Many facility managers view a Surge Protective Device (SPD) as a permanent shield—a “set it and forget it” asset installed once to guard against the rare catastrophic lightning strike. This misconception is costly.

In reality, an SPD is not a shield; it is an energy sponge.

Specifically, the Metal Oxide Varistors (MOVs) inside most industrial SPDs act as sacrificial components. They possess a finite “Joule Account”—a specific capacity to absorb energy over their lifetime. Every voltage spike, whether a massive lightning strike or a minor grid fluctuation caused by a nearby motor starting, withdraws from this account. When the balance hits zero, your expensive PLCs, drives, and sensitive electronics are essentially “naked” against the next surge.

This article explores the electromechanical aging of SPDs, the hidden danger of “Zombie Mode,” and why proactive maintenance of VIOX DIN rail SPDs is critical for industrial reliability.

The Heart of the SPD: The MOV and Its “Joule Account”

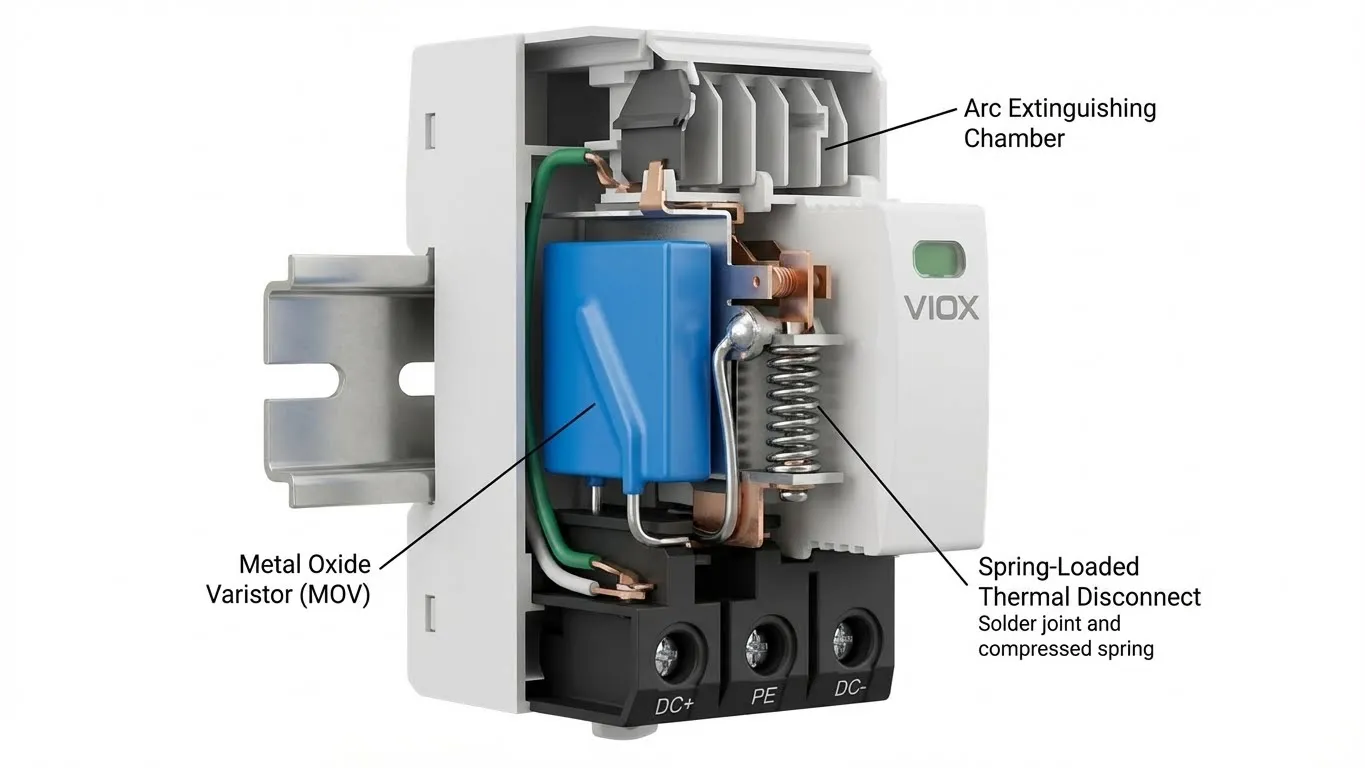

At the core of almost every modern VIOX SPD is the Metal Oxide Varistor (MOV). Under normal conditions, the MOV acts as an insulator with infinite resistance, allowing standard 120V/240V/480V power to pass to your equipment unaffected.

When a voltage spike occurs, the MOV reacts in nanoseconds, changing its state from an insulator to a conductor. It “clamps” the voltage by diverting the excess energy to the ground, dissipating it as heat.

The Mechanics of Degradation

Think of the MOV’s Joule rating (e.g., 20,000 Joules) not as a maximum limit for a single event, but as a lifetime fuel tank. This tank can be emptied in two ways:

- Catastrophic Consumption: A single, massive 20,000-Joule lightning strike hits the line. The MOV absorbs it all, saves the equipment, and sacrifices itself instantly.

- Chronic Consumption (The Silent Killer): The MOV absorbs 20,000 small, 1-Joule surges over three years. These micro-surges come from grid switching, capacitor bank operations, or heavy inductive loads (like elevators or HVAC systems) cycling on and off.

Key Takeaway: Even without a thunderstorm, your SPD is slowly dying. The zinc oxide grains within the MOV suffer microscopic physical damage with every clamp event, gradually lowering the device’s threshold and increasing leakage current.

The Hidden Danger: “Zombie Mode” vs. Fail-Safe Design

The most dangerous SPD is one that looks like it’s working but isn’t.

In many basic consumer-grade surge strips or lower-end industrial protectors, when the MOV fails, it simply disconnects from the circuit while the power continues to flow to the load. This is “Zombie Mode.” The machine is running, the power light is on, but the protection path is severed. The next surge travels straight into your variable frequency drive (VFD) or control board.

The VIOX Standard: Thermal Disconnect

Industrial-grade VIOX SPDs operate differently. We acknowledge that the MOV is a sacrificial component. Therefore, our design priority is status indication and controlled failure.

When a VIOX MOV approaches the end of its life, it doesn’t just quietly quit. It is designed to trigger a clear alert before it loses total protection capability, ensuring facility teams know exactly when the “shield” is down.

Thermal Runaway: Physics, Not Just Electronics

Why do SPDs need to be replaced before they fail completely? The answer lies in Thermal Runaway.

As an MOV degrades, its clamping voltage drops, and it begins to conduct a small amount of current during normal operation (leakage current). This resistive leakage generates heat.

- The Cycle: Heat lowers the MOV’s resistance further, drawing more current, which generates more heat.

- The Risk: Without intervention, this cycle accelerates exponentially, potentially causing the device to overheat, smoke, or catch fire.

To prevent this, VIOX SPDs utilize a TPMOV (Thermally Protected MOV) design. A spring-loaded thermal fuse is soldered directly to the MOV. If the MOV overheats due to degradation, the special solder melts, and the spring mechanism physically disconnects the MOV component from the power source to prevent fire.

Crucially, this physical disconnection triggers the mechanical status flag on the front of the unit to flip from Green to Red.

The VIOX Solution: Visualizing the Invisible

Since you cannot see the microscopic degradation of zinc oxide grains, VIOX engineers have built the diagnostics into the hardware.

1. The Green/Red Visual Indicator

Every VIOX DIN rail SPD (Type 1 and Type 2) features a mechanical status window.

- Green: Healthy. The “Joule Account” has sufficient balance.

- Red: End of Life. The thermal fuse has tripped. The module must be replaced immediately.

Note: This is mechanical, not an LED. It works even if power is lost.

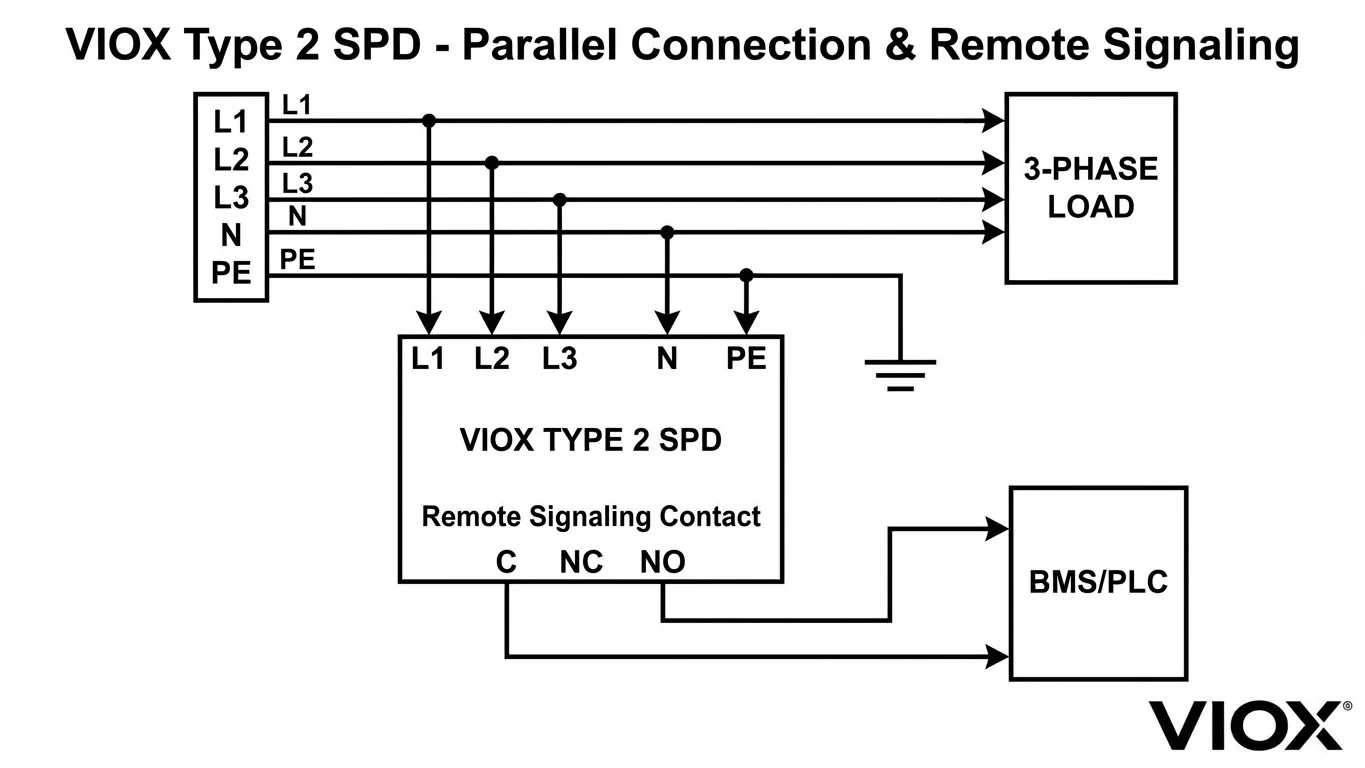

2. Remote Signaling Contacts

For critical facilities where daily visual inspection isn’t feasible, VIOX SPDs include a dry contact (Remote Signaling Contact). This can be wired into your PLC or Building Management System (BMS).

- Logic: If the SPD fails, the contact opens/closes, triggering an alarm in the control room. “Panel 4 SPD Failure” appears on your SCADA screen, eliminating the need for manual rounds.

3. Pluggable Modules

In the past, replacing a hardwired surge suppressor meant shutting down the entire panel and rewiring the unit—a 30-minute task requiring an electrician.

VIOX’s Modular Design: The base remains wired to the DIN rail. When a module turns red, you simply pull it out and plug in a new cartridge.

- Downtime: 0 seconds (hot-swappable).

- Maintenance Time: 10 seconds.

Consumer vs. Industrial SPD: What’s the Difference?

Why invest in VIOX industrial SPDs instead of generic power strip protection?

| Feature | Consumer / Basic Surge Strip | VIOX Industrial SPD (DIN Rail) |

|---|---|---|

| Primary Technology | Small MOV (often <14mm) | Large Block MOV (>20mm-34mm) or Spark Gap |

| Joule Capacity | Low (hundreds of Joules) | High (thousands to tens of thousands) |

| End-of-Life Mode | Silent Fail (Zombie Mode): Power stays on, protection gone. | Fail-Safe: Thermal disconnect trips, status indicator changes. |

| Status Indication | Tiny LED (often obscured or ignored). | High-visibility Mechanical Flag (Green/Red) + Remote Alarm. |

| Enclosure | Plastic, flammable. | UL94 V-0 Flame Retardant / Industrial Housing. |

| Maintenance | Disposable (throw away entire strip). | Modular (replace only the used cartridge). |

How Long Will My SPD Last?

There is no fixed expiration date for an SPD, as lifespan depends entirely on the quality of power at your facility. However, we can estimate based on environmental factors.

| Environment | Typical Stressors | Estimated VIOX SPD Lifespan |

|---|---|---|

| Clean Grid (Data Center) | Rare external surges, stable voltage. | 10+ Years |

| Standard Commercial | Occasional storms, HVAC cycling. | 5 – 7 Years |

| Heavy Industrial | VFDs, welding equipment, large motors starting frequently. | 3 – 5 Years |

| High Lightning Area | Direct or nearby strikes, unstable rural grid. | 1 – 3 Years (or single event) |

Summary: Proactive Protection

An SPD is not a one-time purchase; it is a critical maintenance consumable. By understanding the “Joule Account,” facility managers can shift from reactive repairs to proactive lifecycle management.

Your Action Plan:

- Audit: Check all installed SPDs during your next scheduled maintenance.

- Verify: Ensure all indicators are Green.

- Upgrade: Replace “blind” hardwired units with VIOX Pluggable DIN Rail SPDs for instant status visibility and rapid replacement.

Don’t wait for the smoke to clear to realize your protection had expired months ago.

Frequently Asked Questions (FAQ)

Q: Can I reset a VIOX SPD module after it turns red?

A: No. A red indicator means the internal thermal fuse has permanently disconnected the MOV to prevent safety hazards. The physical elements inside have sacrificed themselves to protect your equipment. You must replace the pluggable module.

Q: Does the SPD cut off power to my equipment when it fails?

A: Typically, no. VIOX SPDs are installed in parallel (shunt) to the load. When they fail safe, they disconnect themselves from the circuit, allowing your equipment to keep running. However, your equipment is now unprotected. This is why the remote signaling contact is vital for immediate notification.

Q: What is the difference between Type 1 and Type 2 SPDs?

A: Type 1 SPDs are installed before the main service entrance disconnect and can handle high-energy surges from external lightning. Type 2 SPDs (the most common for machines) are installed after the disconnect on the load side, protecting against residual lightning energy and internal switching surges.

Q: Why do I need an SPD if I have a circuit breaker?

A: Circuit breakers protect wires from current overload (amperage) and short circuits to prevent fire. They are too slow to stop voltage surges. SPDs protect equipment from voltage spikes (overvoltage). You need both.

Q: How do I choose the right Joule rating?

A: In industrial settings, look for kA (kiloamp) surge current ratings rather than just Joules. A higher kA rating (e.g., 40kA vs 20kA) generally implies a larger MOV with a higher Joule capacity, offering a longer lifespan in harsh electrical environments.