Understanding High-Current Terminal Blocks in Industrial Applications

Industrial electrical panels demand reliable, high-performance connection solutions capable of handling substantial current loads while maintaining safety and operational integrity. High-current terminal blocks serve as the critical junction points where power distribution meets precision engineering—yet the choice between ceramic and UKK terminal blocks continues to challenge procurement engineers and electrical designers.

The distinction matters. A poorly specified terminal block in a 400A motor control panel can lead to connection failures, thermal runaway, or catastrophic system downtime. Ceramic terminal blocks excel in extreme temperature environments, while UKK (Universal Klemmblock) power distribution blocks deliver modular flexibility for complex branching circuits. Understanding their fundamental differences, technical specifications, and application suitability ensures optimal panel design and long-term reliability.

This comprehensive guide provides electrical engineers and procurement specialists with data-driven selection criteria, performance comparisons, and real-world application insights for specifying high-current terminal blocks in industrial panels.

What Are High-Current Terminal Blocks?

High-current terminal blocks are specialized electrical connectors designed to safely handle current loads exceeding 20 amperes, typically ranging from 30A to 600A in industrial applications. Unlike standard terminal blocks rated for 10-15A, high-current variants incorporate enhanced conductor cross-sections, superior contact materials, and advanced thermal management features.

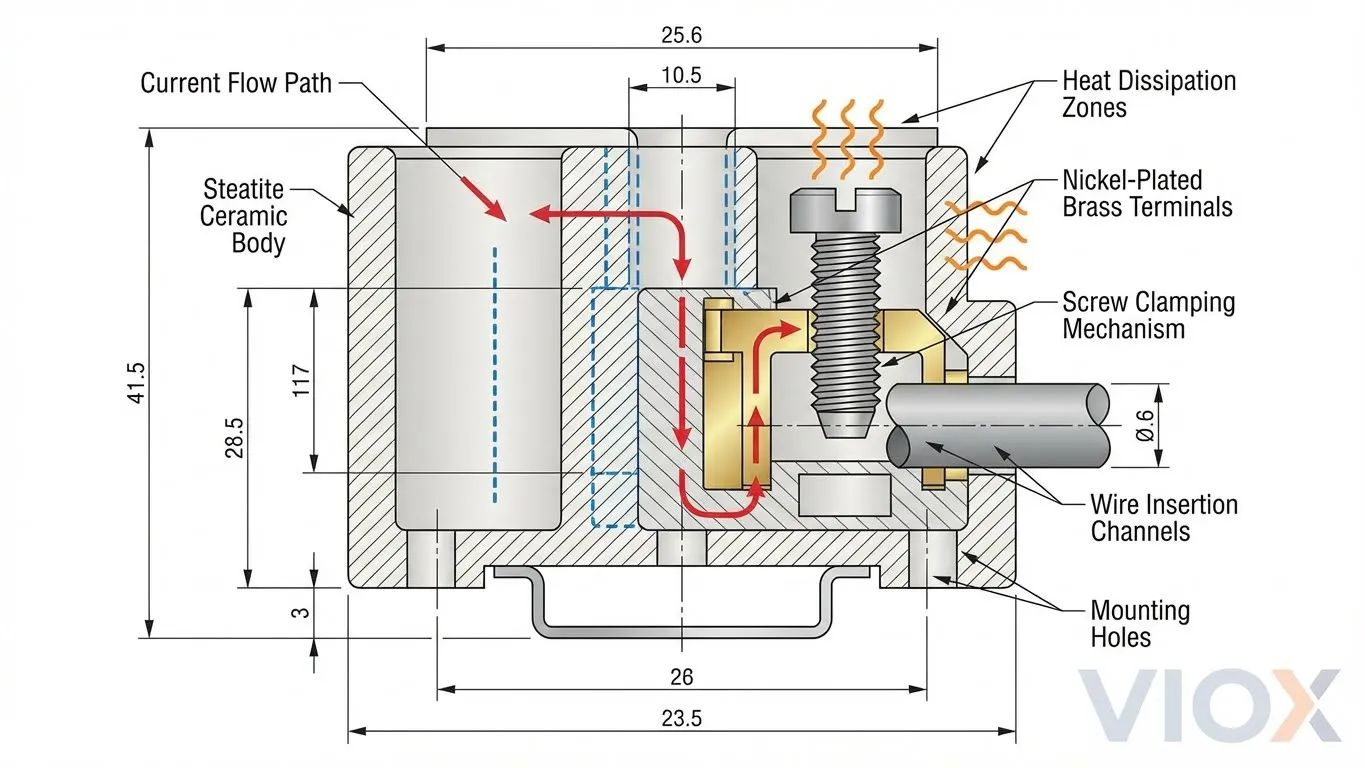

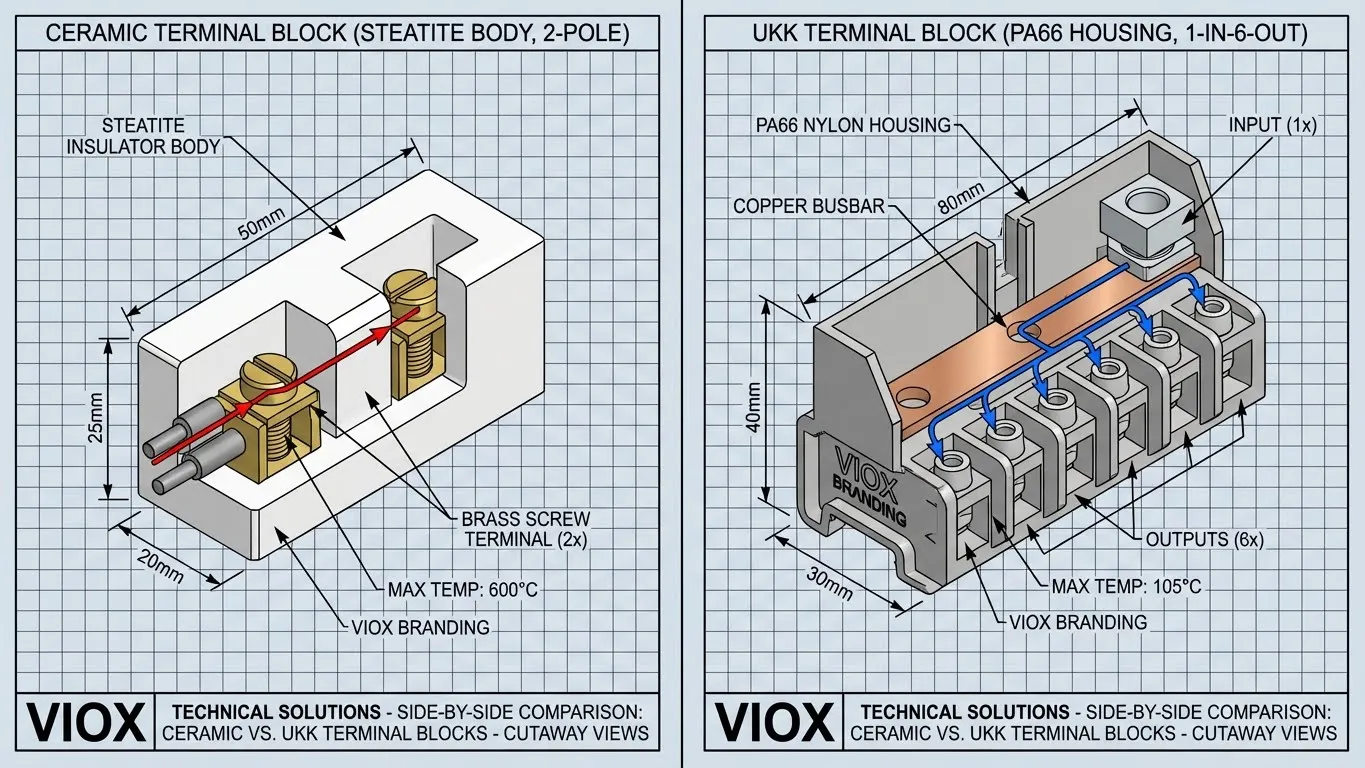

These components serve three primary functions: secure mechanical connection of multiple conductors, electrical isolation between adjacent circuits, and heat dissipation under continuous high-load operation. Terminal block construction typically consists of insulating housings (ceramic or engineered polymers), conductive busbars (copper or brass), and clamping mechanisms (screw terminals or spring clamps).

Current ratings depend on multiple factors: conductor material cross-section, ambient temperature, installation density, and ventilation conditions. A 150A-rated terminal block at 40°C ambient may require derating to 120A at 60°C ambient—a critical consideration for industrial furnace control panels or outdoor enclosures.

Ceramic Terminal Blocks: Technical Specifications and Advantages

Material Properties and Temperature Performance

Ceramic terminal blocks utilize high-grade porcelain or steatite bodies capable of withstanding continuous operating temperatures from -40°C to 800°C, significantly outperforming polymer alternatives limited to 105°C maximum. This extraordinary thermal resistance derives from the crystalline structure of ceramic materials, which maintain dimensional stability and dielectric strength at temperatures that would melt or degrade plastic housings.

Key material specifications include:

- Dielectric strength: >15 kV/mm for high-grade steatite

- Thermal conductivity: 0.5-3.0 W/m·K (moderate, enabling controlled heat dissipation)

- Coefficient of thermal expansion: 8-10 × 10⁻⁶/K (low, ensuring dimensional stability)

- Mechanical strength: High resistance to impact, vibration, and mechanical stress

Electrical Specifications

Ceramic terminal blocks typically support voltage ratings from 380V to 1000V+ and current capacities ranging from 15A to 100A per pole, depending on configuration. The electrical rating parameters include:

| Specification | Range | Standard |

|---|---|---|

| Rated Voltage | 380V-1000V | IEC 60947-7-1 |

| Rated Current | 15A-100A | UL 1059 |

| Wire Size Capacity | 0.5-16 mm² | – |

| Poles | 1-4 | – |

| Dielectric Test Voltage | 1000V + 2× rated voltage | 1 minute test |

Applications and Use Cases

Ceramic terminal blocks excel in high-temperature and harsh-environment applications:

- Industrial furnaces and kilns: Heating element connections operating at 400-800°C

- High-intensity lighting systems: Industrial halogen and specialized lighting fixtures

- Ceramic and glass manufacturing: Equipment subjected to radiant heat exposure

- Power generation facilities: High-temperature process control instrumentation

- Solar photovoltaic installations: Junction boxes in high-ambient-temperature climates

The selection criteria for ceramic terminal blocks centers on temperature resistance requirements. Proper ceramic terminal block selection begins with verifying that ambient operating temperature plus heat generated by conductor resistance remains within the rated temperature range with adequate safety margin (typically 20-25%).

UKK Terminal Blocks: Modular Power Distribution Solutions

Design Architecture and Construction

UKK (Universal Klemmblock) terminal blocks represent a different engineering approach—modular power distribution blocks designed for high-current branching applications in industrial control panels. These DIN rail-mountable units feature a single high-current input terminal branching to multiple lower-current output terminals, enabling efficient power distribution within enclosures.

Construction specifications include:

- Housing material: Flame-retardant PA66 nylon (UL 94 V-0 rated)

- Conductor material: Nickel-plated copper or brass busbars

- Fastening: Zinc-plated steel screws with specified torque ratings (2.5-6.0 N·m)

- Mounting: 35mm DIN rail snap-fit or panel mounting (depending on current rating)

Current Ratings and Configurations

UKK terminal blocks are available in standardized current ratings from 80A to 500A, with common configurations including:

| Model | Input Rating | Input Terminal | Output Terminals | Typical Application |

|---|---|---|---|---|

| UKK-80A | 80A | 1×16 mm² | 2×16 mm² + 4×10 mm² | Small motor control panels |

| UKK-125A | 125A | 1×25 mm² | 6×10 mm² outputs | Medium distribution panels |

| UKK-160A | 160A | 1×35 mm² | 11×6 mm² outputs | Complex branching circuits |

| UKK-250A | 250A | 1×95 mm² | 6×16 mm² outputs | High-power distribution |

| UKK-400A | 400A | 1×185 mm² | Multiple output configs | Industrial main feeders |

These blocks support rated voltages up to 690V AC/DC and are widely used in industrial automation, building management systems, and renewable energy installations.

Advantages and Application Benefits

UKK terminal blocks deliver several operational advantages:

- Space efficiency: Single-point input reduces panel wiring complexity

- Modular scalability: Easy addition of distribution branches without custom busbars

- Visual inspection capability: Many models feature transparent covers for connection verification

- Time savings: Faster installation compared to traditional busbar fabrication

- Cost optimization: Reduced material and labor costs for multi-branch circuits

Common applications include automation control cabinets, lighting control panels, HVAC distribution systems, solar combiner boxes, and electric vehicle charging infrastructure.

Comparative Analysis: Ceramic vs. UKK Terminal Blocks

Technical Performance Comparison

| Parameter | Ceramic Terminal Blocks | UKK Terminal Blocks |

|---|---|---|

| Operating Temperature | -40°C to +800°C | -40°C to +105°C |

| Voltage Rating | 380V-1000V | Up to 690V AC/DC |

| Current Capacity | 15A-100A per pole | 80A-500A (single input) |

| Material Durability | Excellent (porcelain/steatite) | Very good (PA66 nylon) |

| Thermal Cycling Resistance | Superior | Good |

| Vibration Resistance | Excellent | Good |

| Chemical Resistance | Excellent | Good (flame retardant) |

| Installation Type | Panel mount (fixed) | DIN rail or panel mount |

| Modularity | Low (fixed pole count) | High (scalable outputs) |

| Cost (relative) | Moderate to high | Moderate |

Application Suitability Matrix

| Application Type | Ceramic Recommended | UKK Recommended |

|---|---|---|

| High-temperature environments (>150°C) | ✓✓✓ | ✗ |

| Standard industrial panels (≤60°C) | ✓ | ✓✓✓ |

| Multi-branch power distribution | ✗ | ✓✓✓ |

| Furnace/kiln control systems | ✓✓✓ | ✗ |

| Automation control cabinets | ✓ | ✓✓✓ |

| Solar PV combiner boxes | ✓✓ | ✓✓ |

| Motor control centers | ✓ | ✓✓✓ |

| Outdoor enclosures (moderate temp) | ✓ | ✓✓ |

| Chemical processing equipment | ✓✓✓ | ✓ |

Note: ✓✓✓ = Optimal choice, ✓✓ = Suitable, ✓ = Acceptable with considerations, ✗ = Not recommended

Cost Analysis Considerations

Total cost of ownership extends beyond initial purchase price:

Ceramic Terminal Blocks:

- Higher unit cost ($8-30 per block depending on rating)

- Lower installation labor (simpler connections)

- Minimal replacement frequency in proper applications

- No derating required in high-temperature environments

- Higher reliability in extreme conditions

UKK Terminal Blocks:

- Moderate unit cost ($15-80 depending on current rating)

- Time savings on panel wiring (single input point)

- Reduced copper busbar fabrication costs

- Lower total panel material costs for complex distributions

- Standardized inventory for multiple projects

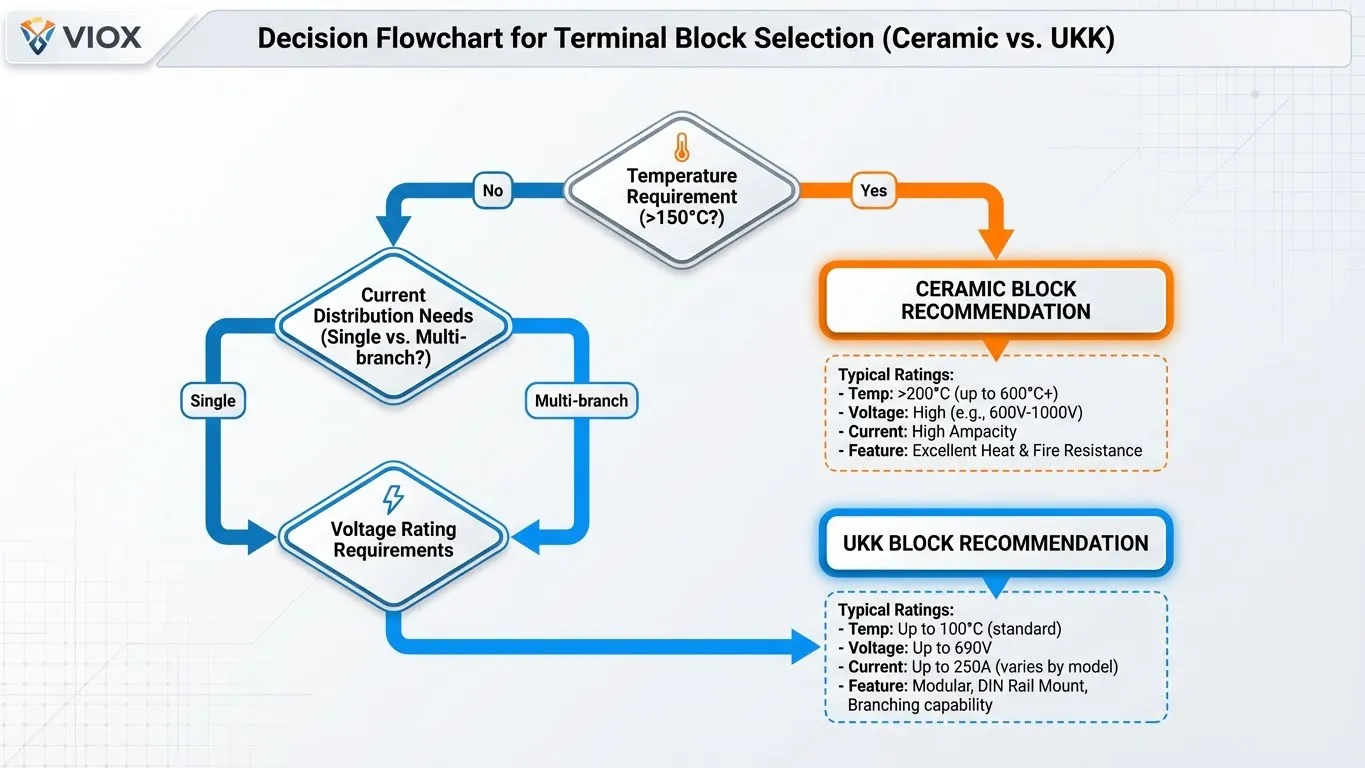

Selection Criteria for Industrial Panel Applications

Step-by-Step Selection Process

- 1. Determine Operating Environment:

- Ambient temperature range

- Presence of chemical exposure

- Vibration and shock conditions

- Humidity and condensation potential

- 2. Calculate Electrical Requirements:

- Maximum continuous current (apply 150% safety margin)

- System voltage (select rated voltage ≥ system voltage)

- Number of circuits requiring connection

- Expected current distribution across branches

- 3. Evaluate Installation Constraints:

- Available panel space (depth, width, height)

- DIN rail availability vs. fixed mounting

- Access requirements for maintenance

- Wire routing and bending radius limitations

- 4. Consider Future Scalability:

- Potential for system expansion

- Standardization across product lines

- Spare terminal capacity requirements

- Maintenance accessibility

Practical Selection Examples

Example 1: Industrial Furnace Control Panel

- Requirement: 600°C ambient, 40A heating element connections, 480V

- Selection: Ceramic terminal blocks (TC-660 series, 4-pole, 600V/65A rated)

- Rationale: Only ceramic blocks withstand continuous 600°C operation

Example 2: Automation Control Cabinet

- Requirement: 45°C ambient, 200A main feed to 8 branch circuits (20-40A each), 400V

- Selection: UKK-250A distribution block (1×95mm² input, 6×16mm² + 2×10mm² outputs)

- Rationale: Modular distribution reduces wiring complexity and panel space

Example 3: Solar Combiner Box

- Requirement: 65°C peak ambient, 60A string current, 1000V DC, outdoor installation

- Selection: Ceramic terminal blocks for high voltage + temperature combination

- Rationale: Superior UV resistance and thermal performance in direct sun exposure

Installation and Safety Considerations

Torque Specifications and Wire Management

Proper installation directly impacts terminal block performance and safety. Key installation parameters include:

- Torque values: Ceramic blocks typically require 1.2-2.0 N·m; UKK blocks require 2.5-6.0 N·m depending on current rating

- Wire preparation: Strip length per manufacturer specification (typically 8-12mm)

- Ferrule use: Recommended for stranded conductors in screw terminals

- Derating factors: Apply 0.8% per °C above 40°C ambient temperature

Never exceed maximum torque specifications—over-tightening ceramic terminal blocks can crack the porcelain body, while under-tightening any terminal block creates high-resistance connections leading to overheating.

Standards Compliance

Ensure specified terminal blocks meet relevant international standards:

- IEC 60947-7-1: Low-voltage switchgear and controlgear – Terminal blocks

- UL 1059: Terminal blocks for industrial use

- CSA 22.2 No. 158: Terminal blocks

- CE marking: Electromagnetic compatibility and safety directives

Terminal block selection should always verify certification marks match the intended installation region and application requirements.

Frequently Asked Questions

Q1: Can UKK terminal blocks be used in high-temperature applications above 105°C?

No. UKK terminal blocks utilize PA66 nylon housings rated for maximum 105°C continuous operation. Applications with ambient temperatures exceeding 90°C require ceramic terminal blocks with appropriate temperature ratings. Always apply derating factors when ambient temperatures approach maximum ratings.

Q2: What is the typical lifespan of ceramic vs. UKK terminal blocks?

Ceramic terminal blocks in properly specified applications can last 25+ years with minimal degradation. UKK terminal blocks typically provide 15-20 years of reliable service in standard industrial environments. Lifespan depends heavily on environmental conditions, thermal cycling, vibration exposure, and maintenance practices.

Q3: Are ceramic terminal blocks more difficult to install than UKK blocks?

Installation complexity differs based on configuration. Ceramic terminal blocks require panel mounting with individual hole drilling, while UKK blocks snap onto standard DIN rail. However, UKK blocks require precise torque application to multiple output terminals, whereas ceramic blocks typically have fewer connection points. Proper installation technique matters more than block type.

Q4: Can I mix ceramic and UKK terminal blocks in the same panel?

Yes, mixing terminal block types is acceptable and often optimal. Use ceramic blocks for high-temperature zones or critical high-voltage connections, and UKK blocks for standard-temperature power distribution sections. Ensure proper labeling and documentation of different terminal types for maintenance personnel.

Q5: What conductor size ranges do ceramic and UKK terminal blocks accept?

Ceramic terminal blocks typically accommodate 0.5-16 mm² conductors (20-6 AWG) depending on current rating. UKK distribution blocks feature different ratings for input and output terminals—for example, UKK-160A accepts 1×35 mm² input and multiple 6-10 mm² outputs. Always verify conductor compatibility with specific terminal block datasheets.

Q6: Do UKK terminal blocks require special DIN rail mounting accessories?

Most UKK blocks rated 80A-250A mount directly on standard 35mm DIN rail (EN 60715). Higher-current models (400A-500A) may require panel mounting due to size and weight. DIN rail mounting selection should verify load capacity and mechanical stability for the specific terminal block model.

Conclusion: Optimal Terminal Block Selection for Industrial Reliability

The ceramic vs. UKK terminal block decision fundamentally depends on application temperature requirements and power distribution architecture. Ceramic terminal blocks remain the uncompromising choice for high-temperature environments exceeding 150°C, offering superior thermal stability, excellent dielectric properties, and decades-long reliability in harsh conditions. UKK power distribution blocks excel in standard industrial panels requiring efficient multi-branch power distribution, combining modular flexibility with simplified installation and reduced panel complexity.

Successful terminal block specification requires systematic evaluation of electrical parameters (voltage, current, conductor sizing), environmental conditions (temperature, chemical exposure, vibration), installation constraints (space, mounting options, accessibility), and total cost of ownership. The 150% current safety margin rule, proper torque application, and standards compliance verification form the foundation of reliable industrial panel design.

For applications involving furnaces, kilns, or extreme thermal cycling, ceramic terminal blocks provide the necessary thermal performance margins. For automation panels, motor control centers, and power distribution systems operating below 90°C ambient, UKK terminal blocks deliver superior installation efficiency and space optimization.

Ready to specify the optimal terminal block solution for your industrial panel project? Contact VIOX Electric’s technical team for application-specific guidance, certified product datasheets, and custom configuration support. Our engineering experts provide comprehensive terminal block selection assistance backed by 40+ years of manufacturing expertise and global standards compliance. Explore our complete terminal block portfolio or request technical consultation for your specific application requirements.