Introduction

As photovoltaic installations scale in size and complexity, the solar combiner box has become an indispensable component for safe and efficient power consolidation. For commercial and utility-scale solar projects, 1000V DC systems have emerged as the industry standard, balancing cost efficiency, performance optimization, and component availability. A properly specified 1000V solar combiner box protects your investment, ensures code compliance, and prevents costly field failures that can halt operations.

For electrical contractors, EPC companies, and equipment distributors, selecting the right solar combiner box requires more than comparing price sheets. You need to verify voltage ratings, understand compliance requirements across multiple standards, evaluate environmental protection, and ensure every internal component can handle the demanding conditions of high-voltage DC solar applications.

This comprehensive guide covers the essential design considerations and compliance requirements for 1000V solar combiner boxes. Whether you’re specifying equipment for a 500kW commercial rooftop or a multi-megawatt solar farm, these criteria will help you make informed decisions that pass inspection, protect personnel, and deliver reliable performance over decades of operation.

What Is a Solar Combiner Box?

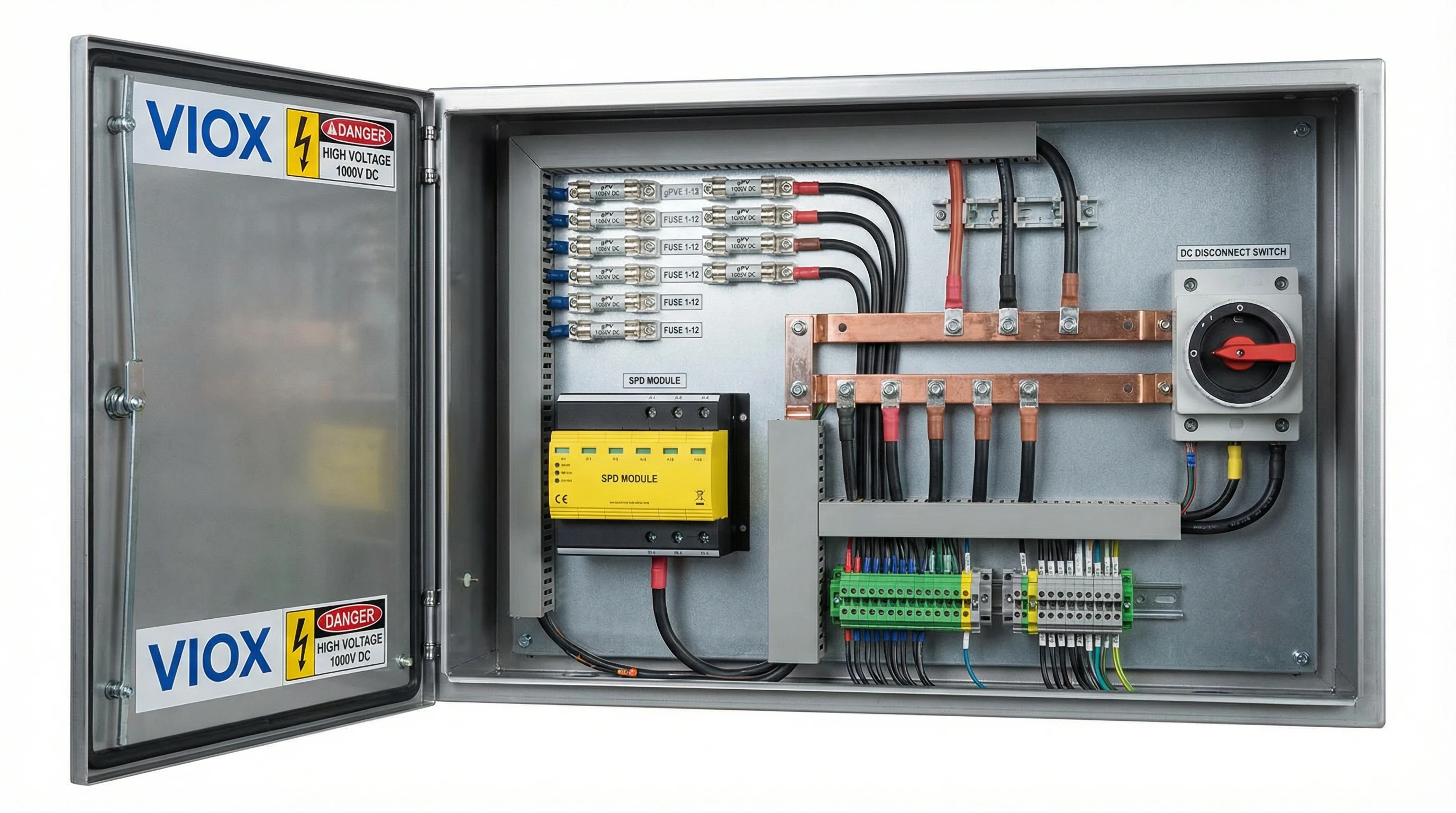

A solar combiner box is a weatherproof electrical enclosure that consolidates DC output from multiple photovoltaic strings into a single or reduced number of outputs feeding the inverter. In large-scale solar installations with dozens or hundreds of panel strings, running individual conductors from each string to the inverter would be impractical and prohibitively expensive.

The combiner box serves three critical functions:

Power Consolidation: Aggregates current from 4-24 individual strings (depending on configuration) into a unified output, dramatically reducing cable runs and connection points between the solar array and inverter equipment.

Overcurrent Protection: Houses string-level fuses or circuit breakers that protect individual circuits from reverse current, ground faults, and short-circuit conditions. This localized protection prevents a fault in one string from compromising the entire array.

System Isolation: Provides accessible disconnecting means for safe maintenance, troubleshooting, and emergency shutdown. The DC disconnect switch allows technicians to isolate the combiner box from the rest of the system without approaching energized inverter equipment.

Modern PV combiner boxes also integrate surge protection devices (SPDs) to safeguard against lightning-induced transients, and increasingly include string monitoring capabilities that track voltage and current for each input—enabling rapid fault diagnosis and performance optimization.

For a 1000V DC system, every component within the combiner box (from terminal blocks to busbars to protective devices) must be rated to safely handle the elevated voltage and withstand the unique challenges of DC fault interruption, which differs significantly from AC switching.

Why 1000V DC Systems Dominate Commercial Solar

The progression from 600V to 1000V DC system architecture represents one of the most significant cost-reduction advances in commercial solar engineering. Understanding why 1000V became the standard for commercial and industrial installations helps clarify the design requirements for combiner boxes.

Reduced Balance of System (BOS) Costs: Higher system voltage allows more solar modules to be connected in series within a single string. A 1000V system can accommodate 25-30 modules per string (depending on module specifications), compared to 15-18 modules in a 600V system. Fewer strings mean:

- Fewer combiner boxes for the same array capacity

- Shorter cable runs and reduced conductor costs

- Lower labor hours for installation and connection

- Simplified array layout and reduced mounting hardware

For a 1MW commercial installation, the BOS savings from moving to 1000V can reach 10-15% of total project cost.

Lower Resistive Losses: Basic electrical physics dictates that power loss in conductors is proportional to current squared (I²R losses). By operating at higher voltage, you transmit the same power at lower current. A 1000V system carries 40% less current than a 600V system for identical power output, resulting in measurably lower energy losses and improved system efficiency.

Optimal Technology Sweet Spot: While 1500V systems offer additional efficiency gains and are increasingly deployed in utility-scale solar farms, 1000V systems represent the optimal balance for commercial and mid-scale utility applications:

- Component Availability: Mature supply chains for 1000V-rated combiner boxes, fuses, disconnects, and monitoring equipment

- Cost Balance: 1000V components are significantly more affordable than 1500V equivalents while delivering most of the efficiency benefits

- Proven Reliability: Extensive field history with 1000V systems provides confidence in long-term performance

- Code Acceptance: Widely recognized and accepted by electrical inspectors and AHJs (Authorities Having Jurisdiction)

For residential installations, 600V remains the maximum allowed voltage in most jurisdictions due to safety regulations. But for commercial rooftops, ground-mount solar farms, and industrial installations, 1000V DC architecture has become the engineering standard that delivers maximum value.

Key Design Considerations for 1000V Solar Combiner Boxes

Proper combiner box specification balances electrical performance, environmental protection, thermal management, and future serviceability. Each consideration directly impacts system safety and long-term reliability.

String Configuration and Current Rating

The combiner box must accommodate your array’s string configuration and handle the combined short-circuit current with appropriate safety margins.

Input Capacity: Standard combiner boxes accept 4, 6, 8, 12, 16, or 24 string inputs. Select capacity based on your current array size plus 10-20% expansion margin. Oversizing by one or two extra positions provides flexibility for future array additions without requiring combiner box replacement.

Current Calculation: Each string input should be protected by an overcurrent device rated at 125% of the string’s short-circuit current (Isc), per NEC Article 690 requirements. The main busbar and output must handle the sum of all string currents multiplied by 1.25. For example, if you have 12 strings each producing 10A Isc:

- Individual string protection: 10A × 1.25 = 12.5A (select 15A fuse)

- Main busbar rating: 12 strings × 10A × 1.25 = 150A minimum

Voltage Verification: All components must be rated for at least 1000V DC, but best practice requires verifying against your array’s maximum open-circuit voltage (Voc) at the coldest expected ambient temperature. Module Voc increases with colder temperatures, and string Voc is the sum of all series-connected module voltages. Always add a 25% safety margin to calculated maximum voltage when specifying components.

Environmental Protection (IP and NEMA Ratings)

Solar combiner boxes face harsh outdoor conditions—UV exposure, temperature extremes, dust, precipitation, and in some environments, salt spray or chemical exposure.

Minimum Protection Level: For standard outdoor installations, specify IP65 rating (dust-tight, protected against water jets) as the absolute minimum. This ensures the enclosure can withstand rain, snow, and routine washdown without water ingress.

Enhanced Protection: For harsh environments, upgrade to IP66 (powerful water jets) or IP67 (temporary immersion). Coastal installations, industrial sites with chemical exposure, or areas prone to flooding require these higher protection levels.

NEMA Ratings: North American specifications often reference NEMA ratings:

- NEMA 3R: Rainproof and sleet-resistant (minimum for outdoor use)

- NEMA 4/4X: Watertight and corrosion-resistant (recommended for most installations; 4X indicates stainless steel construction)

Gasket Integrity: The enclosure door gasket is the primary line of defense against moisture ingress. Verify the manufacturer uses UV-resistant silicone or EPDM gaskets that maintain compression over decades of thermal cycling.

Thermal Management and Ventilation

Current flowing through busbars, terminals, and protective devices generates heat. In a sealed enclosure under direct sunlight, internal temperatures can exceed 70°C (158°F), accelerating component degradation and potentially causing nuisance tripping.

Ambient Temperature Rating: Verify all internal components are rated for the expected operating temperature range. Quality combiner boxes specify operation from -40°C to +70°C, covering extreme climate conditions.

Ventilation Strategy: While maintaining IP rating integrity, the enclosure should incorporate passive ventilation when possible. Some designs use breathable membranes that equalize pressure while blocking moisture, or strategic vent placement that prevents direct water entry.

Installation Location: Position the combiner box in a shaded location when feasible—north-facing walls (northern hemisphere) or beneath array structures. Avoid mounting on metal surfaces that conduct additional heat into the enclosure.

Color Selection: White or light-gray enclosures reflect more solar radiation than dark colors, reducing internal temperature rise by 5-10°C in direct sunlight.

Accessibility and Maintenance Considerations

Your combiner box will require periodic inspection, occasional fuse replacement, and potential troubleshooting. Design for safe, convenient access.

Mounting Height: Install between 1.2m-1.8m (4-6 feet) above grade for comfortable access without ladders while remaining above typical snow accumulation and flood levels.

Clear Working Space: NEC and IEC standards require minimum working clearances around electrical equipment. Ensure at least 1 meter of clear space in front of the combiner box for safe maintenance.

Labeling and Documentation: The exterior should display clear warning labels indicating DC voltage, maximum power, and disconnect procedures. Internally, label each string input with its corresponding array location. Affix a weatherproof pocket containing wiring diagrams and emergency contact information.

Tool-Free Access: Quality designs use quarter-turn latches or captive screws rather than requiring specialized tools for door opening, facilitating faster routine inspections.

Essential Components of a 1000V Solar Combiner Box

Every component must be specifically rated for 1000V DC photovoltaic applications. Using AC-rated components or devices designed for 600V systems creates serious safety hazards.

String Overcurrent Protection: Fuses vs. Circuit Breakers

Individual string protection is your first line of defense against overcurrent conditions.

DC Fuses (gPV Class): The most common choice, solar-rated fuses comply with IEC 60269-6 and are specifically engineered for photovoltaic applications. Key specifications:

- Voltage rating: 1000V DC minimum (1200V DC preferred for safety margin)

- Current rating: 125% of string Isc (common ratings: 10A, 15A, 20A, 25A, 32A)

- Breaking capacity: Minimum 33kA to safely interrupt maximum prospective fault current

- gPV characteristic curve: Optimized for fast breaking at low overcurrents typical in PV systems

Fuses provide reliable, low-cost protection without maintenance requirements. However, fuse replacement requires the combiner box to be de-energized and fuses properly stored on-site.

DC Circuit Breakers: Higher initial cost but offering resetability and easier maintenance. When specifying DC breakers for solar applications, verify:

- Certification for PV use (not standard AC breakers repurposed)

- Breaking capacity at 1000V DC (substantially different from AC interruption)

- Trip curve appropriate for solar string currents

Some modern combiner boxes incorporate hybrid protection: fuses for primary overcurrent protection with circuit breakers serving as convenient disconnect means.

Surge Protection Devices (SPD)

Lightning strikes and grid transients can inject catastrophic overvoltages into your DC system. Quality SPDs are essential insurance.

Type and Class: For combiner boxes, specify Type 2 SPDs (per IEC classification), which protect against indirect lightning effects and switching transients. In regions with high lightning activity or exposed installations, consider Type 1 SPDs rated for direct lightning strikes.

Voltage Rating (Ucpv): The SPD’s Maximum Continuous Operating Voltage (MCOV) must exceed your array’s maximum Voc by at least 10%. For a 1000V system with 850V maximum string Voc, specify an SPD with minimum 935V MCOV (935V = 850V × 1.1).

Discharge Current: Minimum nominal discharge current (In) of 20kA per the 8/20 µs waveform is recommended. For exposed sites, 40kA provides additional safety margin.

Compliance: Verify certification to IEC 61643-31 (SPDs for photovoltaic installations) or UL 1449 for North American projects.

Installation: SPDs must be properly grounded with short, direct ground connections (minimize wire length to maintain effectiveness). Replace SPDs when their wear indicators signal end of life—typically after absorbing multiple surge events.

DC Disconnect Switch

A manually operated switch that provides visible isolation for maintenance safety.

Standards Compliance: Specify switches certified to IEC 60947-3 (DC switches for industrial use) or UL 98B (enclosed switches), specifically noting the DC-PV2 category for photovoltaic applications.

Ratings:

- Voltage: 1000V DC minimum

- Current: Must handle maximum combined array current with 1.25 safety factor

- Poles: 2-pole for ungrounded systems, 3-pole or 4-pole for grounded configurations

Visible Break: The switch should provide visible verification that contacts are open—either through a window in the enclosure or a clearly labeled external indicator. Never rely solely on position indicators without visible confirmation.

Load Break Capability: Verify the switch is rated for breaking load current, not just isolation. Some disconnects are only rated for opening under no-load conditions, which is inadequate for emergency situations.

Busbars and Terminals

These unglamorous components carry the full system current and are common failure points when improperly specified.

Busbar Material: Copper or tin-plated copper busbars provide optimal conductivity. Aluminum is sometimes used in very large installations but requires careful attention to thermal expansion and connection methodology.

Current Capacity: Size busbars for at least 125% of maximum combined string current with derating for ambient temperature. For 150A total current at 40°C ambient, specify minimum 190A rated busbars.

Terminal Blocks: Must be rated for 1000V DC with appropriate current capacity. Spring-clamp terminals provide more reliable connections than screw terminals, maintaining contact pressure through thermal cycling. Verify compatibility with your conductor sizes (typically 4-10mm² for string wiring).

Optional: String Monitoring Systems

Advanced combiner boxes integrate monitoring hardware that measures voltage and current for each string, enabling:

- Real-time fault detection and alerts

- Performance optimization by identifying underperforming strings

- Predictive maintenance based on gradual degradation patterns

- Compliance with insurance requirements for large installations

While adding 15-30% to combiner box cost, monitoring systems typically pay for themselves through reduced downtime and optimized energy production in commercial and utility-scale projects.

Compliance Standards & Certifications You Must Verify

Certifications are not suggestions—they represent documented proof that equipment has survived rigorous testing protocols. For 1000V solar combiner boxes, verify compliance with regional standards before procurement.

IEC Standards (International and European Markets)

IEC 60947-3: Governs DC switches and disconnectors, ensuring they can safely break and isolate PV loads. Verify the disconnect switch carries DC-PV2 certification, indicating suitability for high-voltage solar applications with significant arc generation during switching.

IEC 60269-6: Specifies requirements for solar fuses (gPV class), ensuring they have appropriate breaking capacity at low overcurrents typical in photovoltaic systems. Standard AC fuses cannot safely interrupt DC fault currents.

IEC 61439-1/2: Modern combiner boxes are increasingly certified as complete low-voltage switchgear assemblies under this standard. IEC 61439-2 verifies thermal and mechanical integrity of the entire assembly through type testing, providing higher confidence than component-level certifications alone.

IEC 61643-31: Specific to surge protective devices in photovoltaic installations. SPDs must meet these requirements to ensure they can withstand the unique conditions of DC solar systems.

CE Marking: For European market installations, CE marking indicates the combiner box complies with applicable EU directives, including the Low Voltage Directive (LVD) and Electromagnetic Compatibility (EMC) Directive.

North American Standards (US and Canadian Markets)

UL 1741: The primary standard for distributed energy resource equipment, including solar combiner boxes. UL 1741 certification covers:

- Complete assembly testing (not just component certification)

- Construction and material suitability for intended environment

- Dielectric withstand testing to verify insulation integrity at high voltage

- Temperature rise testing confirming busbars and connections stay within safe thermal limits

- Short-circuit testing validating that overcurrent devices safely interrupt fault currents

Critical Note: Individual components carrying UL ratings does NOT certify the complete assembly. The entire combiner box assembly must be UL 1741 listed with a specific model number and configuration matching your project requirements.

NEC Article 690 (Installation Requirements): While not a product standard, NEC Article 690 dictates how combiner boxes must be installed and integrated:

- Overcurrent devices rated at 125% of maximum calculated currents (690.8)

- Conductors sized at 125% of maximum currents before temperature correction (690.8)

- Required disconnecting means for isolation (690.13-690.17)

- Mandatory warning labels indicating DC voltage, maximum current, and arc flash hazard (690.56)

- Proper grounding and bonding requirements (690.43-690.45)

Your electrician must follow Article 690, but the combiner box manufacturer should provide installation instructions that facilitate compliance.

UL 98B: Covers enclosed switches, relevant when the combiner box incorporates a DC disconnect switch.

Verification Checklist

Before committing to a supplier, demand:

✓ Complete type test reports from ISO/IEC 17025 accredited laboratories

✓ Certification documents with specific model numbers matching your procurement

✓ Verification that certifications cover your voltage (1000V DC) and current requirements

✓ For UL 1741, confirm the ENTIRE assembly is listed, not just components

✓ CE Declaration of Conformity (European projects)

✓ Manufacturer’s ISO 9001 quality management certification

Viox Electric maintains complete IEC 60947-3, IEC 61439-2, and UL 1741 certifications for our 1000V solar combiner box product line. All certification documents and type test reports are available for buyer verification, and our manufacturing facility holds ISO 9001:2015 certification.

Material & Construction Requirements

Component specifications matter, but the physical enclosure and its construction quality determine whether your combiner box survives decades of outdoor exposure.

Enclosure Material Selection

Polycarbonate: Lightweight, excellent UV resistance, good impact strength, and naturally non-conductive. Preferred for small to mid-size combiner boxes (up to 16 strings). Quality polycarbonate enclosures use UV-stabilized resins that resist yellowing and embrittlement over 25+ years.

Fiberglass (GRP): Superior corrosion resistance and excellent for coastal or chemical environments. Heavier than polycarbonate but maintains structural integrity in extreme conditions. Often used in utility-scale installations.

Stainless Steel (304/316): Ultimate durability and EMC shielding properties. Type 316 stainless is essential for marine environments. Higher thermal conductivity requires careful attention to heat dissipation. The premium choice for mission-critical installations where reliability justifies higher cost.

Powder-Coated Aluminum: Lightweight and corrosion-resistant when properly coated. Requires quality powder coating with adequate thickness (minimum 80 microns) to prevent oxidation. Good balance of cost and performance.

Avoid: Standard painted steel enclosures, unless hot-dip galvanized with premium coating systems. Paint failure leads to rapid corrosion in outdoor solar environments.

UV Resistance and Weatherproofing

Direct sun exposure in solar installations subjects enclosures to intense UV radiation equivalent to decades of typical outdoor exposure.

UV Stabilization: Plastic enclosures must incorporate UV stabilizers throughout the material (not just surface treatment). Request data on accelerated UV aging tests showing minimal degradation after 2000+ hours of exposure.

Gasket Longevity: The door seal is your primary water barrier. Specify UV-resistant silicone or EPDM gaskets that maintain elasticity after years of thermal cycling. Budget gaskets become brittle and crack within 3-5 years.

Hardware Corrosion: All fasteners, hinges, and latches should be stainless steel (minimum grade 304). Zinc-plated hardware fails rapidly in outdoor solar environments.

Terminal and Busbar Specifications

Connection Reliability: Screw terminals must specify minimum/maximum torque values (typically 2.5-3.5 N⋅m for string connections). Over-torquing damages terminals; under-torquing creates high-resistance connections that overheat.

Busbar Joints: Where busbars connect, the joint should use tin plating or silver-loaded contact grease to prevent oxidation and ensure low contact resistance over decades.

Wire Compatibility: Verify terminals accept your conductor type and size. Most combiner boxes accommodate 2.5-10mm² conductors for string connections. Output terminals should accept larger conductors (16-35mm²) for main feeds to inverters.

Viox Electric combiner boxes use UV-stabilized polycarbonate or Type 316 stainless steel enclosures with silicone gaskets rated for 25+ year lifespan. All internal terminals are rated for 1000V DC with spring-clamp technology that maintains connection integrity through thermal cycling.

Solar Combiner Box Selection Checklist

Use this practical checklist when evaluating suppliers and specifying equipment:

Electrical Specifications

⬜ Voltage rating verified at 1000V DC minimum (1200V DC preferred)

⬜ Current capacity calculated at 125% of total string Isc

⬜ Input capacity matches string count plus 10-20% expansion margin

⬜ Fuses or breakers rated for gPV/photovoltaic DC applications

⬜ SPD specified with appropriate MCOV and discharge current rating

⬜ DC disconnect switch certified to IEC 60947-3 or UL 98B

Compliance and Certification

⬜ UL 1741 listing (North America) OR IEC 61439-2 certification (International)

⬜ Complete type test reports available for review

⬜ Certification covers specific model and configuration being purchased

⬜ Manufacturer holds ISO 9001 quality management certification

⬜ Installation complies with NEC Article 690 requirements

Environmental Protection

⬜ Minimum IP65 (NEMA 4) rating verified

⬜ Enclosure material appropriate for installation environment

⬜ UV resistance validated through aging tests

⬜ Temperature rating covers site ambient conditions (-40°C to +70°C recommended)

⬜ Gaskets use UV-resistant silicone or EPDM materials

Construction Quality

⬜ Busbars sized for current capacity with temperature derating

⬜ Terminal blocks rated for 1000V DC with appropriate current capacity

⬜ All hardware is stainless steel (minimum grade 304)

⬜ Clear labeling on all components and connection points

⬜ Accessible cable glands maintain IP rating integrity

Supplier Qualifications

⬜ Manufacturer has 5+ years of solar combiner box production experience

⬜ Reference projects in similar applications available

⬜ Technical support capable of application-specific guidance

⬜ Warranty minimum 5 years for outdoor solar installations

⬜ Lead times and MOQ requirements acceptable for project timeline

Specify with Confidence

The 1000V solar combiner box is not a commodity component—it’s the critical junction point where string-level protection, system isolation, and power consolidation converge. Proper specification requires verifying electrical ratings, confirming compliance with IEC and UL standards, evaluating environmental protection, and validating construction quality.

For commercial and utility-scale solar projects, the combiner box you select will operate outdoors for 25+ years, protecting multi-million dollar investments and ensuring personnel safety. Under-specification or procurement based solely on price creates risks far exceeding any initial cost savings.

Viox Electric has manufactured solar combiner boxes for 1000V and 1500V photovoltaic systems since 2012, with installations in over 40 countries spanning desert, coastal, and industrial environments. Our complete product line includes:

- 4-24 string capacity configurations

- IP65 and IP66 protection ratings

- Both polycarbonate and stainless steel enclosures

- UL 1741 and IEC 61439-2 certified models

- Optional integrated string monitoring

- Custom branding and configuration for OEM partners

Every Viox combiner box ships with complete type test reports, installation documentation, and technical support from our experienced solar engineering team.

Contact Viox Electric for 1000V Solar Combiner Box Solutions

Whether you’re an EPC company specifying equipment for a 5MW solar farm, a distributor building your product portfolio, or an electrical contractor seeking reliable suppliers, Viox Electric provides the quality, compliance, and support you need.

Request:

- Technical specifications and datasheets for our complete combiner box line

- Project-specific quotes with volume pricing

- Certification documents and type test reports

- Sample units for evaluation

- Custom configuration for OEM applications

Viox Electric Company

Email: [email protected]

Phone: +86-18066396588

Website: www.viox.com

Secure your 1000V solar combiner box supply today and build photovoltaic installations with confidence.