Direct Answer: Motor starters are electrical devices that safely start, stop, and protect electric motors from damage. The five main types are Direct-On-Line (DOL) starters, Star-Delta starters, Soft Starters, Variable Frequency Drives (VFDs), and Auto-Transformer starters. Each type serves specific applications based on motor size, starting current requirements, and operational needs. DOL starters suit motors up to 5 HP, Star-Delta handles 5-100 HP, while Soft Starters and VFDs are preferred for larger motors requiring controlled acceleration and energy efficiency.

Key Takeaways

- DOL starters are the simplest and most cost-effective solution for small motors (up to 5 HP) but produce high inrush current (5-8x full load current)

- Star-Delta starters reduce starting current to approximately 33% of DOL but require motors with accessible six-terminal windings

- Soft starters provide smooth acceleration with programmable ramp times, reducing mechanical stress and extending equipment lifespan by 20-30%

- VFDs offer complete motor control throughout operation, achieving energy savings of 20-50% in variable-load applications

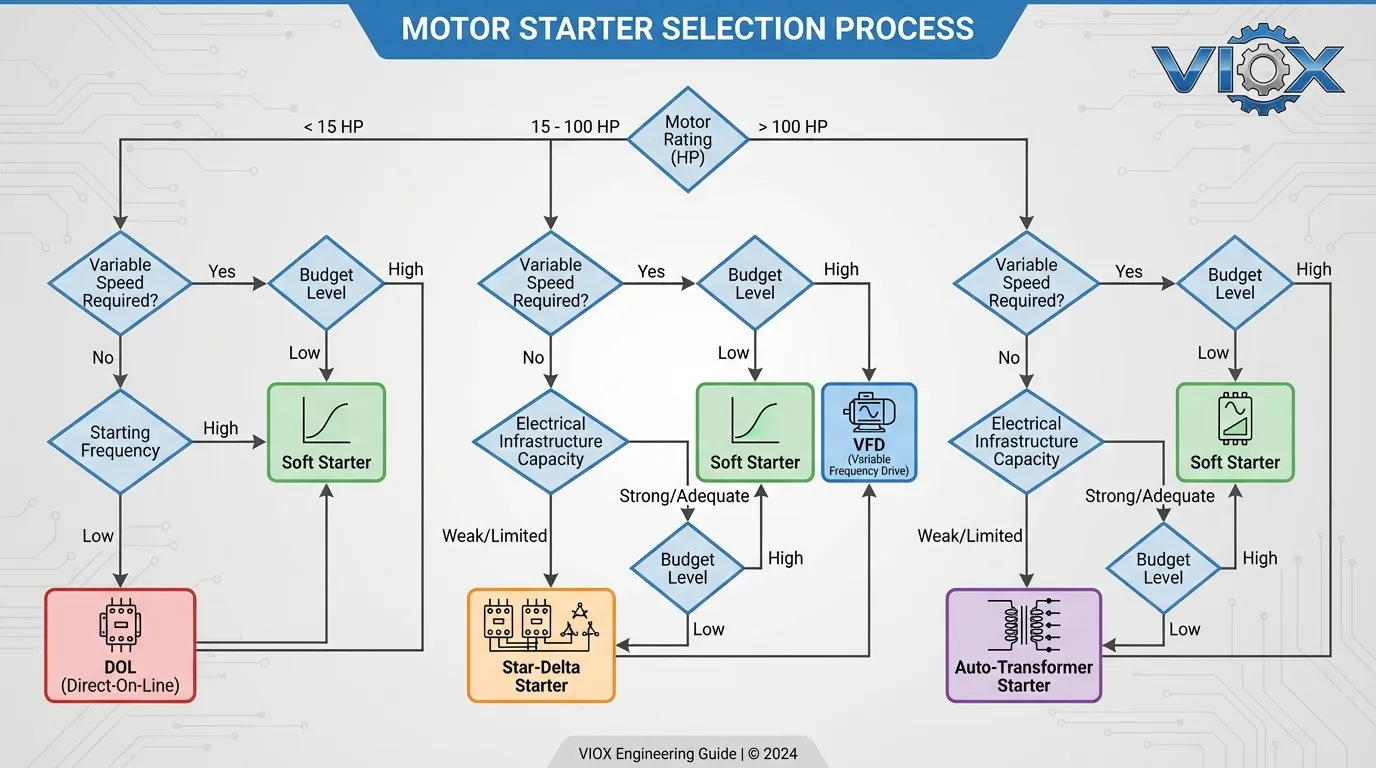

- Proper starter selection depends on motor size, load characteristics, starting frequency, and electrical infrastructure capacity

Understanding Motor Starters: Why They Matter

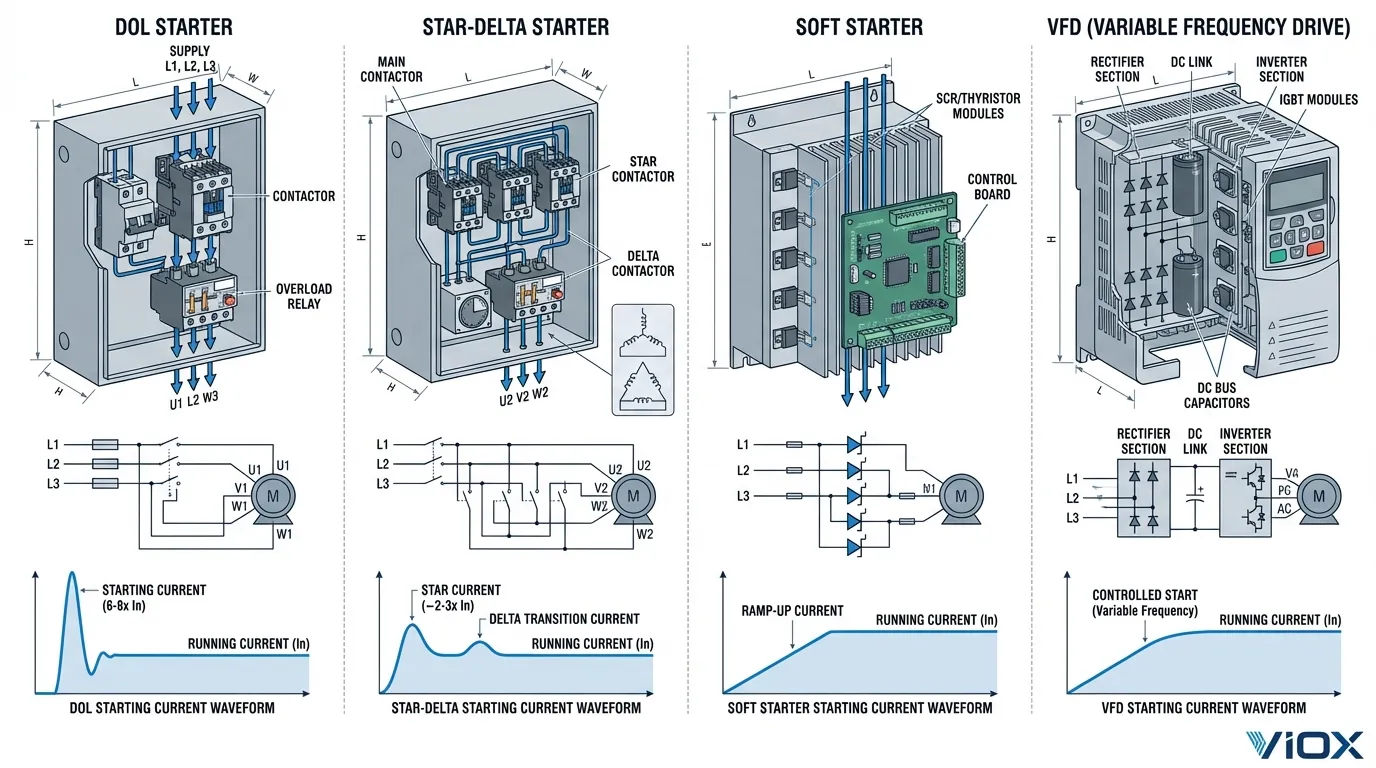

Electric motors draw significantly higher current during startup compared to normal operation—typically 5 to 8 times the full load current. This sudden surge creates voltage dips across the electrical system, potentially damaging connected equipment, tripping protection devices, and reducing motor lifespan. Motor starters address this challenge by controlling how electrical power is applied to the motor during the critical starting phase.

Beyond current management, modern motor starters incorporate essential protection features including overload protection, short-circuit protection, and phase failure detection. These integrated safeguards prevent costly motor failures and unplanned downtime in industrial environments. Selecting the appropriate starter type directly impacts operational efficiency, maintenance costs, and equipment longevity.

The Five Main Types of Motor Starters

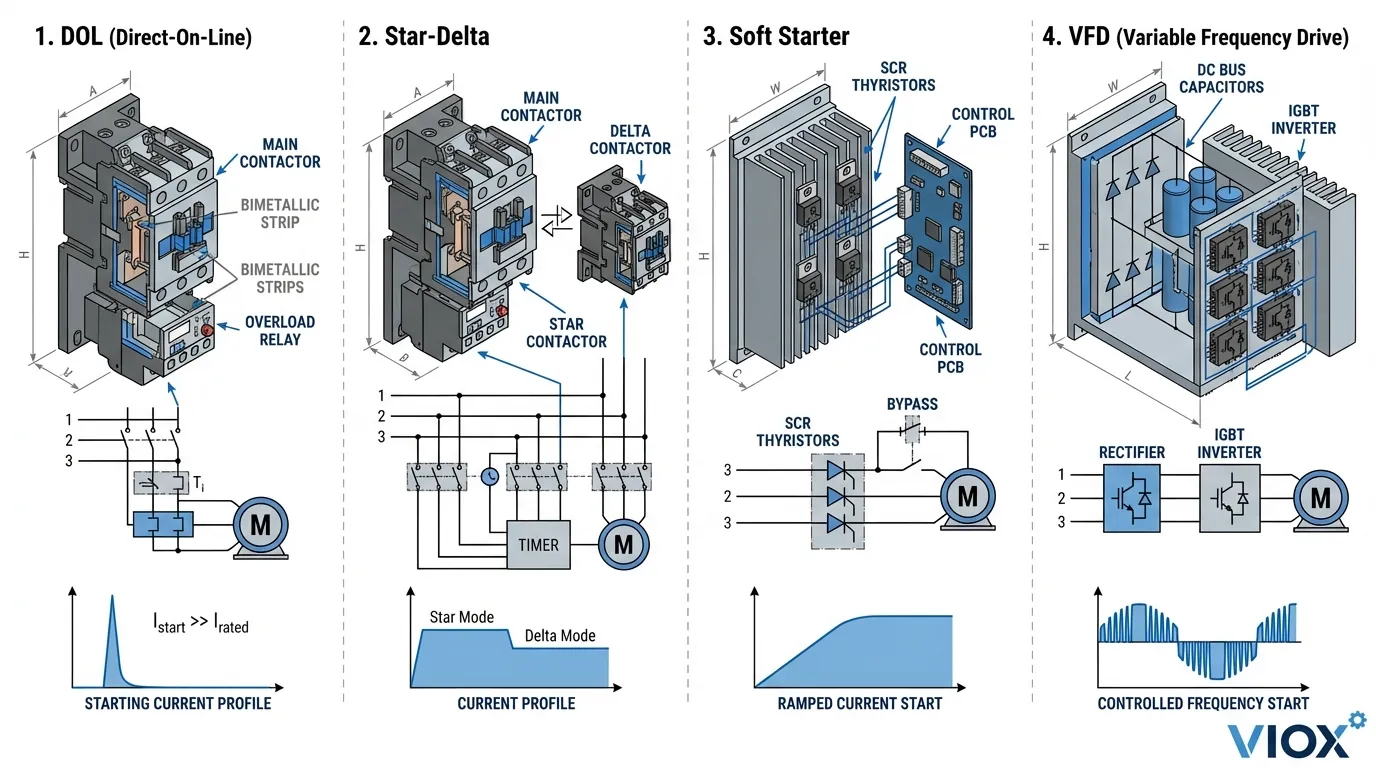

1. Direct-On-Line (DOL) Starter

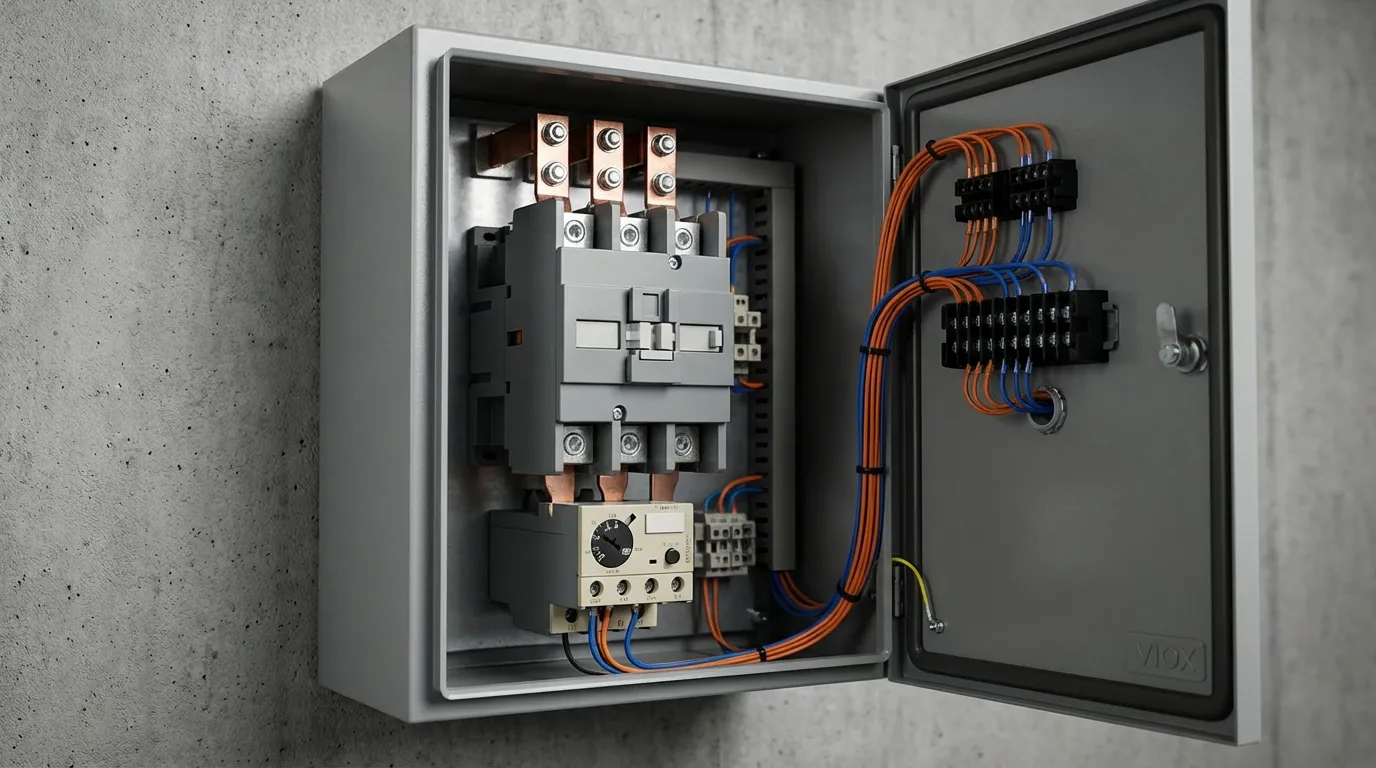

The DOL starter represents the most straightforward motor starting method, connecting the motor directly to the full supply voltage in a single operation. This approach uses a contactor to switch power and typically includes a thermal overload relay for motor protection.

How It Works: When the start button is pressed, the contactor coil energizes, closing the main contacts and applying full voltage directly to all three motor phases simultaneously. The motor accelerates rapidly to full speed, drawing maximum starting current throughout the acceleration period.

Technical Specifications:

- Starting current: 5-8x full load current (FLC)

- Starting torque: 100% of rated torque

- Acceleration time: 1-3 seconds (depending on load)

- Typical motor range: 0.5-5 HP (0.37-3.7 kW)

Advantages:

- Simple design with minimal components reduces initial cost

- Easy installation and maintenance with straightforward wiring

- Immediate full torque delivery suitable for high-inertia loads

- High reliability due to fewer failure points

Limitations:

- High inrush current can cause voltage dips affecting other equipment

- Mechanical shock from rapid acceleration increases wear on couplings and gearboxes

- Not suitable for weak electrical infrastructure

- Limited to smaller motor applications

Best Applications: Small pumps, fans, conveyors, and machinery where starting current is not a concern and full torque is required immediately.

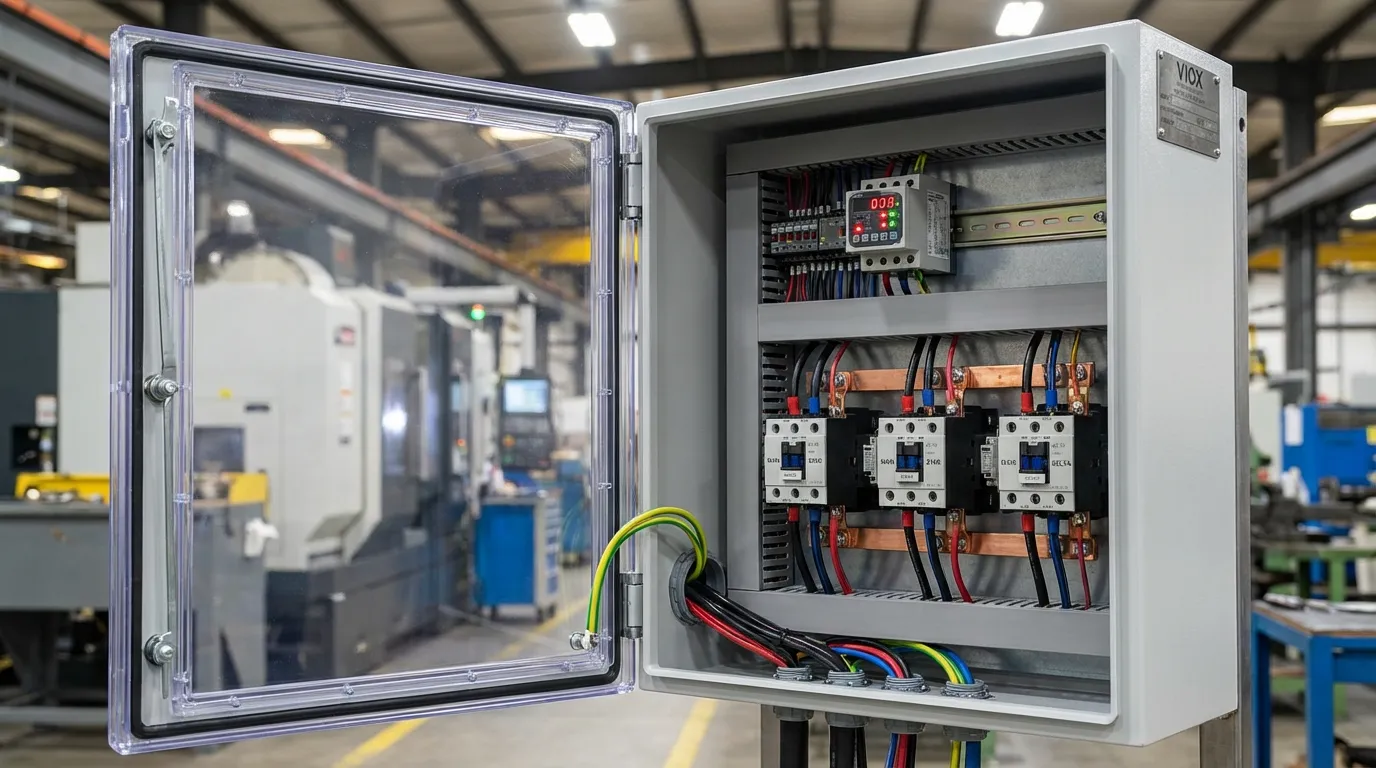

2. Star-Delta Starter

The Star-Delta starter reduces starting current by initially connecting motor windings in a star (wye) configuration, then switching to delta configuration once the motor reaches approximately 75-80% of full speed. This method is one of the most widely used reduced-voltage starting techniques for three-phase induction motors.

How It Works: During startup, the motor windings connect in star configuration, reducing the voltage across each winding to 58% (1/√3) of line voltage. After a preset time delay (typically 5-15 seconds), a timer triggers contactors to switch the windings to delta configuration for normal running operation. This transition must occur smoothly to avoid current spikes during changeover.

Technical Specifications:

- Starting current: Reduced to 33% of DOL starting current (approximately 2-3x FLC)

- Starting torque: Reduced to 33% of DOL starting torque

- Motor requirements: Six accessible terminals, delta-connected for normal operation

- Typical motor range: 5-100 HP (3.7-75 kW)

Advantages:

- Significant reduction in starting current minimizes electrical infrastructure stress

- Lower cost compared to electronic soft starters

- Proven technology with widespread industry acceptance

- Suitable for medium-sized motors with moderate starting torque requirements

Limitations:

- Requires motors with six accessible terminals (not all motors qualify)

- Momentary power interruption during star-to-delta transition can cause current spikes

- Reduced starting torque (33%) may be insufficient for high-inertia loads

- More complex wiring compared to DOL starters

- Mechanical stress during transition switching

Best Applications: Centrifugal pumps, fans, compressors, and conveyors where load torque increases with speed. Not recommended for applications requiring high starting torque or frequent starts. For detailed wiring configurations, refer to our Star-Delta Starter Wiring Guide.

3. Soft Starter (Solid-State Starter)

Soft starters use power electronics—typically silicon-controlled rectifiers (SCRs) or thyristors—to gradually ramp up voltage supplied to the motor. This electronic control provides smooth, stepless acceleration without the mechanical switching required by Star-Delta starters.

How It Works: The soft starter controls the firing angle of SCRs in each phase, progressively increasing the effective voltage from a preset initial value (typically 30-70% of line voltage) to full voltage over a programmable time period (1-60 seconds). Advanced models offer current limiting, torque control, and soft-stop functionality to prevent water hammer in pump applications.

Technical Specifications:

- Starting current: Adjustable, typically limited to 2-4x FLC

- Starting torque: Adjustable based on initial voltage setting

- Ramp time: Programmable from 1-60 seconds

- Typical motor range: 5-1000+ HP (3.7-750+ kW)

- Heat dissipation: 1-3% of motor power during starting

Advantages:

- Smooth, stepless acceleration eliminates mechanical shock and extends equipment life

- Programmable parameters allow optimization for specific applications

- Built-in motor protection features including overload, phase loss, and ground fault

- Soft-stop capability prevents water hammer and reduces mechanical stress

- No voltage interruption during operation

- Compact design compared to electromechanical alternatives

Limitations:

- Higher initial cost than DOL or Star-Delta starters

- Generates heat during starting, requiring adequate ventilation

- Cannot control motor speed during normal operation

- May introduce harmonics into the electrical system

- Requires proper sizing to handle motor starting characteristics

Best Applications: Pumps (especially to prevent water hammer), fans, compressors, conveyors, and any application requiring controlled acceleration. Particularly valuable in systems with aging mechanical components or sensitive processes. Learn more about industrial contactor maintenance to complement soft starter installations.

4. Variable Frequency Drive (VFD)

VFDs represent the most sophisticated motor control technology, converting fixed-frequency AC power to variable-frequency AC power. This capability enables precise control of motor speed throughout the entire operating range, not just during starting.

How It Works: The VFD operates in three stages: First, a rectifier converts incoming AC power to DC. Second, a DC bus filters and stores this energy using capacitors. Third, an inverter section uses insulated gate bipolar transistors (IGBTs) to reconstruct AC power at the desired frequency and voltage. By controlling output frequency (typically 0-60 Hz or higher), the VFD directly controls motor speed according to the relationship: Speed = (120 × Frequency) / Number of Poles.

Technical Specifications:

- Starting current: Typically limited to 100-150% of FLC

- Speed control range: 0-100% (some applications extend to 200%)

- Frequency range: 0-400 Hz (depending on model)

- Typical motor range: 0.5-10,000+ HP (0.37-7,500+ kW)

- Efficiency: 95-98% at rated load

Advantages:

- Complete speed control throughout operation enables process optimization

- Significant energy savings (20-50%) in variable-load applications like pumps and fans

- Soft starting capability with minimal inrush current

- Eliminates mechanical throttling devices (valves, dampers) improving system efficiency

- Advanced protection features and diagnostic capabilities

- Precise torque control across the speed range

- Can eliminate mechanical transmission components

Limitations:

- Highest initial cost among motor starters

- Requires specialized knowledge for programming and troubleshooting

- Generates electrical noise and harmonics requiring filtering

- Motor cable length limitations (typically 300-500 feet without reactors)

- Heat generation requires adequate cooling

- May require motor derating for certain applications

Best Applications: Variable-speed processes including HVAC systems, pumps with varying demand, conveyor systems requiring speed adjustment, and any application where energy savings justify the investment. VFDs excel in applications requiring precise speed control, such as CNC machines and packaging equipment. For protection considerations, see our guide on circuit breaker selection.

5. Auto-Transformer Starter

Auto-transformer starters use a three-phase auto-transformer to reduce voltage applied to the motor during starting. While less common today due to the prevalence of soft starters and VFDs, they remain relevant in specific high-power applications.

How It Works: The auto-transformer provides tapped outputs (typically 50%, 65%, and 80% of line voltage). During starting, reduced voltage is applied to the motor through the selected tap. Once the motor reaches approximately 80-90% of full speed, contactors switch the motor to full voltage while disconnecting the transformer.

Technical Specifications:

- Starting current: Reduced proportionally to voltage squared (e.g., 65% voltage = 42% current)

- Starting torque: Reduced proportionally to voltage squared

- Common taps: 50%, 65%, 80% of line voltage

- Typical motor range: 25-10,000 HP (18.5-7,500 kW)

Advantages:

- Provides higher starting torque per ampere than Star-Delta starters

- Multiple tap settings allow optimization for different loads

- No motor terminal configuration requirements (unlike Star-Delta)

- Suitable for very large motors where soft starters become impractical

Limitations:

- Large, heavy, and expensive equipment

- Requires significant installation space

- Complex wiring with multiple contactors and timers

- Transition switching creates momentary current spike

- Largely superseded by soft starters in modern installations

Best Applications: Large motors (above 500 HP) in applications requiring moderate starting torque, particularly in older installations or where electronic starters face environmental challenges.

Motor Starter Comparison Table

| Feature | DOL Starter | Star-Delta Starter | Soft Starter | VFD | Auto-Transformer |

|---|---|---|---|---|---|

| Starting Current | 5-8x FLC | 2-3x FLC (33% of DOL) | 2-4x FLC (adjustable) | 1-1.5x FLC | 2.5-4x FLC (tap dependent) |

| Starting Torque | 100% | 33% of DOL | Adjustable (30-80%) | 100% at low speed | 42-64% (tap dependent) |

| Motor Size Range | 0.5-5 HP | 5-100 HP | 5-1000+ HP | 0.5-10,000+ HP | 25-10,000 HP |

| Initial Cost | $ | $ | $$ | $$ | $$ |

| Speed Control | No | No | No | Yes (full range) | No |

| Energy Efficiency | Standard | Standard | Standard | High (20-50% savings) | Standard |

| Complexity | Very Simple | Moderate | Moderate | High | High |

| Maintenance | Low | Moderate | Low | Moderate | High |

| Transition Smoothness | Abrupt | Momentary jerk | Smooth | Smooth | Momentary jerk |

| Space Requirements | Minimal | Moderate | Compact | Moderate | Large |

| Best For | Small motors, simple loads | Medium motors, pump/fan | Controlled starts, sensitive equipment | Variable speed, energy savings | Very large motors |

Motor Starter Selection Guide

Choosing the right motor starter requires evaluating multiple factors beyond simple motor horsepower. This decision impacts operational costs, equipment lifespan, and system reliability for years to come.

Selection Criteria

1. Motor Size and Power Rating

- Under 5 HP: DOL starters typically suffice unless electrical infrastructure is weak

- 5-100 HP: Star-Delta or Soft Starters depending on starting frequency and torque requirements

- Above 100 HP: Soft Starters or VFDs recommended for controlled starting and potential energy savings

- Above 500 HP: VFDs or Auto-Transformer starters for large industrial applications

2. Load Characteristics

- Constant Speed, Light Starting Load: DOL or Star-Delta starters

- Constant Speed, Heavy Starting Load: Soft Starter or Auto-Transformer

- Variable Speed Requirements: VFD is the only practical option

- High Inertia Loads: Soft Starter or VFD to manage extended acceleration time

3. Starting Frequency

- Infrequent Starts (< 5/hour): Any starter type suitable based on other criteria

- Frequent Starts (> 10/hour): Soft Starter or VFD to reduce thermal and mechanical stress

- Very Frequent Starts: VFD with proper thermal management

4. Electrical Infrastructure

- Strong Grid (low impedance): DOL acceptable for appropriate motor sizes

- Weak Grid or Shared Transformer: Reduced-voltage starting (Star-Delta, Soft Starter, or VFD) essential

- Sensitive Equipment on Same Circuit: Soft Starter or VFD to minimize voltage disturbances

5. Budget Considerations

- Initial Cost Priority: DOL or Star-Delta

- Total Cost of Ownership: VFD often justified through energy savings in variable-load applications

- Maintenance Budget: Electronic starters (Soft Starter, VFD) require less mechanical maintenance

6. Environmental Conditions

- Harsh Environments: Electromechanical starters (DOL, Star-Delta) may be more robust

- Clean Environments: Electronic starters perform well with proper cooling

- Temperature Extremes: Consider derating requirements for electronic starters

For comprehensive protection system design, consult our Circuit Protection Selection Framework.

Application-Specific Recommendations

Pumps and Water Systems

Recommended: Soft Starters or VFDs

- Soft-stop prevents water hammer damage

- VFDs enable flow control without throttling valves, saving 20-40% energy

- Gradual acceleration reduces pipe stress and extends seal life

Fans and Blowers

Recommended: VFDs for variable-load; Star-Delta for constant-speed

- VFDs provide dramatic energy savings following fan affinity laws (power ∝ speed³)

- Soft starting reduces belt and bearing wear

- Speed control eliminates damper losses

Conveyors

Recommended: Soft Starters or VFDs

- Controlled acceleration prevents product spillage

- Soft stopping reduces mechanical shock

- VFDs enable speed matching between conveyor sections

Compressors

Recommended: Star-Delta or Soft Starters for fixed-speed; VFDs for variable-demand

- Reduced starting torque acceptable for unloaded starting

- VFDs enable capacity matching to demand, improving efficiency

- Controlled starting extends valve and coupling life

Crushers and Mills

Recommended: DOL or Soft Starters

- High starting torque often required (DOL advantage)

- Soft Starters reduce mechanical shock in drive train

- Frequent reversing applications may require specialized contactors

For motor protection considerations, review our article on thermal overload relays.

Installation and Safety Considerations

Proper motor starter installation directly impacts safety, reliability, and performance. All installations must comply with relevant electrical codes including NEC (National Electrical Code), IEC 60947, and local regulations.

Critical Installation Requirements:

- Proper Sizing: Starter components must be rated for motor full-load current with appropriate safety margins. Contactors typically require 115-125% of motor FLC rating.

- Overload Protection: Thermal overload relays should be set to 105-115% of motor nameplate current, adjusting for service factor and ambient temperature.

- Short-Circuit Protection: Circuit breakers or fuses must be coordinated with starter components to provide selective protection without nuisance tripping.

- Enclosure Selection: Choose appropriate IP/NEMA ratings based on environmental conditions. Indoor applications typically require IP54/NEMA 12, while outdoor installations need IP65/NEMA 4X minimum.

- Ventilation: Electronic starters (Soft Starters, VFDs) generate significant heat. Ensure adequate ventilation or cooling to maintain components within rated temperature ranges.

- Grounding: Proper grounding is essential for safety and noise immunity, particularly with VFDs. Follow manufacturer specifications for grounding conductor sizing and routing.

- Cable Considerations: VFD output cables may require shielding and special routing to minimize electromagnetic interference. Observe maximum cable length specifications.

For control panel component selection, see our Industrial Control Panel Components Guide.

Maintenance and Troubleshooting

Regular maintenance extends starter life and prevents unexpected failures. Maintenance requirements vary significantly by starter type.

DOL and Star-Delta Starters:

- Inspect contactor contacts every 6-12 months for pitting or burning

- Check tightness of all electrical connections quarterly

- Verify overload relay calibration annually

- Clean dust accumulation from enclosures

- Replace contactors after 1-2 million operations (depending on load)

Soft Starters:

- Verify cooling fan operation monthly

- Check for error codes or fault history quarterly

- Clean cooling fins and air filters every 3-6 months

- Verify parameter settings remain correct

- Monitor heat sink temperatures during operation

VFDs:

- Inspect and clean cooling fans monthly

- Check DC bus capacitor condition annually (measure capacitance and ESR)

- Verify proper ventilation and temperature rise

- Review fault logs for recurring issues

- Update firmware as recommended by manufacturer

Common Troubleshooting Issues:

- Motor won’t start: Check control power, verify contactor coil voltage, inspect overload reset

- Nuisance tripping: Verify overload settings, check for voltage imbalance, measure actual motor current

- Excessive heating: Confirm proper ventilation, check for overloading, verify voltage supply

- Erratic operation: Inspect control wiring for loose connections, check for electromagnetic interference

For detailed troubleshooting procedures, refer to our Contactor Troubleshooting Guide.

Future Trends in Motor Starting Technology

Motor starter technology continues evolving toward greater intelligence, connectivity, and energy efficiency. Several trends are reshaping the industry:

Smart Motor Controllers: Integration of IoT capabilities enables predictive maintenance, remote monitoring, and data analytics. These systems detect developing problems before failure occurs, reducing unplanned downtime.

Energy Efficiency Regulations: Increasingly stringent efficiency standards drive adoption of VFDs and premium efficiency motors. Many jurisdictions now mandate VFDs for specific applications.

Integrated Solutions: Manufacturers increasingly offer integrated starter-motor packages optimized for specific applications, simplifying selection and installation.

Advanced Protection: Modern starters incorporate sophisticated protection algorithms detecting conditions like phase imbalance, ground faults, and bearing failures.

Cybersecurity: As starters gain network connectivity, cybersecurity features become essential to protect industrial control systems from threats.

FAQ Section

Q: Can I use a DOL starter for a 10 HP motor?

A: While technically possible, it’s generally not recommended unless your electrical infrastructure can handle the high starting current (50-80 amps for a 10 HP motor). Star-Delta or Soft Starters are better choices for motors above 5 HP.

Q: What’s the difference between a soft starter and a VFD?

A: Soft starters control voltage during starting and stopping only, while VFDs control both voltage and frequency, enabling speed control throughout operation. VFDs cost more but offer energy savings and complete speed control.

Q: How often should motor starters be replaced?

A: Electromechanical starters (DOL, Star-Delta) typically last 10-15 years with proper maintenance. Electronic starters (Soft Starters, VFDs) may last 15-20 years, though capacitors may need replacement after 7-10 years.

Q: Do I need special motors for VFDs?

A: Standard motors work with VFDs for most applications, but inverter-duty motors are recommended for continuous operation below 30 Hz, applications requiring frequent speed changes, or when motor cable runs exceed 100 feet.

Q: Can I retrofit a DOL starter to a soft starter?

A: Yes, retrofitting is straightforward in most cases. The soft starter replaces the contactor while retaining the overload relay and disconnect. Ensure adequate enclosure space and ventilation.

Q: Why does my Star-Delta starter cause a current spike during transition?

A: The momentary disconnection during star-to-delta switching causes the motor to decelerate slightly. When delta connection engages, the speed difference creates a current spike. Proper timer adjustment minimizes this effect.

Conclusion

Selecting the appropriate motor starter requires balancing technical requirements, budget constraints, and operational goals. DOL starters offer simplicity and low cost for small motors, while Star-Delta starters provide a cost-effective reduced-current solution for medium-sized motors. Soft Starters deliver smooth, controlled starting with advanced protection features, and VFDs offer complete motor control with significant energy savings potential for variable-load applications.

As motor starter technology advances, the trend clearly favors electronic solutions offering intelligence, connectivity, and energy efficiency. However, traditional electromechanical starters remain relevant for specific applications where simplicity, robustness, and low cost are paramount.

VIOX Electric manufactures a comprehensive range of motor starters and control components designed to meet diverse industrial requirements. Our engineering team can assist with starter selection, system design, and technical support to ensure optimal motor protection and performance for your specific application.