Fork-type and pin-type busbars are essential components in electrical power distribution systems, each offering unique advantages in design, conductivity, and installation for different applications.

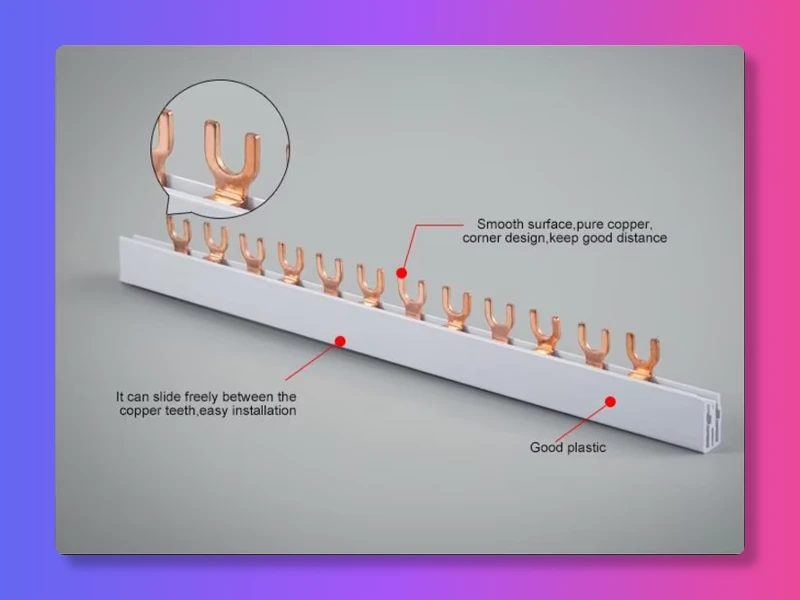

Fork-Type Busbar Design

Fork-type busbars, also known as spade terminals, feature a distinctive fork-like shape that allows for easy connection and disconnection from terminal points. This design offers several advantages:

- Secure connections, reducing the risk of electrical faults.

- Quick disconnection and reconnection without removing the entire terminal.

- Excellent conductivity and reliability in electrical systems.

- Robust structure, making them suitable for construction machinery and heavy electrical devices.

- Organized wiring systems, minimizing clutter and enhancing safety in switchgear and distribution boards.

The fork-shaped design of these busbars contributes to their versatility and efficiency in various electrical applications, particularly where two input terminals are required.

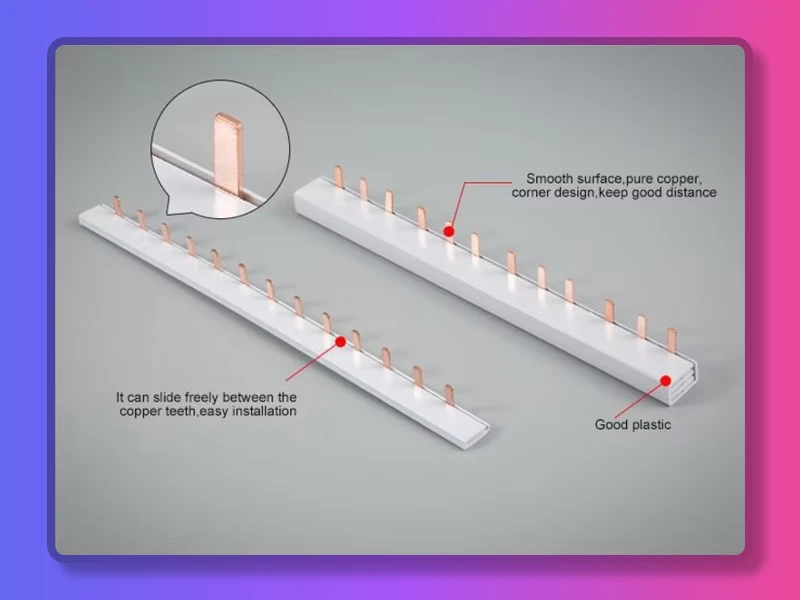

Pin-Type Busbar Design

Pin-type busbars feature a pole-like structure that allows for connections through pins, offering a compact and versatile design. These busbars can be customized in length to suit various applications, making them ideal for personalized or space-constrained installations. Key characteristics of pin-type busbars include:

- Compact nature, suitable for low-voltage power boxes and illuminated boxes.

- Customizable length for flexibility in different applications.

- Efficient handling of electrical loads while minimizing energy loss.

- Low contact resistance, ensuring good conductivity.

- Ideal for circuit breakers and essential electrical installations where space optimization is crucial.

The pole-like design of pin-type busbars contributes to their ease of installation and adaptability in various electrical systems, particularly in environments where space efficiency is a priority.

Busbar Conductivity Comparison

When comparing the conductivity of fork-type and pin-type busbars, both exhibit strong performance, but there are subtle distinctions. Fork-type busbars are renowned for their excellent conductivity, providing reliable and safe connections in electrical systems. Their design helps maintain a secure connection, reducing the risk of electrical faults and enhancing system reliability. On the other hand, pin-type busbars also offer good conductivity with low contact resistance, efficiently handling electrical loads while minimizing energy loss. Their compact design supports efficient power distribution in space-constrained environments.

Applications and Installation

Fork-type busbars excel in construction machinery and heavy electrical devices due to their robustness and reliability. Their design facilitates organized wiring in switchgear and distribution boards, enhancing safety and reducing clutter. In contrast, pin-type busbars are widely used in circuit breakers, low-voltage power boxes, and illuminated boxes where space optimization is crucial. Installation-wise, pin-type busbars generally offer faster and easier setup, making them suitable for personalized or space-constrained installations, while fork-type options, though straightforward to install, may require more space.