliver 24/7 automated monitoring.

Pre-Wired Terminal Blocks:

Our SPD remote signaling terminals ship with clearly labeled screw terminals (NO, COM, NC) and integrated strain relief. This standardized interface reduces installation time by 40% compared to post-installation wire termination and virtually eliminates field wiring errors. Terminals accept wire sizes from 0.75mm² to 2.5mm² with or without ferrules.

Hot-Swappable Cartridge Design:

For utility-scale applications where downtime must be minimized, VIOX DC-1500V SPDs feature plug-in protection modules that can be replaced without interrupting DC circuits. The remote signaling contact remains functional during module replacement, providing continuous status monitoring throughout the maintenance procedure. This design enables sub-5-minute replacement times compared to 30-60 minutes for traditional SPD replacement requiring circuit de-energization.

Compliance and Certification:

- IEC 61643-11 (AC systems) and IEC 61643-31 (DC photovoltaic systems)

- UL 1449 4th Edition (North American markets)

- TÜV product certification (European markets)

- IP65-rated enclosures for outdoor combiner box installations

- Operating temperature range: -40°C to +85°C for extreme climate deployments

Integration Support

VIOX provides comprehensive technical support for SCADA integration:

- Modbus RTU register maps for direct PLC integration

- BACnet object definitions for BMS platforms

- Sample ladder logic code for common PLC brands (Allen-Bradley, Siemens, Schneider)

- Detailed wiring diagrams for NO/NC configuration options

- Remote commissioning support via video conference for large deployments

For complete specifications and ordering information, visit our SPD product page.

Comparison Table: With vs. Without Remote Signaling

The following table quantifies the operational differences between traditional manual SPD monitoring and modern remote signaling infrastructure:

| Parameter | Without Remote Signaling | With Remote Signaling |

|---|---|---|

| Initial Cost (per SPD) | $150-$250 | $200-$350 (+$50-$100 premium) |

| Detection Time | Days to months (until next scheduled inspection) | Immediate (<5 seconds from failure event) |

| Inspection Frequency | Monthly to quarterly physical site visits | Annual validation + continuous automated monitoring |

| Labor Cost (100 SPDs, annual) | $15,000-$25,000 (quarterly manual checks) | $2,000-$4,000 (annual system validation only) |

| Risk of Secondary Equipment Damage | High (40-60% probability if surge occurs before detection) | Near zero (<5% residual risk from alarm system failure) |

| Mean Time to Repair (MTTR) | 7-30 days (discovery delay + parts procurement) | 1-3 days (immediate notification enables advance parts ordering) |

| Suitable Site Sizes | <50kW (where frequent manual checks feasible) | Any size; essential for >500kW installations |

| Downtime Impact | Potential weeks of unprotected operation | Minutes to hours (alarm to technician dispatch) |

| Documentation for Compliance | Manual logbooks, prone to gaps | Automatic timestamped event logs, audit trail |

| Integration with Maintenance Systems | Manual work order creation after inspection | Automated work order generation via SCADA/CMMS integration |

| Alarm Escalation | Not applicable | Multi-level (email → SMS → phone call) based on priority |

| Historical Trending | Limited (manual records) | Comprehensive (failure patterns, MTBF analysis, surge event correlation) |

| Insurance/Warranty Benefits | Standard coverage | Potential premium reductions; warranty protection proof |

| Compliance Level | Meets minimum code requirements | Exceeds standards; demonstrates proactive risk management |

| Recommended For | Residential solar (<10kW), easily accessible locations | Commercial solar (>50kW), industrial facilities, remote sites, critical infrastructure |

Key Insight: The typical payback period for SPD remote signaling investment is 6-18 months for commercial installations and 3-12 months for utility-scale or industrial facilities when factoring in reduced labor costs and prevented equipment damage.

Installation Best Practices

Proper implementation of SPD remote signaling requires attention to both electrical and commissioning details:

Electrical Installation Guidelines

- Proximity to Protected Equipment

- Mount SPDs within 1 meter of the equipment they protect whenever possible

- This minimizes lead length, reducing inductance and improving surge clamping effectiveness

- For solar combiner boxes, SPDs mount on DIN rail adjacent to DC fuses and disconnect switches

- Remote Signal Cable Specification

- Use twisted-pair shielded cable (minimum 0.75mm²/18AWG conductors)

- Shield provides electromagnetic interference (EMI) protection in high-noise environments

- Maximum recommended cable length: 500 meters for 24VDC systems (voltage drop considerations)

- For longer runs, use relay amplification at intermediate junction points

- Shield Grounding Methodology

- Ground cable shield at ONE END ONLY—typically at the PLC/SCADA receiver end

- Grounding both ends creates a ground loop that can induce noise or damage equipment during ground potential rise events

- Use insulated shield drain wire, secure to PLC chassis ground with dedicated terminal

- Document shield grounding point in as-built drawings

- Strain Relief and Cable Management

- Install cable glands or strain relief connectors at all enclosure entries

- Maintain minimum bend radius (10× cable diameter) to prevent shield damage

- Route signal cables separately from high-power conductors (maintain 150mm separation where possible)

- Use cable ties at 300mm intervals for mechanical support

Commissioning and Testing

- Pre-Energization Contact Verification

- Before connecting to SCADA/PLC, verify contact states using digital multimeter:

- NO-COM: Infinite resistance (open circuit) in normal state

- NC-COM: <1Ω resistance (closed circuit) in normal state

- Simulate failure condition (if SPD includes test button) and verify contacts reverse

- Check for intermittent connections by gently moving wires—resistance should remain stable

- Before connecting to SCADA/PLC, verify contact states using digital multimeter:

- SCADA Integration Testing

- Program PLC with correct input logic (NO vs NC configuration)

- Test alarm propagation: simulate SPD failure and verify alarm appears in SCADA HMI within defined latency (typically <10 seconds)

- Verify alarm priority level configuration (HIGH for critical equipment, MEDIUM for redundant protection points)

- Test escalation sequence: email alerts, SMS notifications, auto-dialer functionality

- Document PLC tag names and alarm text in system documentation

- Documentation Requirements

- Create single-line diagram showing all SPD locations, device tag numbers, and SCADA input assignments

- Label each SPD with site-specific identifier matching SCADA tag (e.g., “CB-12-SPD-DC1”)

- Document NO/NC configuration choice in electrical as-built drawings (critical for future maintenance)

- Include remote contact specifications in O&M manual for maintenance contractor reference

- Photograph final installation showing terminal connections for future troubleshooting reference

Ongoing Maintenance

- Alarm Response Procedures

- Establish standard operating procedure (SOP) for alarm response:

- Immediate acknowledgment in SCADA (within 1 hour)

- Site visit scheduled within 24 hours for critical systems, 72 hours for non-critical

- Advance parts ordering based on SPD model identified in alarm

- Track alarm response metrics (alarm-to-dispatch time, dispatch-to-repair time) for continuous improvement

- Establish standard operating procedure (SOP) for alarm response:

- Annual System Validation

- Perform end-to-end testing annually: simulate SPD failure at device, verify alarm in SCADA

- Check cable integrity with insulation resistance test (minimum 10MΩ @ 500VDC)

- Verify contact ratings haven’t degraded (resistance still <1Ω for NC in normal state)

- Update SCADA system software and verify alarm logic remains functional after updates

- Integration with CMMS

- Link SPD alarm events to maintenance work orders in computerized maintenance management system (CMMS)

- Auto-generate preventive maintenance tasks when SPDs approach typical service life (often 5-10 years depending on surge duty)

- Track spare parts inventory based on failure rates (stock replacement SPDs for 5% annual failure rate)

For facilities implementing rapid shutdown systems, coordinate SPD alarm testing with rapid shutdown function testing to minimize site disruption.

Common Mistakes to Avoid

Field experience from thousands of installations reveals recurring errors that compromise remote signaling reliability:

1. Contact Configuration Errors (NO vs NC)

The Problem:

Engineers specify or wire NO (Normally Open) contacts when the SCADA system expects NC (Normally Closed) logic, or vice versa. This results in either continuous false alarms or complete failure to detect actual SPD failures.

Why It Happens:

- Inconsistent terminology: some manufacturers label “alarm” output differently

- Pre-existing SCADA logic designed for opposite contact type

- Miscommunication between electrical contractor and controls integrator

The Solution:

- Review SCADA alarm logic BEFORE procurement—specify SPD contact type to match existing infrastructure

- If mismatch is discovered after delivery, use external relay for contact inversion rather than attempting field modification

- During commissioning, test both normal and failure states to verify correct alarm behavior

- Document actual contact configuration (NO vs NC) in as-built drawings, not just manufacturer generic specs

2. Skipping Commissioning Testing

The Problem:

Contractors complete installation, verify continuity, but never simulate an actual SPD failure to confirm end-to-end alarm functionality. Months later, a real SPD failure occurs with no alarm, and the investigation reveals the remote signal was never properly connected to the SCADA input.

Why It Happens:

- Pressure to complete project on schedule

- Assumption that if wiring continuity checks pass, the system must work

- Lack of test button on some SPD models (requiring simulation methods)

The Solution:

- Include mandatory commissioning test in project specifications: “Contractor shall simulate SPD failure condition and demonstrate alarm visibility in SCADA HMI”

- For SPDs without test buttons, briefly disconnect the thermal element or use manufacturer-approved test procedure

- Document commissioning test results with timestamped screenshots showing alarm in SCADA

- Treat this test with same importance as rapid shutdown commissioning—it’s a life-safety adjacent system

3. Ignoring Alarm Signals

The Problem:

The monitoring infrastructure works perfectly, but alarm response procedures aren’t established or enforced. SPD failures generate alarms that sit unacknowledged for weeks until secondary equipment damage occurs.

Why It Happens:

- Operations team overwhelmed with nuisance alarms from other systems

- Lack of clear ownership (whose responsibility to respond?)

- Assumption that visual inspection can wait until next scheduled maintenance

- Failure to communicate urgency: “It’s just a protection device, the system still runs”

The Solution:

- Establish clear alarm escalation procedures with defined response timeframes

- Configure different priority levels: CRITICAL for SPDs protecting high-value equipment, WARNING for redundant protection

- Integrate SPD alarms with maintenance work order systems—automatic ticket generation

- Track key performance indicators (KPIs): alarm-to-acknowledgment time, alarm-to-repair time

- Educate operations staff: “SPD failure means your $150K inverter is now unprotected—treat this like a fire alarm, not a door ajar warning”

4. Undersized or Incorrect Cable

The Problem:

Using standard signal cable without shielding, or undersized conductors for long cable runs, resulting in electromagnetic interference (EMI) coupling or excessive voltage drop that causes intermittent alarm behavior.

Why It Happens:

- Cost optimization: shielded cable costs 2-3× more than unshielded

- Lack of awareness about EMI in solar farms (DC circuits, inverter switching noise, nearby lightning strikes)

- Using spare cable from other applications without verifying specifications

The Solution:

- Always specify twisted-pair shielded cable for SPD remote signaling (minimum 0.75mm²/18AWG)

- Calculate voltage drop for cable runs >100 meters (particularly important for 24VDC systems)

- For runs >500 meters, use intermediate relay amplification or 48VDC control voltage

- Install cable in separate conduit from power conductors, maintain 150mm separation where parallel routing necessary

- Properly ground shield at ONE END ONLY to prevent ground loop issues

5. Lack of Documentation

The Problem:

Three years after installation, an SPD alarm triggers. The maintenance electrician can’t determine which physical combiner box corresponds to “SPD-CB-47” in the SCADA alarm. Site drawings don’t show contact configuration. Troubleshooting takes 8 hours instead of 30 minutes.

Why It Happens:

- As-built documentation not updated when field changes occur

- Generic labels (“SPD-1”, “SPD-2”) that don’t correspond to physical location

- Contact configuration (NO vs NC) assumed to be “standard” and not recorded

- Original system integrator no longer available for support

The Solution:

- Create comprehensive as-built documentation including:

- Site map with all SPD locations marked

- Unique device tags matching both physical labels AND SCADA tag database

- Contact configuration explicitly stated (NO or NC) for each device

- Cable routing diagrams showing junction box locations

- PLC program with comments explaining alarm logic

- Use weatherproof labels on combiner boxes matching SCADA tag names exactly

- Include photos in O&M manual showing terminal connections and device locations

- Store electronic copies in multiple locations (site file cabinet, cloud backup, O&M contractor archive)

6. Single Points of Failure in Alarm Path

The Problem:

All SPD remote signals connect to a single PLC input card. When that card fails, monitoring for the entire site goes dark with no indication that the monitoring system itself is compromised.

Why It Happens:

- Desire to minimize costs by concentrating all I/O on one hardware module

- Lack of redundancy planning in control system architecture

- Assumption that PLC hardware is 100% reliable

The Solution:

- Distribute critical SPD signals across multiple PLC input cards or separate RTUs

- Implement supervisory monitoring of the alarm system itself (heartbeat signals, watchdog timers)

- Use NC contact configuration where fail-safe monitoring is critical—broken wire = alarm

- Consider redundant monitoring paths for mission-critical facilities: primary SCADA plus independent SMS gateway

- Test alarm system integrity quarterly by forcing test alarms from representative SPDs

Frequently Asked Questions

What does “dry contact” mean in SPD remote signaling?

A dry contact is a switch contact that carries no voltage or current of its own—it’s simply an open or closed circuit provided by the SPD. The monitoring system (SCADA/PLC) supplies the voltage and reads the contact state. This isolation prevents electrical interference between the surge protection circuit and control system, and allows the same SPD to integrate with different control voltages (24VDC, 48VDC, 120VAC, etc.) without modification. The term “dry” distinguishes it from “wet contacts” which carry their own supply voltage.

Can I retrofit remote signaling to existing SPDs?

It depends on the SPD model. Some manufacturers offer plug-in remote signaling modules that retrofit into existing SPD housings—these require field installation and typically cost $80-$150 per module plus labor. However, many SPD designs don’t support retrofitting, as the relay mechanism must integrate with the internal thermal disconnect. In these cases, complete SPD replacement is necessary. For large installations where retrofitting isn’t feasible, consider installing remote signaling on strategic SPD locations (main service entrance, high-value equipment) rather than replacing all units immediately. Future replacements at end-of-life can specify remote signaling models.

What’s the difference between NO and NC contacts?

NO (Normally Open) contacts are open circuit (infinite resistance) during normal SPD operation and close (short circuit) when the SPD fails—this creates an alarm signal. NC (Normally Closed) contacts are closed during normal operation and open when the SPD fails—this breaks a supervisory circuit to trigger an alarm. The choice depends on your control system logic and fail-safe requirements. NO contacts are simpler and more common for alarm systems. NC contacts provide higher reliability because they also detect wiring failures (cut wire = alarm), making them preferred for critical facilities. Some systems use both: NO for alarm reporting, NC for supervisory monitoring.

How far can the remote signal cable run?

Maximum distance depends on control voltage and acceptable voltage drop. For 24VDC systems using 0.75mm² (18AWG) cable, practical maximum is 500 meters with 2A relay contact current (results in approximately 2.4V drop, acceptable for most PLCs). For longer distances: (1) Use larger conductors (1.5mm²/16AWG extends to 1000m), (2) Increase control voltage to 48VDC (doubles distance for same drop), (3) Install intermediate relay amplifiers at 500m intervals, or (4) Use fiber optic or wireless solutions (see next question). Always maintain twisted-pair shielded construction regardless of distance to minimize EMI susceptibility.

Do I need remote signaling for residential SPDs?

For residential installations under 10kW, remote signaling is typically not cost-justified unless the home is remote/vacation property or part of a monitored smart home system. Residential SPDs are easily accessible (garage, basement electrical panel) making monthly visual checks practical. However, remote signaling adds value for: (1) Premium smart home integration where homeowners receive notifications via app, (2) Solar lease/PPA arrangements where O&M provider manages multiple residential sites remotely, (3) Insurance requirements for high-value homes in lightning-prone areas. The technology works identically at any scale—the decision is purely economic based on monitoring labor cost vs. remote signaling premium.

What happens if the alarm circuit fails?

This depends on contact configuration. With NO (Normally Open) contacts, an alarm circuit failure (broken wire, PLC input card failure) appears identical to normal operation—the system shows “no alarm” when in fact monitoring is compromised. This is why NC (Normally Closed) supervisory circuits are preferred for critical facilities: any failure in the alarm path (broken wire, relay failure, PLC input failure) triggers an alarm, alerting operators to check the system. Best practice for high-reliability applications: use NC contacts with regular supervisory testing (quarterly forced alarm tests), or implement redundant monitoring (primary SCADA + independent SMS gateway). Document alarm system testing in maintenance logs for compliance and insurance purposes.

Can remote signaling work with wireless systems?

Yes, wireless solutions are increasingly common for retrofit applications or sites where conduit installation is cost-prohibitive. Implementation options include: (1) Wireless I/O modules: battery or solar-powered transmitters connect to SPD dry contacts and communicate via LoRaWAN, Zigbee, or proprietary protocols to a central receiver/gateway (range: 1-10km depending on protocol), (2) Cellular IoT devices: 4G LTE-M or NB-IoT modems connect to SPD contacts and send alerts via SMS or cloud API (requires cellular coverage and data plan, typically $5-$15/month per device), (3) Bluetooth mesh networks: suitable for shorter distances (<300m) with multiple SPD nodes forming self-healing mesh. Wireless adds cost ($150-$400 per SPD node) and introduces battery maintenance requirements, but eliminates trenching/conduit costs. Most viable for retrofit projects or installations on difficult terrain where conduit routing is impractical.

Conclusion: Remote Signaling as Essential Infrastructure

SPD remote signaling transforms surge protection from a passive “install and hope” safety measure into an actively managed infrastructure component. For commercial and utility-scale solar installations, the ROI is irrefutable: a $50-$200 investment per SPD prevents equipment damage costing tens of thousands while reducing inspection labor by 60-80%. The technology integrates seamlessly with existing SCADA and BMS platforms, providing immediate notification when protection fails—the difference between a $200 SPD replacement and an $80,000 inverter catastrophe.

As solar and industrial facilities scale in size and geographical distribution, remote monitoring transitions from optional upgrade to operational necessity. The question isn’t whether to implement SPD remote signaling, but how quickly you can retrofit existing sites and standardize it across new installations.

Ready to implement SPD remote signaling at your facility? Contact VIOX Electric’s technical team for site-specific recommendations, SCADA integration support, and specification assistance. Our engineers provide complimentary system design reviews for projects over 500kW. Visit viox.com/spd or reach out through our technical support portal for immediate assistance.

VIOX Electric: Engineering reliable surge protection solutions for solar and industrial applications since 2008. ISO 9001 certified manufacturing, TÜV product certification, comprehensive technical support.