Direct Answer

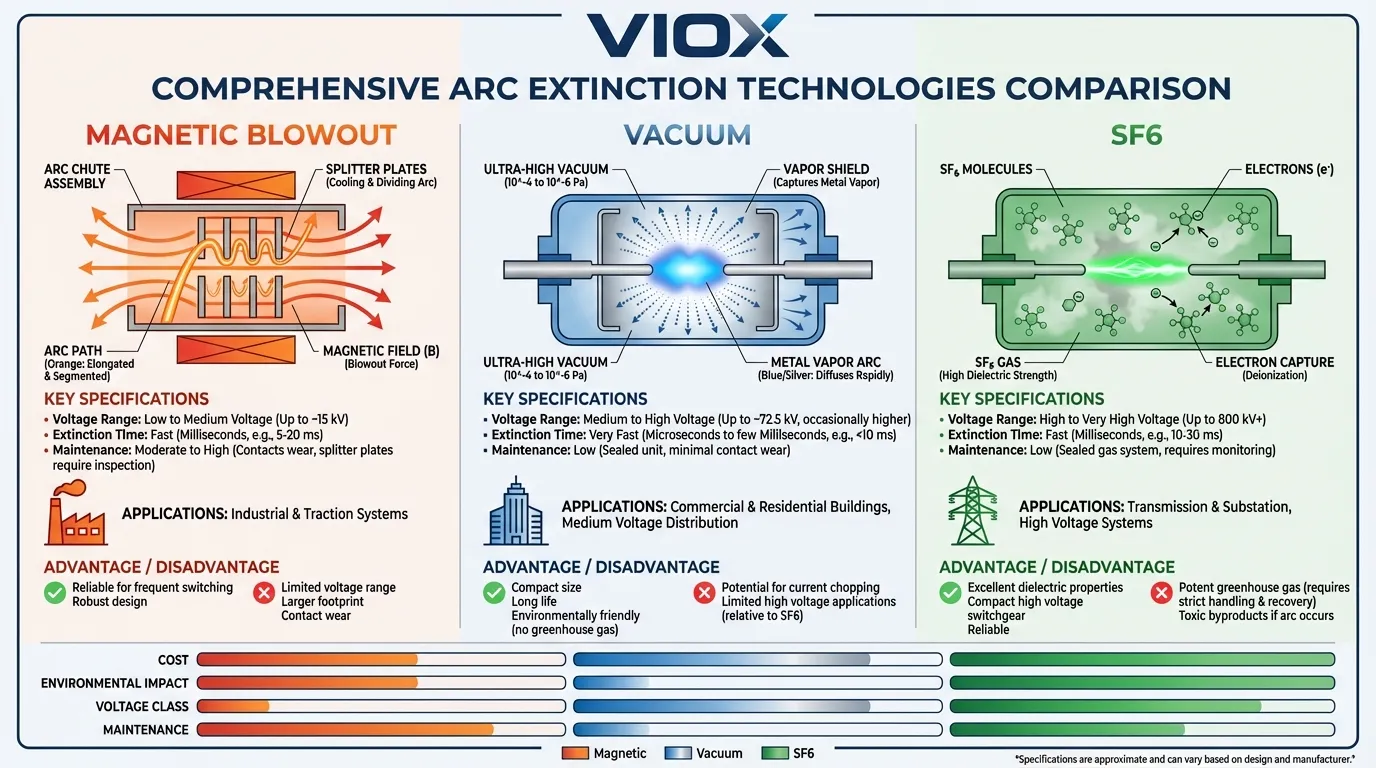

Magnetic blowout, vacuum, and SF6 represent three fundamentally different approaches to arc extinction in circuit breakers. Magnetic blowout uses electromagnetic force to physically stretch and cool arcs in air (common in MCCBs and ACBs up to 6.3kA), vacuum technology eliminates the ionization medium entirely for rapid extinction in 3-8ms (ideal for 3-40.5kV systems), while SF6 gas leverages superior electronegativity to absorb free electrons and achieve interrupting capacities exceeding 100kA in high-voltage applications up to 800kV. The choice between these technologies depends on voltage class, fault current magnitude, environmental considerations, and total cost of ownership—with magnetic blowout dominating low-voltage industrial applications, vacuum leading the medium-voltage market, and SF6 remaining essential for extra-high voltage transmission despite environmental concerns.

Key Takeaways

- Magnetic blowout systems use Lorentz force (F = I × B) to drive arcs into splitter plates, achieving arc voltages of 80-200V in compact designs suitable for 16-1600A MCCBs and ACBs

- Vacuum circuit breakers exploit the absence of ionization medium to extinguish arcs within microseconds at current zero, offering maintenance-free operation for 10,000+ mechanical cycles

- SF6 technology provides 2-3 times the dielectric strength of air and exceptional arc-quenching through electron capture, enabling interruption of fault currents exceeding 63kA at transmission voltages

- Selection criteria must balance interrupting capacity (kA rating), voltage class, contact life expectancy, environmental impact (SF6 has 23,900× CO2 GWP), and maintenance requirements

- Hybrid approaches are emerging, including vacuum interrupters with magnetic assist for DC applications and SF6 alternatives using fluoronitrile mixtures to reduce greenhouse gas emissions

The Arc Extinction Challenge: Why Technology Matters

When circuit breaker contacts separate under load, an electrical arc forms—a high-temperature plasma channel (15,000-20,000°C) that attempts to maintain current flow despite physical contact separation. This arc represents one of the most destructive phenomena in electrical systems, capable of vaporizing copper contacts, igniting fires, and causing catastrophic equipment failure if not extinguished within milliseconds.

The fundamental challenge lies in the arc’s self-sustaining nature. The plasma contains free electrons and ionized particles that create a conductive path, while the arc’s intense heat continuously generates more charge carriers through thermal ionization. Breaking this cycle requires sophisticated physics-based approaches that either remove the ionization medium, increase arc resistance beyond sustainable levels, or leverage the natural current zero crossing in AC systems.

Modern circuit breaker technology employs three primary arc extinction methods, each exploiting different physical principles. Understanding these mechanisms is essential for electrical engineers specifying protection equipment, facility managers maintaining critical infrastructure, and manufacturers like VIOX Electric designing next-generation circuit breakers for industrial, commercial, and utility applications.

Magnetic Blowout Technology: Electromagnetic Arc Control

Physical Principles

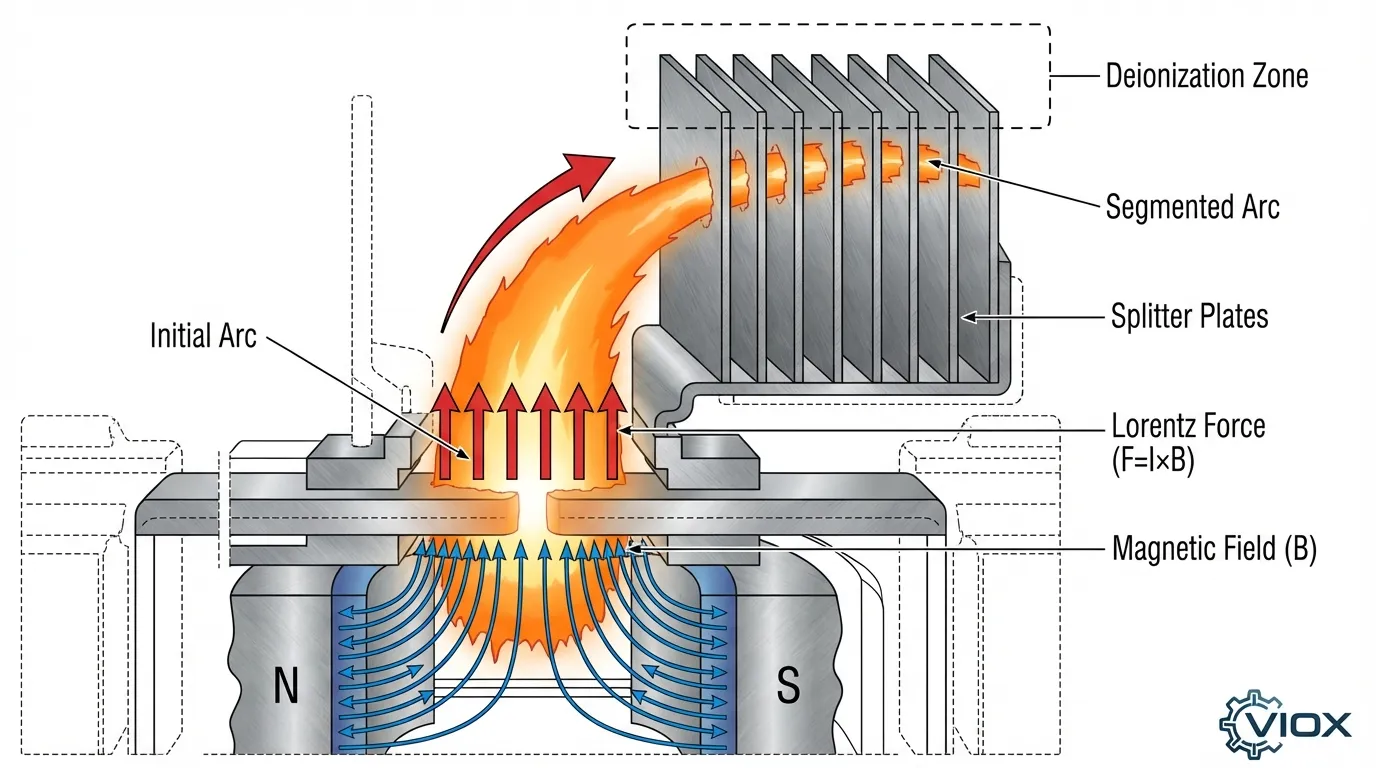

Magnetic blowout arc extinction exploits the Lorentz force law, where a current-carrying conductor in a magnetic field experiences a perpendicular force: F = I × L × B (where I is arc current, L is arc length, and B is magnetic flux density). In circuit breakers, this electromagnetic force physically drives the arc away from the main contacts into specially designed arc chutes containing splitter plates.

The process begins when contacts separate and an arc forms. Current flowing through the arc interacts with a magnetic field generated either by permanent magnets or electromagnetic blowout coils connected in series with the circuit. This interaction produces a force that propels the arc upward and outward at velocities exceeding 100 m/s, stretching it into progressively cooler regions where deionization can occur.

Arc Chute and Splitter Plate Design

Modern magnetic blowout systems employ arc chutes containing 7-15 ferromagnetic splitter plates (typically steel or copper-coated steel) spaced 2-5mm apart. When the elongated arc enters the chute, it divides into multiple series arcs across each plate gap. This segmentation serves three critical functions:

- Voltage multiplication effect: Each arc segment develops its own anode and cathode voltage drops (approximately 15-20V per segment). With 10 plates creating 9 gaps, total arc voltage can reach 135-180V, significantly exceeding the system voltage and forcing current toward zero.

- Enhanced cooling: The metal plates act as heat sinks, rapidly extracting thermal energy from the arc plasma. Steel plates provide good magnetic properties that enhance blowout force, while copper-coated variants reduce voltage drop across the chute assembly.

- Gas generation: Arc heat vaporizes polymer or fiber arc chute components, generating hydrogen-rich deionizing gases that help cool and extinguish the arc. This controlled gas evolution is a deliberate design feature in many MCCB arc chambers.

VIOX MCCBs utilize optimized arc chute geometry with progressive plate spacing—narrower at the entry to ensure arc capture, wider at the top to accommodate arc expansion—achieving reliable interruption in 10-16ms at rated fault currents up to 100kA.

Applications and Limitations

Magnetic blowout technology dominates low-voltage circuit breakers across multiple categories:

- Miniature Circuit Breakers (MCBs): 6-125A residential/commercial applications using simplified magnetic systems with 4-6 splitter plates

- Molded Case Circuit Breakers (MCCBs): 16-1600A industrial workhorse with sophisticated arc chutes achieving 6-100kA interrupting capacity

- Air Circuit Breakers (ACBs): 800-6300A frame sizes with large electromagnetic blowout coils for open-air arc extinction up to 100kA

The primary limitation is voltage class. Magnetic blowout becomes impractical above 1000V AC due to the excessive contact separation and arc chute dimensions required. Additionally, DC applications present challenges since there is no natural current zero crossing—DC magnetic blowout breakers require 3-5× faster contact opening speeds (3-5 m/s vs. 1-2 m/s for AC) and may still struggle with arc re-ignition.

Vacuum Circuit Breaker Technology: Eliminating the Medium

The Vacuum Advantage

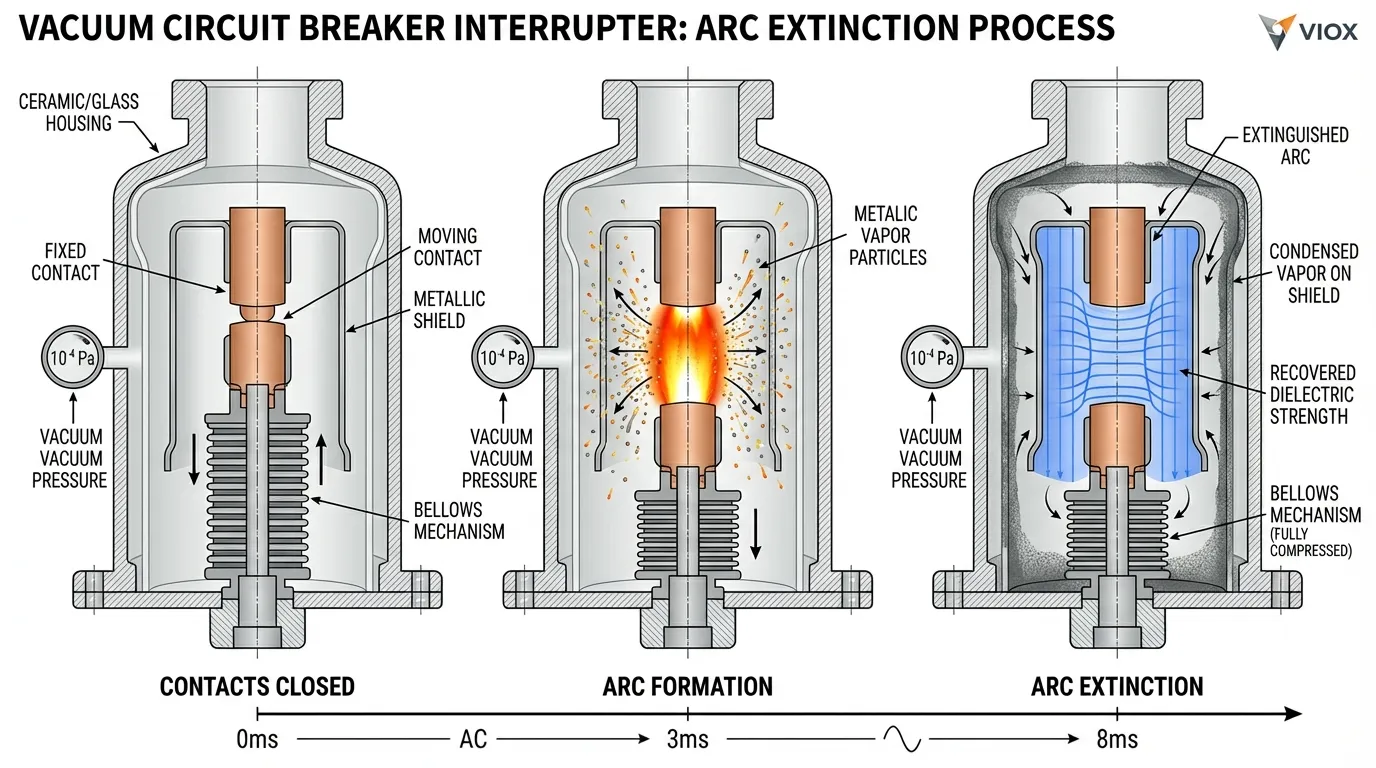

Vacuum circuit breakers (VCBs) employ a radically different approach: eliminate the ionization medium entirely. Operating at pressures below 10⁻⁴ Pa (approximately one-millionth of atmospheric pressure), the vacuum interrupter contains so few gas molecules that arc plasma cannot sustain itself through conventional ionization mechanisms.

When VCB contacts separate, the arc initially forms through metal vapor evaporated from the contact surfaces by the intense heat. However, in the near-perfect vacuum environment, this metallic vapor diffuses rapidly to the surrounding shield surfaces where it condenses and solidifies. At the next current zero crossing (in AC systems), the arc extinguishes naturally, and the contact gap recovers dielectric strength at extraordinary rates—up to 20kV/μs compared to 1-2kV/μs in air.

This rapid dielectric recovery prevents arc re-ignition even as the recovery voltage rises across the contacts. The entire interruption process occurs within 3-8 milliseconds, significantly faster than magnetic blowout systems.

Contact Design and Arc Diffusion

VCB contacts employ specialized geometries to control arc behavior and minimize contact erosion:

- Butt contacts feature simple flat or slightly contoured surfaces suitable for currents below 10kA. The arc concentrates at a single point, leading to localized heating but simple manufacturing.

- Spiral or cup-shaped contacts incorporate slots or grooves that generate an axial magnetic field (AMF) when current flows. This self-generated field causes the arc to rotate rapidly around the contact surface (up to 10,000 rpm), distributing erosion evenly and preventing concentrated hot spots. AMF contacts are essential for medium-voltage VCBs handling 25-40kA interrupting currents.

The vacuum interrupter housing—typically ceramic or glass-ceramic—must maintain hermetic sealing for 20-30 years while withstanding mechanical shock and thermal cycling. Internal metal shields prevent metal vapor deposition on insulating surfaces, which would compromise dielectric strength.

Performance Characteristics

Vacuum technology offers compelling advantages for medium-voltage applications (3kV to 40.5kV):

- Maintenance-free operation: No consumable arc-quenching medium, no gas monitoring, no contact cleaning. Typical mechanical life exceeds 10,000 operations at rated current, with electrical life of 50-100 full-current interruptions.

- Compact footprint: Absence of arc chutes and gas reservoirs enables 40-60% size reduction compared to equivalent SF6 breakers. A 12kV VCB panel occupies approximately 0.4m² versus 0.7m² for SF6 technology.

- Environmental safety: No toxic gases, no fire hazard, no greenhouse gas emissions. Vacuum interrupters are fully recyclable at end-of-life.

- Fast operation: 3-8ms arc extinction enables rapid reclosing for transient fault clearing in distribution networks.

The primary limitation remains voltage class. Above 40.5kV, the contact gap required for dielectric withstand becomes impractical, and manufacturing challenges increase exponentially. Additionally, vacuum technology struggles with DC interruption—the absence of current zero crossing means arcs can persist indefinitely unless forced extinction through external circuits.

SF6 Circuit Breaker Technology: Electron Capture Mechanism

SF6 Gas Properties

Sulfur hexafluoride (SF6) revolutionized high-voltage circuit breaker design through its exceptional electrical properties. This colorless, odorless, non-toxic gas exhibits dielectric strength 2.5 times that of air at atmospheric pressure and 2-3 times at typical operating pressures (4-6 bar absolute). More critically, SF6 is strongly electronegative—it aggressively captures free electrons to form stable negative ions (SF6⁻).

This electron capture mechanism is the key to SF6’s arc-quenching superiority. When an arc forms in SF6 gas, the plasma contains free electrons that maintain conductivity. However, SF6 molecules rapidly attach to these electrons, converting them into heavy, relatively immobile negative ions. This process dramatically reduces the number of charge carriers available to sustain the arc, enabling extinction at current zero.

The attachment coefficient of SF6 is approximately 100 times greater than air, meaning electron capture occurs orders of magnitude faster. Combined with excellent thermal conductivity (SF6 efficiently removes heat from the arc column), this creates ideal conditions for rapid arc extinction in high-voltage applications.

Puffer and Self-Blast Designs

Modern SF6 circuit breakers employ two primary arc interruption techniques:

- Puffer-type breakers use mechanical energy from the operating mechanism to compress SF6 gas in a puffer cylinder. When contacts separate, the compressed gas blasts through a nozzle across the arc at high velocity (approaching 300 m/s), simultaneously cooling the plasma and sweeping ionized particles away from the contact gap. The combination of forced gas flow, electron capture, and thermal cooling extinguishes arcs within 10-20ms even at fault currents exceeding 63kA.

- Self-blast (thermal expansion) breakers eliminate the puffer cylinder, instead using arc heat to generate pressure rise. The arc forms in a sealed chamber where thermal expansion creates a pressure differential that drives gas flow through the arc. This design reduces mechanical complexity and operating energy, making it suitable for frequent switching operations. Modern self-blast designs incorporate auxiliary puffer mechanisms for reliable small-current interruption.

Both designs utilize insulating nozzles (typically PTFE) that shape the gas flow and withstand the arc’s thermal assault. Nozzle geometry is critical—too narrow and gas flow becomes turbulent (reducing cooling efficiency), too wide and the arc diffuses without adequate cooling.

High-Voltage Applications

SF6 technology dominates transmission and subtransmission voltage classes:

- 72.5kV to 145kV: Standard distribution substation applications with 31.5-40kA interrupting capacity

- 245kV to 420kV: Transmission network protection with 50-63kA fault current capability

- 550kV to 800kV: Extra-high voltage systems where SF6 remains the only proven technology for reliable arc interruption

A single SF6 interrupter can interrupt currents that would require multiple vacuum bottles in series. For example, a 145kV SF6 breaker uses one interrupter per phase, while an equivalent vacuum design would need 4-6 interrupters in series—dramatically increasing complexity, cost, and failure modes.

Environmental Concerns and Alternatives

The critical drawback of SF6 is environmental impact. With a global warming potential (GWP) of 23,900 times CO2 and atmospheric lifetime exceeding 3,200 years, SF6 is one of the most potent greenhouse gases. Despite industry efforts to minimize leakage (modern breakers achieve <0.1% annual leak rates), atmospheric SF6 concentrations continue rising.

This has driven intensive research into SF6 alternatives:

- Fluoronitrile mixtures (C4F7N + CO2 buffer gas) offer 80-90% of SF6’s dielectric performance with <1% GWP. However, these mixtures require higher operating pressures and have lower temperature ranges.

- Vacuum-SF6 hybrid designs use vacuum interrupters for medium-voltage sections and minimal SF6 only where absolutely necessary, reducing total gas inventory by 60-80%.

- Clean air technology employs compressed air or nitrogen with advanced nozzle designs, suitable for voltages up to 145kV though with larger footprints than SF6 equivalents.

Despite these developments, SF6 remains essential for 245kV+ applications where no proven alternative yet exists at comparable cost and reliability.

Comparative Analysis: Technology Selection Matrix

Selecting the appropriate arc extinction technology requires balancing multiple technical and economic factors. The following comparison table synthesizes key performance parameters:

| Parameter | Magnetic Blowout | Vacuum | SF6 |

|---|---|---|---|

| Voltage Range | Up to 1kV AC | 3kV – 40.5kV | 12kV – 800kV |

| Typical Current Rating | 16A – 6,300A | 630A – 4,000A | 630A – 5,000A |

| Interrupting Capacity | 6kA – 100kA | 25kA – 50kA | 31.5kA – 100kA+ |

| Arc Extinction Time | 10-20ms | 3-8ms | 10-20ms |

| Mechanical Life | 10,000 – 25,000 ops | 30,000 – 50,000 ops | 10,000 – 30,000 ops |

| Electrical Life (full current) | 25-50 interruptions | 50-100 interruptions | 100-200 interruptions |

| Maintenance Interval | 1-2 years | 5-10 years | 2-5 years |

| Environmental Impact | Minimal | None | High (GWP 23,900) |

| Footprint (relative) | Medium | Small | Large |

| Initial Cost | Low | Medium | High |

| Operating Cost | Medium | Low | Medium-High |

| DC Capability | Limited (with modifications) | Poor (requires forced commutation) | Good (with special designs) |

| Altitude Derating | Required above 1,000m | Minimal | Required above 1,000m |

| Noise Level | Moderate | Low | Moderate-High |

| Fire Hazard | Low (arc products) | None | None |

Application-Specific Recommendations

- Industrial facilities (480V-690V): Magnetic blowout MCCBs and ACBs provide optimal cost-performance balance. VIOX MCCBs with thermal-magnetic trip units and 50kA interrupting capacity suit most motor control centers, distribution boards, and machinery protection applications.

- Commercial buildings (up to 15kV): Vacuum circuit breakers offer maintenance-free operation ideal for limited electrical staff. VCB-equipped switchgear reduces lifecycle costs through extended service intervals and eliminates environmental compliance burden.

- Utility substations (72.5kV+): SF6 technology remains necessary for reliable transmission-voltage protection despite environmental concerns. Modern gas-insulated switchgear (GIS) with SF6 monitoring and leak detection minimizes environmental impact while providing compact, weather-resistant installations.

- Renewable energy systems: Solar and wind applications increasingly use vacuum technology for medium-voltage collection systems (12-36kV), with magnetic blowout DC breakers for battery storage and PV string protection. The maintenance-free nature suits remote installations.

- Data centers and critical facilities: Vacuum or air magnetic blowout breakers avoid SF6 environmental reporting requirements while providing reliable protection. Fast interruption times (3-8ms for vacuum) minimize voltage sag duration during fault clearing.

Performance Comparison Table: Arc Extinction Physics

Understanding the fundamental physics differences helps explain performance characteristics:

| Physical Mechanism | Magnetic Blowout | Vacuum | SF6 |

|---|---|---|---|

| Primary Extinction Method | Arc elongation + cooling | Medium elimination | Electron capture + cooling |

| Arc Voltage Development | 80-200V (splitter plates) | 20-50V (short gap) | 100-300V (gas compression) |

| Dielectric Strength Recovery | 1-2 kV/μs | 15-20 kV/μs | 3-5 kV/μs |

| Deionization Mechanism | Gas cooling + recombination | Metal vapor diffusion | Electron attachment (SF6⁻) |

| Current Zero Dependency | High (AC only) | High (AC only) | Medium (can interrupt DC) |

| Contact Erosion Rate | High (0.1-0.5mm per 1000 ops) | Medium (0.01-0.05mm per 1000 ops) | Low (0.005-0.02mm per 1000 ops) |

| Arc Energy Dissipation | Splitter plates + gas | Contact surfaces + shield | Gas compression + nozzle |

| Pressure Dependency | Minimal | Critical (vacuum integrity) | High (gas density) |

| Temperature Sensitivity | Moderate (-40°C to +70°C) | Low (-50°C to +60°C) | High (-30°C to +50°C for standard SF6) |

Emerging Technologies and Future Trends

The circuit breaker industry is experiencing significant innovation driven by environmental regulations, renewable energy integration, and digitalization:

- Solid-state circuit breakers (SSCBs) using power semiconductors (IGBTs, SiC MOSFETs) eliminate mechanical contacts entirely, achieving sub-millisecond interruption times. While currently limited to low-voltage DC applications (data centers, EV charging), SSCB technology is advancing toward medium-voltage AC systems. The absence of mechanical wear enables millions of operations, though semiconductor costs remain prohibitive for utility-scale applications.

- Hybrid circuit breakers combine mechanical contacts for normal conduction (minimizing losses) with parallel semiconductor paths for ultra-fast interruption. During fault conditions, current commutates to the semiconductor branch within microseconds, then interrupts through controlled turn-off. This approach suits HVDC transmission where conventional breakers struggle with DC arc extinction.

- Digital twin technology enables predictive maintenance through continuous monitoring of contact resistance, operating mechanism performance, and (for SF6 breakers) gas quality. Machine learning algorithms detect degradation patterns before failure, optimizing maintenance intervals and reducing unplanned outages.

- Alternative gas research continues intensifying, with fluoronitrile mixtures (C4F7N/CO2) now deployed in commercial 145kV breakers. Next-generation candidates include fluoroketones and perfluorinated compounds with <100 GWP. However, none yet match SF6’s combination of dielectric strength, arc-quenching performance, and temperature range.

FAQ Section

Q: Can magnetic blowout circuit breakers interrupt DC current?

A: Standard magnetic blowout breakers designed for AC cannot reliably interrupt DC because there is no natural current zero crossing. DC-rated magnetic blowout breakers require specialized designs with 3-5× faster contact opening speeds, enhanced arc chute configurations with 15-25 splitter plates, and often auxiliary arc extinction mechanisms. Even then, interrupting capacity is typically limited to 1000V DC and 10kA. For higher DC ratings, vacuum or solid-state technology is preferred.

Q: How long does a vacuum circuit breaker maintain its vacuum integrity?

A: Quality vacuum interrupters maintain operational vacuum (<10⁻⁴ Pa) for 20-30 years under normal conditions. The hermetic seal uses metal-to-ceramic brazing or glass-to-metal sealing that doesn’t degrade with time. However, vacuum integrity can be compromised by mechanical shock during shipping, excessive contact erosion that generates metal particles, or manufacturing defects. Annual testing using high-voltage withstand tests indirectly verifies vacuum quality—voltage breakdown indicates vacuum loss.

Q: Why is SF6 still used despite environmental concerns?

A: SF6 remains essential for transmission voltages (245kV+) because no alternative technology currently offers equivalent performance at comparable cost and reliability. A 420kV SF6 breaker interrupts 63kA faults reliably in a compact footprint; achieving this with vacuum would require 8-12 interrupters in series (dramatically increasing failure probability), while alternative gases don’t yet provide adequate dielectric strength. The industry is transitioning to SF6 alternatives at distribution voltages (72.5-145kV) but transmission applications lack proven replacements.

Q: What causes circuit breaker contact welding, and how do different technologies prevent it?

A: Contact welding occurs when arc heat melts contact surfaces, creating a metallurgical bond. Magnetic blowout systems use dedicated arcing contacts (sacrificial copper-tungsten alloys) that absorb arc energy while protecting main contacts. Vacuum breakers employ copper-chromium contacts with high resistance to welding, plus the rapid arc extinction minimizes heat transfer. SF6 breakers use the gas blast to cool contacts immediately after separation, preventing weld formation. Proper contact pressure (typically 150-300N) and anti-weld coatings also help.

Q: How does altitude affect circuit breaker performance?

A: Altitude reduces air density, which impacts magnetic blowout and SF6 breakers differently. Magnetic blowout breakers experience reduced cooling efficiency above 1,000m elevation—derating of approximately 10% per 1,000m is typical. SF6 breakers maintain gas density through sealed construction, so altitude effects are minimal unless the breaker is opened for maintenance. Vacuum breakers are unaffected by altitude since they operate in vacuum regardless of external pressure. For installations above 2,000m, consult manufacturer derating curves or specify altitude-compensated designs.

Q: Can I retrofit an SF6 circuit breaker with vacuum technology?

A: Direct replacement is generally not feasible because SF6 and vacuum breakers have different mounting dimensions, operating mechanisms, and control interfaces. However, manufacturers offer “drop-in” vacuum replacements for common SF6 switchgear lineups, maintaining the same busbar connections and panel footprint. This requires replacing the entire circuit breaker assembly but avoids switchgear replacement. The retrofit eliminates SF6 environmental compliance, reduces maintenance costs, and often improves reliability. Consult manufacturers like VIOX Electric for compatibility assessments.

Conclusion: Matching Technology to Application

Arc extinction technology selection fundamentally shapes circuit breaker performance, lifecycle costs, and environmental impact. Magnetic blowout systems provide cost-effective protection for low-voltage industrial applications where compact design and proven reliability matter most. Vacuum technology dominates medium-voltage distribution through maintenance-free operation and environmental safety. SF6 remains essential for transmission voltages despite greenhouse gas concerns, though alternative gases are gradually displacing it at lower voltage classes.

For electrical engineers specifying protection equipment, the decision matrix must consider voltage class, fault current magnitude, environmental regulations, maintenance capabilities, and total cost of ownership. A 480V motor control center optimally uses magnetic blowout MCCBs; a 12kV distribution switchgear benefits from vacuum technology; a 145kV substation may still require SF6 despite environmental costs.

As the industry evolves toward renewable energy integration, DC power systems, and stricter environmental standards, emerging technologies like solid-state breakers and alternative gases will gradually reshape this landscape. However, the fundamental physics of arc extinction—whether through electromagnetic force, medium elimination, or electron capture—will continue governing circuit breaker design for decades to come.

VIOX Electric continues advancing all three technologies through our research and manufacturing facilities, providing industrial, commercial, and utility customers with optimized arc extinction solutions for every voltage class and application. For technical specifications, selection guidance, or custom circuit breaker solutions, contact our engineering team.

Related Resources

- What is an Arc in a Circuit Breaker? – Complete technical guide to arc physics and formation

- Understanding Circuit Breaker Disconnection: The Essential Role of Electric Arcs – Deep dive into arc phenomena

- Types of Circuit Breakers – Comprehensive classification guide

- MCCB vs MCB – Low-voltage breaker comparison

- Complete Guide to Air Circuit Breakers (ACB) – Magnetic blowout applications

- DC vs AC Circuit Breakers: Essential Differences – Arc extinction challenges in DC systems

- Circuit Breaker Ratings: ICU, ICS, ICW, ICM – Understanding interrupting capacity

- Current Limiting Circuit Breaker Guide – Advanced arc voltage techniques

- Single Break vs Double Break MCCB Guide – Contact configuration impact

- ACB vs VCB – Air vs vacuum technology comparison