Introduction

In modern electrical systems, protecting equipment from overvoltage events is critical for operational continuity and safety. While the terms “surge arrester” and “lightning arrester” are often used interchangeably, these devices serve distinct purposes in comprehensive protection strategies. Understanding the differences between surge arresters and lightning arresters is essential for engineers, facility managers, and procurement professionals tasked with designing effective electrical protection systems.

Lightning strikes remain one of nature’s most destructive forces, capable of delivering instantaneous surges exceeding 100,000 amperes. However, electrical systems face numerous other threats including switching transients, power fluctuations, and induced overvoltages. This article clarifies the technical distinctions between lightning arresters and surge arresters, examines their respective applications, and provides guidance for selecting appropriate protection devices for your facility.

What is a Lightning Arrester?

Definition and Primary Purpose

A lightning arrester is a protective device specifically engineered to safeguard electrical infrastructure from direct or nearby lightning strikes. Its primary mission is to intercept massive electrical surges caused by lightning and provide a low-resistance path to safely divert this enormous current to ground, preventing catastrophic damage to structures, transmission lines, and connected equipment.

Lightning arresters are typically installed at service entrances, on rooftops, along overhead power lines, and at substations where exposure to direct lightning strikes is highest. These devices are designed to handle extremely high discharge currents—often exceeding 10,000 amperes (10 kA)—with very steep wavefronts characteristic of lightning events.

Working Principle

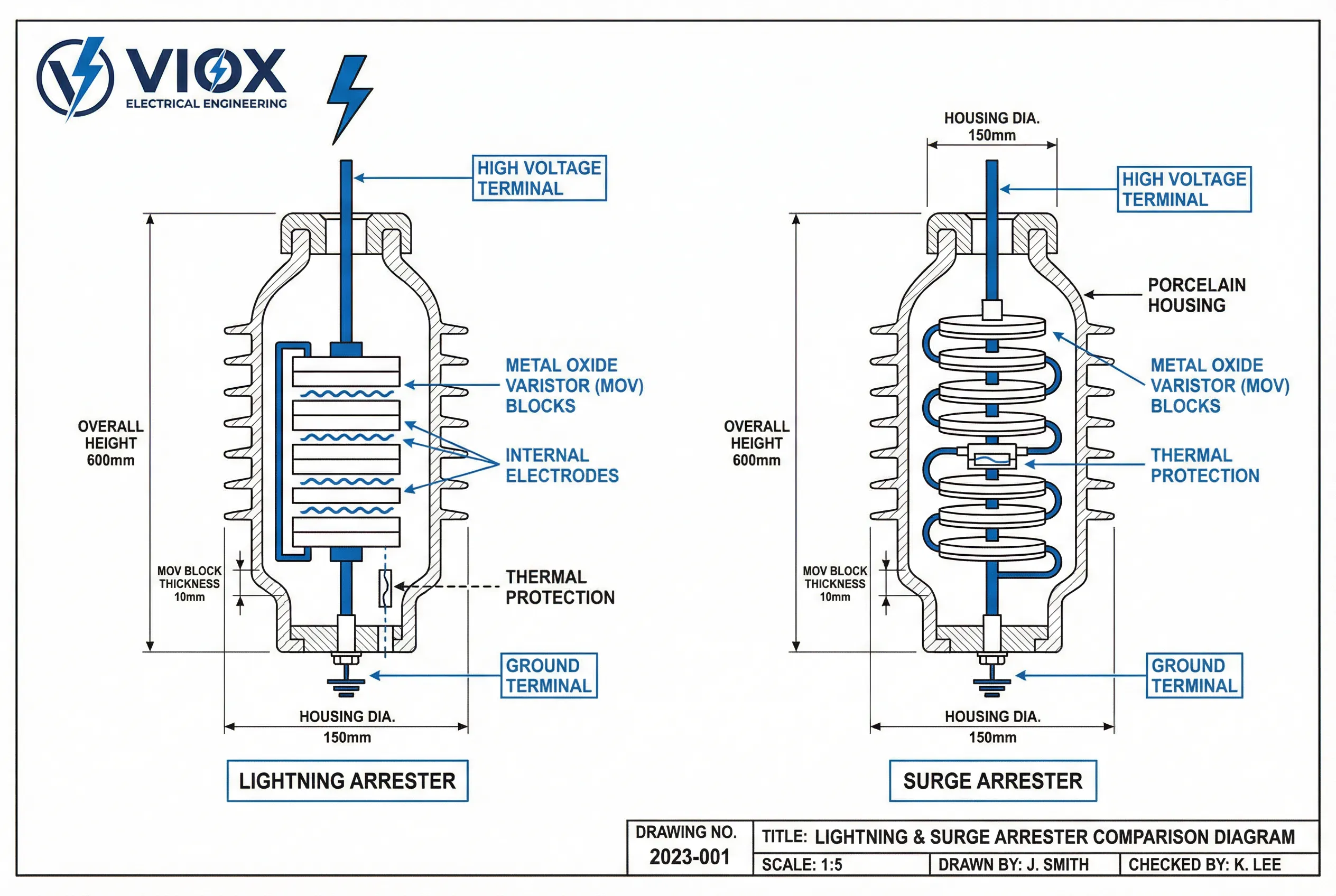

The lightning arrester operates based on voltage-dependent impedance characteristics. Under normal operating conditions, the arrester maintains high impedance and does not affect circuit operation. When a lightning-induced voltage surge exceeds the arrester’s threshold voltage, the device rapidly transitions to a low-impedance state, creating a preferred conductive path to ground.

This discharge process diverts the lightning current away from sensitive equipment, limiting the voltage to safe levels. Once the surge passes, the arrester automatically returns to its high-impedance state, restoring normal system operation without interruption. Modern lightning arresters utilize metal oxide varistor (MOV) technology, primarily zinc oxide (ZnO), which provides excellent non-linear voltage-current characteristics and self-restoration capabilities.

What is a Surge Arrester?

Definition and Primary Purpose

A surge arrester, also known as a surge protective device (SPD) or transient voltage surge suppressor (TVSS), is designed to protect electrical and electronic equipment from transient overvoltages caused by internal system disturbances. These disturbances include switching operations, capacitor bank switching, motor startups, load variations, and indirect lightning-induced surges.

Unlike lightning arresters that handle direct high-energy lightning strikes, surge arresters address smaller, more frequent voltage spikes that occur within the electrical distribution system. They are installed closer to sensitive equipment—inside electrical panels, at branch circuits, and near critical loads requiring protection from operational transients.

Working Principle

Surge arresters function by continuously monitoring the voltage in the electrical system. Under normal conditions, the device remains in a high-impedance state with minimal effect on circuit operation. When a transient overvoltage is detected—whether from switching events or induced surges—the surge arrester rapidly decreases its impedance, clamping the voltage to a safe level and diverting excess current to ground.

The clamping voltage (also called voltage protection level or Up) is a critical specification that determines the maximum voltage appearing across protected equipment terminals during a surge event. High-quality surge arresters provide fast response times (typically nanoseconds to microseconds) and precise voltage limiting to protect sensitive electronic components from damage or degradation.

Key Differences Between Lightning Arrester and Surge Arrester

Comprehensive Comparison

While both devices protect against overvoltage, their design, application, and protective capabilities differ significantly:

| Aspect | Lightning Arrester | Surge Arrester |

|---|---|---|

| Primary Purpose | Protection against direct lightning strikes and associated high-energy surges | Protection against switching transients and operational overvoltages |

| Protection Scope | External electrical infrastructure, service entrance, overhead lines | Internal equipment, branch circuits, sensitive electronics |

| Energy Handling | Extremely high (handles currents up to 100+ kA) | Moderate to low (typically 5-40 kA depending on type) |

| Voltage Range | High voltage systems (3 kV to 1000 kV); Low voltage (0.28-0.5 kV) | Primarily low voltage (≤1.2 kV, commonly 220-380V) |

| Installation Location | Service entrance, substations, transmission towers, rooftops | Distribution panels, branch circuits, near protected equipment |

| Response Time | Fast (microseconds) | Very fast (nanoseconds to microseconds) |

| Current Waveform | 10/350 μs (lightning impulse) | 8/20 μs (switching surge) |

| Standards | IEEE C62.11, IEC 60099-4 | IEC 61643-11, UL 1449, IEEE C62.62 |

| Physical Size | Larger due to external insulation requirements | Compact, suitable for panel mounting |

| Application Context | First line of defense against lightning | Secondary/tertiary protection layer |

Functional Distinction

Lightning arresters are specialized for handling the massive, instantaneous energy discharge from direct lightning strikes. They must withstand peak currents with extremely steep rise times (microseconds) and safely dissipate energy that can exceed 10 megajoules. Their construction prioritizes high discharge capacity and robust external insulation.

Surge arresters focus on suppressing smaller, more frequent transient overvoltages that occur during normal system operation. They provide fine-tuned voltage clamping to protect sensitive electronic circuits, instrumentation, and control systems from degradation caused by repetitive surge exposure.

Types of Lightning Arresters

1. Rod Gap Lightning Arrester

The simplest design featuring a rod electrode with a predetermined gap distance. When voltage exceeds the breakdown threshold, an arc forms across the gap, conducting surge current to ground. These arresters are limited in application and primarily used in low-voltage systems due to their inability to interrupt follow-on current effectively.

2. Horn Gap Lightning Arrester

An improvement over rod gap design, featuring two horn-shaped electrodes separated by an air gap. When lightning strikes, the arc forms at the narrowest point and then rises due to electromagnetic forces and thermal convection. The increasing gap distance helps extinguish the arc naturally. Horn gap arresters are suitable for medium-voltage applications (typically up to 33 kV).

3. Multi-Gap (Expulsion Type) Lightning Arrester

This design incorporates multiple series gaps with fiber tubes or chambers. During operation, the arc generates gas pressure that helps extinguish the arc and interrupt follow-on current. Multi-gap arresters provide better protection than simple gap types but have been largely superseded by modern designs.

4. Valve-Type Lightning Arrester

A significant advancement incorporating non-linear resistors (typically silicon carbide) in series with spark gaps. The non-linear resistance provides low resistance during surge conditions and high resistance during normal operation, effectively limiting follow-on current. Valve-type arresters offer superior protection characteristics and were widely used in medium and high-voltage applications.

5. Metal Oxide (MOV) Lightning Arrester

The most advanced and widely used technology today, metal oxide arresters utilize zinc oxide (ZnO) varistor elements without series gaps. The highly non-linear voltage-current characteristic of zinc oxide provides:

- Excellent surge absorption capability

- No follow-on current issues

- Superior voltage limiting performance

- Long service life with minimal degradation

- Compact design

- Self-restoration after surge events

MOV arresters are available for all voltage levels from low voltage (under 1 kV) to ultra-high voltage (over 800 kV) and have become the industry standard for modern electrical systems.

Types of Surge Arresters (Surge Protective Devices)

According to IEC 61643-11 and related standards, surge arresters are classified based on their protection level and typical installation location:

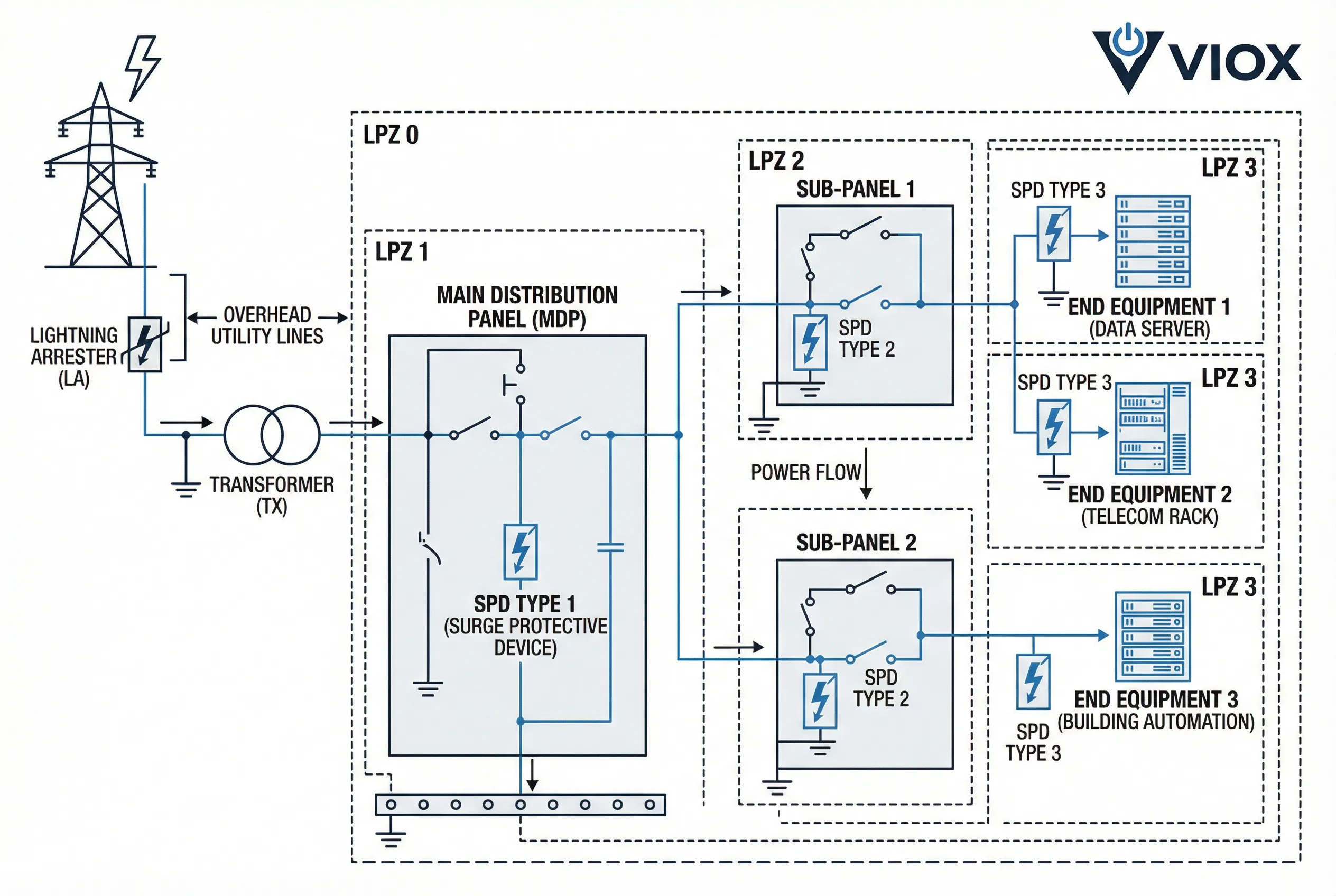

Type 1 (Class I) SPD

Characteristics:

- Tested with 10/350 μs impulse waveform

- Highest energy absorption capability

- Designed to handle direct lightning current

- Typical impulse current (Iimp): 25 kA to 100 kA

- Maximum discharge current: 50 kA to 100 kA

Applications:

- Main distribution boards at service entrance

- Buildings with external lightning protection systems (LPS)

- Facilities in high lightning-risk areas

- Primary protection layer (LPZ 0 to LPZ 1 transition)

Type 2 (Class II) SPD

Characteristics:

- Tested with 8/20 μs impulse waveform

- Moderate energy absorption

- Protects against indirect lightning and switching surges

- Typical nominal discharge current (In): 5 kA to 40 kA

- Most commonly deployed SPD type

Applications:

- Sub-distribution boards

- Industrial control panels

- Commercial electrical installations

- Secondary protection layer (LPZ 1 to LPZ 2 transition)

Type 3 (Class III) SPD

Characteristics:

- Tested with combination wave (1.2/50 μs voltage, 8/20 μs current)

- Lowest energy capacity

- Fine-tuning protection for sensitive equipment

- Typical discharge current: 1.5 kA to 10 kA

- Very low voltage protection level

Applications:

- Socket outlets near sensitive equipment

- Final branch circuits

- IT equipment, instrumentation, and control systems

- Tertiary protection layer (LPZ 2 to LPZ 3 transition)

Coordinated SPD Protection

Modern protection strategies implement cascaded or coordinated SPD installation across multiple protection zones (Lightning Protection Zones – LPZ). Type 1 SPDs at the service entrance handle high-energy surges, Type 2 SPDs at distribution panels provide intermediate protection, and Type 3 SPDs at end-use locations deliver final fine protection for critical equipment.

Technical Specifications Comparison

| Parameter | Lightning Arrester | Surge Arrester (SPD) |

|---|---|---|

| Rated Voltage | 3 kV to 1000 kV (HV); 0.28-0.5 kV (LV) | ≤1.2 kV; typically 230-690V AC |

| Maximum Continuous Operating Voltage (MCOV) | System dependent, typically 0.8-0.84 pu | 1.05-1.15 × nominal voltage |

| Discharge Current Capacity | 10 kA to 100+ kA (10/350 μs) | Type 1: 25-100 kA; Type 2: 5-40 kA; Type 3: 1.5-10 kA (8/20 μs) |

| Voltage Protection Level (Up) | Coordinated with equipment BIL | ≤2.5 × system voltage |

| Response Time | <100 nanoseconds (MOV type) | <25 nanoseconds (Type 3); <100 nanoseconds (Type 1/2) |

| Energy Absorption | Very high (>10 MJ) | Type 1: High (250-500 kJ); Type 2: Moderate (50-150 kJ); Type 3: Low |

| Follow Current Interruption | Self-extinguishing (MOV type) | Self-extinguishing |

| Operating Temperature Range | -40°C to +60°C | -40°C to +85°C |

| Service Life | 20-30 years | 10-25 years (depends on surge exposure) |

| Primary Components | ZnO varistors, ceramic housing | MOV, GDT (Gas Discharge Tube), TVS diodes, filters |

Applications and Installation Locations

Lightning Arrester Applications

Power Transmission & Distribution:

- Overhead transmission lines (all voltage levels)

- Electrical substations (HV, MV, LV)

- Distribution transformers

- Pad-mounted transformers

- Pole-mounted riser poles

Industrial Facilities:

- Manufacturing plants in lightning-prone regions

- Chemical and petrochemical facilities

- Mining operations

- Water treatment plants

- Heavy industrial complexes

Infrastructure:

- Telecommunications towers

- Railway electrification systems

- Airport facilities

- Solar and wind farm collection systems

Surge Arrester (SPD) Applications

Commercial Buildings:

- Office buildings

- Shopping centers

- Hotels and hospitality

- Healthcare facilities

- Educational institutions

Industrial Control Systems:

- Programmable Logic Controllers (PLCs)

- Distributed Control Systems (DCS)

- Variable Frequency Drives (VFDs)

- Motor control centers

- SCADA systems

IT & Telecommunications:

- Data centers

- Server rooms

- Network equipment

- Communication systems

- Building automation systems

Renewable Energy:

- Solar photovoltaic (PV) systems

- Wind turbine systems

- Energy storage systems

- Microgrids

Standards and Compliance

International Standards

IEC Standards:

- IEC 61643-11: Low-voltage SPD requirements and test methods (primary standard for surge arresters)

- IEC 60099-4: Metal oxide surge arresters without gaps for AC systems (lightning arresters)

- IEC 62305: Protection against lightning (overall protection system design)

IEEE Standards:

- IEEE C62.11: Metal oxide surge arresters for AC power circuits (lightning arresters)

- IEEE C62.41: Surge environment characterization

- IEEE C62.62: Test specifications for SPDs

- IEEE C62.72: Application guide for SPDs

Regional Standards:

- UL 1449 (4th Edition): US standard for SPDs

- EN 61643-11: European adoption of IEC standard

- CSA C22.2 No. 269: Canadian SPD standards

Compliance Considerations

When specifying lightning arresters or surge arresters, ensure compliance with:

- Voltage level requirements appropriate for your system

- Discharge current capacity matching expected surge environment

- Voltage protection level compatible with equipment insulation withstand

- Temperature rating suitable for installation environment

- Certification marks from recognized testing laboratories (UL, CE, TÜV, CB)

- Installation standards per NEC Article 285 (US) or local electrical codes

Frequently Asked Questions (FAQ)

1. Can a surge arrester replace a lightning arrester?

No, surge arresters cannot replace lightning arresters for direct lightning strike protection. While a lightning arrester can provide some protection against smaller surges, surge arresters lack the high discharge current capacity (10/350 μs waveform) required to safely handle direct lightning strikes. Comprehensive protection requires both devices in a coordinated system: lightning arresters at the service entrance for primary protection and surge arresters at distribution and end-use locations for secondary protection.

2. How do I determine which type of SPD (Type 1, 2, or 3) is needed?

SPD selection depends on the Lightning Protection Zone (LPZ) concept:

- Type 1 SPD: Install at LPZ 0-1 boundary (service entrance) in buildings with external lightning protection systems or in high-risk lightning areas

- Type 2 SPD: Install at LPZ 1-2 boundary (distribution panels, sub-boards) for general building protection

- Type 3 SPD: Install at LPZ 2-3 boundary (near sensitive equipment) when additional protection is needed

Most facilities require at least Type 2 SPDs. Add Type 1 if you have an LPS or are in high-risk areas. Include Type 3 for critical electronic equipment.

3. What is the difference between MOV and GDT surge protection technologies?

Metal Oxide Varistor (MOV):

- Voltage-dependent resistor using zinc oxide

- Excellent energy absorption

- Low clamping voltage

- Gradually degrades with repeated surges

- Best for high-energy surge suppression

Gas Discharge Tube (GDT):

- Gas-filled ceramic tube with electrodes

- Very high surge current capacity

- Higher clamping voltage

- Slower response time

- Ideal for telecommunications and signal lines

Modern SPDs often combine both technologies: GDT for high-current capability and MOV for fast response and voltage clamping.

4. How often should lightning arresters and surge arresters be tested or replaced?

Lightning Arresters:

- Visual inspection: Annually

- Electrical testing (insulation resistance, power frequency voltage): Every 1-3 years

- Replacement: 20-30 years or after significant lightning events

- Monitor condition indicators if equipped

Surge Arresters (SPDs):

- Visual inspection: Every 6-12 months

- Check status indicators (if present): Monthly

- Electrical testing: As recommended by manufacturer

- Replacement: After significant surge events or when indicators show failure

- Typical service life: 10-25 years depending on surge exposure

Document all maintenance activities and surge event counters (if available) to track device health.

5. What happens if a lightning arrester or SPD fails?

Failure modes vary by design:

Safe failure (preferred):

- Built-in thermal disconnectors activate

- Device becomes open-circuit

- Visual/electrical indicator signals failure

- System continues operating but without surge protection

Catastrophic failure:

- Short-circuit condition may occur

- Upstream overcurrent protection (fuses/breakers) should isolate device

- Risk of fire if thermal protection is inadequate

Quality devices from reputable manufacturers like VIOX Electric incorporate multiple fail-safe mechanisms including thermal disconnectors, pressure relief, and fault indicators to ensure safe failure modes.

6. Do I need lightning protection if my facility has underground power feeds?

Yes, lightning protection remains important even with underground feeds. While underground cables eliminate direct strike risk to power lines, lightning can still affect your facility through:

- Strikes to the building structure itself

- Induced surges from nearby ground strikes propagating through soil

- Surges entering via telecommunications lines, water pipes, or other conductors

- Switching transients from utility grid operations

Install Type 2 SPDs as minimum protection. Consider Type 1 SPDs if your building has an external lightning protection system or is in a high-risk area.

Conclusion: VIOX Electric’s Commitment to Comprehensive Surge Protection

Understanding the differences between surge arresters and lightning arresters is fundamental to designing effective electrical protection systems. While lightning arresters serve as the first line of defense against direct lightning strikes and high-energy surges at service entrances, surge arresters provide critical secondary protection against operational transients and induced overvoltages throughout your facility’s distribution network.

A comprehensive surge protection strategy requires coordinated deployment of both technologies, properly specified according to IEC 61643-11, IEEE C62.11, and applicable regional standards. The selection must account for voltage levels, discharge current capacity, voltage protection levels, and specific application requirements.

VIOX Electric specializes in manufacturing high-quality lightning arresters and surge protective devices engineered to meet stringent international standards. Our product portfolio includes:

- Metal oxide lightning arresters for all voltage classes

- Type 1, Type 2, and Type 3 surge protective devices

- Coordinated surge protection solutions for industrial, commercial, and renewable energy applications

- Custom designs for specialized protection requirements

Our technical team provides expert consultation to help you design optimal protection-in-depth strategies tailored to your facility’s specific risk profile and operational requirements. Don’t compromise on electrical system protection—partner with VIOX Electric for reliable, certified surge protection solutions.

Contact VIOX Electric today for a detailed protection system assessment and discover how our advanced arrester technologies can safeguard your critical infrastructure against lightning strikes and surge events.