The Critical Choice That Determines System Performance

When a 500 HP industrial fan motor starts, it can draw 600% of its rated current—enough to dim lights across an entire facility and stress mechanical components to their limits. This single moment of startup defines why motor control selection matters. Variable Frequency Drives (VFDs) and soft starters both address this challenge, but they do so in fundamentally different ways that impact your system’s performance, energy consumption, and total cost of ownership for decades to come.

The core distinction is straightforward: a soft starter controls only the motor’s starting and stopping by gradually ramping voltage, while a VFD controls motor speed continuously throughout operation by varying both frequency and voltage. This difference cascades into every aspect of system design, from initial capital costs to long-term energy savings, making the selection decision far more consequential than many engineers initially realize.

Key Takeaways

- Soft starters reduce inrush current and mechanical stress during motor startup by gradually increasing voltage over 2-5 seconds, ideal for fixed-speed applications with budget constraints

- VFDs provide continuous speed control by adjusting both frequency and voltage, delivering up to 50% energy savings in variable-load applications despite 2-3× higher initial costs

- Cost analysis shows VFDs typically achieve ROI within 18-36 months for variable-torque loads (fans, pumps), while soft starters remain more economical for fixed-speed applications

- Application selection depends on three factors: need for speed variation, load profile characteristics, and total lifecycle cost analysis

- Standards compliance requires adherence to IEC 61800 series for VFDs and proper coordination with circuit breaker sizing and motor protection devices

Understanding the Fundamental Technologies

How Soft Starters Work

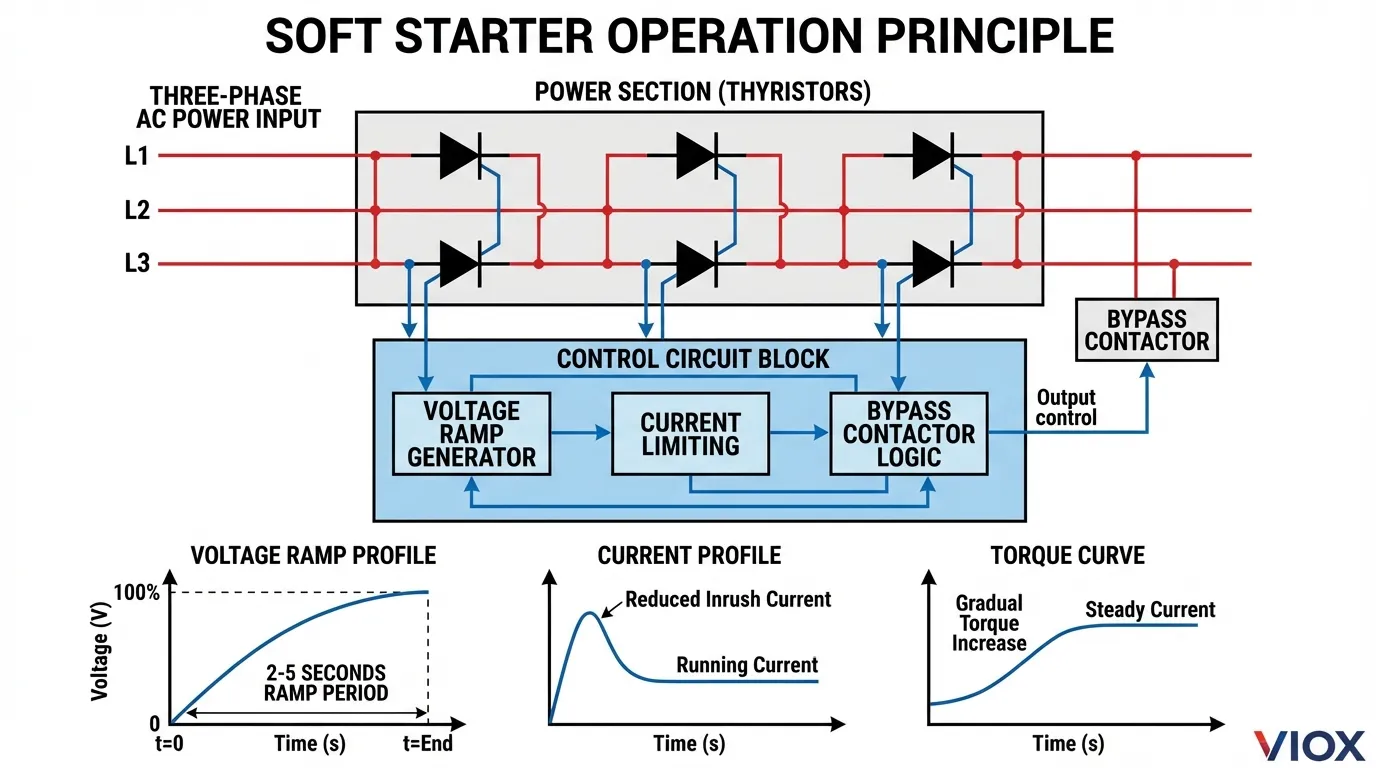

Soft starters employ thyristor (SCR) technology to control the voltage applied to a motor during startup and shutdown. By firing semiconductor switches at precise intervals, they gradually ramp voltage from a reduced level to full rated voltage over a programmable time period—typically 2 to 5 seconds. This controlled acceleration reduces the mechanical shock on driven equipment and limits the electrical stress on the power distribution system.

The operation is elegantly simple: during startup, the soft starter remains in the circuit, controlling current flow. Once the motor reaches full speed, many designs use a bypass contactor to route power directly to the motor, eliminating heat generation and efficiency losses during normal operation. This bypass feature is critical for continuous-duty applications where even small efficiency losses compound into significant energy costs.

How VFDs Work

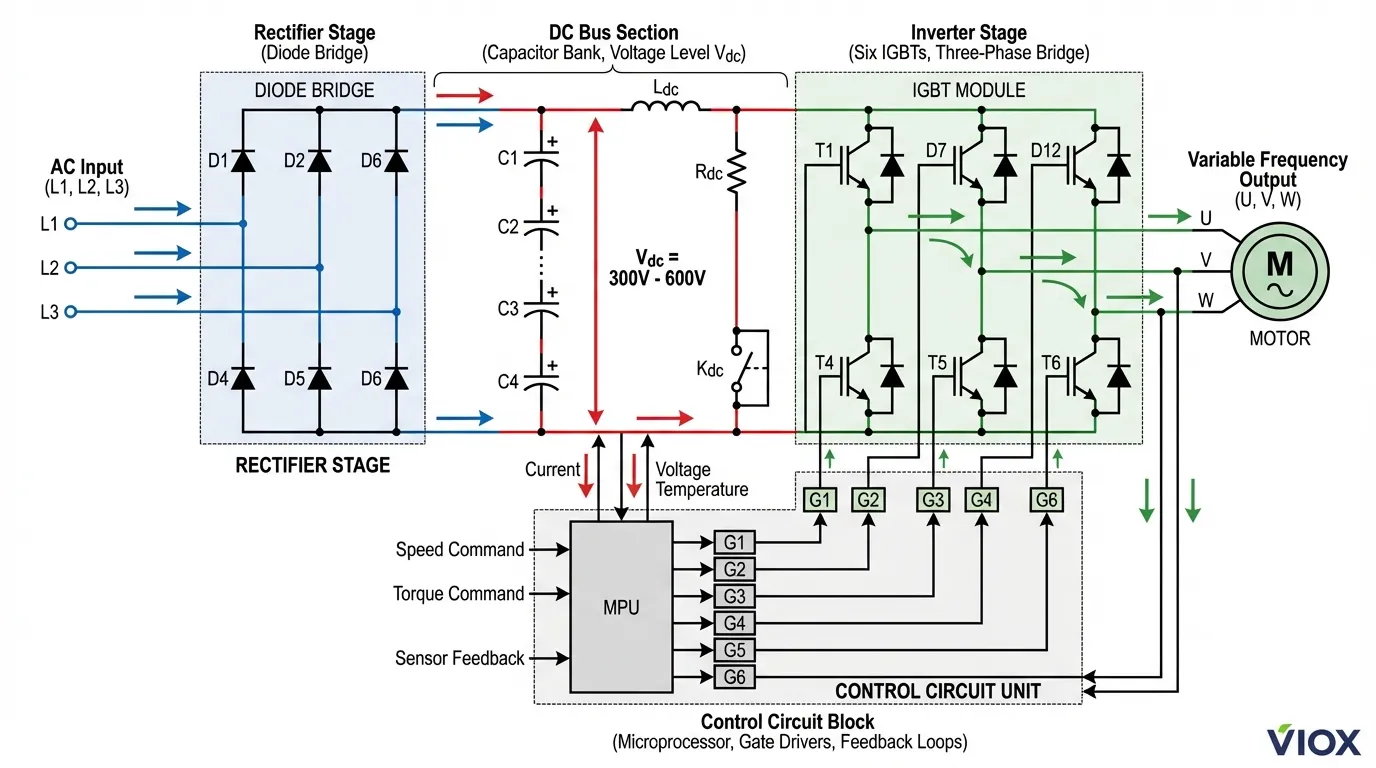

VFDs employ a more sophisticated three-stage power conversion process. First, a rectifier converts incoming AC power to DC. Second, a DC bus with capacitors filters and stabilizes this DC voltage. Third, an inverter section uses Insulated Gate Bipolar Transistors (IGBTs) to reconstruct a variable-frequency, variable-voltage AC output that precisely controls motor speed.

This architecture enables VFDs to adjust motor speed from 0% to 100% of rated speed with exceptional precision. According to IEC 61800-5-1 standards, modern VFDs must incorporate comprehensive protection features including overcurrent, overvoltage, undervoltage, and thermal monitoring to ensure safe operation across the full speed range. The ability to match motor speed exactly to load requirements is what enables the dramatic energy savings VFDs are known for.

Comprehensive Comparison: VFD vs. Soft Starter

| Feature | Soft Starter | Variable Frequency Drive (VFD) |

|---|---|---|

| Primary Function | Controls starting and stopping only | Controls speed continuously during entire operation |

| Speed Control | No speed variation after startup | Full speed control from 0-100% |

| Energy Efficiency | No energy savings during operation | Up to 50% energy savings in variable-load applications |

| Initial Cost | Lower (baseline) | 2-3× higher than soft starter |

| Operating Cost | Higher energy consumption | Lower energy consumption with proper application |

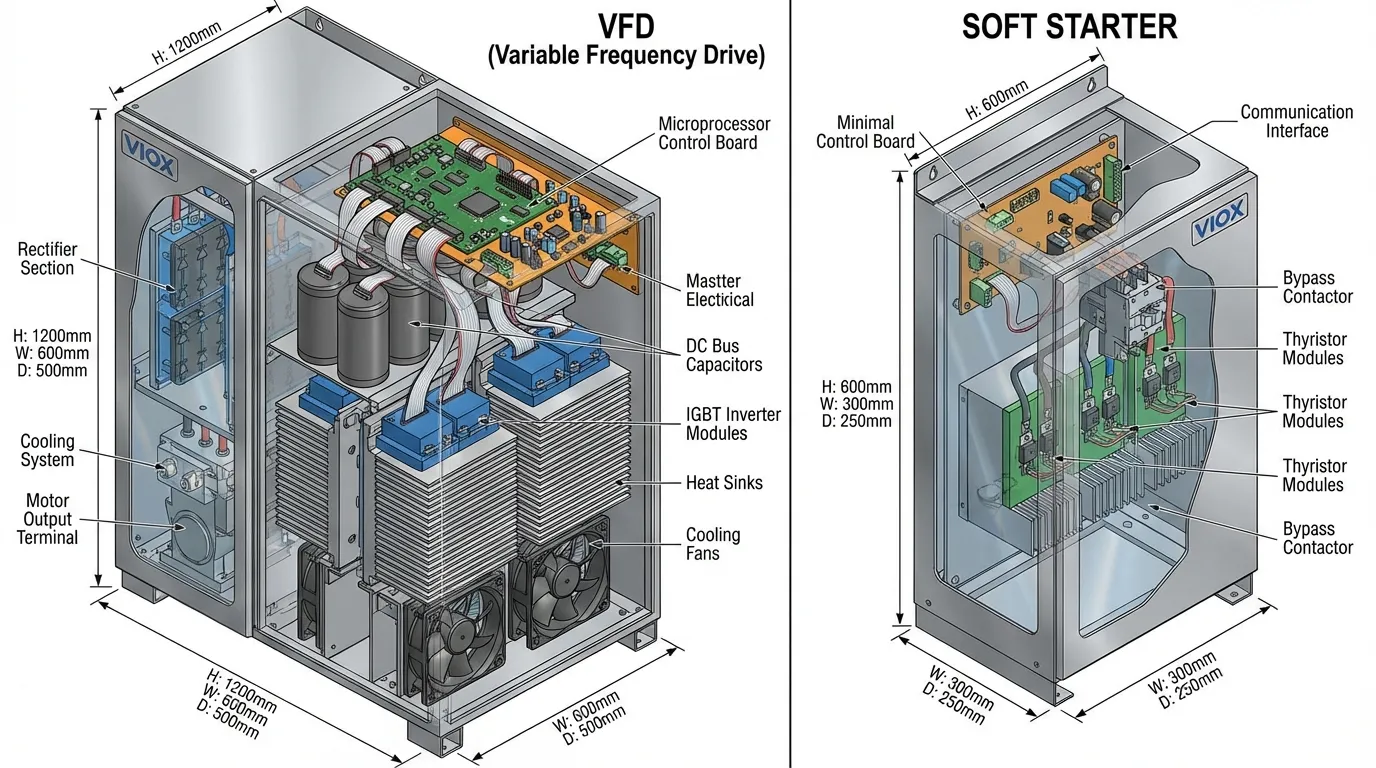

| Footprint | Compact, smaller enclosure | Larger, requires more panel space |

| Heat Generation | Minimal (especially with bypass) | Moderate, requires cooling consideration |

| Inrush Current Reduction | Yes, 2-5 second ramp | Yes, with programmable acceleration |

| Torque Control | Limited to startup/shutdown | Precise control throughout operation |

| Harmonics | Low harmonic injection | Higher harmonics, may require filtering |

| Maintenance | Lower complexity, fewer components | More complex, requires periodic inspection |

| Best Applications | Fixed-speed pumps, compressors, conveyors | Variable-speed fans, pumps, process control |

| ROI Timeline | N/A (no energy savings) | 18-36 months for variable-torque loads |

| Standards Compliance | Basic motor protection standards | IEC 61800 series, EMC requirements |

When to Choose a Soft Starter

Ideal Applications

Soft starters excel in applications where motors operate at constant speed after startup but require protection from high inrush currents. Consider a soft starter when:

Fixed-speed pumping systems where flow rate remains constant and the primary concern is reducing water hammer and mechanical stress on piping systems. Municipal water distribution, fire protection systems, and constant-pressure applications benefit from the gentle acceleration soft starters provide without the complexity of variable speed control.

Belt-driven conveyors that operate at fixed speeds but require gradual acceleration to prevent belt slippage and reduce tension spikes that can damage mechanical components. The controlled torque ramp protects gearboxes, bearings, and coupling systems from the destructive forces of instant-on starting.

Large compressors in applications where compressed air demand remains relatively constant. The soft starter reduces electrical stress on the distribution system while protecting mechanical components from shock loading during startup.

Space-constrained installations where panel space is limited and the smaller footprint of soft starters provides a practical advantage. When combined with bypass contactors, soft starters can be remarkably compact while still delivering essential motor protection.

Economic Considerations

For fixed-speed applications, soft starters typically cost 30-40% less than equivalent VFDs, making them the economical choice when speed variation isn’t required. A 50 HP soft starter might cost $800-1,200, while a comparable VFD could cost $2,000-3,500. When no operational energy savings are possible, the lower capital cost makes soft starters the clear winner.

When to Choose a VFD

Ideal Applications

VFDs deliver maximum value in applications where load varies and motor speed can be adjusted to match demand. The energy savings potential is substantial:

HVAC fan systems represent the textbook VFD application. Fan power consumption follows the cube law—reducing speed by 20% cuts energy consumption by nearly 50%. A 500 HP fan operating between 30-80% speed can generate over $100,000 in annual energy savings, achieving VFD payback in under two years. This makes VFDs essentially mandatory for variable air volume (VAV) systems and any application with varying ventilation requirements.

Variable-flow pumping where demand fluctuates throughout the day or season. Rather than throttling valves to control flow (which wastes energy), VFDs adjust pump speed to match demand precisely. This approach eliminates throttling losses and dramatically reduces energy consumption in applications like cooling tower pumps, process water systems, and irrigation.

Process control applications requiring precise speed regulation for product quality. Extruders, mixers, conveyors with variable throughput, and material handling systems benefit from the precise speed control VFDs provide. The ability to maintain exact speeds regardless of load variations ensures consistent product quality.

Applications requiring multiple speed setpoints such as machine tools, packaging equipment, and automated manufacturing systems. VFDs can store multiple speed presets and transition smoothly between them, enabling complex motion profiles that would be impossible with fixed-speed motors.

Energy Savings Analysis

The energy savings potential of VFDs in variable-torque applications cannot be overstated. For centrifugal loads (fans and pumps), the affinity laws govern the relationship between speed and power:

- Flow varies directly with speed

- Pressure varies with speed squared

- Power varies with speed cubed

This cubic relationship means that operating a fan at 80% speed reduces power consumption to approximately 51% of full-speed power—a 49% energy reduction. For a 100 HP fan motor operating 6,000 hours annually at $0.10/kWh, this translates to over $21,000 in annual savings. With a VFD cost of perhaps $8,000-12,000, payback occurs in less than one year.

Technical Considerations for Selection

Power Quality and Harmonics

VFDs generate harmonic currents that can affect power quality and interfere with sensitive equipment. The IGBT switching in the inverter section creates harmonic distortion that may require input line reactors or harmonic filters to meet IEEE 519 and IEC 61000 standards. Soft starters, by contrast, generate minimal harmonics since they simply control voltage without frequency conversion.

For facilities with sensitive electronic equipment or strict power quality requirements, this harmonic consideration may influence the decision. However, modern VFDs with active front ends or multi-pulse designs can achieve very low total harmonic distortion (THD) when properly specified.

Motor Compatibility

VFDs require careful motor selection and may necessitate derating for certain applications. The variable frequency output can cause additional motor heating, and the high dv/dt (voltage rise time) can stress motor insulation. Motors must meet NEMA MG-1 Part 31 standards for inverter duty, with enhanced insulation systems rated for the voltage spikes VFDs produce.

Soft starters, operating at line frequency, impose no special requirements on motors beyond standard design specifications. This compatibility with existing motors makes soft starters attractive for retrofit applications where motor replacement isn’t feasible.

Protection and Safety

Both technologies must integrate with comprehensive motor protection schemes. VFDs typically include built-in overload protection, but may still require external thermal overload relays for certain applications. Soft starters generally require separate overload protection devices.

For applications requiring functional safety, VFDs can incorporate Safe Torque Off (STO) and other safety functions per IEC 61800-5-2 standards. This capability is essential in machinery applications where rapid shutdown without mechanical braking is required for operator safety.

Integration with Control Systems

Modern VFDs offer extensive communication capabilities including Modbus, Ethernet/IP, PROFINET, and other industrial protocols. This connectivity enables integration with building automation systems, SCADA, and Industry 4.0 initiatives. The ability to monitor energy consumption, operating hours, fault history, and performance parameters makes VFDs valuable data sources for predictive maintenance programs.

Soft starters typically offer more limited communication options, though modern units increasingly include network connectivity. For applications requiring basic start/stop control without extensive data collection, the simpler interface of soft starters may be advantageous.

Decision Framework: Choosing the Right Technology

The Three-Question Method

Question 1: Does the application require variable speed operation?

If yes, a VFD is mandatory. If no, proceed to question 2.

Question 2: What is the load profile?

- Variable torque (fans, pumps): VFD likely justified by energy savings

- Constant torque (conveyors, compressors): Soft starter typically more economical

- High-inertia loads: Consider starting requirements and acceleration time

Question 3: What is the total lifecycle cost?

Calculate:

- Initial equipment cost (VFD typically 2-3× soft starter cost)

- Installation costs (VFDs require more complex installation)

- Energy costs over expected equipment life (15-20 years typical)

- Maintenance costs (VFDs require more periodic maintenance)

For a 50 HP pump operating 4,000 hours annually with 40% average load, a VFD might save $4,000-6,000 annually in energy costs. With a price premium of $2,000-3,000 over a soft starter, payback occurs in 6-12 months, making the VFD the clear choice despite higher initial cost.

Industry-Specific Recommendations

HVAC applications: VFDs are standard practice for any fan or pump over 10 HP due to the dramatic energy savings potential and the inherently variable nature of heating and cooling loads.

Water and wastewater: VFDs for variable-flow applications; soft starters for constant-speed lift stations and fixed-flow processes.

Manufacturing: VFDs for process control and variable-speed machinery; soft starters for fixed-speed conveyors and auxiliary equipment.

Mining and aggregate: Soft starters for crushers and fixed-speed conveyors; VFDs for variable-speed conveyors and material handling systems requiring precise speed control.

Installation and Integration Best Practices

Electrical Design Considerations

Proper circuit breaker sizing is critical for both VFDs and soft starters. VFDs require special consideration for input circuit protection since their capacitive input can cause nuisance tripping with standard molded case circuit breakers. Many manufacturers recommend instantaneous trip settings of 10-12× rated current for VFD input protection.

Soft starters with bypass contactors require coordination between the starter’s internal protection and external motor circuit protection. The bypass contactor must be rated for the motor’s full load current and locked rotor current.

Grounding and EMC

VFDs generate high-frequency noise that requires careful grounding and shielding practices. Use shielded VFD-rated cable for motor connections, maintain 360-degree shield termination at both ends, and route motor cables separately from control wiring. Proper grounding per IEC 61800-3 EMC standards is essential to prevent interference with adjacent equipment.

Panel Design

VFDs generate significantly more heat than soft starters and require adequate ventilation or cooling. Calculate heat dissipation based on VFD efficiency (typically 95-98%) and ensure panel cooling capacity exceeds heat generation by at least 20%. Many engineers underestimate VFD cooling requirements, leading to premature failures and derating.

Soft starters with bypass contactors generate minimal heat during normal operation, simplifying panel thermal design. However, ensure adequate space for the bypass contactor and associated control components.

Common Mistakes to Avoid

- Using a VFD when speed control isn’t needed: This wastes capital on unnecessary functionality and introduces complexity without benefit. A 75 HP constant-speed compressor doesn’t need a $5,000 VFD when a $1,500 soft starter provides adequate protection.

- Choosing a soft starter for variable-load applications: Missing energy savings opportunities. A 200 HP cooling tower fan with a soft starter might consume $30,000 annually in excess energy compared to a VFD-controlled system—the VFD pays for itself in months.

- Ignoring total lifecycle costs: Focusing solely on initial price without considering 15-20 years of operating costs. Energy savings often dwarf initial cost differences.

- Inadequate motor cable specification: Using standard cable for VFD applications leads to EMC problems and potential motor insulation failure. Always specify VFD-rated cable with proper shielding.

- Neglecting harmonic analysis: Installing VFDs without considering power quality impacts can affect sensitive equipment and violate utility interconnection agreements.

Future Trends and Emerging Technologies

The line between VFDs and soft starters continues to blur as manufacturers introduce “smart soft starters” with limited speed control capabilities and “compact VFDs” that approach soft starter pricing. However, the fundamental physics remain: true variable speed control requires frequency conversion, which necessitates the rectifier-inverter architecture of VFDs.

Emerging trends include:

- Silicon carbide (SiC) semiconductors enabling more compact, efficient VFDs with reduced cooling requirements and higher switching frequencies for better motor control.

- Integrated motor-drive systems where the VFD is built into the motor housing, eliminating motor cables and associated EMC challenges.

- Cloud-connected drives providing remote monitoring, predictive maintenance, and energy optimization through machine learning algorithms.

- Functional safety integration with VFDs increasingly incorporating safety functions that eliminate separate safety relays and contactors.

Despite these advances, the fundamental selection criteria remain unchanged: choose soft starters for fixed-speed applications requiring gentle starting, and VFDs for applications where variable speed control enables energy savings or process improvement.

FAQ: VFD vs. Soft Starter Selection

Q: Can I use a VFD as a soft starter?

A: Yes, VFDs include soft start functionality and can be programmed to ramp motors up and down just like dedicated soft starters. However, using a VFD solely for soft starting wastes capital on unused speed control capabilities. The exception is when future speed control requirements are anticipated—installing a VFD initially may be more economical than retrofitting later.

Q: Do I need a soft starter if I already have a VFD?

A: No, VFDs provide all the starting control that soft starters offer, plus continuous speed control. Using both in series is redundant and adds unnecessary complexity. The only exception is specialized applications with multiple motors where a VFD controls overall system speed while individual soft starters protect specific motors during frequent start-stop cycles.

Q: What is the typical payback period for a VFD?

A: For variable-torque loads (fans and pumps) operating with significant speed variation, payback typically occurs in 18-36 months. Applications with greater speed variation and longer operating hours achieve faster payback. A 100 HP fan operating 6,000 hours annually at an average 70% speed might achieve payback in 12-18 months. Constant-torque loads rarely justify VFDs based on energy savings alone.

Q: Can existing motors be used with VFDs?

A: Most modern motors can operate with VFDs, but older motors may require evaluation. Motors should meet NEMA MG-1 Part 31 inverter duty standards with enhanced insulation systems. Motors with standard insulation may experience premature failure due to voltage spikes from VFD switching. Consult motor manufacturers for specific compatibility guidance, and consider derating motors by 10-15% when used with VFDs if not specifically rated for inverter duty.

Q: How do I size circuit breakers for VFDs?

A: VFD input circuit breakers should be sized based on VFD input current (typically 1.2-1.5× motor FLA) with instantaneous trip settings of 10-12× rated current to prevent nuisance tripping during VFD charging. Output circuit protection is typically provided by the VFD’s internal overload protection. Refer to circuit breaker sizing guidelines and coordinate with VFD manufacturer recommendations for specific applications.

Q: What maintenance do VFDs and soft starters require?

A: Soft starters require minimal maintenance—primarily periodic inspection of connections and bypass contactors if equipped. VFDs require more attention: cooling fan inspection/replacement every 3-5 years, capacitor testing/replacement every 5-10 years, and regular cleaning of heat sinks and air filters. Proper maintenance extends VFD life to 15-20 years; neglected VFDs often fail prematurely at 5-8 years.

Q: Can VFDs and soft starters be used outdoors?

A: Both can be used outdoors with proper enclosures. Specify NEMA 3R (rain-tight) or NEMA 4X (corrosive environment) enclosures as appropriate. VFDs require special attention to cooling in high-ambient-temperature environments and may require derating above 40°C (104°F). Soft starters are more tolerant of extreme temperatures, especially designs with bypass contactors that eliminate heat generation during normal operation.

Q: What about power factor correction?

A: VFDs typically have power factor of 0.95-0.98 at the input due to their rectifier design, potentially improving overall facility power factor. However, they don’t provide reactive power compensation for other loads. Soft starters don’t affect power factor—motors operate at their natural power factor determined by load. For facilities with poor power factor, power factor correction should be addressed separately from motor starter selection.

About VIOX Electric

VIOX Electric is a leading B2B manufacturer of electrical equipment, specializing in motor control solutions, circuit protection devices, and industrial automation components. Our comprehensive product line includes contactors, motor starters, circuit breakers, and complete motor protection systems designed to meet the demanding requirements of industrial applications worldwide.