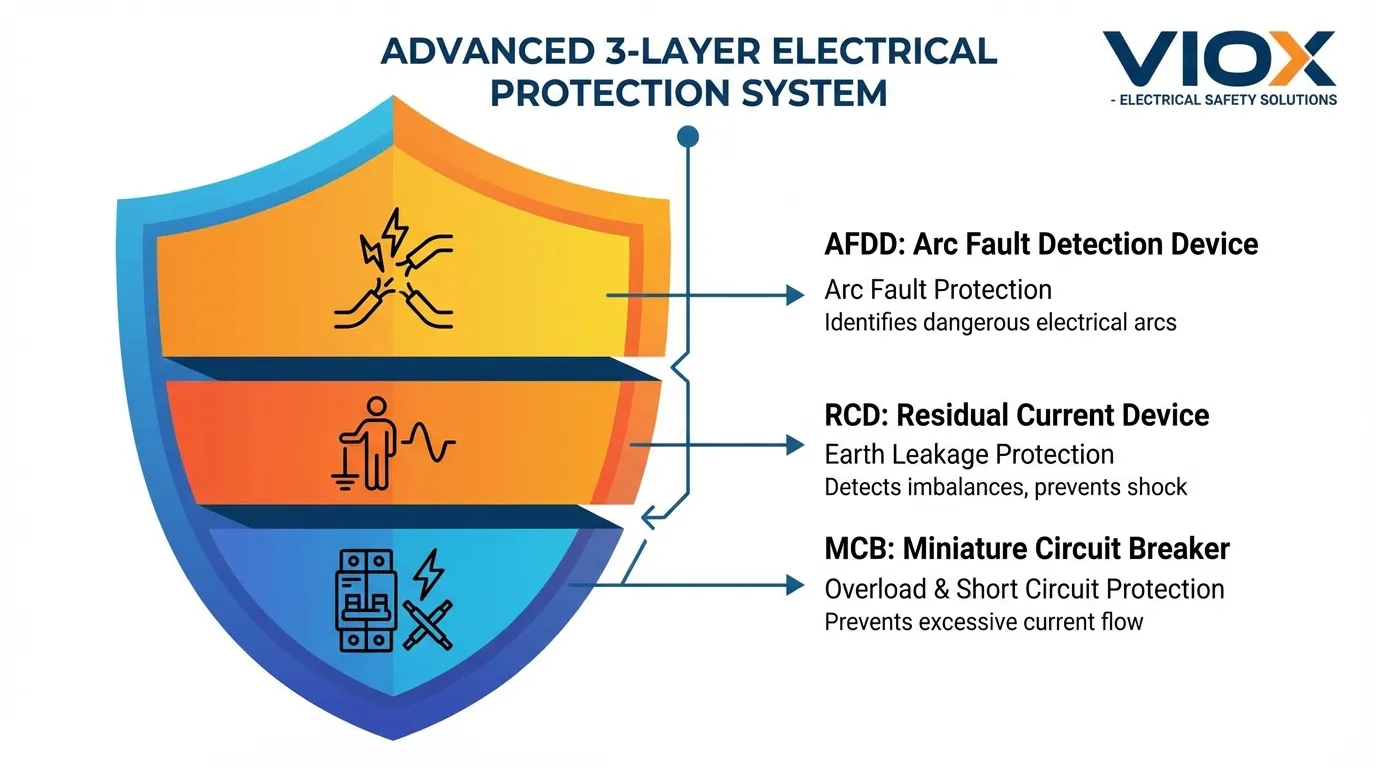

Electrical fires remain one of the most significant risks in residential and commercial buildings, with a substantial percentage attributed to arc faults. While standard circuit protection devices like Miniature Circuit Breakers (MCBs) and Residual Current Devices (RCDs) are essential, they have a blind spot: they cannot detect the unique signature of a dangerous electrical arc.

This is where the Arc Fault Detection Device (AFDD) becomes critical. As a leading manufacturer of electrical protection equipment, VIOX Electric is committed to advancing safety standards through compliant, high-performance technology.

This guide explores the engineering behind AFDDs, the rigorous requirements of the IEC 62606 standard, and why integrating these devices is no longer optional for modern electrical safety strategies.

What is an AFDD and Why Does It Matter?

An Arc Fault Detection Device (AFDD) is a protection device designed to mitigate the risk of fire in final circuits of a fixed installation due to the effect of arc fault currents.

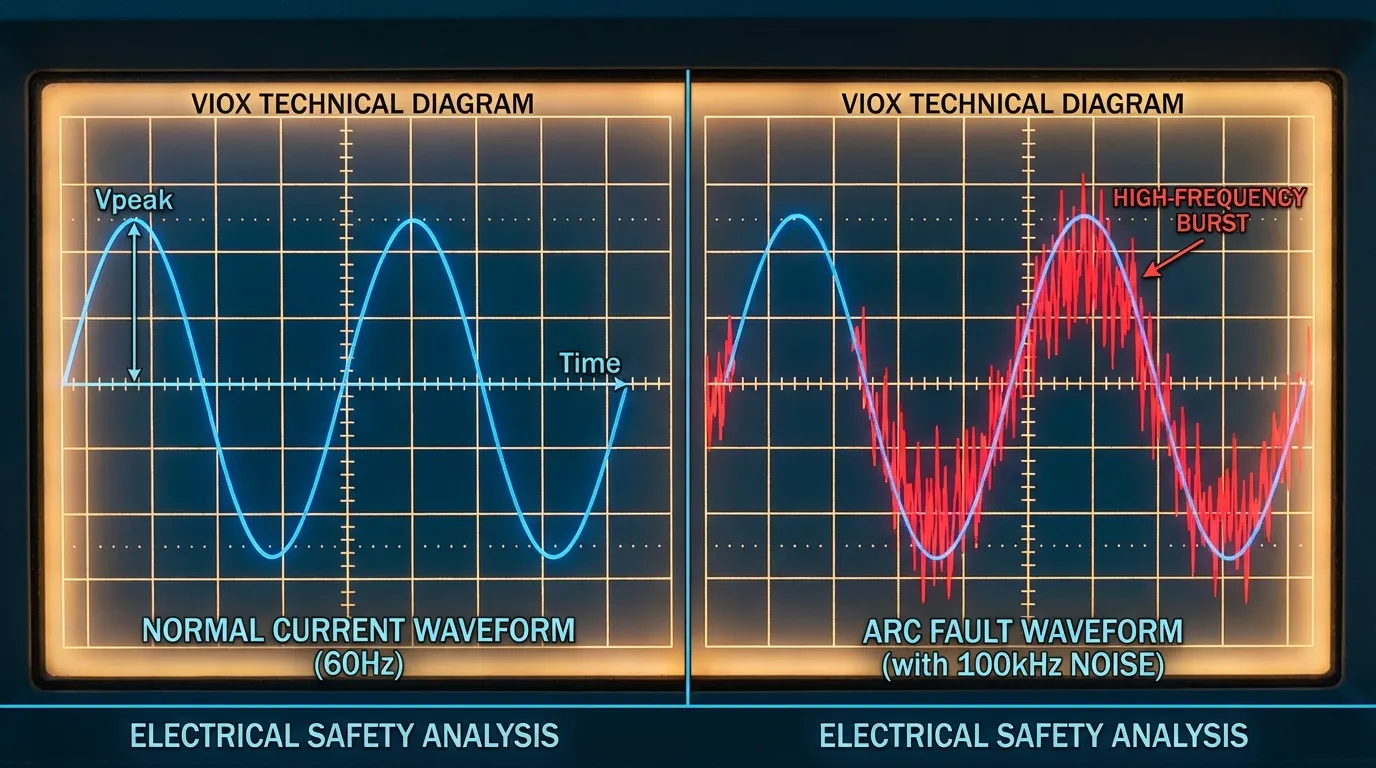

An electrical arc is a luminous discharge of electricity across an insulating medium, usually accompanied by the partial volatilization of electrode material. These arcs can generate temperatures exceeding 6,000°C, easily igniting surrounding insulation, wood, or dust.

Traditional protection devices have specific limitations:

- MCBs are designed to trip during overloads or short circuits (high current events).

- RCDs detect current leaking to earth (shock protection).

Neither device can reliably detect a series arc fault (where a wire is broken but not touching earth) or a high-resistance parallel arc fault where the current is below the magnetic trip threshold of an MCB. AFDDs fill this critical safety gap.

The IEC 62606 Standard: The Global Benchmark

The international standard governing the construction, testing, and performance of AFDDs is IEC 62606: “General requirements for arc fault detection devices.”

For B2B buyers and panel builders, ensuring compliance with IEC 62606 is non-negotiable. This standard mandates that an AFDD must:

- Detect dangerous arc faults.

- Discriminate between dangerous arcs and operational arcs (like those from brushed motors or light switches).

- Isolate the circuit within specified time limits to prevent fire ignition.

IEC 62606 Construction Types

The standard allows for three main methods of construction, giving panel builders flexibility in design:

| Construction Type | Description | Integration |

|---|---|---|

| Integrated AFDD | One single device comprising both the AFD unit and a protective device (MCB or RCBO). | Most common for space-saving in consumer units. |

| Pod/Add-on AFDD | An AFD unit designed to be mechanically and electrically assembled on-site with a specific protective device. | Flexible for retrofitting existing panels. |

| Standalone AFDD | A single device that only provides arc detection and opening means, without built-in short circuit or earth leakage protection. | Rare; usually requires upstream protection. |

How AFDD Technology Works

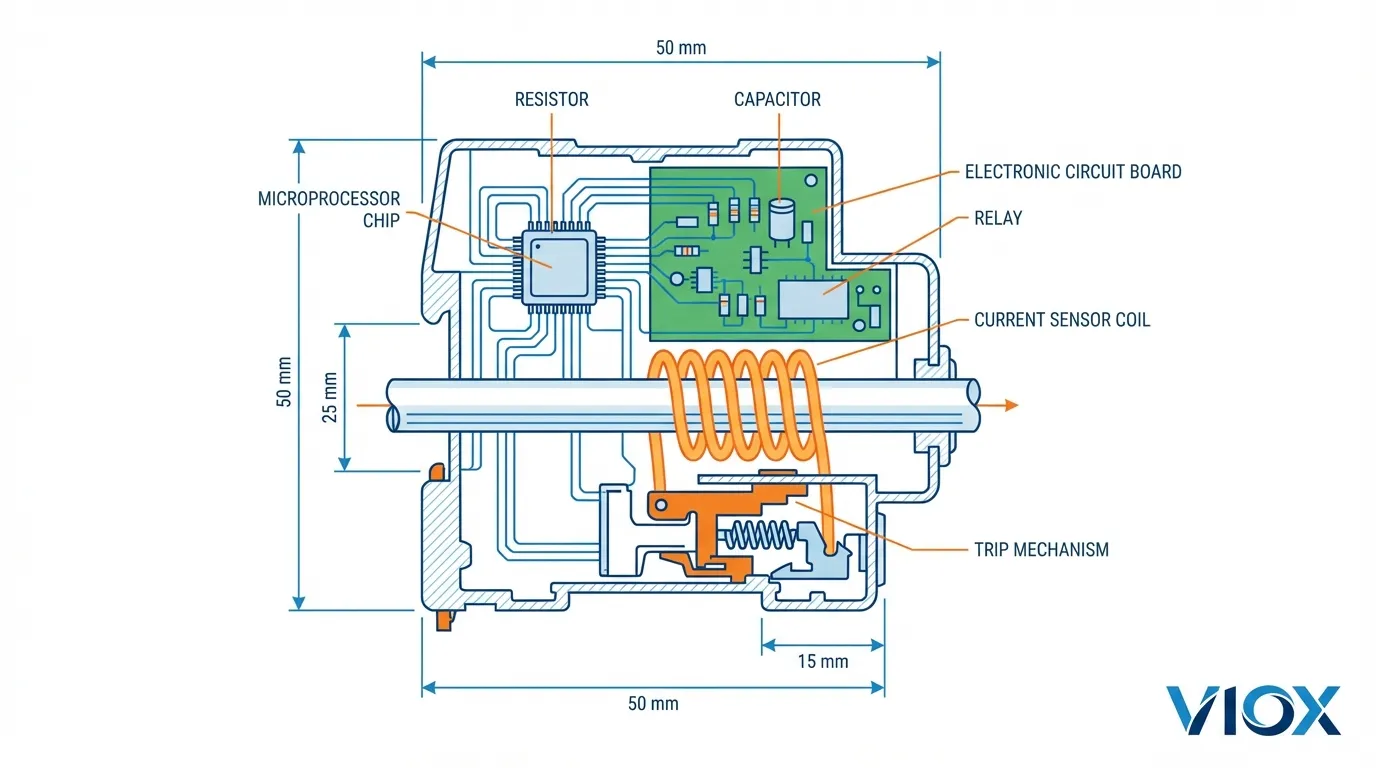

Unlike electromechanical breakers, AFDDs are fully electronic devices. They utilize advanced microprocessors and complex algorithms to continuously analyze the electrical waveform of the circuit.

The Detection Algorithm

The device monitors the circuit for specific characteristics of an arc:

- High-Frequency Noise: Arcs generate “noise” across a wide frequency spectrum. AFDDs typically monitor the 100 kHz to 1 MHz range.

- Current Waveform Irregularities: The microprocessor looks for “shoulders” or gaps in the sine wave (zero-current periods) that are characteristic of arcing.

- Duration & Energy: To avoid nuisance tripping, the device calculates the total energy of the arc to determine if it poses a fire risk.

Response Time Requirements

IEC 62606 dictates strict maximum break times based on the arc current intensity. The higher the current, the faster the device must trip.

| Arc Test Current (A) | Max Break Time (Seconds) | Rationale |

|---|---|---|

| 2.5 A | 1.0 s | Lower energy, slower heating. |

| 5 A | 0.5 s | Moderate risk. |

| 10 A | 0.25 s | High risk of ignition. |

| 32 A | 0.12 s (120ms) | Immediate fire danger; rapid disconnection required. |

Types of Arc Faults: Series vs. Parallel

Understanding the physics of arcing is essential for selecting the right protection. For a deeper dive into how arcs affect circuit disconnection, see our guide on circuit breaker disconnection and electric arcs.

| Feature | Series Arc Fault | Parallel Arc Fault |

|---|---|---|

| Definition | An arc occurring within a single conductor (e.g., a broken wire or loose terminal). | An arc occurring between two different conductors (Phase-Neutral or Phase-Earth). |

| Current Level | Low: Limited by the load impedance. Usually <20A. | High: Limited only by the system impedance. Can be >75A. |

| MCB Detection? | No. Current is below the tripping threshold. | Sometimes. Only if current exceeds magnetic trip level. |

| RCD Detection? | No. No leakage to earth. | Yes (if Phase-Earth). No (if Phase-Neutral). |

| AFDD Detection? | Yes. Primary function. | Yes. Primary function. |

AFDD vs. AFCI: Understanding the Difference

B2B distributors often confuse the IEC-standard AFDD with the UL-standard AFCI used in North America. While they serve similar purposes, they are not interchangeable.

| Feature | AFDD (IEC 62606) | AFCI (UL 1699) |

|---|---|---|

| Primary Region | Europe, UK, Australia, International (IEC). | USA, Canada, North America (NEC/UL). |

| Voltage/Freq | 230V / 50Hz (typically). | 120V / 60Hz. |

| Detection Scope | Focuses heavily on both series and parallel arcs. | Early versions focused mainly on parallel arcs; modern “Combination” AFCIs cover both. |

| Trip Threshold | 2.5 Amps (minimum detection). | 5 Amps (typically). |

| Integration | Often combined with RCBOs (Overcurrent + Residual Current). | Often combined with standard thermal-magnetic breakers. |

For a detailed comparison of protection devices, refer to our RCBO vs AFDD difference guide.

Comprehensive Protection Strategy

AFDDs are not replacements for MCBs or RCDs; they are complementary. A complete protection strategy involves three layers of defense.

Protection Comparison Table

| Fault Type | MCB | RCD/RCCB | AFDD |

|---|---|---|---|

| Overload | ✅ | ❌ | ❌ (unless integrated) |

| Short Circuit | ✅ | ❌ | ❌ (unless integrated) |

| Earth Leakage | ❌ | ✅ | ❌ (unless integrated) |

| Parallel Arc (L-N) | ⚠️ (Only high current) | ❌ | ✅ |

| Parallel Arc (L-E) | ⚠️ (Only high current) | ✅ | ✅ |

| Series Arc | ❌ | ❌ | ✅ |

For more on selecting the right combination of devices, review our circuit protection selection framework.

Installation and Applications

According to IEC 60364-4-42, the installation of AFDDs is highly recommended (and in some countries mandatory) for specific high-risk environments.

Key Application Areas

| Location Type | Examples | Risk Factor |

|---|---|---|

| Sleeping Accommodation | Hotels, hostels, bedrooms, care homes. | Slow evacuation times during fire. |

| High Fire Risk | Barns, woodworking shops, paper mills. | Presence of flammable materials. |

| Combustible Construction | Wooden buildings. | Rapid fire spread. |

| Irreplaceable Goods | Museums, galleries, data centers. | High asset value. |

When installing AFDDs, ensure you are also compliant with electrical cabinet fire protection guidelines.

Integration Tips for Panel Builders

- Busbar Compatibility: Ensure the AFDD fits the existing busbar system. VIOX AFDDs are designed for standard DIN rail mounting.

- Neutral Connection: Most AFDDs are electronic and require a functional earth or neutral reference to operate. Ensure correct polarity.

- Testing: Unlike MCBs, AFDDs have a test button. This tests the electronic arc detection circuit, not just the mechanical trip.

Benefits for B2B Customers

For distributors and contractors, offering VIOX AFDDs provides significant value:

- Enhanced Safety Reputation: Providing the highest level of fire protection builds trust with end-clients.

- Regulatory Compliance: Meeting the latest amendments of wiring regulations (like the 18th Edition in the UK or local IEC adoptions).

- Reduced Liability: Mitigating the risk of electrical fires protects both the installer and the building owner.

- Diagnostic Capabilities: VIOX AFDDs often feature LED indicators that help electricians identify why a trip occurred (series arc vs. parallel arc vs. overvoltage), saving troubleshooting time. See our circuit breaker buzzing diagnostic guide for related troubleshooting.

Key Takeaways

- Gap in Protection: Standard MCBs and RCDs cannot detect series arc faults; AFDDs are required to fill this gap.

- Standard Compliance: IEC 62606 is the governing standard, requiring tripping within 120ms for high-current arcs.

- Technology: AFDDs use microprocessors to analyze high-frequency noise (~100kHz) and waveform irregularities.

- Versatility: They protect against both series and parallel arcs, preventing fires that reach temperatures >6,000°C.

- Integration: Best practice involves using AFDDs alongside RCBOs or as integrated units for comprehensive protection against overloads, short circuits, earth leakage, and arc faults.

FAQ

Q: Can I use an AFDD instead of an RCD?

A: No. An AFDD detects arc faults (fire risk), while an RCD detects earth leakage (shock risk). They serve different purposes. However, you can buy an AFDD with integrated RCD protection (often called an AFDD+RCBO). Learn more about RCD vs MCB differences here.

Q: Do AFDDs cause nuisance tripping?

A: Early generations had some issues, but modern VIOX AFDDs compliant with IEC 62606 use advanced algorithms to distinguish between dangerous arcs and normal operation (like power drills or vacuum cleaners).

Q: Are AFDDs mandatory?

A: It depends on your local regulations. In many countries following IEC 60364-4-42, they are mandatory for sleeping accommodations, locations with fire risks, and buildings with irreplaceable goods.

Q: What is the lifespan of an AFDD?

A: Like most electronic protection devices, they are designed for long service life. However, regular testing via the test button is recommended.

Q: How do I select the right AFDD rating?

A: The current rating (In) of the AFDD should match the circuit design current, similar to selecting an MCB. Refer to our MCB buying checklist for sizing principles.

Q: Can standard AFDDs be used on DC circuits (like Solar PV or Battery Storage)?

A: No, absolutely not. Standard AFDDs complying with IEC 62606 are designed exclusively for AC circuits (typically 230V, 50/60Hz). They cannot be used on DC circuits for two critical reasons:

-

Detection Algorithm Mismatch: AFDD microprocessors are programmed to analyze the specific waveform signatures of AC arcs, often relying on the “zero-crossing” point of the AC sine wave to identify faults. DC current has no zero-crossing, so the device would fail to detect the arc.

-

Arc Quenching Safety: DC arcs are much harder to extinguish than AC arcs because the current never naturally drops to zero. An AC-rated switching mechanism may fail to break a DC arc, leading to catastrophic damage or fire within the breaker itself.

For DC applications (such as Solar PV), you must use specific DC Arc Fault protection (often integrated into inverters or specialized DC combiners). For more on DC protection, see our guide on DC Circuit Breaker vs Fuse.