Ground Fault Circuit Interrupters (GFCIs) represent one of the most critical safety innovations in electrical protection systems. Since their widespread adoption in the 1970s, GFCI devices have prevented thousands of electrocutions and significantly reduced electrical shock incidents in commercial and industrial facilities. However, when a GFCI outlet becomes wet—whether from flooding, equipment leaks, or environmental conditions—immediate and proper response is essential to maintain facility safety and electrical system integrity.

Water exposure to GFCI outlets creates serious hazards including electrical shock risk, potential equipment damage, fire hazards, and system downtime. For facility managers, electrical contractors, and industrial operations teams, understanding the correct emergency response procedures can prevent injury, minimize equipment loss, and ensure regulatory compliance with National Electrical Code (NEC) requirements.

How GFCI Technology Works: Technical Overview

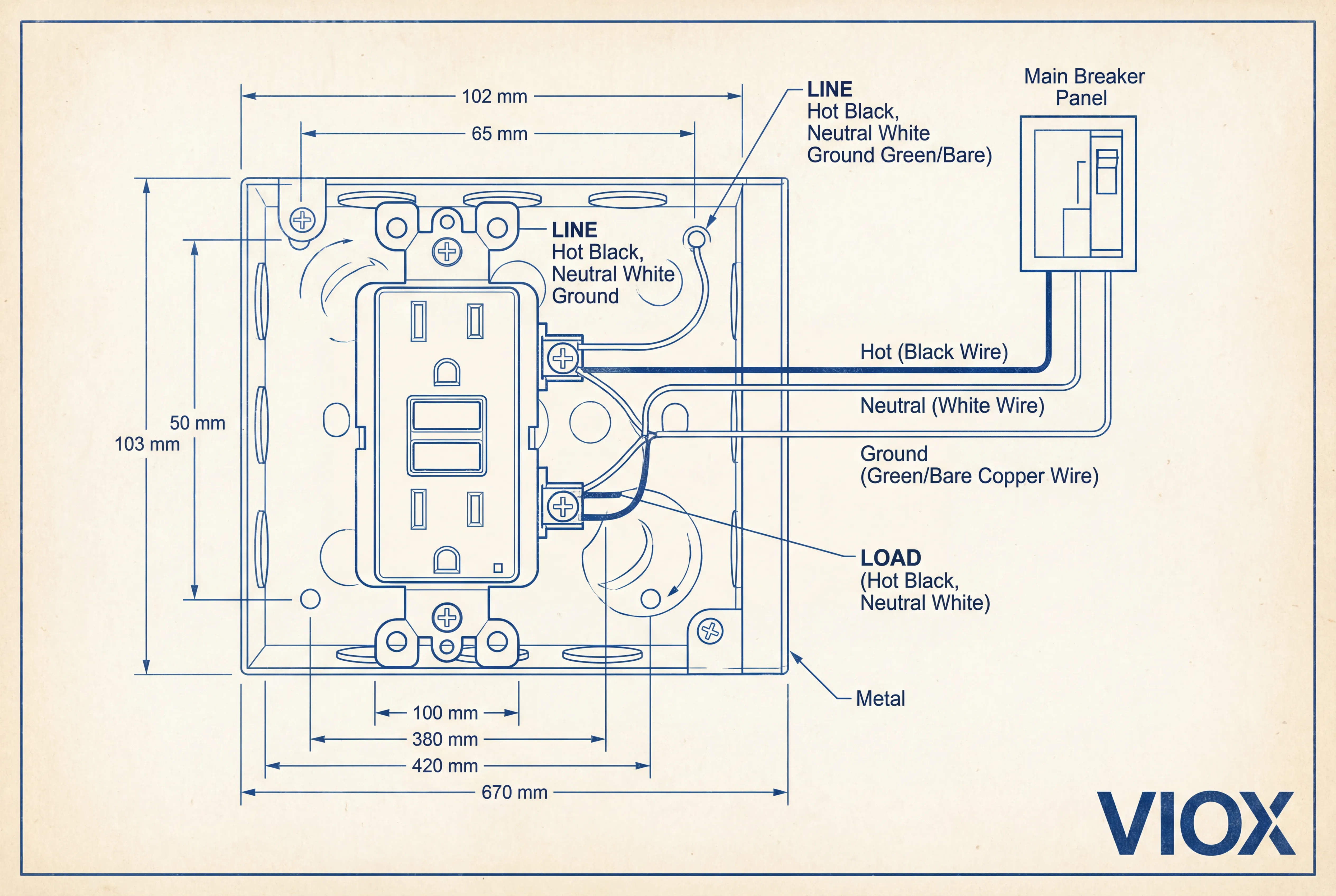

GFCI devices function by continuously monitoring electrical current balance between the hot (energized) conductor and the neutral return conductor. Under normal operating conditions, current flowing through both conductors should be identical. The GFCI’s internal sensing mechanism detects imbalances as small as 4-6 milliamperes (mA)—far below the threshold that could cause serious injury or electrocution.

When the GFCI detects a ground fault—indicating current is escaping through an unintended path such as water, a person, or damaged equipment—it interrupts the circuit within 25-40 milliseconds. This response time is critical; electrical current above 10mA can cause muscle contractions preventing a person from releasing the electrical source, while currents above 75mA can cause ventricular fibrillation and death.

Key GFCI Components and Operation

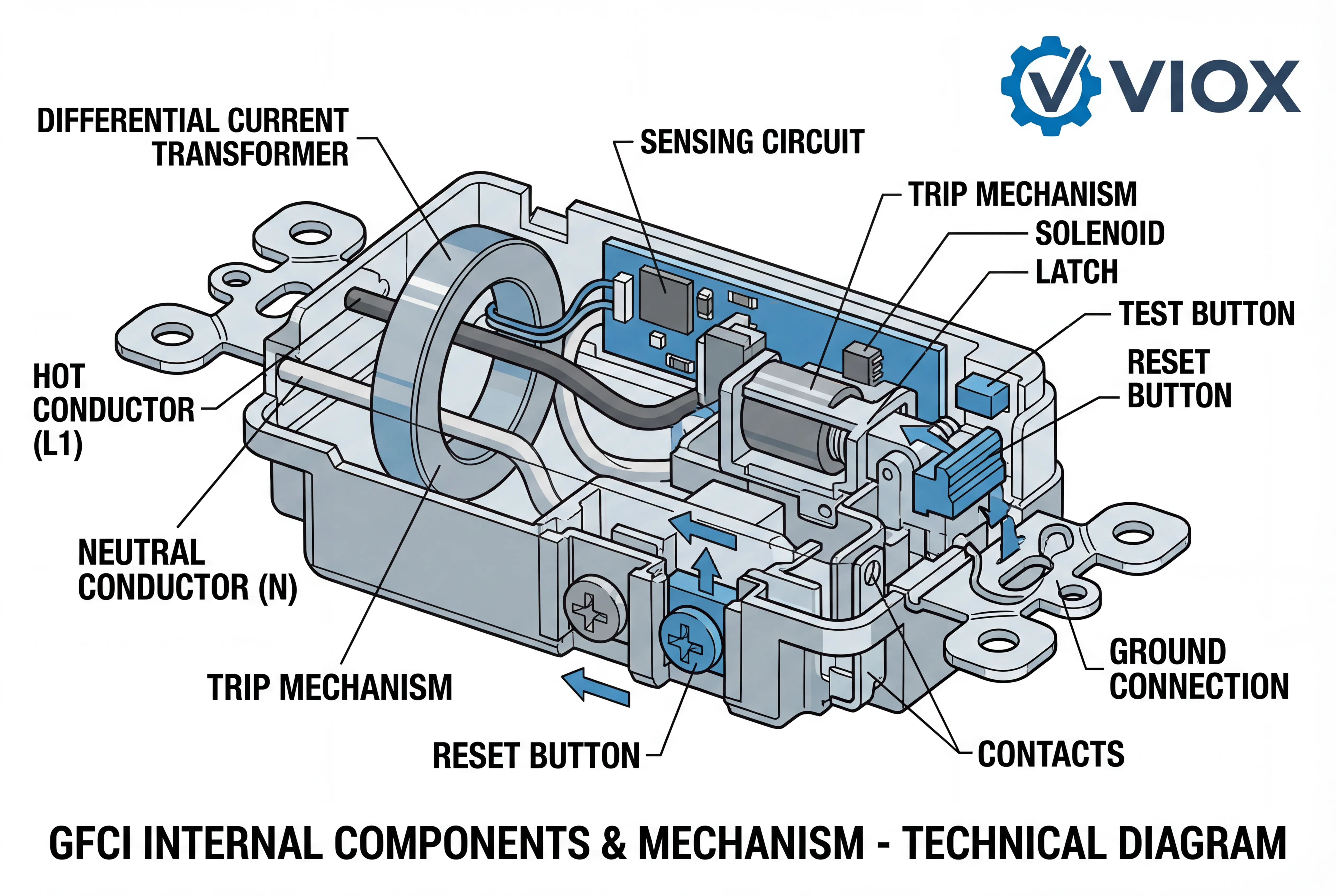

The typical GFCI outlet contains several essential components:

- Differential current transformer: Monitors current balance between hot and neutral conductors

- Sensing circuit: Detects imbalances and triggers the trip mechanism

- Trip mechanism: Mechanical relay that interrupts circuit power

- Test and reset buttons: Allow manual testing and circuit restoration

- Self-test circuitry (modern units): Automatically verifies GFCI functionality

VIOX Electric’s commercial-grade GFCI products incorporate advanced sensing technology with enhanced environmental protection ratings, specifically engineered for demanding industrial applications where moisture exposure is common.

Immediate Response Protocol: What to Do When a GFCI Gets Wet

When you discover a wet GFCI outlet, following the correct sequence of actions is critical for safety and equipment preservation. Never touch a wet electrical outlet or attempt to dry it while power is active.

Step 1: Shut Down the GFCI Outlet

If the GFCI has not automatically tripped, manually deactivate it immediately by simultaneously pressing both the TEST and RESET buttons. This action should interrupt power to the outlet. In many cases, water exposure will cause the GFCI to trip automatically, but manual verification is essential for safety.

Important: Do not assume the GFCI has tripped even if the outlet appears non-functional. Always verify power status using appropriate testing equipment.

Step 2: De-Energize the Circuit at the Breaker Panel

Proceed to your electrical panel and locate the circuit breaker controlling the affected GFCI outlet. Switch the breaker to the OFF position. This step is critical even if the GFCI appears to have tripped, as it provides an additional layer of protection during inspection and drying procedures.

For facilities with multiple wet outlets or extensive water damage, consider shutting down the main breaker to ensure complete system safety. Use a voltage tester or multimeter to confirm the circuit is de-energized before proceeding.

Step 3: Conduct Thorough Visual Inspection

Once power is confirmed OFF, carefully inspect the outlet and surrounding area:

- Check for visible water accumulation inside the outlet box

- Look for signs of corrosion on terminals and conductors

- Examine the outlet face for cracks, discoloration, or physical damage

- Inspect the wall cavity (if accessible) for moisture infiltration

- Assess the extent of water exposure (surface moisture vs. submersion)

Document the damage with photographs for insurance purposes and maintenance records. If water has penetrated deeply into the wall cavity or if multiple outlets are affected, professional assessment is strongly recommended.

Step 4: Allow Proper Drying Time

Drying time varies significantly based on exposure severity, ambient conditions, and outlet construction. Never attempt to restore power to a wet or damp outlet.

Natural drying method: Remove the outlet cover plate and allow air circulation for 24-48 hours minimum. Position fans to promote airflow without directly blowing into the electrical box, which could drive moisture deeper into the system.

Accelerated drying method: Use a cool-setting hair dryer or compressed air at low pressure to remove surface moisture. Avoid heat sources that could damage outlet components or surrounding materials. Professional-grade desiccant systems may be appropriate for severe water exposure.

Step 5: Testing and Verification

After the drying period, conduct comprehensive testing before restoring power:

- Visual confirmation: Ensure no visible moisture remains in outlet box or on components

- Resistance testing: Use a megohmmeter to verify insulation resistance between conductors

- Continuity testing: Check conductor integrity and proper connections

- GFCI functionality test: After cautiously restoring power, use the TEST button to verify proper trip function

- Load testing: Monitor the outlet under normal operating conditions for several hours

If the GFCI fails any test, replacement is mandatory. Do not attempt to bypass safety features or operate compromised equipment.

GFCI Types and Applications: Selection Guide

Different GFCI configurations serve specific applications in commercial and industrial environments. Understanding these options helps facility managers select appropriate protection for various locations.

| GFCI Type | Installation Location | Protection Scope | Typical Applications | VIOX Product Features |

|---|---|---|---|---|

| Receptacle-Type | Individual outlets | Single outlet or downstream devices | Bathrooms, kitchens, temporary power | Weather-resistant housings, 20A rating |

| Circuit Breaker | Electrical panel | Entire circuit branch | Multiple outlets, whole-room protection | Self-test technology, remote monitoring |

| Portable/Temporary | Mobile applications | Connected equipment only | Construction sites, outdoor events | Rugged construction, NEMA 4X rated |

| Cord-Connected | Equipment cord | Specific appliance | Pool equipment, portable tools | Industrial-duty cord, impact resistance |

Drying Times and Environmental Factors

The time required for a GFCI outlet to safely dry depends on multiple variables. Rushing this process creates serious safety risks and may result in equipment failure, electrical fires, or injury.

| Damage Severity | Drying Time | Conditions Required | Recommended Actions |

|---|---|---|---|

| Minor Surface Moisture | 10-12 hours | Low humidity, good airflow | Natural air drying, verify with visual inspection |

| Moderate Exposure | 24-48 hours | Temperature 65-75°F, humidity < 50% | Fan-assisted drying, remove cover plate |

| Significant Submersion | 48-72+ hours | Controlled environment, professional monitoring | Dehumidification equipment, component inspection |

| Extensive Water Damage | Replace immediately | N/A | Professional assessment, likely replacement required |

Critical factors affecting drying time:

- Ambient temperature: Higher temperatures accelerate evaporation but should not exceed 85°F to prevent damage

- Relative humidity: Lower humidity levels (below 40%) significantly reduce drying time

- Air circulation: Adequate airflow is essential; stagnant air prolongs drying

- Water type: Clean water dries faster than contaminated water with mineral deposits or sewage

- Box material and design: Metal boxes with drainage holes dry faster than plastic enclosures

- Wall cavity moisture: Hidden moisture behind walls extends drying requirements

Common Causes of GFCI Water Exposure

Understanding how GFCI outlets become wet helps facilities implement effective prevention strategies:

Facility-Related Causes:

- Roof leaks allowing water to track down through walls

- HVAC condensation drain failures or overflow

- Plumbing leaks from pipes, fixtures, or appliances

- Fire suppression system activation or testing

- Flooding from weather events or drainage failures

Equipment-Related Causes:

- Manufacturing process water spray or mist

- Pressure washing or steam cleaning operations

- Beverage or liquid dispensing equipment leaks

- Laboratory or medical facility liquid spills

- Food service cleaning and sanitization procedures

Environmental Causes:

- High humidity environments causing condensation

- Direct rain exposure on outdoor or poorly protected outlets

- Snow or ice melt infiltration

- Groundwater seepage in below-grade installations

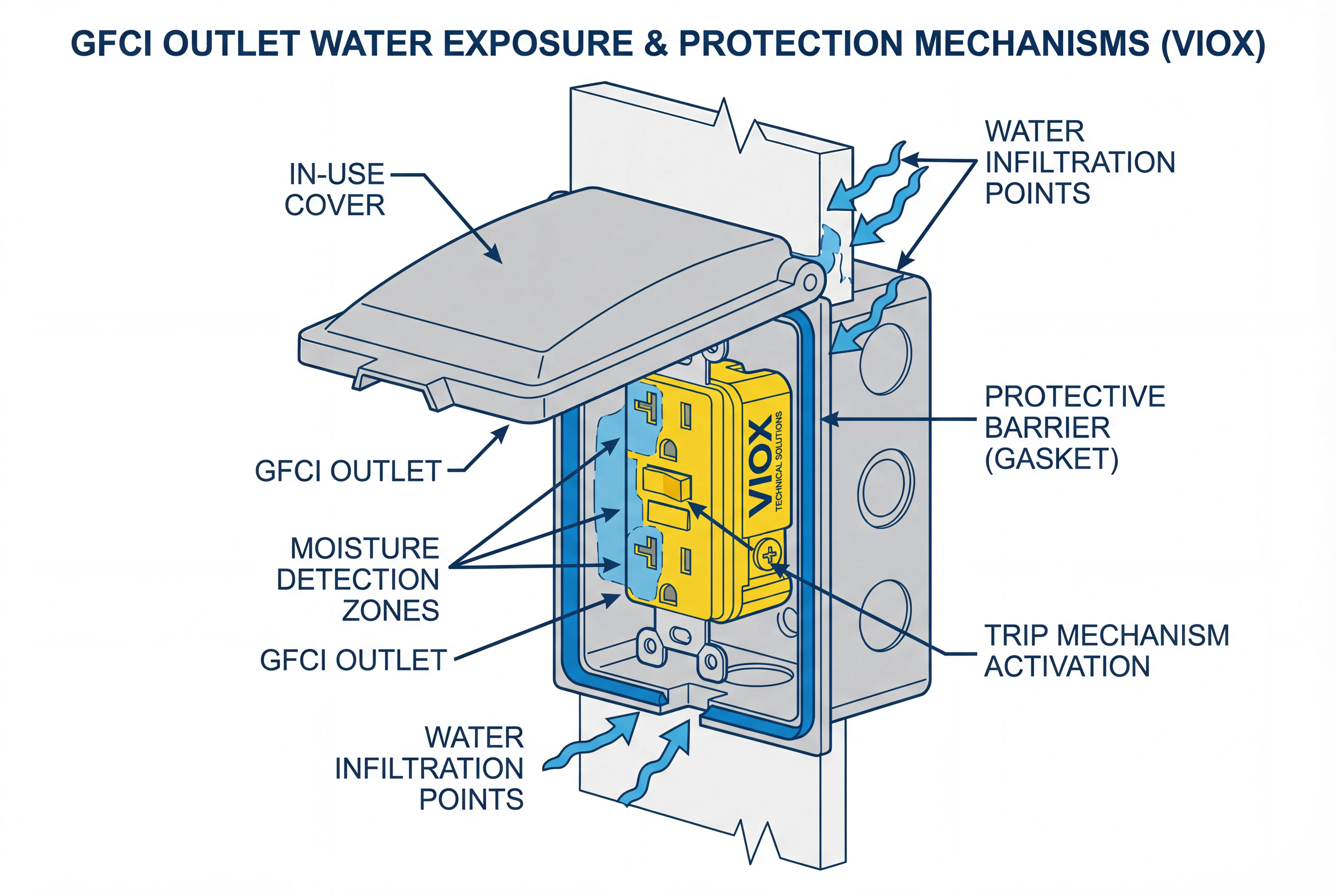

VIOX Electric’s commercial GFCI solutions address these challenges with IP67/NEMA 4X rated enclosures specifically designed for harsh industrial environments where water exposure is inevitable.

Repair vs. Replacement Decision Matrix

Determining whether to repair or replace a water-damaged GFCI requires careful evaluation of multiple factors. In most cases, replacement is the safer and more cost-effective option.

When Replacement is Mandatory:

- Visible corrosion on terminals, conductors, or internal components

- Failed functionality testing after thorough drying

- Physical damage including cracks, discoloration, or melted components

- Repeated water exposure events affecting the same outlet

- Age exceeding 10-15 years, regardless of apparent functionality

- Contaminated water exposure (sewage, chemicals, saltwater)

- Insurance or code compliance requirements

When Repair May Be Considered:

- Minor surface moisture with no penetration into components

- Immediate post-exposure intervention preventing internal damage

- Recently installed outlets (less than 2 years) with minimal exposure

- Clean water exposure with proper drying protocol followed

- Professional assessment confirms integrity of all components

Cost-Benefit Analysis: While replacement may seem more expensive initially, the liability risks and potential for system failure make it the prudent choice in commercial and industrial settings. VIOX Electric recommends establishing a replacement protocol rather than attempting repairs on water-compromised GFCIs.

GFCI Testing Procedures and Safety Verification

Regular testing ensures GFCI protection remains effective, particularly after water exposure incidents. NEC guidelines recommend monthly testing for critical protection circuits.

| Test Method | Purpose | Frequency | Required Equipment | Pass Criteria |

|---|---|---|---|---|

| Manual Button Test | Verify trip mechanism | Monthly | None (built-in buttons) | Outlet trips when TEST pressed, restores with RESET |

| Plug-In Tester | Confirm wiring and ground | After installation, quarterly | GFCI receptacle tester | Device indicates proper wiring, triggers trip |

| Multimeter Testing | Measure voltage and continuity | After water exposure | Digital multimeter | 0V when tripped, proper voltage when reset |

| Megohmmeter Test | Verify insulation resistance | Post-water exposure | Megger or insulation tester | >1 MΩ between conductors and ground |

| Trip Time Testing | Confirm response speed | Annual, professional service | Specialized GFCI analyzer | Trip within 25-40 milliseconds |

Prevention Strategies for Commercial and Industrial Facilities

Proactive measures significantly reduce GFCI water exposure incidents and associated downtime:

Installation Best Practices:

- Install weather-resistant GFCI outlets (WR marking) in all outdoor and wet locations

- Use appropriate in-use covers that protect outlets even when cords are connected

- Position outlets above typical flood levels (minimum 18 inches above floor in flood-prone areas)

- Ensure proper sealing around outlet boxes and conduit entries

- Implement secondary containment in areas with liquid handling

Maintenance Protocols:

- Conduct quarterly visual inspections of all GFCI outlets in wet locations

- Test GFCI functionality monthly using the TEST button

- Replace outlets showing signs of wear, damage, or approaching 10-year service life

- Document all testing and maintenance activities for compliance records

- Train facility staff on proper GFCI operation and emergency procedures

Environmental Controls:

- Maintain facility humidity levels below 60% where possible

- Ensure adequate ventilation in moisture-prone areas

- Address plumbing and roof leaks promptly

- Install water detection systems in critical electrical rooms

- Implement preventive maintenance schedules for equipment that could leak

Design Considerations:

VIOX Electric recommends incorporating GFCI protection at both the circuit breaker and receptacle level for critical applications, providing redundant protection in high-risk environments such as food processing facilities, commercial kitchens, healthcare facilities, and outdoor industrial operations.

NEC Requirements and Compliance Considerations

The National Electrical Code (NEC) mandates GFCI protection in specific locations where water and electricity may intersect. Compliance with these requirements is not optional—it is essential for facility safety, insurance coverage, and legal liability protection.

Current NEC GFCI Requirements (2023 Edition):

- All 125-volt, 15- and 20-ampere receptacles in bathrooms

- Kitchen receptacles serving countertop surfaces

- Outdoor receptacles accessible at grade level

- Garages, accessory buildings, and unfinished basements

- Crawl spaces and areas at or below grade level

- Laundry areas, utility rooms, and sump pump receptacles

- Receptacles within 6 feet of sinks, bathtubs, or shower stalls

For commercial and industrial facilities, additional considerations apply including specialized equipment protection, temporary power installations, and maintenance area outlets.

Post-Water Exposure Compliance:

After a GFCI water exposure incident, facilities must ensure restored outlets meet all original code requirements. Documentation of testing and replacement decisions supports regulatory compliance and provides legal protection in the event of future incidents.

When to Call a Professional Electrician

While facility maintenance teams can handle minor GFCI issues, certain situations require professional electrical contractor intervention:

- Multiple outlets affected by water exposure

- Uncertain circuit identification or complex electrical systems

- Visible damage to wiring, conduit, or electrical panels

- Recurring GFCI trip issues indicating underlying problems

- Water exposure in electrical rooms or main distribution panels

- Insurance claim requirements for professional assessment and remediation

- Regulatory inspection preparation following major water events

- Facility expansion or GFCI system upgrades

VIOX Electric partners with qualified electrical contractors nationwide, providing technical support and professional-grade products for commercial and industrial GFCI applications. Our technical team offers consultation services for complex installations and water damage assessment.

Frequently Asked Questions

How long should I wait before using a GFCI outlet that got wet?

Wait a minimum of 24 hours for minor surface moisture, 48-72 hours for significant exposure. Never restore power until the outlet is completely dry and has passed visual inspection and electrical testing. When in doubt, replacement is safer than risking equipment failure or electrical hazards.

Can a GFCI outlet be damaged even if it still works after getting wet?

Yes. Internal components may suffer corrosion or degradation that isn’t immediately apparent. A GFCI that continues to function initially may fail unexpectedly later, leaving circuits unprotected. Water exposure, even if the outlet appears functional, typically warrants replacement in commercial settings.

Do GFCI outlets automatically turn off when they get wet?

GFCI outlets should trip automatically when water creates a ground fault condition. However, surface moisture or humidity may not always trigger the device. Never rely on automatic tripping—always manually verify power status and shut off the circuit breaker when water exposure occurs.

What is the difference between weatherproof and regular GFCI outlets?

Weather-resistant (WR) GFCI outlets feature enhanced internal sealing, corrosion-resistant components, and materials designed to withstand moisture, temperature extremes, and UV exposure. They are required by NEC for all outdoor locations and recommended for any wet or damp environments. VIOX weather-resistant models exceed minimum code requirements for industrial durability.

How often should GFCI outlets be replaced in wet locations?

Industry best practice recommends replacement every 10 years for standard environments, and 5-7 years for outlets in harsh conditions with frequent moisture exposure. Any outlet experiencing water submersion should be replaced regardless of age. Modern self-testing GFCI devices provide status indication when replacement is needed.

Can I use a standard outlet cover in wet locations, or do I need special protection?

Wet locations require weatherproof covers that maintain protection even when cords are plugged in (in-use covers). Standard covers that only protect unused outlets do not meet NEC requirements for outdoor or wet location applications. VIOX offers commercial-grade in-use covers rated for industrial environments with enhanced impact resistance and UV stability.

VIOX Electric specializes in commercial and industrial-grade electrical protection equipment, including advanced GFCI solutions engineered for demanding applications. Our technical support team provides consultation services for facility electrical safety, code compliance, and product selection. For more information about VIOX GFCI products or professional installation support, contact our commercial sales division.