Introduction: The Anatomy of Connection

When specifying terminal blocks for control panels, industrial automation systems, or power distribution applications, engineers often focus on current ratings, voltage classes, and wire compatibility. Yet the true performance—and potential failure points—reside in the terminal block’s internal construction. Understanding terminal block components isn’t academic; it’s essential for making informed specification decisions that affect installation efficiency, long-term reliability, and safety compliance.

Terminal blocks are engineered systems, not mere connectors. Each component serves a specific function: insulating housings prevent electrical shock, conductive busbars carry current, clamping mechanisms maintain contact pressure, and mounting systems ensure mechanical stability. The materials selected for each component—from glass-reinforced polyamide to chrome-nickel spring steel—determine performance under vibration, temperature extremes, and chemical exposure.

This guide provides a systematic breakdown of terminal block construction, examining each component’s function, materials, and standards requirements. Whether you’re designing a new control panel, selecting replacements for maintenance, or evaluating suppliers, this anatomy lesson will help you specify terminal blocks with confidence.

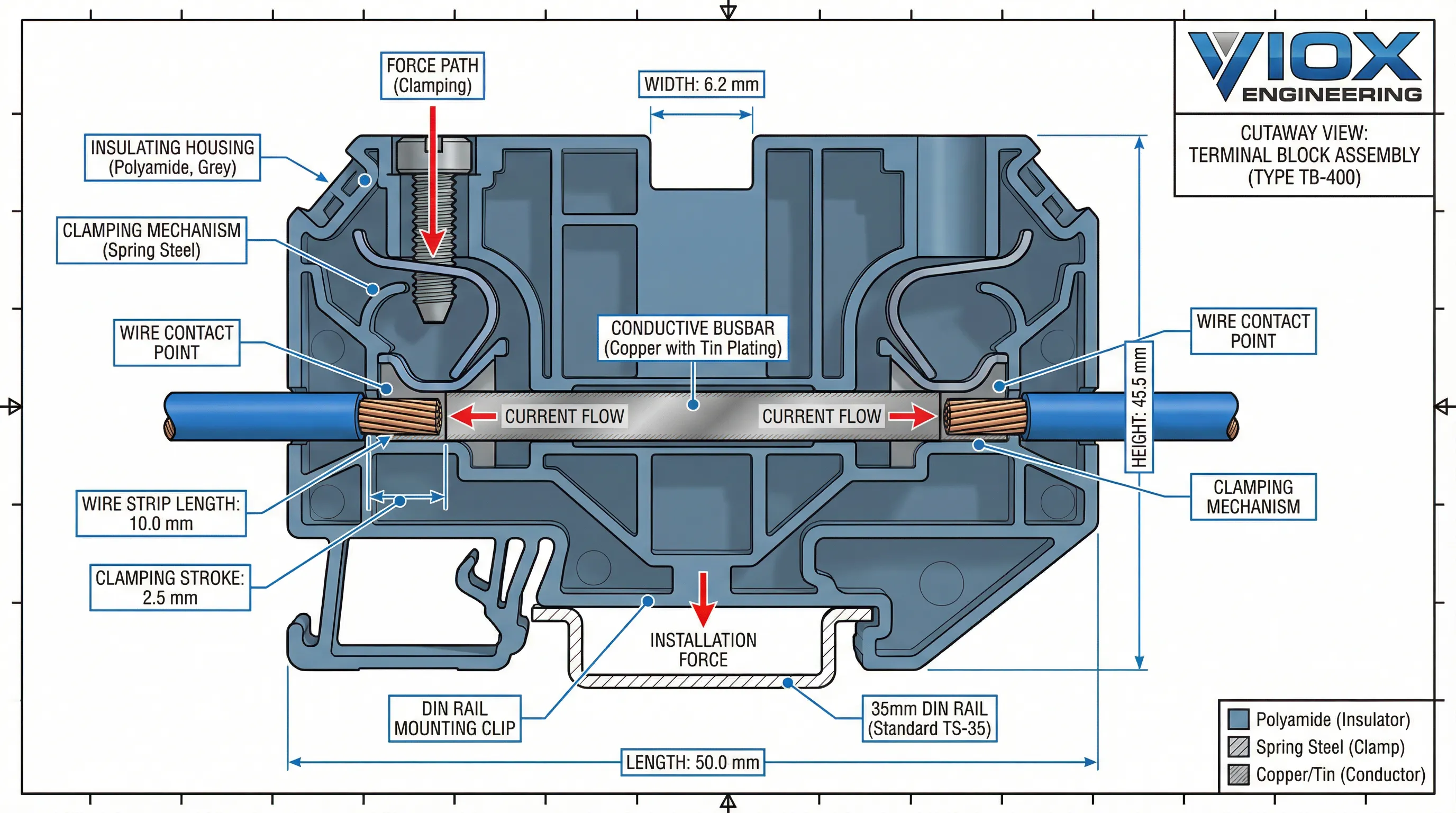

Core Components: What Makes a Terminal Block Work

Every terminal block, regardless of connection technology, consists of four primary functional components working together as an engineered system. Understanding these components—their functions, materials, and interactions—is fundamental to proper specification and application.

1. Insulating Housing (Body)

The housing serves as the non-conductive frame that contains all internal components while protecting users from electrical shock. More than just a plastic shell, the housing must withstand mechanical stress during installation, maintain dimensional stability across temperature ranges, and provide adequate creepage and clearance distances between conductors.

2. Conductive Busbar (Current-Carrying Element)

This metal “bridge” forms the electrical path between connected wires. The busbar’s material, cross-sectional area, and surface plating determine its current-carrying capacity, resistance, and corrosion resistance. Proper busbar design ensures minimal voltage drop and heat generation under load.

3. Clamping Mechanism

The clamping mechanism physically secures the wire to the busbar, maintaining constant contact pressure over time. Different technologies—screw, spring-cage, push-in—offer trade-offs between installation speed, vibration resistance, and wire compatibility.

4. Mounting System

Mounting systems attach terminal blocks to DIN rails, panels, or PCBs, providing mechanical stability and proper alignment. The mounting method affects installation density, accessibility for wiring, and resistance to vibration or mechanical shock.

These components work in concert: the housing insulates, the busbar conducts, the clamp secures, and the mounting system stabilizes. Material selection for each component creates a terminal block optimized for specific environmental conditions and performance requirements.

Table 1: Terminal Block Component Functions and Materials

| Component | Primary Function | Common Materials | Standards Requirements |

|---|---|---|---|

| Insulating Housing | Electrical insulation, mechanical protection, environmental resistance | Polyamide 6.6 (PA66), PBT, Polycarbonate (PC) | UL 94V-0 flame rating, IEC 60664-1 creepage/clearance |

| Conductive Busbar | Current carrying, low resistance path | Electrolytic copper, brass (tin/nickel/silver plated) | IEC 60947-7-1 current rating, temperature rise limits |

| Clamping Mechanism | Secure wire connection, maintain contact pressure | Screw: zinc-plated steel; Spring: chrome-nickel steel; Push-in: stainless steel | Mechanical endurance (IEC 60947-7-1), vibration resistance (IEC 60068-2-6) |

| Mounting System | Mechanical attachment, alignment, vibration resistance | Spring-steel clips, screw-type feet, snap-on designs | DIN rail standards (IEC 60715), retention force requirements |

| Auxiliary Parts | Additional functionality, marking, protection | Jumpers (copper/brass), end plates (PA66/PBT), marking tags | Compatibility with main components, secondary standards |

Housing & Insulation: Safety and Durability

The insulating housing is the terminal block’s first line of defense against electrical shock, environmental hazards, and mechanical damage. More than just a plastic shell, the housing must meet precise engineering requirements for dielectric strength, flame resistance, mechanical toughness, and dimensional stability across operating temperatures.

Material Selection: Engineering Thermoplastics vs. Thermosets

Industrial terminal blocks primarily use three engineering thermoplastics, each with distinct properties:

Polyamide 6.6 (Nylon 66) – The industry standard for general-purpose applications:

- Key Properties: High mechanical strength, flexibility (resists cracking during installation), excellent heat resistance (typically 125°C continuous)

- Common Use: Glass-reinforced versions (PA66 GF30) for added stiffness and dimensional stability

- Flame Rating: UL 94V-0 standard for self-extinguishing behavior

PBT (Polybutylene Terephthalate) – The choice for precision and moisture resistance:

- Key Properties: Low moisture absorption (<0.1%), exceptional dimensional stability, good chemical resistance

- Common Use: High-humidity environments, applications requiring tight tolerances

- Temperature Range: Typically 130-140°C continuous

Polycarbonate (PC) – For transparency and impact resistance:

- Key Properties: Excellent clarity, high impact strength, good thermal stability

- Limitations: Sensitive to certain chemicals (solvents, alkalis)

- Common Use: Transparent covers, applications requiring visual inspection

Critical Design Considerations

Creepage and Clearance Distances: The housing must maintain minimum distances between conductors based on voltage ratings (IEC 60664-1). Higher voltage blocks require larger physical dimensions.

Temperature Class: Housing materials must withstand maximum operating temperatures without deformation or loss of dielectric properties. Industrial applications typically require 105°C minimum, with 125°C becoming standard for modern equipment.

Flame Retardancy: UL 94V-0 certification indicates the material self-extinguishes within 10 seconds and doesn’t drip flaming particles—essential for control panel safety.

Chemical Resistance: Terminal blocks in chemical plants, marine environments, or food processing must resist oils, solvents, acids, and alkalis without degradation.

The housing’s material selection directly impacts installation experience (flexibility vs. rigidity), long-term reliability (moisture absorption), and safety compliance (flame ratings).

Clamping Mechanisms: Screw, Spring, and Push-in Technologies

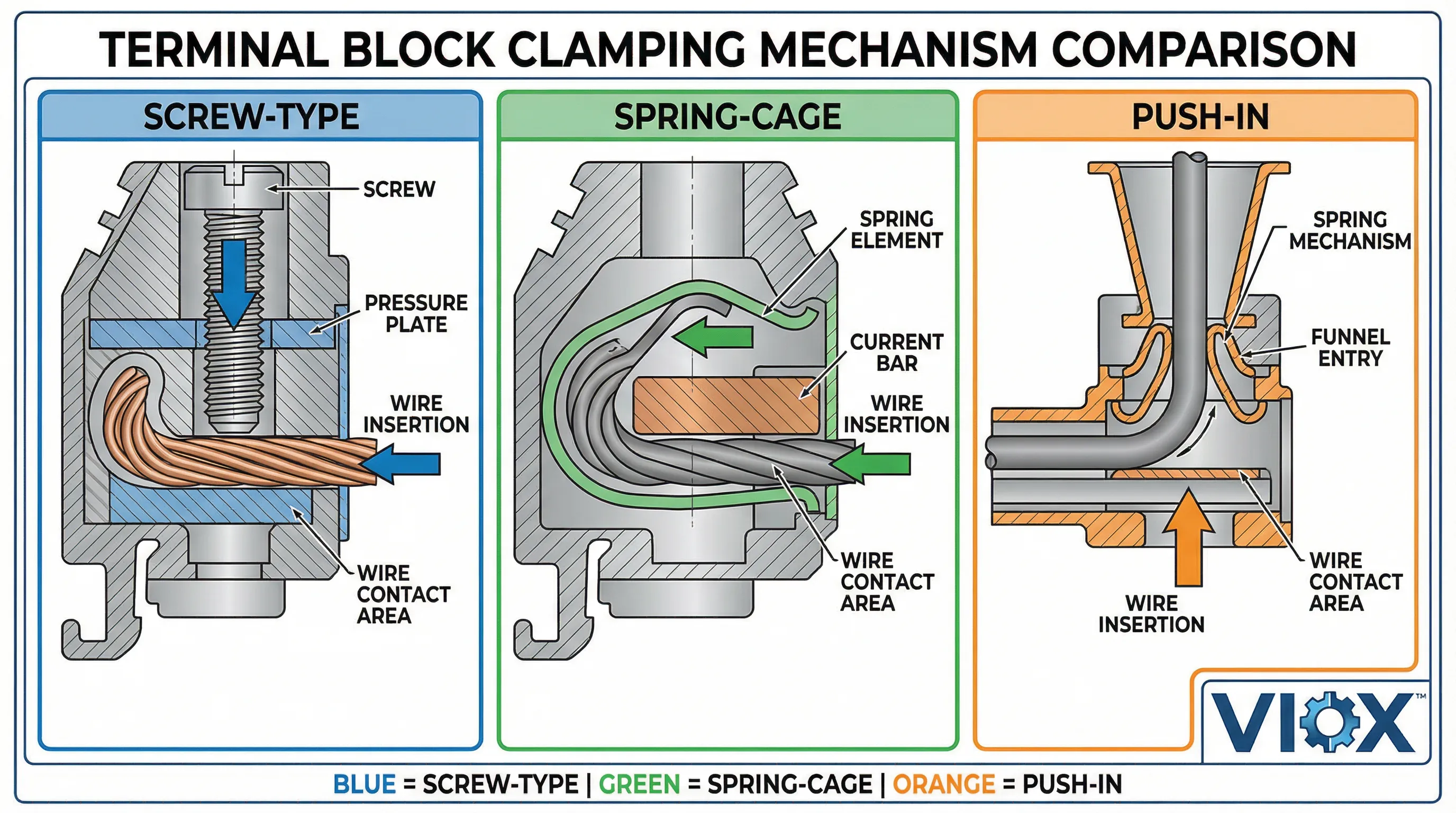

The clamping mechanism is the terminal block’s active component—the interface where wire meets busbar. Three primary technologies dominate industrial applications, each with distinct operating principles, advantages, and ideal use cases.

1. Screw-Type Clamping

Operating Principle: A hardened steel screw compresses the wire against the busbar through direct mechanical force. The screw applies pressure via a metal cage or pressure plate that distributes force across the conductor.

Key Components:

- Screw: Zinc-plated or galvanized steel for corrosion resistance

- Pressure Plate/Cage: Brass or steel to distribute clamping force

- Threaded Insert: Brass or steel for durability

Advantages:

- Universal wire compatibility (solid, stranded, fine-stranded)

- High clamping force for large conductors

- Visual verification of connection tightness

- Field serviceable with standard tools

Limitations:

- Installation time (requires torque-controlled tools)

- Vibration susceptibility (requires periodic retightening)

- Torque sensitivity (overtightening damages conductors)

2. Spring-Cage Clamping (CAGE CLAMP®)

Operating Principle: A chrome-nickel spring steel element provides constant pressure on the conductor. Insertion requires opening the spring with a tool; removal similarly requires tool operation.

Key Components:

- Spring Element: Chrome-nickel steel for elasticity and corrosion resistance

- Current Bar: Electrolytic copper with tinned surface

- Operating Lever: Integrated tool access point

Advantages:

- Maintenance-free (constant spring pressure)

- Vibration-proof connections

- Fast installation after initial tool use

- Wide conductor range (0.08–35 mm² / 28–2 AWG)

Limitations:

- Requires tool for insertion/removal

- Limited to compatible wire types

- Higher initial component cost

3. Push-in Spring Clamping

Operating Principle: A spring mechanism allows tool-less insertion of rigid conductors. The conductor’s rigidity provides counterforce against the spring; removal requires a tool.

Key Components:

- Spring Mechanism: Stainless steel or chrome-nickel alloy

- Funnel Entry: Guides conductor to contact point

- Separate Clamping Units: Prevents multiple conductors per point

Advantages:

- Tool-less installation (significant time savings)

- Positive connection feedback

- Compact design for high density

- Ideal for rigid or ferruled conductors

Limitations:

- Requires tool for removal

- Limited to specific conductor types

- Not suitable for all stranded wires without ferrules

Technology Selection Matrix

Each clamping technology excels in specific applications:

- Screw-type: High-current power distribution, mixed wire types, field service requirements

- Spring-cage: Vibration environments, maintenance-free applications, wide conductor ranges

- Push-in: High-volume panel assembly, time-critical installations, rigid conductor applications

Table 2: Clamping Mechanism Comparison

| Feature | Screw-Type | Spring-Cage | Push-in |

|---|---|---|---|

| Operation | Tool required (torque driver) | Tool for insertion/removal | Tool-less insertion, tool removal |

| Wire Compatibility | Universal (solid, stranded, fine-stranded) | Wide range (0.08-35 mm²) | Rigid conductors (solid, ferruled stranded) |

| Installation Speed | Slow (requires torque control) | Medium (tool operation) | Fast (tool-less) |

| Vibration Resistance | Requires periodic retightening | Excellent (constant spring pressure) | Good (spring-loaded) |

| Maintenance | Field serviceable, requires inspection | Maintenance-free | Low maintenance |

| Ideal Applications | High-current power distribution, mixed wire types | Vibration environments, maintenance-free requirements | High-volume panel assembly, time-critical installations |

| Standards Compliance | IEC 60947-7-1, UL 1059 (Group C) | IEC 60947-7-1, UL 1059 (Group B/C) | IEC 60947-7-1, UL 1059 (Group B/C) |

The clamping mechanism choice directly affects installation efficiency, long-term reliability, and total cost of ownership across the equipment lifecycle.

Conductor Contact & Current Path

The conductor contact interface is where electrical performance meets mechanical design. A proper connection requires sufficient contact area, appropriate pressure, and corrosion-resistant materials to maintain low resistance over the terminal block’s service life.

Contact Materials and Plating

Base Materials:

- Electrolytic Copper: Highest conductivity (100% IACS), ideal for high-current applications

- Brass (Copper-Zinc): Good conductivity (28% IACS) with higher mechanical strength

- Phosphor Bronze: Excellent spring properties for clamping mechanisms

Surface Plating:

- Tin (Sn): Standard plating for general use, prevents copper oxidation

- Nickel (Ni): Enhanced corrosion resistance, higher temperature tolerance

- Silver (Ag): Superior conductivity and oxidation resistance for high-voltage applications

- Gold (Au): Limited to signal-level applications requiring minimal contact resistance

Contact Pressure and Resistance

Optimal Contact Pressure:

- Solid Conductors: 15-25 N (newtons) per contact point

- Stranded Conductors: 20-30 N to compensate for surface irregularities

- Fine-Stranded with Ferrules: 25-35 N for secure crimped connections

Contact Resistance:

- High-quality terminal blocks maintain <0.5 mΩ per connection

- Resistance increases with temperature (typically 0.4% per °C)

- Proper torque/spring force minimizes resistance variation over time

Current Path Design

Cross-Sectional Area:

- Busbar dimensions must support rated current without excessive temperature rise

- Typical design: 1 mm² cross-section per 5-8A continuous current (copper)

- Derating required for ambient temperatures above 40°C

Heat Dissipation:

- Contact resistance generates heat (P = I²R)

- Housing design must allow heat transfer to environment

- Multi-level blocks require additional thermal considerations

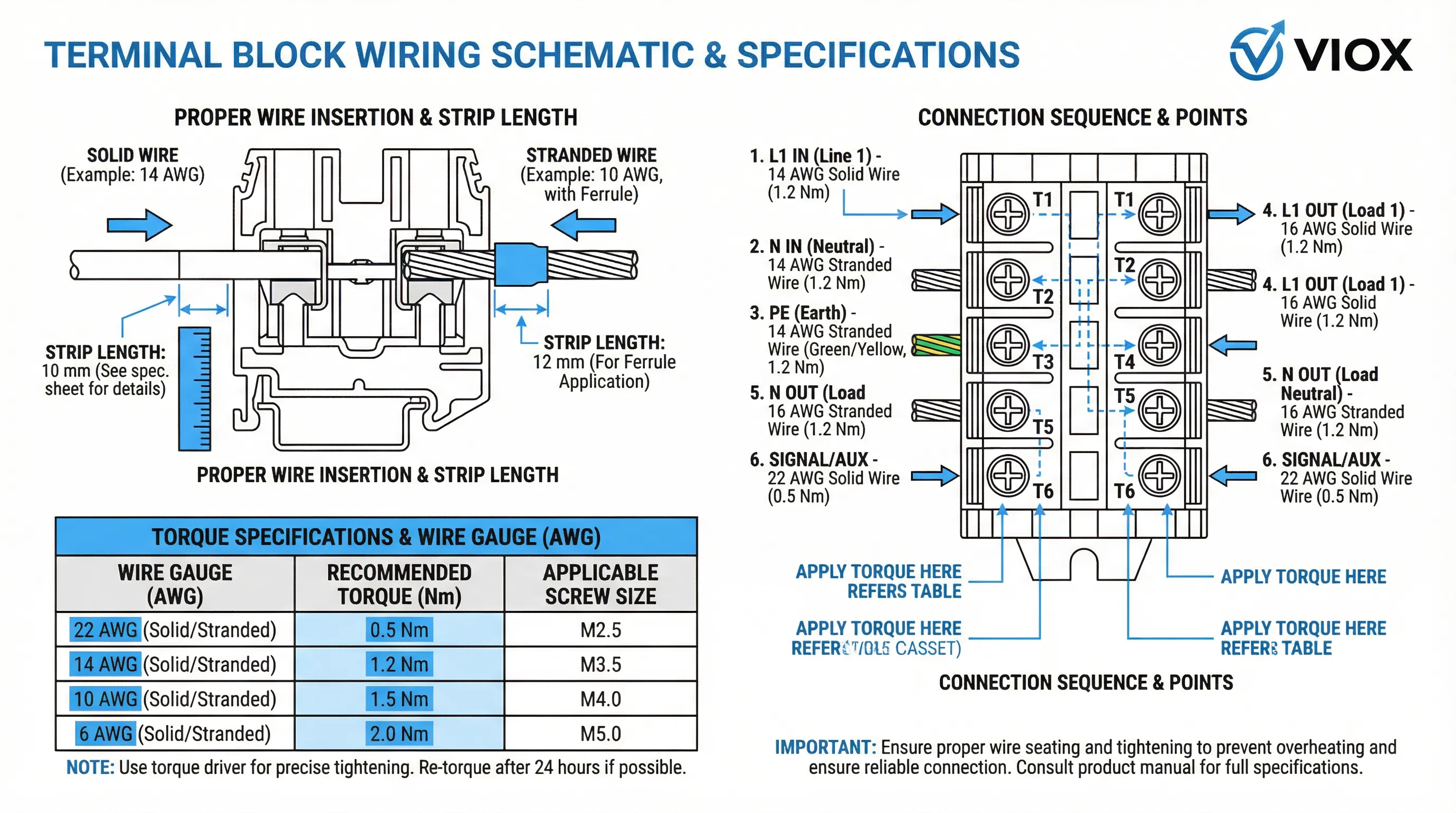

Wire Compatibility Factors

Conductor Type:

- Solid Wire: Best for screw-type terminals, maintains shape under pressure

- Stranded Wire: Requires higher clamping force, benefits from ferrules

- Fine-Stranded: Must use ferrules with spring/push-in terminals

Stripping Length:

- Insufficient stripping exposes insulation to clamping pressure

- Over-stripping reduces contact area and increases oxidation risk

- Manufacturer specifications typically indicate optimal strip length

The conductor contact interface represents the terminal block’s electrical “bottleneck.” Proper material selection, adequate pressure, and appropriate wire preparation ensure minimal resistance, reduced heat generation, and long-term reliability.

Mounting Systems: DIN Rail and Panel Integration

Mounting systems provide mechanical stability, ensure proper alignment, and facilitate installation density. The choice between DIN rail mounting, panel mounting, or PCB mounting affects installation workflow, maintenance accessibility, and resistance to vibration or mechanical shock.

DIN Rail Mounting Standards

Primary DIN Rail Types:

- Top Hat Rail (TH35): 35mm width, 7.5mm height – European standard (IEC 60715)

- G-Rail (G32): 32mm width – North American standard

- Mini Rail (15mm): For compact applications

Mounting Mechanisms:

- Spring-Loaded Clip: Quick installation without tools, vibration resistant

- Screw-Type Foot: Positive mechanical lock, higher retention force

- Snap-On Design: Tool-less mounting for high-volume applications

Critical Mounting Considerations

Vibration Resistance:

- Spring-clip designs maintain tension under vibration

- Screw-type mounts require locking washers or thread-locking compounds

- DIN rail material (steel vs aluminum) affects damping characteristics

Thermal Expansion:

- Terminal block and DIN rail materials must have compatible expansion coefficients

- Plastic housings expand more than metal rails (typically 8-10x)

- Design must accommodate differential expansion without stress concentration

Installation Density:

- Pitch dimensions determine blocks per meter of rail

- Multi-level blocks increase density but reduce heat dissipation

- Minimum spacing requirements for wire bending radius

Panel and PCB Mounting Alternatives

Panel Mounting:

- Direct screw mounting to enclosure backplane

- Requires drilled/tapped holes or mounting brackets

- Provides maximum mechanical stability

PCB Mounting:

- Through-hole or surface-mount designs

- Pitch must match PCB grid (typically 2.54mm, 5.08mm, 7.62mm)

- Wave soldering compatibility requirements

Hybrid Systems:

- DIN rail mounted terminal blocks with pluggable PCB connectors

- Panel-mounted terminal strips with field-wiring access

Standards Compliance

DIN Rail Standards:

- IEC 60715: Dimensions and mounting of low-voltage switchgear on rails

- UL 508A: Industrial control panels (includes terminal block mounting)

- EN 50022: TH35 rail specifications

Mechanical Testing:

- Vibration resistance (IEC 60068-2-6)

- Shock resistance (IEC 60068-2-27)

- Mechanical endurance (IEC 60947-7-1)

The mounting system represents the terminal block’s mechanical foundation. Proper selection ensures stable connections, facilitates maintenance access, and withstands environmental stresses throughout the equipment’s operational life.

Technical Specifications & Ratings

Terminal block performance is quantified through standardized specifications that define electrical, mechanical, and environmental capabilities. Understanding these ratings ensures proper application and compliance with industry standards.

Electrical Ratings

Current Rating (Amperage):

- Defined by maximum continuous current without exceeding temperature limits

- Typically rated at 40°C ambient temperature

- Derating required for higher ambient temperatures (typically 0.8% per °C above 40°C)

Voltage Rating:

- Working Voltage: Maximum continuous operating voltage (typically 600V AC/DC)

- Impulse Voltage: Short-duration withstand voltage (typically 6kV for 1.2/50µs)

- Insulation Voltage: Voltage between conductors and mounting rail (typically 2500V AC)

Contact Resistance:

- Measured in milliohms (mΩ) per connection

- Quality terminal blocks: <0.5 mΩ initial resistance

- Increases with temperature and aging

Mechanical Specifications

Wire Range:

- Expressed in AWG (American Wire Gauge) and mm² (square millimeters)

- Typical industrial ranges: 22-10 AWG (0.5-6 mm²) to 4-2/0 AWG (25-95 mm²)

- Must accommodate both solid and stranded conductors

Table 3: Wire Gauge Compatibility and Current Ratings

| Wire Size (AWG) | Cross-Section (mm²) | Solid Conductor | Stranded Conductor | Ferrules Required | Typical Current Rating |

|---|---|---|---|---|---|

| 22-18 | 0.5-1.0 | Yes | Yes (spring/push-in) | Optional (push-in) | 5-15A |

| 16-14 | 1.5-2.5 | Yes | Yes | Recommended | 20-32A |

| 12-10 | 4.0-6.0 | Yes | Yes | Recommended | 30-50A |

| 8-6 | 10-16 | Yes | Limited (screw-type) | Required (spring/push-in) | 60-100A |

| 4-2 | 25-35 | Yes | Limited (screw-type) | Required (spring/push-in) | 100-150A |

| 1/0-2/0 | 50-70 | Yes | Limited (screw-type) | Required (spring/push-in) | 150-200A |

Note: Ratings assume 40°C ambient temperature, derating required for higher temperatures.

Torque Specifications:

- Screw-type terminals: 0.5-2.5 Nm depending on wire size

- Spring-cage terminals: Pre-set spring force (typically 15-30 N)

- Critical for proper contact pressure without conductor damage

Mounting Pitch:

- Center-to-center distance between terminals

- Common pitches: 5mm, 5.08mm, 6.2mm, 8.2mm, 10mm, 12mm

- Determines installation density and clearance distances

Environmental Ratings

Temperature Range:

- Operating: Typically -40°C to +105°C or +125°C

- Storage: -40°C to +85°C

- Material-dependent limitations

IP Rating (Ingress Protection):

- IP20: Standard for control panel interior use

- IP65/IP67: For exposed or washdown applications

- Requires gaskets, seals, or special housings

Flame Retardancy:

- UL 94V-0: Self-extinguishing within 10 seconds

- IEC 60695: Glow-wire testing standards

- Material certification requirements

Standards Compliance

IEC 60947-7-1:

- Primary international standard for terminal blocks

- Defines temperature rise limits (45K maximum)

- Specifies mechanical endurance testing

UL 1059:

- North American component standard

- Stricter temperature rise limits (30K maximum)

- Use Group classifications (A, B, C, D)

DIN Rail Standards:

- IEC 60715: Rail dimensions and mounting

- EN 50022: TH35 rail specifications

- Mechanical retention force requirements

Table 4: Standards Compliance Matrix: IEC, UL, DIN

| Standard Category | IEC (International) | UL / CSA (North America) | DIN / EN (Europe) |

|---|---|---|---|

| Terminal Block (General) | IEC 60947-7-1 (Power) IEC 60947-7-2 (Protective Earth) |

UL 1059 CSA C22.2 No. 158 |

EN 60947-7-1 VDE 0611 |

| Mounting Rail | IEC 60715 | UL 508A (Reference) | EN 50022 (TH35) DIN 46277 |

| Flammability / Fire Safety | IEC 60695-2 (Glow Wire) | UL 94 (V-0, V-1, V-2) | EN 45545-2 (Railway) DIN 5510-2 |

| Degree of Protection (IP) | IEC 60529 (IP Code) | NEMA 250 (Enclosure Types) | EN 60529 DIN 40050 |

| Vibration & Shock | IEC 60068-2-6 (Vibration) IEC 60068-2-27 (Shock) |

UL 1059 (Secureness Test) | EN 61373 (Railway Rolling Stock) |

| Clearance & Creepage | IEC 60664-1 | UL 840 | EN 60664-1 VDE 0110 |

Understanding technical specifications enables proper terminal block selection based on actual application requirements rather than marketing claims. Always verify ratings against applicable standards for your geographic region and industry sector.

Component Selection for Application Requirements

Selecting terminal blocks based on application requirements rather than generic specifications ensures optimal performance, reliability, and total cost of ownership. The following decision framework addresses common industrial scenarios.

Application-Specific Selection Criteria

Control Panel Wiring (General Purpose):

- Housing: Polyamide 6.6 (PA66) with glass reinforcement

- Clamping: Spring-cage for vibration resistance

- Wire Range: 22-10 AWG (0.5-6 mm²)

- Current Rating: 20-32A continuous

- Standards: IEC 60947-7-1, UL 1059 Group C

Power Distribution (High Current):

- Housing: PBT for dimensional stability

- Clamping: Screw-type for high clamping force

- Wire Range: 14-2/0 AWG (2.5-95 mm²)

- Current Rating: 40-125A continuous

- Standards: IEC 60947-7-1 with derating for ambient >40°C

Vibration-Prone Environments (Transportation, Machinery):

- Housing: PA66 with enhanced impact resistance

- Clamping: Spring-cage with positive lock mechanism

- Materials: Stainless steel springs, corrosion-resistant plating

- Testing: IEC 60068-2-6 vibration compliance

High-Humidity or Corrosive Environments (Marine, Chemical):

- Housing: PBT or polycarbonate with chemical resistance

- Clamping: Screw-type with stainless steel components

- Plating: Nickel or silver for corrosion protection

- IP Rating: IP65 minimum for exposed applications

Decision Matrix for Common Scenarios

| Application | Priority Criteria | Recommended Technology | Key Standards |

|---|---|---|---|

| General Control Panel | Vibration resistance, maintenance-free | Spring-cage | IEC 60947-7-1, UL 1059 Group C |

| High-Current Feeder | Clamping force, thermal dissipation | Screw-type | IEC 60947-7-1 with derating |

| High-Volume Assembly | Installation speed, density | Push-in spring | IEC 60947-7-1, UL 1059 Group B/C |

| Harsh Environment | Chemical resistance, corrosion protection | Screw-type with stainless components | IP65, IEC 60068-2-11 |

| Mixed Wire Types | Universal compatibility | Screw-type | IEC 60947-7-1, UL 1059 Group C |

Critical Considerations

Total Cost of Ownership:

- Initial component cost vs. installation labor

- Maintenance requirements and downtime

- Long-term reliability and replacement frequency

Standards Compliance:

- Geographic requirements (IEC vs. UL/NEC)

- Industry-specific certifications (ATEX, marine, railway)

- Customer specification compliance

Future-Proofing:

- Spare capacity for future expansion

- Compatibility with existing systems

- Availability of replacement parts

Application-driven selection moves beyond catalog specifications to match terminal block capabilities with actual operating conditions. This approach minimizes field failures, reduces total lifecycle costs, and ensures compliance with relevant standards.

Frequently Asked Questions

1. What’s the difference between terminal block housing materials (PA66 vs PBT vs PC)?

PA66 (Polyamide 6.6) offers excellent mechanical strength and flexibility, making it ideal for general industrial applications. PBT (Polybutylene Terephthalate) provides superior dimensional stability and moisture resistance for precision applications. PC (Polycarbonate) delivers high impact strength and transparency for visual inspection requirements. Selection depends on environmental conditions and mechanical requirements.

2. How do I choose between screw, spring-cage, and push-in clamping mechanisms?

Screw-type terminals provide universal wire compatibility and field serviceability. Spring-cage terminals offer maintenance-free, vibration-resistant connections. Push-in terminals enable tool-less installation for rigid conductors. Choose based on installation speed, maintenance requirements, and environmental conditions.

3. What current rating should I select for my application?

Select a terminal block rated for at least 150% of your maximum expected continuous current. Apply derating for ambient temperatures above 40°C (typically 0.8% per °C). Consider both the terminal block rating and the wire’s ampacity.

4. How do IEC 60947-7-1 and UL 1059 standards differ?

IEC 60947-7-1 is the international standard with 45K maximum temperature rise. UL 1059 is the North American standard with stricter 30K temperature rise limits and Use Group classifications (A, B, C, D). Products may have dual ratings with different values for each standard.

5. What wire preparation is required for different terminal types?

Screw-type: Solid or stranded wires, strip length per manufacturer specs. Spring-cage: Solid, stranded, or fine-stranded with proper strip length. Push-in: Rigid conductors (solid or ferruled stranded), precise strip length critical. Always follow manufacturer specifications.

6. How do terminal blocks handle vibration and thermal cycling?

Quality terminal blocks use spring-loaded mechanisms that maintain constant pressure during vibration. Materials with compatible thermal expansion coefficients prevent stress concentration. Designs include positive locking features and corrosion-resistant components for harsh environments.

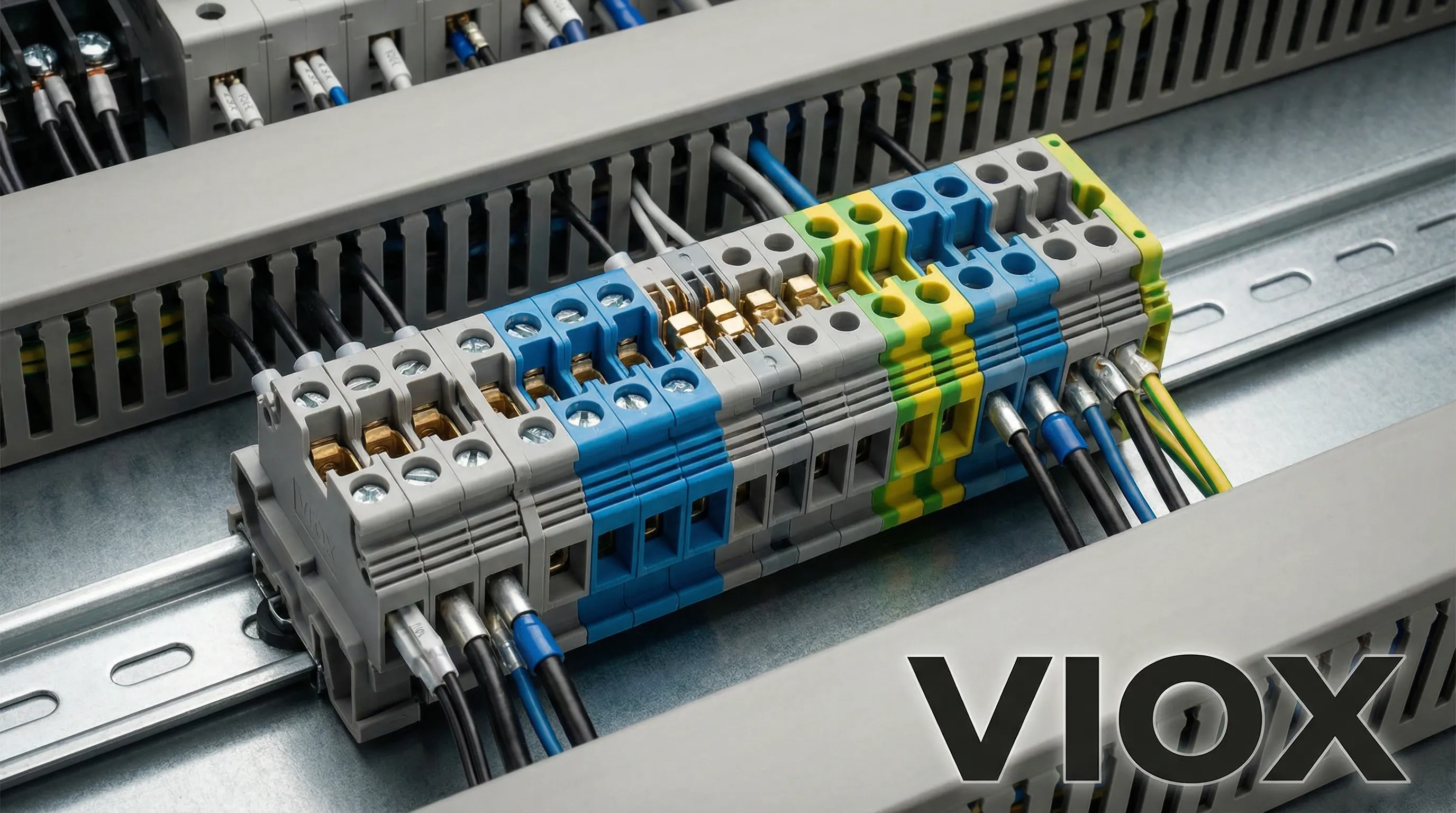

VIOX Terminal Block Solutions

VIOX Electric designs and manufactures terminal blocks engineered for industrial reliability and performance. Our product range combines material science expertise with precision manufacturing to deliver connection solutions that withstand demanding operating conditions.

VIOX Terminal Block Features:

- Material Engineering: Glass-reinforced PA66, moisture-resistant PBT, and impact-resistant polycarbonate housings

- Clamping Technologies: Screw-type, spring-cage, and push-in mechanisms for diverse application requirements

- Standards Compliance: Dual-rated products meeting IEC 60947-7-1 and UL 1059 standards with global approvals

- Thermal Performance: Optimized designs for heat dissipation with derating guidance for elevated ambient temperatures

- Installation Efficiency: Tool-less and tool-assisted options balancing speed with reliability

Technical Support and Specification Assistance:

Our engineering team provides application-specific guidance for terminal block selection based on:

- Current and voltage requirements

- Environmental conditions (temperature, humidity, chemical exposure)

- Vibration and mechanical stress factors

- Standards compliance needs (IEC, UL, ATEX, marine)

- Installation workflow optimization

Explore VIOX Terminal Block Products: https://viox.com/terminal-block

For technical specifications, application guidance, or custom solution inquiries, contact our engineering support team through the VIOX website or your local VIOX representative.