Introduction

Picture this: You’re standing in front of a 50-horsepower industrial motor at 3 AM, and production has ground to a halt. The plant manager is breathing down your neck, and you need to diagnose the problem—fast. You check the circuit breaker (it’s fine), inspect the wiring (no issues), and then your eyes land on a small rectangular device humming near the control panel. That’s your contactor, and it might just be the culprit behind your $10,000-per-hour downtime crisis.

If you’ve ever wondered what that mysterious box actually does, or why every motor control system seems to have one, you’re in the right place. This comprehensive guide will demystify the electrical contactor, explain how it works, and show you why it’s one of the most critical—yet often overlooked—components in modern electrical systems.

Quick Answer: What is a Contactor?

A contactor is an electromechanical switch designed to repeatedly make and break electrical circuits carrying high current loads. Unlike manual switches, contactors use electromagnetic force to control power flow remotely, making them essential for motor control, HVAC systems, industrial automation, and any application requiring safe, reliable switching of heavy electrical loads (typically 9A to 800A+).

What is a Contactor? Extended Definition

At its core, a contactor is a specialized relay engineered to handle high-power electrical circuits—the kind that would instantly destroy a standard switch or relay. Think of it as the heavy-duty workhorse of electrical control systems, capable of switching currents ranging from 9 amperes to over 800 amperes, thousands of times per day, for years on end.

The fundamental principle behind every contactor is electromagnetic switching. When you apply a low-voltage control signal (typically 24V, 110V, or 230V) to the contactor’s coil, it generates a magnetic field that physically pulls metal contacts together, completing the circuit and allowing power to flow to your load—whether that’s a motor, heating element, lighting system, or industrial machinery.

Here’s what makes contactors different from ordinary switches: they’re designed for continuous duty cycles under harsh conditions. Industrial contactors routinely operate in environments with extreme temperatures, vibration, dust, and electrical noise. They feature advanced arc suppression systems to safely interrupt currents during switching, preventing the dangerous electrical arcs that could weld contacts together or cause fires.

The term “contactor” itself derives from the device’s primary function: making and breaking contact between electrical conductors. Modern magnetic contactors have evolved significantly since their invention in the early 1900s, but the core electromagnetic principle remains unchanged. According to IEC 60947-4 standards, devices switching more than 15 amperes or circuits rated above a few kilowatts are classified as contactors, distinguishing them from lower-power relays.

In practical terms, contactors serve as the “on/off switch” for equipment too powerful to control directly. Without contactors, you’d need massive manual switches—dangerous to operate and prone to failure—or you’d be forced to run high-voltage wiring directly to control panels, creating serious safety hazards. Contactors solve both problems by enabling safe, remote control of heavy loads using low-voltage signals.

How Does a Contactor Work?

Understanding the operating principle of a contactor requires diving into the physics of electromagnetism, specifically Faraday’s Law of Electromagnetic Induction. Don’t worry—we’ll keep this practical.

The Electromagnetic Switching Process

Step 1: Coil Energization

When you close a control switch (or a PLC output activates), electrical current flows through the contactor’s electromagnetic coil. This coil consists of thousands of turns of insulated copper wire wound around a laminated iron core. As current passes through the coil, it generates a magnetic field according to the right-hand rule—the magnetic flux (Φ) is directly proportional to the current (I) and the number of coil turns (N):

Φ = N × I / R_magnetic

Where R_magnetic is the magnetic reluctance of the core material.

Step 2: Armature Attraction

The magnetic field creates a powerful attractive force that pulls the movable armature (a spring-loaded metal plate) toward the fixed iron core. The force generated is proportional to the square of the magnetic flux density:

F = B² × A / (2μ₀)

Where B is flux density, A is pole face area, and μ₀ is the permeability of air.

Step 3: Contact Closure

As the armature moves, it mechanically pushes the movable contacts into firm contact with the stationary contacts. Contact pressure is critical—too little and you get arcing; too much and you accelerate wear. Typical contact pressures range from 0.5 to 2.0 N/mm² depending on current rating.

Step 4: Current Flow

With contacts closed, full load current flows through the main power terminals (typically labeled L1/L2/L3 to T1/T2/T3 for three-phase applications). Contact resistance should be minimal—typically under 1 milliohm for large contactors—to prevent excessive heating.

Step 5: De-energization

When the control circuit opens, current ceases in the coil, and the magnetic field collapses. A spring mechanism (or gravity in some designs) immediately pushes the armature back to its open position, separating the contacts. This mechanical separation must overcome any tendency for contacts to weld together due to arc energy.

Arc Suppression: The Hidden Challenge

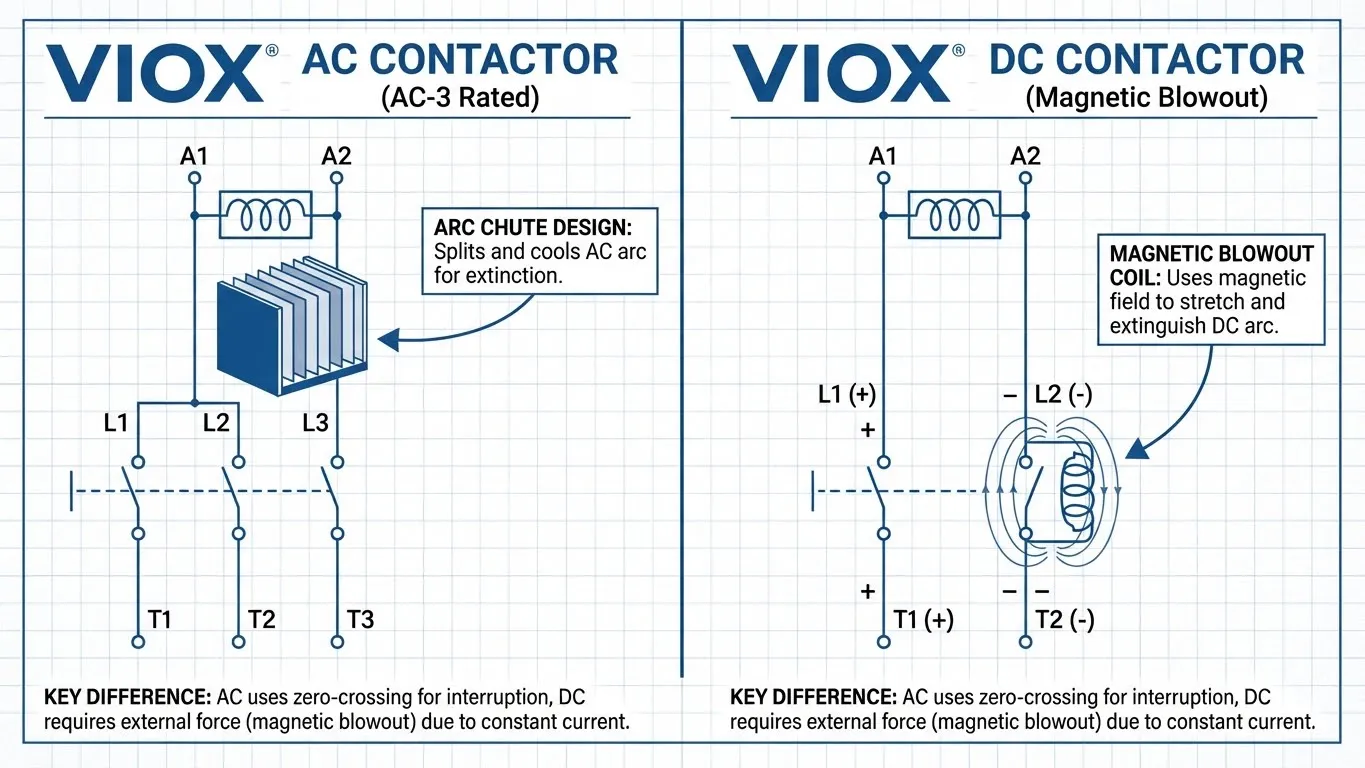

Here’s where contactors get interesting. When you break an inductive load like a motor, the collapsing magnetic field in the motor windings generates a high-voltage spike that tries to maintain current flow across the opening contacts. This creates an electrical arc—essentially a plasma channel conducting current through air.

For AC Contactors:

Arc suppression is easier because AC current naturally crosses zero 100 or 120 times per second (for 50Hz or 60Hz systems). Contactors use arc chutes—insulated metal plates that lengthen and cool the arc, extinguishing it at the zero crossing.

For DC Contactors:

DC arcs don’t have zero crossings, making them much harder to extinguish. DC contactors employ magnetic blowout coils that generate a magnetic field perpendicular to the arc, physically pushing it into arc chutes where it’s stretched and cooled until it breaks.

The energy dissipated in an arc can be calculated as:

E_arc = 0.5 × L × I²

Where L is the circuit inductance and I is the current at the moment of interruption.

This is why contactors are rated by utilization category (AC-1, AC-3, AC-4, etc.)—each category specifies the maximum current the contactor can safely interrupt under specific load conditions.

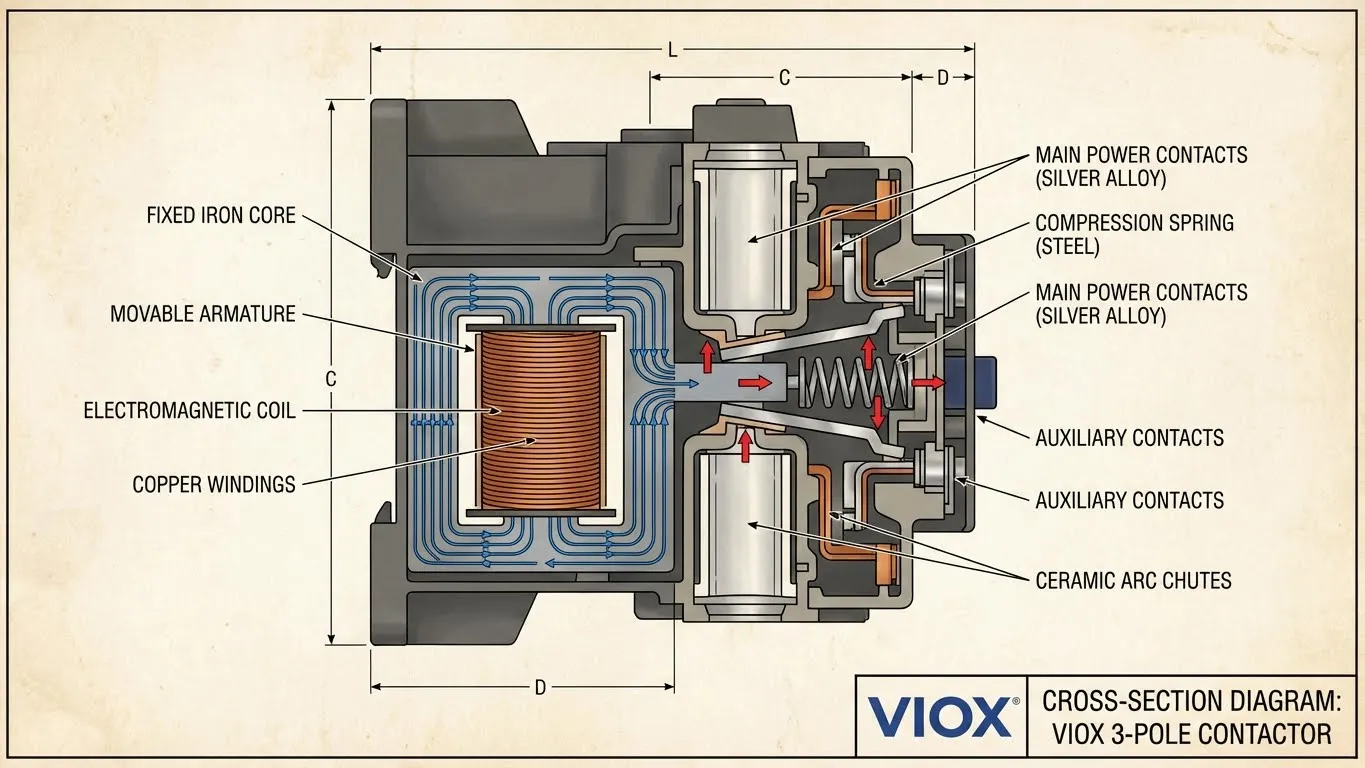

Anatomy of a Contactor: 8 Core Components

Let’s dissect a contactor to understand what makes it tick. Every contactor, from a compact 9A model to a massive 800A industrial beast, contains these eight essential components:

1. Electromagnetic Coil (The Heart)

The coil is the contactor’s power source. It typically consists of:

- 1,000-3,000 turns of enameled copper wire (more turns = lower current requirement)

- Laminated iron core (for AC) or solid steel core (for DC) to concentrate magnetic flux

- Insulation class (typically Class F/155°C or Class H/180°C) to withstand heat

- Coil resistance of 100-500Ω for AC coils, 50-200Ω for DC coils

Pro Tip: Always measure coil resistance when troubleshooting. A shorted coil shows near-zero resistance; an open coil shows infinite resistance.

2. Main Power Contacts (The Muscle)

These current-carrying contacts are the business end of the contactor:

- Contact material: Silver-cadmium oxide (AgCdO) for general purpose, silver-nickel (AgNi) for high-switching duty, or tungsten alloys for DC applications

- Contact configuration: Single-pole (1P), two-pole (2P), three-pole (3P), or four-pole (4P) depending on application

- Contact pressure: Spring-loaded to maintain 0.5-2.0 N/mm² force

- Contact resistance: Less than 1mΩ when new, should not exceed 5mΩ before replacement

3. Arc Suppression System

This critical safety feature prevents contact welding:

- Arc chutes: Parallel metal plates that divide and cool the arc

- Magnetic blowout: Additional coils (DC contactors) that deflect the arc into chutes

- Arc runners: Copper or steel plates that guide the arc away from main contacts

4. Movable Armature

The mechanical link between the coil and contacts:

- Material: Laminated steel for AC (reduces eddy current losses), solid steel for DC

- Travel distance: Typically 2-5mm movement to close contacts

- Actuating force: Must overcome contact spring pressure plus any contact welding

5. Return Spring Mechanism

Ensures fail-safe opening:

- Spring rate: Calibrated to reliably open contacts when coil is de-energized

- Material: Stainless steel or spring steel for corrosion resistance

- Redundancy: Many industrial contactors use dual springs for reliability

6. Auxiliary Contacts

These smaller contacts (rated for 6-10A) serve control functions:

- Normally Open (NO): Close when contactor energizes

- Normally Closed (NC): Open when contactor energizes

- Applications: Interlocking, status indication, PLC feedback

- Configuration: Available as 1NO+1NC, 2NO+2NC, 4NO, etc.

7. Enclosure Frame

The protective housing:

- Materials: Thermoplastic (for DIN-rail mounting), metal (for harsh environments)

- IP ratings: IP20 (standard indoor), IP54 (dustproof), IP65 (water-resistant)

- Flame resistance: UL 94 V-0 rating for fire safety

- Arc containment: Must withstand internal arc energy without rupturing

8. Terminal Connections

The interface to the rest of your system:

- Power terminals: Screw-type (M4-M8) or pressure-plate style for main contacts

- Coil terminals: Typically labeled A1/A2 (or sometimes 1/2)

- Auxiliary terminals: Usually numbered sequentially (13/14, 21/22, etc.)

- Wire capacity: Specified by cross-sectional area (e.g., 1.5-6mm² for small contactors)

Common Mistake: Many technicians ignore auxiliary contacts during troubleshooting. These small contacts fail more frequently than main contacts but can cause identical symptoms (equipment won’t start).

Types of Contactors

Contactors come in numerous varieties, each optimized for specific applications. Understanding these distinctions is crucial for proper specification.

AC Contactors vs. DC Contactors

AC Contactors are designed for alternating current circuits:

- Coil design: Use laminated cores to reduce eddy current losses (which would otherwise heat the coil)

- Arc extinction: Rely on natural current zero crossings (50Hz = 100 zero crossings/second, 60Hz = 120 zero crossings/second)

- Utilization categories: AC-1 (resistive), AC-2 (slip ring motors), AC-3 (squirrel cage motors), AC-4 (plugging/jogging)

- Voltage ratings: Common ratings include 230V, 400V, 500V, 690V AC

- Applications: Industrial motors, HVAC compressors, lighting control, heating elements

Example model: VIOX CT1-32, rated 32A at AC-3, 400V, suitable for motors up to 15kW.

DC Contactors are engineered for direct current:

- Coil design: Solid steel cores (no lamination needed—DC doesn’t induce eddy currents)

- Arc extinction: Magnetic blowout coils essential (DC arcs have continuous energy, no zero crossings)

- Polarity sensitivity: Must connect positive/negative correctly to ensure proper arc extinction

- Voltage drop: Higher than AC (typically 0.8-1.5V across closed contacts vs. 0.3-0.5V for AC)

- Applications: Solar PV systems, battery banks, electric vehicle charging, DC motor control, renewable energy

Example model: VIOX DC-250, rated 250A at 1000V DC, suitable for solar combiner boxes.

Magnetic vs. Manual Contactors

Magnetic Contactors (most common):

- Electrically operated via coil

- Enable remote control

- Integrate with automation systems

- Require control voltage source

Manual Contactors:

- Mechanically operated by hand lever

- No coil required

- Used where remote control isn’t needed

- Often called “motor switches”

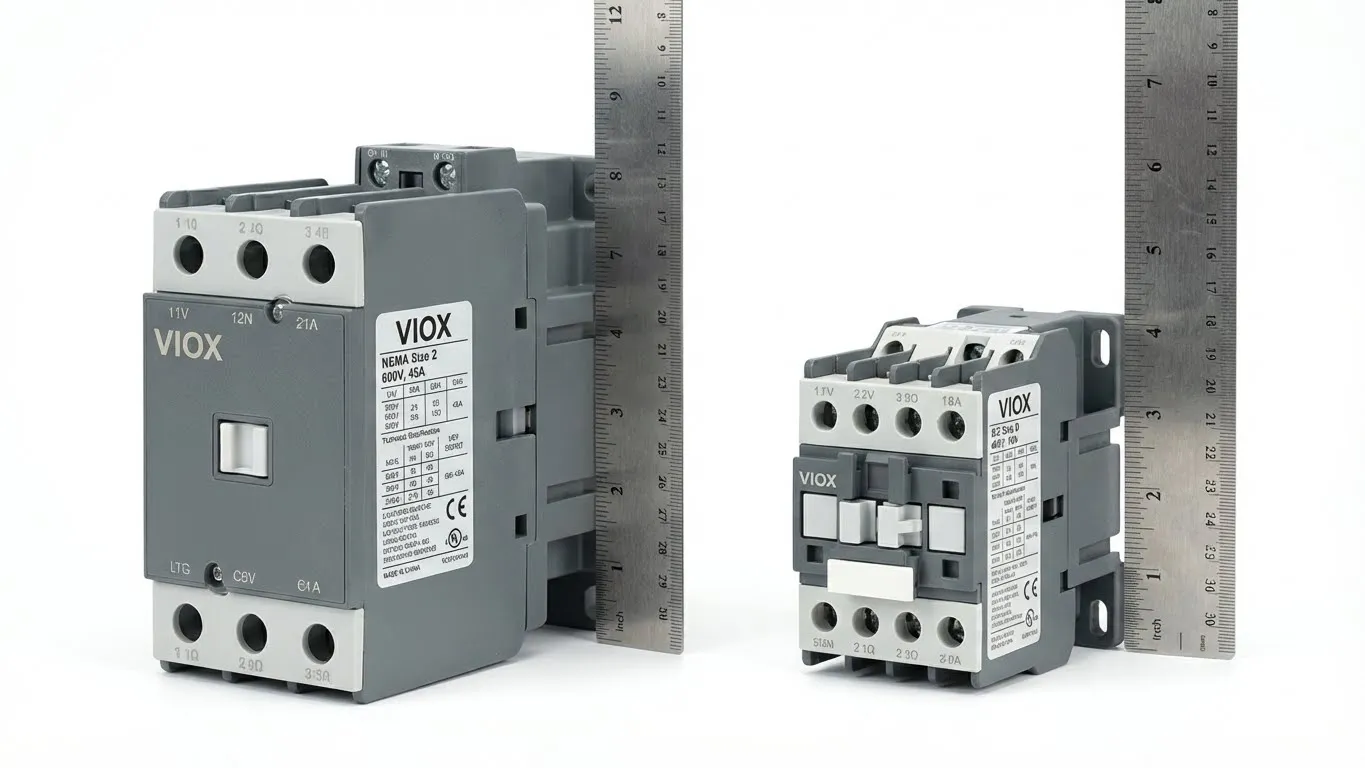

NEMA vs. IEC Contactors

Two competing standards dominate the market:

NEMA (National Electrical Manufacturers Association):

- Sizing: Designated by number (Size 00, 0, 1, 2, 3, 4, 5, 6, 7, 8, 9)

- Rating method: By horsepower at specific voltages (e.g., “Size 2 = 25HP @ 230V, 50HP @ 460V”)

- Design: Larger physical size with built-in safety margins

- Market: Predominantly North America

- Example: Schneider Electric 8910DPA, Square D 8536

IEC (International Electrotechnical Commission):

- Sizing: Designated by letters (Size A, B, C, D, E, F, G, H, J, K, L, M, N)

- Rating method: By current at specific utilization categories (e.g., “32A @ AC-3, 400V”)

- Design: More compact, requires external overload protection

- Market: Europe, Asia, increasingly global

- Example: Siemens 3RT2, ABB AF, Schneider LC1D

Specialty Contactor Types

Reversing Contactors:

- Two mechanically interlocked contactors for motor direction reversal

- Prevents simultaneous energization (which would cause short circuit)

- Essential for conveyor systems, hoists, cranes

Capacitor Switching Contactors:

- Special contacts resist welding from high inrush currents

- Often include pre-insertion resistors to limit inrush

- Used for power factor correction banks

Lighting Contactors:

- Rated for tungsten lamp inrush (up to 10× steady-state current)

- Often include auxiliary switches for indicator lamps

- Available in NEMA 0-9 and IEC 20A-400A ratings

Vacuum Contactors:

- Medium-voltage applications (1kV-38kV)

- Contacts operate in sealed vacuum bottles

- Exceptionally long electrical life (100,000+ operations)

- Used in mining, utilities, large industrial facilities

Contactor vs. Relay vs. Circuit Breaker

Engineers frequently confuse these three devices. While they share electromagnetic operating principles, their functions and applications differ significantly. Here’s the definitive comparison:

| Feature | Contactor | Relay | Circuit Breaker |

|---|---|---|---|

| Primary Function | Switching high-power loads ON/OFF | Logic control, signal switching | Overcurrent and short-circuit protection |

| Current Rating | 9A – 800A+ | 0.5A – 40A (most under 10A) | 0.5A – 6,300A |

| Voltage Rating | Up to 1,000V AC/DC | Typically ≤250V | Up to 1,200V AC |

| Arc Suppression | Advanced (arc chutes, blowout) | Minimal (small contacts) | Advanced (magnetic blowout) |

| Contact Material | AgCdO, AgNi, tungsten alloys | Silver, silver-nickel | Copper-tungsten, silver alloys |

| Mechanical Life | 10 million operations | 10-50 million operations | 10,000-25,000 operations |

| Electrical Life | 1-5 million (load-dependent) | 100,000-1 million | 5,000-10,000 operations |

| Manual Override | No (electrical operation only) | No (electrical operation only) | Yes (trip/reset mechanism) |

| Protection Function | None (switching only) | None (switching only) | Yes (trips on overload/fault) |

| Contact Configuration | Usually NO (normally open) | NO, NC, changeover | Usually fixed (trip-open) |

| Control Circuit | Separate low-voltage circuit | Separate low-voltage circuit | Self-contained (thermal/magnetic) |

| Response Time | 20-100ms | 5-20ms | <10ms (magnetic), seconds (thermal) |

| Cost Range | $15-$300 | $3-$50 | $5-$5,000+ |

| Physical Size | Medium to large | Small | Small to very large |

| Typical Applications | Motor starters, HVAC, lighting | Control circuits, automation | Panel protection, motor feeders |

Critical Distinction: A contactor is not a protective device. It will happily continue passing fault current until the load or contactor itself is destroyed. Always pair contactors with circuit breakers or fuses for overcurrent protection.

For a deeper dive into this crucial distinction, see our comprehensive guide: Contactor vs. Circuit Breaker.

Why You Can’t Substitute:

- Using a relay for a 50A motor → Relay contacts weld together instantly

- Using a contactor instead of a circuit breaker → No protection against overloads or short circuits

- Using a circuit breaker as a contactor → Premature failure from excessive cycling (circuit breakers aren’t designed for frequent on/off operation)

Applications of Contactors

Contactors are ubiquitous in modern electrical systems. Here are eight major application categories:

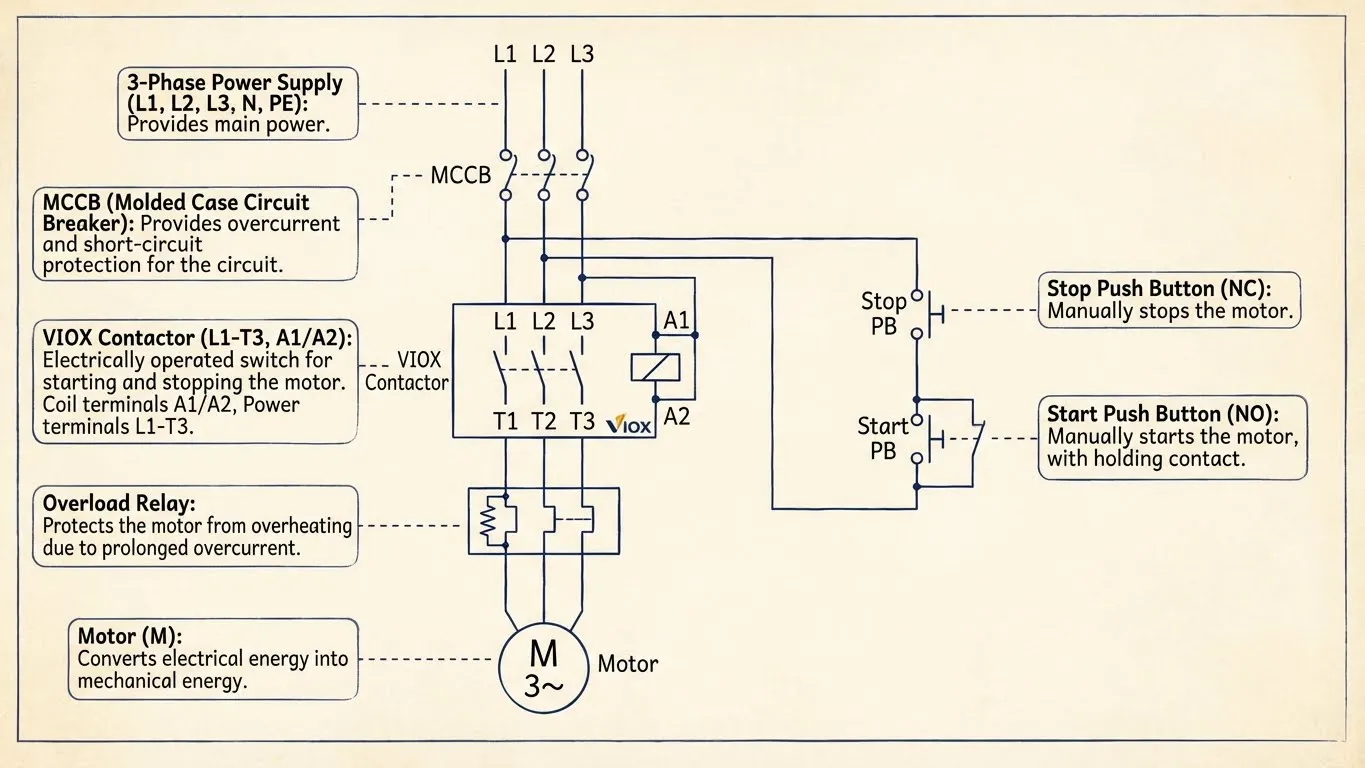

1. Motor Control & Automation

This is the single largest application for contactors. In direct-on-line (DOL) motor starters, the contactor performs the heavy lifting:

How it works:

- PLC or manual switch sends 24V signal to contactor coil

- Contactor closes, applying full three-phase power to motor

- Overload relay monitors current; if excessive, it opens the control circuit

- Emergency stop button immediately de-energizes contactor

Why contactors are essential:

Motor starting current can be 6-8× full load current. A 10HP motor drawing 14A at full load pulls 84-112A during start-up. Only contactors rated for AC-3 or AC-4 duty can handle this repeated stress.

Advanced applications:

- Star-delta starting: Uses two contactors to reduce starting current by 33%

- Reversing control: Two interlocked contactors swap two phases for direction reversal

- Soft-start integration: Contactor bypasses soft-start after ramp-up

For detailed motor starter information, see: Contactor vs. Motor Starter.

2. HVAC Systems

Commercial heating, ventilation, and air conditioning systems depend on contactors for compressor and fan control:

Residential applications (1-5 ton units):

- Single-pole or two-pole contactors (20A-40A typical)

- Control voltage: Usually 24V AC from thermostat transformer

- Failure mode: Most HVAC “won’t start” calls involve failed contactors

Commercial applications (10-100+ ton units):

- Three-pole contactors (60A-200A+)

- Multiple stages with sequenced start-up

- Life expectancy: 5-10 years with seasonal use, 3-5 years with continuous use

Pro Tip: HVAC contactors are the #1 failure point in air conditioning systems. Insects (particularly ants) are attracted to electrical fields and frequently nest in contactors, preventing contact closure.

3. Solar PV & Energy Storage Systems

The renewable energy revolution has created massive demand for DC contactors:

String isolation:

DC contactors disconnect individual solar strings for maintenance or emergencies. Critical for:

- Rapid shutdown compliance (NEC 690.12)

- Array maintenance without de-energizing entire system

- Fire safety (allows firefighters to de-energize rooftop arrays)

Battery bank protection:

In Battery Energy Storage Systems (BESS), contactors provide:

- Pre-charge circuit control (limits inrush to DC bus capacitors)

- Emergency disconnect for thermal runaway events

- Module isolation for maintenance

Voltage considerations:

Solar systems operate at 600V-1500V DC, requiring specialized contactors with:

- High voltage isolation (3kV+ between coil and contacts)

- Robust magnetic blowout (DC arc extinction is challenging)

- Outdoor-rated enclosures (IP65+)

Explore solar applications in detail: Solar Combiner Box vs. Y-Branch Connectors.

4. EV Charging Infrastructure

Electric vehicle charging stations use contactors for safety and control:

Level 2 AC Chargers (7-22kW):

- AC contactors disconnect power when:

- Charging cable unplugged

- Ground fault detected

- Vehicle signals charge complete

- Typical rating: 40A-80A, 230V-400V AC

DC Fast Chargers (50-350kW):

- High-voltage DC contactors (250A-500A, 500V-1000V DC)

- Pre-charge contactors limit inrush to vehicle battery

- Positive and negative pole contactors for complete isolation

5. Industrial Lighting Control

Large commercial and industrial facilities use lighting contactors for:

Centralized control:

- Single contactor controls hundreds of fixtures

- Time clock or photocell operation

- Energy management integration

Typical ratings:

- NEMA lighting contactors: 20A-400A

- Electrically held (mechanically latching) or mechanically held (toggle action)

- Often include auxiliary contacts for status indication

6. Heating Element Control

Electric heating systems require contactors for:

Industrial ovens/furnaces:

- Contactors switch resistive heating elements (50kW-500kW+)

- AC-1 utilization category (resistive loads)

- Higher continuous current rating than motor-duty contactors

Building heating:

- Rooftop heater units

- Process heating tanks

- Temporary construction heating

7. Capacitor Banks (Power Factor Correction)

To reduce reactive power charges, industrial facilities use contactor-switched capacitor banks:

Application specifics:

- Capacitor contactors rated for high inrush current (up to 200× steady-state)

- Pre-insertion resistors limit inrush

- Discharge resistors bleed residual charge after disconnection

Switching sequence:

- Controller monitors power factor

- Switches capacitor steps in/out to maintain target PF (typically 0.95-0.98)

8. Conveyor Systems & Material Handling

Contactor-based control enables:

Zone control:

- Each conveyor section has dedicated contactor

- Sequential start-up prevents overload

- Emergency stop de-energizes all zones simultaneously

Reversing operation:

- Mechanically interlocked forward/reverse contactors

- Prevents simultaneous energization (would cause short circuit)

How to Select the Right Contactor

Selecting the correct contactor requires evaluating ten critical parameters. Get this wrong and you’ll face premature failure, safety hazards, or system inefficiency.

1. Voltage Rating (Ue)

Operational voltage (Ue) is the maximum voltage the contactor can safely switch. It must meet or exceed your system voltage:

Common AC voltage ratings:

- Single-phase: 110V, 230V, 277V, 400V, 480V

- Three-phase: 230V, 400V, 480V, 600V, 690V

Common DC voltage ratings:

- Low voltage: 12V, 24V, 48V, 110V

- Solar/industrial: 250V, 500V, 750V, 1000V, 1500V

Derating for altitude:

Above 1000m elevation, derate voltage by 10% per 1000m. At 2000m altitude, a contactor rated 1000V DC should only be used up to 800V DC.

2. Current Rating (Ie)

This is where most specification errors occur. You must consider:

Rated operational current (Ie):

The maximum continuous current the contactor can carry without overheating. This is typically specified at 40°C ambient temperature.

For motor loads (AC-3 rated): Select based on motor Full Load Amps (FLA) from nameplate:

- 15kW motor @ 400V 3-phase: FLA ≈ 30A → Select 40A contactor

- Add 25% safety margin for frequent starts or harsh environments

Formula for motor current: I = P / (√3 × V × cos φ × η)

Where:

- P = motor power (watts)

- V = line voltage

- cos φ = power factor (typically 0.85-0.9 for motors)

- η = efficiency (typically 0.85-0.95)

For resistive loads (AC-1 rated):

- 15kW heater @ 400V: I = 15,000W ÷ 400V = 37.5A → Select 40A contactor

Pro Tip: A common mistake is sizing based on motor nameplate horsepower rather than actual FLA. Always use FLA as your primary sizing parameter.

3. Utilization Category (IEC 60947-4)

This specification defines the contactor’s ability to make and break specific types of loads:

| Category | Application | Make Current | Break Current |

|---|---|---|---|

| AC-1 | Non-inductive or slightly inductive (heaters, resistors) | 1.5× Ie | 1× Ie |

| AC-2 | Slip ring motors (starting, switching during running) | 2.5× Ie | 2.5× Ie |

| AC-3 | Squirrel cage motors (starting, switching during running) | 6× Ie | 1× Ie |

| AC-4 | Squirrel cage motors (starting, plugging, inching) | 6× Ie | 6× Ie |

| DC-1 | Non-inductive or slightly inductive DC loads | 1.5× Ie | 1× Ie |

| DC-3 | DC motors (starting, plugging, inching, dynamic braking) | 2.5× Ie | 2.5× Ie |

Why this matters:

An AC-3 rated contactor can only interrupt 1× Ie. For applications involving plugging (reversing a running motor) or jogging (frequent short bursts), you need AC-4 rated contactors that can safely interrupt 6× Ie.

Example:

A 32A AC-3 contactor can start a motor drawing 192A inrush (6× 32A) but can only safely interrupt 32A. If you reverse the motor while running at 32A, you create an effective current of 64A (forward + reverse), which exceeds the AC-3 breaking capacity. You need a 32A AC-4 contactor instead.

4. Coil Voltage

The electromagnetic coil must match your control circuit voltage:

Common coil voltages:

- AC: 24V, 48V, 110V, 120V, 208V, 220V, 230V, 240V, 277V, 400V, 415V, 440V, 480V, 500V, 600V

- DC: 12V, 24V, 48V, 110V, 125V, 220V

Voltage tolerance:

- AC coils: Typically ±15% (e.g., 230V coil operates 195V-265V)

- DC coils: Typically ±20% (e.g., 24V DC coil operates 19V-29V)

Best practice for PLC control: Use 24V DC coils whenever possible. Benefits include:

- Noise immunity (AC coils can chatter with voltage fluctuations)

- Universal PLC compatibility

- Lower power consumption (10-15W vs. 20-40W for AC coils)

- No inrush current issues

Coil power consumption:

Small contactors (9-32A): 2-15W

Medium contactors (40-95A): 15-40W

Large contactors (150A+): 40-150W

5. Auxiliary Contacts

These smaller contacts (typically rated 6A-10A) provide control circuit functionality:

Standard configurations:

- 1NO (one normally open)

- 1NC (one normally closed)

- 1NO+1NC

- 2NO+2NC

- 4NO

Common applications:

- Interlock circuits: NO auxiliary contact of Contactor A wired in series with coil of Contactor B prevents simultaneous operation

- Status indication: NO auxiliary contact powers green “motor running” pilot light

- PLC feedback: NO auxiliary contact provides digital input to PLC confirming contactor closed

- Control circuit sealing: NO auxiliary contact maintains coil energization after momentary start button released

Pro Tip: When designing motor control circuits, always specify extra auxiliary contacts. The cost difference is minimal ($5-15), but retrofitting is expensive and time-consuming.

6. Mechanical & Electrical Life

Contactor lifespan depends on load type and switching frequency:

Mechanical life (no load):

- Standard contactors: 10 million operations

- High-duty contactors: 20 million operations

- Testing standard: IEC 60947-4-1

Electrical life (under load):

| Load Type | Electrical Life @ Rated Current |

|---|---|

| AC-1 (resistive) | 2-5 million operations |

| AC-3 (motors, normal duty) | 1-2 million operations |

| AC-4 (motors, heavy duty) | 200,000-500,000 operations |

| DC-3 (DC motors) | 100,000-300,000 operations |

Derating for frequent operation:

For applications cycling more than 100 times/hour, upsize by one NEMA size or select a higher IEC frame size. Example: If calculation yields 32A, specify 40A for high-cycle applications.

Real-world failure rates:

- Well-maintained contactors in proper application: 0.5-1% annual failure rate

- Oversized contactors with protective devices: 0.1-0.3% annual failure rate

- Undersized or improperly applied contactors: 5-10% annual failure rate

7. Environmental Protection (IP Rating)

The Ingress Protection rating defines enclosure sealing:

| IP Rating | Solid Particle Protection | Liquid Ingress Protection | Typical Application |

|---|---|---|---|

| IP20 | >12.5mm objects | None | Indoor panels, climate-controlled |

| IP40 | >1mm objects | None | Indoor industrial, dust-present |

| IP54 | Dust-protected | Splash-resistant | Outdoor enclosures, washdown areas |

| IP65 | Dust-tight | Water jet resistant | Outdoor, wet environments |

| IP67 | Dust-tight | Temporary immersion | Underground, flood-prone |

Selection guide:

- Indoor panels: IP20 sufficient

- Industrial facilities (dust, debris): IP40 minimum, IP54 recommended

- Outdoor installations: IP54 minimum, IP65 recommended for severe weather

- Washdown areas (food processing, car washes): IP65 minimum

8. Ambient Temperature & Derating

Contactors are typically rated for 40°C (104°F) ambient temperature. Operating above this requires derating:

Temperature derating curve:

- 40°C (104°F): 100% rated current

- 50°C (122°F): 90% rated current

- 60°C (140°F): 75% rated current

- 70°C (158°F): 50% rated current

Example:

A 63A contactor in a 55°C panel should be derated to: 63A × 0.85 = 53.5A maximum

Altitude derating:

At high altitudes, thinner air reduces cooling and voltage breakdown strength:

- Sea level to 1000m: 100% rated values

- 1000m to 2000m: 90% rated values

- 2000m to 3000m: 80% rated values

9. Mechanical Interlock Requirements

For reversing or bypass applications, mechanical interlocks prevent simultaneous energization:

Mechanical interlock types:

- Push-rod style: Physical rod prevents both contactors closing

- Slide-bar style: Bar mechanism blocks armature movement

- Auxiliary contact interlock: Electrical only (less reliable than mechanical)

Applications requiring mechanical interlocks:

- Forward/reverse motor control

- Star-delta starting

- Auto/manual transfer switches

- Primary/secondary power switching

Code requirements:

NEC 430.87 and IEC 60947-4-1 require mechanical interlocks for reversing applications. Electrical interlocks alone are insufficient for safety-critical applications.

10. Standards Compliance

Ensure contactors meet applicable safety and performance standards:

North American standards:

- UL 508: Industrial Control Equipment

- CSA C22.2 No. 14: Industrial Control Equipment

- NEMA ICS 2: Standards for Contactors

International standards:

- IEC 60947-4-1: Low-Voltage Switchgear and Controlgear – Contactors and Motor-Starters

- CE marking: Required for European market

- CCC: China Compulsory Certificate (Chinese market)

Installation Best Practices

- Coil Connections (A1/A2):

- Always verify coil voltage before energizing

- Use suppression diodes/varistors for DC coils to prevent voltage spikes

- Power Terminals (L1/L2/L3 → T1/T2/T3):

- Tighten to manufacturer’s torque specification (typically 1.2-2.5 Nm)

- Use copper conductors sized for 125% of rated current

- Apply anti-oxidant compound for aluminum conductors

- Phasing:

- Maintain phase sequence (L1→T1, L2→T2, L3→T3) to prevent motor rotation errors

Thermal Management

- Derating: Reduce contactor capacity by 20% if ambient temperature exceeds 40°C

- Ventilation: Ensure 50mm clearance above/below contactor for heat dissipation

- Panel sizing: Avoid overcrowding—excessive heat reduces contactor lifespan

Safety Interlocks

For reversing or bypass applications, use:

- Mechanical interlocks: Physical bars prevent simultaneous closure

- Electrical interlocks: Auxiliary NC contacts in opposing coil circuits

Learn more about safety applications in our guide: Safety Contactor vs. Standard Contactor.

NEMA vs. IEC Standards

The electrical world is divided between two contactor standards: NEMA (North American) and IEC (International). Understanding these differences is critical for global projects and equipment sourcing.

Size Designation Philosophy

NEMA:

Contactors designated by numbers (00, 0, 1, 2, 3, 4, 5, 6, 7, 8, 9) with ratings based on horsepower at specific voltages.

Example: NEMA Size 2

- 25 HP @ 200V, 3-phase

- 50 HP @ 460V, 3-phase

- 60 HP @ 575V, 3-phase

IEC:

Contactors designated by letters (A, B, C, D, E, F, G, H, K, L, M, N) with ratings based on current at specific utilization categories.

Example: IEC Size D

- 32A @ AC-3, 400V

- (Equivalent to ~15 HP motor)

Physical Size Comparison

For equivalent electrical ratings, NEMA contactors are typically 30-50% larger than IEC contactors. This size difference stems from design philosophy:

- NEMA: Conservative design with built-in safety margins

- IEC: Compact design requiring external overload protection

Technical Specification Differences

| Specification | NEMA | IEC |

|---|---|---|

| Current rating basis | HP at voltage | Amperes at utilization category |

| Overload protection | Often integral | Must be added separately |

| Safety factor | Built into device | Added by user |

| Contact ratings | Conservative | Optimized |

| Enclosure ratings | NEMA 1, 3R, 4, 4X, 12 | IP20, IP40, IP54, IP65 |

| Standards body | UL 508, NEMA ICS 2 | IEC 60947-4-1 |

| Testing requirements | UL certification | CE marking, IEC compliance |

Cost Comparison

For equivalent motor control applications:

- NEMA contactors: Typically 20-40% more expensive

- IEC contactors: Lower initial cost, but requires separate overload relay

Total system cost often similar, but IEC offers more flexibility in selecting exact overload characteristics.

Geographic Market Penetration

NEMA dominance:

- United States

- Canada

- Mexico

- Some Caribbean nations

IEC dominance:

- Europe (exclusively)

- Asia

- Middle East

- Africa

- South America

- Increasingly penetrating North American market

Interchangeability

Can you replace NEMA with IEC or vice versa?

Physically: Yes, but may require panel modifications due to size differences

Electrically: Usually, but consider:

- Verify current rating adequate for application

- Add overload relay if replacing NEMA with IEC

- Confirm coil voltage matches control circuit

- Check auxiliary contact configuration matches control circuit requirements

Pro Tip: For new designs, IEC contactors offer advantages:

- Smaller footprint (more capacity per panel square inch)

- Lower cost (particularly for large quantities)

- Greater global availability

- Modular accessories (easier to add functions)

Cost Analysis and ROI

Understanding the total cost of ownership helps justify quality contactor specifications and preventive maintenance programs.

Initial Purchase Cost (2026 Market Data)

NEMA Contactors:

| Size | Current Rating | Typical Cost | Application |

|---|---|---|---|

| Size 00 | 9A | $25-45 | Small motors (1/2-1 HP) |

| Size 0 | 18A | $35-60 | Motors up to 5 HP |

| Size 1 | 27A | $50-90 | Motors 5-10 HP |

| Size 2 | 45A | $80-150 | Motors 10-25 HP |

| Size 3 | 90A | $150-280 | Motors 25-50 HP |

| Size 4 | 135A | $300-550 | Motors 50-100 HP |

IEC Contactors:

| Size | Current Rating | Typical Cost | NEMA Equivalent |

|---|---|---|---|

| Size A | 9A | $15-30 | Size 00 |

| Size B | 12A | $18-35 | Size 0 |

| Size C | 25A | $30-55 | Size 1 |

| Size D | 40A | $45-85 | Size 2 |

| Size E | 65A | $80-140 | Size 3 |

| Size F | 95A | $120-220 | Size 3-4 |

Specialty Contactors:

- DC contactors: Add 40-100% premium

- Vacuum contactors: $500-$5,000+

- Reversing contactors: 180-200% of single contactor cost

Total Cost of Ownership (5-Year Analysis)

Example: 50HP Motor Application

Option 1: Budget IEC Contactor ($65)

- Initial cost: $65

- Overload relay: $45

- Installation: $100

- Expected failures (5 years): 2

- Replacement cost: $65 × 2 = $130

- Downtime cost: $500 × 2 = $1,000

- Total: $1,340

Option 2: Premium NEMA Contactor ($180)

- Initial cost: $180

- Overload integral: $0

- Installation: $100

- Expected failures (5 years): 0.5

- Replacement cost: $180 × 0.5 = $90

- Downtime cost: $500 × 0.5 = $250

- Total: $620

ROI of Quality: The premium contactor saves $720 over 5 years despite higher initial cost.

Downtime Cost Calculation

Unplanned downtime is the hidden cost driver:

Manufacturing facility example:

- Production line output: $10,000/hour

- Average contactor failure diagnosis time: 30 minutes

- Average replacement time: 30 minutes

- Total downtime: 1 hour = $10,000 cost

Even with spare parts on hand, lost production far exceeds contactor cost.

Preventive Maintenance ROI

Annual PM program cost: $50 per contactor (inspection, cleaning, testing)

Without PM:

- Annual failure rate: 5%

- 100 installed contactors → 5 failures/year

- Cost per failure: $1,500 average (parts + downtime)

- Total annual cost: $7,500

With PM:

- Annual failure rate: 1%

- 100 installed contactors → 1 failure/year

- PM cost: $50 × 100 = $5,000

- Failure cost: $1,500 × 1 = $1,500

- Total annual cost: $6,500

Net savings: $1,000/year + improved reliability + extended equipment life

Frequently Asked Questions

1. What is the difference between a contactor and a relay?

The primary distinction is power handling capacity. Contactors are designed for high-current applications (9A-800A+) with robust arc suppression systems, while relays typically handle low-power switching (0.5A-40A) for control circuits and automation. Contactors use larger electromagnetic coils, heavier-duty contacts made from silver alloys, and arc chutes for safe current interruption. Relays are smaller, faster-switching (5-20ms vs. 20-100ms for contactors), and less expensive, but cannot safely interrupt motor starting currents or high-power loads. For detailed comparison, see Contactors vs. Relays: Understanding the Key Differences.

2. Can I use an AC contactor for DC applications?

No—this is extremely dangerous. AC contactors lack the magnetic blowout coils required to extinguish DC arcs. When AC current crosses zero 100-120 times per second, the arc naturally extinguishes. DC current has no zero crossing—the arc sustains itself indefinitely, causing contacts to weld together, housing to melt, and potential fire hazards. DC arcs can sustain at voltages as low as 12V. Always use DC-rated contactors for solar PV, battery systems, electric vehicles, and DC motor control. DC contactors incorporate permanent magnet or electromagnetic blowout systems that physically push the arc into arc chutes where it’s stretched and cooled until it breaks.

3. Why does my contactor have two voltage ratings on the coil?

Many contactors specify a voltage range rather than single voltage (e.g., “220-240V AC”). This indicates the electromagnetic coil design tolerates both voltages within its operating window. The coil generates sufficient magnetic force at the lower voltage (220V) to reliably close contacts, yet doesn’t overheat at the higher voltage (240V). This flexibility accommodates voltage variations in power distribution systems (±10% tolerance is common). However, you cannot use a 110V coil on a 220V circuit—the range must encompass your control voltage. For PLC applications, specifying 24V DC coils eliminates this ambiguity and provides superior noise immunity compared to AC coils.

4. How do I size a contactor for a 3-phase motor?

Use the motor’s Full Load Amperage (FLA) from the nameplate, not horsepower or locked rotor current. Formula: Select a contactor with Ie rating ≥ FLA. For AC-3 duty (normal motor starting): Add 25% safety margin for motors with frequent starts, high-inertia loads, or harsh environments. For AC-4 duty (plugging, jogging, reversing): Add 50-100% safety margin. Example: 15kW motor @ 400V, FLA = 30A → Select 40A AC-3 contactor for normal duty, or 50A AC-4 contactor for heavy-duty applications. Verify the contactor’s utilization category matches your application—using AC-3 rated contactors for plugging applications causes premature failure. For complete selection guidance, see How to Select Contactors and Circuit Breakers Based on Motor Power.

5. What is the purpose of auxiliary contacts on a contactor?

Auxiliary contacts are small, low-current contacts (typically rated 6A-10A) that operate simultaneously with the main power contacts but serve control circuit functions rather than carrying load current. Common applications include: Interlocking (NO auxiliary contact of contactor A wired in series with coil of contactor B prevents simultaneous operation in reversing applications); Status indication (NO auxiliary contact powers “motor running” pilot light or sends feedback to PLC); Control circuit sealing (NO auxiliary contact maintains coil energization after momentary start button is released—this is called a “seal-in” circuit); Alarm activation (NC auxiliary contact opens when contactor energizes, triggering alarm if unexpected operation occurs). Auxiliary contacts significantly enhance system functionality at minimal additional cost ($5-15 per set).

6. Do contactors provide overcurrent protection?

No. This is a critical misconception. Contactors are purely switching devices with no protective function. They will continue passing fault current until either the contactor is destroyed or the load fails catastrophically. You must always pair contactors with appropriately sized circuit breakers, fuses, or overload relays to protect against short circuits and overloads. The protective device sizes based on conductor ampacity and fault current, while the contactor sizes based on load requirements. Typical configuration: Circuit breaker (protection) → Contactor (switching) → Overload relay (motor protection) → Motor. For comprehensive understanding of protection requirements, see Circuit Breaker vs. Isolator Switch.

7. How long do contactors last?

Contactor lifespan depends on two factors: Mechanical life (no load): 10-20 million operations depending on quality and size. Electrical life (under load): Highly variable based on application. AC-1 (resistive loads): 2-5 million operations. AC-3 (motors, normal duty): 1-2 million operations. AC-4 (motors, heavy duty/plugging): 200,000-500,000 operations. DC-3 (DC motors): 100,000-300,000 operations. Real-world service life typically: 5-10 years for HVAC (seasonal use), 3-5 years for continuous industrial applications, 10-15 years for lighting control. Proper maintenance, correct sizing, and adequate cooling significantly extend life. Regular inspection every 6-12 months helps detect wear before failure occurs.

8. What causes contactor coil failure and how can I prevent it?

Primary failure modes: Overvoltage (>110% rated voltage causes insulation breakdown and overheating—verify control voltage matches coil rating); Undervoltage (<85% rated voltage prevents reliable closure, causes chattering and accelerated wear—check for voltage drop in control circuits); Overheating (ambient temperature >40°C without derating shortens coil life—ensure adequate panel ventilation); Contamination (moisture, dust, chemical fumes degrade insulation—specify appropriate IP rating for environment); Mechanical damage (excessive vibration or impact fractures coil windings—use vibration damping mounts). Prevention strategies: Measure and document coil voltage during commissioning; Install RC snubbers or MOV surge suppressors on DC coils; Maintain panel temperature ≤40°C; Use 24V DC coils for PLC control (superior noise immunity); Specify environmentally rated contactors (IP54+ for harsh conditions). Annual insulation resistance testing (coil-to-frame should be >1MΩ) identifies deteriorating coils before failure.

9. Can I parallel contactors to increase current capacity?

Not recommended for several critical reasons: Unequal current sharing (manufacturing tolerances mean contact resistance varies between contactors—one carries majority of current, defeating the purpose); Synchronization issues (contactors don’t close simultaneously—first contactor sees full current until second closes, often exceeding rating); Unequal contact wear (differential wear accelerates, causing one contactor to fail prematurely); Contact welding risk (inrush current through first-to-close contactor may exceed interrupting capacity). Proper solution: Specify single contactor rated for full load current. If no single contactor suffices, consider: Circuit breaker with contactor function (combination motor starters), Vacuum contactors (higher ratings available), Multiple motors on separate contactors (distribute load). The only acceptable parallel application is mechanically interlocked redundant contactors for critical safety functions—but even this requires careful engineering and load balancing circuitry.

10. What maintenance does a contactor require?

Monthly visual inspection: Check for discoloration (overheating), unusual noise (chattering/humming), burning odor, loose connections, dust accumulation. Quarterly thermal imaging: Under load, scan with IR camera—flag temperatures >20°C above ambient or hot spots at terminals. Annual comprehensive inspection (de-energize and lock out first): Measure contact resistance (<1-5mΩ acceptable, >5mΩ indicates wear); Inspect contacts for pitting (replace if depth >0.5mm); Clean contacts with electrical contact cleaner (never use oil or grease); Measure coil resistance (should match manufacturer specs ±20%); Test insulation resistance coil-to-frame (should be >1MΩ); Verify auxiliary contacts operate correctly; Check spring tension and armature free movement; Clean pole faces to remove oxidation; Tighten all power connections to specified torque. Replace when: Contact resistance >5mΩ; Pitting depth >0.5mm; Visible cracks in housing; Coil resistance deviates >20% from spec; Contacts have welded (even once); After >80% of rated electrical life. Critical: Most modern contactors are maintenance-free—do not lubricate unless specifically required by manufacturer for large vacuum or draw-out types.

Conclusion

Contactors are the unsung heroes of modern electrical systems—reliably switching heavy loads millions of times throughout their service life, enabling automation, protecting operators from dangerous voltages, and making remote control possible for equipment from small motors to utility-scale solar arrays.

Understanding how contactors work, how to select them properly, and how to maintain them transforms you from someone who simply replaces failed components to an electrical professional who designs reliable systems. The knowledge in this guide—from electromagnetic principles to troubleshooting techniques—empowers you to specify the right contactor for every application, diagnose problems systematically, and prevent premature failures through preventive maintenance.

Whether you’re an electrical distributor sourcing components for customers, an EPC designing a solar farm, a facility manager responsible for uptime, or a maintenance technician troubleshooting equipment at 3 AM, mastering contactors is essential to your success.

Why Choose VIOX Contactors?

At VIOX Electric, we manufacture industrial-grade contactors engineered to meet the demanding requirements of modern electrical systems:

Technical Excellence:

- IEC 60947-4 & UL 508 certified for global compliance

- Silver alloy contacts (AgCdO, AgNi) for superior conductivity and arc resistance

- Wide coil voltage range (24V-400V AC/DC options)

- Extended electrical life: Up to 2 million operations at AC-3 rated current

- IP20-IP65 environmental protection options

Business Advantages:

- Factory-direct pricing: 30-40% below international brands

- MOQ flexibility: Start with 50 units (sample orders available)

- Custom branding: OEM/ODM services for private label programs

- Fast lead times: 15-day production for standard models

- Technical support: Application engineering assistance available

Quality Assurance:

- 100% factory testing before shipment

- Compliance with CE, CCC, and regional standards

- 2-year warranty on all contactors

- ISO 9001 certified manufacturing

Ready to source reliable contactors for your next project? Contact VIOX for technical specifications, pricing, samples, and application engineering support. Our team of electrical engineers can help you specify the optimal contactor solution for motors, HVAC, solar PV, industrial automation, or any high-power switching application.

Related Articles

- Contactor vs. Motor Starter: Understanding the Key Differences

- How to Test a Contactor: Skill Level Guide

- Safety Contactor vs. Standard Contactor: Force-Guided Contacts Guide

- Modular Contactor vs. Traditional Contactor

- 2-Wire vs. 3-Wire Control: Motor Safety Guide

- Contactors vs. Relays: Understanding the Key Differences

- Circuit Breaker vs. Isolator Switch