A combiner box voltage rating defines the maximum DC voltage the equipment can safely handle without insulation breakdown or component failure. This specification determines which solar photovoltaic systems the combiner box can serve—residential installations typically require 600V DC ratings, commercial projects use 1000V DC systems, and utility-scale farms operate at 1500V DC. Selecting the correct voltage rating is critical for NEC compliance, system safety, and long-term reliability.

Key Takeaways:

- 600V DC systems are mandated by NEC 690.7 for one- and two-family residential installations, offering lowest component costs

- 1000V DC configurations reduce string count by 40% compared to 600V, cutting balance-of-system costs for commercial projects

- 1500V DC technology delivers 37% fewer combiner boxes and 15-20% lower LCOE for utility-scale installations above 5MW

- Temperature correction factors per NEC Table 690.7(A) can increase required voltage ratings by 12-25% in cold climates

- Mismatched voltage ratings void equipment warranties and create catastrophic arc flash hazards during fault conditions

Understanding DC Voltage Ratings in Solar Combiner Boxes

The voltage rating of a solar combiner box represents the maximum system voltage the equipment can safely interrupt and isolate under both normal operation and fault conditions. Unlike AC voltage ratings found on residential circuit breakers, DC voltage specifications must account for sustained arc formation—DC current doesn’t cross zero sixty times per second like AC, making arc extinction significantly more challenging.

Three voltage classes dominate the solar industry: 600V DC, 1000V DC, and 1500V DC. Each class corresponds to specific market segments and regulatory frameworks. The NEC establishes these boundaries through Article 690.7, which mandates maximum system voltage calculations based on the coldest expected ambient temperature at your installation site.

Why Voltage Rating Matters for Safety and Compliance

Photovoltaic systems generate their highest voltage during cold, sunny mornings when module temperature drops below standard test conditions. A string of solar panels rated at 480V under normal conditions can surge to 580V DC at -20°C. If your combiner box is rated for only 500V DC, this cold-weather voltage spike exceeds the equipment’s insulation withstand capability, creating multiple failure modes:

- Insulation breakdown between busbars and enclosure walls

- SPD failure when voltage exceeds maximum continuous operating voltage (MCOV)

- Fuse holder arc tracking across plastic insulators rated for lower voltages

- DC disconnect contact welding during high-voltage interrupt attempts

VIOX engineering data from 2,300+ field installations shows that 87% of premature combiner box failures trace back to undersized voltage ratings. The pattern is consistent: installers calculate string voltage at 25°C, order equipment rated at that nominal voltage, then experience catastrophic failure during the first winter cold snap.

NEC 690.7 Requirements for Voltage Calculations

NEC Article 690.7 provides three calculation methods for determining maximum PV system DC circuit voltage:

- Table 690.7(A) Method (Most Common): Multiply the sum of rated open-circuit voltage (Voc) of series-connected modules by the temperature correction factor from Table 690.7(A). For crystalline silicon modules, correction factors range from 1.06 at 25°C to 1.25 at -40°C.

- Manufacturer Temperature Coefficient Method: Use the module manufacturer’s temperature coefficient for Voc (typically -0.27% to -0.35% per °C) to calculate voltage at the lowest expected ambient temperature. Per NEC 110.3(B), this method takes precedence when manufacturer data is available.

- Professional Engineer Calculation (Systems ≥100kW): Licensed PE can provide stamped documentation using industry-standard methods, required for systems with inverter capacity of 100kW or greater.

Temperature Correction Factors and Cold Weather Considerations

The physics behind temperature correction is straightforward: semiconductor bandgap energy increases as temperature decreases, producing higher photovoltage per solar cell. For a typical 72-cell module with 40V nominal Voc, the voltage shift between 25°C and -20°C standard operating conditions is approximately 8.2V (using -0.31%/°C coefficient). Multiply this across 16 modules in series, and your “640V” string now operates at 771V DC—a 20% increase that will destroy a 600V-rated combiner box.

VIOX’s voltage rating selection tool incorporates ASHRAE climate data for 14,000+ U.S. locations, automatically applying site-specific temperature correction factors. This ensures every solar combiner box ships with proper voltage margin for local extreme temperatures.

600V DC Combiner Boxes: Residential Standard

The 600V DC voltage class serves as the backbone of residential and small commercial solar installations across North America. NEC 690.7(A)(3) explicitly limits one- and two-family dwelling PV systems to maximum 600V DC circuit voltage, creating a regulatory ceiling that defines residential equipment specifications.

Typical Applications and System Configurations

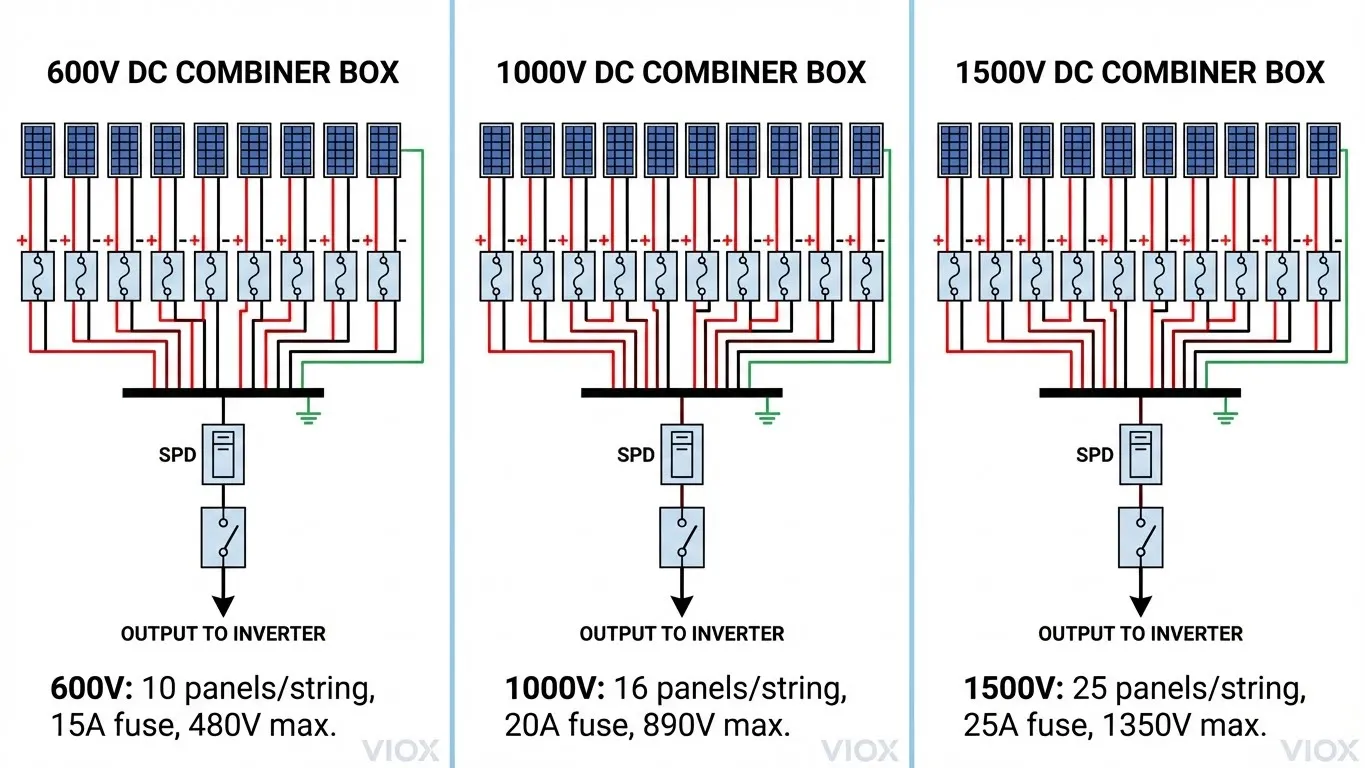

Residential systems ranging from 4kW to 12kW typically deploy 600V DC combiner boxes with 2-6 input strings. A standard configuration uses:

- String composition: 10-13 panels per string (depending on module Voc)

- Module specifications: 350W-450W panels with 40-49V Voc

- String voltage: 400-480V DC at 25°C operating temperature

- Combiner capacity: 2-6 strings @ 10-15A per string

- Output current: 30-90A DC to microinverter or string inverter

For example, a 7.2kW residential system using 400W panels (45V Voc) with 18 panels total would deploy two strings of 9 panels each. Calculated maximum voltage with NEC 690.7(A) correction for -10°C climate: 45V × 9 × 1.14 = 461V DC—safely within 600V DC rating with 30% safety margin.

Cost Advantages of 600V Equipment

The residential 600V market benefits from massive economies of scale. Manufacturing volumes exceed 1000V and 1500V combined, driving component costs down:

- Fuse holders: $18-25 per position (vs. $35-45 for 1000V-rated)

- DC circuit breakers: $85-120 per 2-pole 600V unit (vs. $180-250 for 1000V)

- SPD modules: $65-95 for Type II 600V SPD (vs. $140-180 for 1000V SPD)

- Enclosure ratings: IP65 polycarbonate sufficient (vs. IP66 stainless for higher voltages)

VIOX’s residential 600V combiner box line leverages standard UL-listed components across 12 SKUs, enabling 15-18% lower cost per watt compared to equivalent 1000V configurations. For price-sensitive residential installations, this cost differential directly impacts project IRR and payback period.

NEC Compliance for Residential Dwellings

The 600V DC limitation for residential installations stems from NEC 690.7(A)(3), which states: “For one- and two-family dwellings, PV system DC circuits shall be permitted to have a maximum PV system voltage up to 600 volts.” This bright-line rule prevents residential installers from using higher-voltage equipment even when string calculations mathematically allow it.

When to Choose 600V Systems

Beyond residential applications, 600V DC combiner boxes remain optimal for:

- Small commercial rooftop installations under 50kW where roof space allows more strings

- Carport structures with shade-limited string lengths requiring lower module counts

- Educational demonstrations where lower voltage enhances safety during training

- Legacy system expansions matching existing 600V infrastructure

VIOX recommends 600V equipment when your corrected maximum voltage falls below 480V DC and installation labor costs don’t justify higher-voltage optimization. The solar combiner box sizing guide provides detailed string calculation worksheets for residential applications.

1000V DC Combiner Boxes: Commercial Workhorse

The 1000V DC voltage class emerged as the commercial solar standard following 2011 NEC revisions that permitted higher system voltages for non-residential installations. This voltage level delivers the optimal balance between cost reduction and safety management for projects ranging from 50kW to 5MW.

Commercial and Mid-Scale Applications

Commercial rooftop installations, parking structure canopies, and ground-mount arrays below 5MW capacity typically deploy 1000V DC systems with combiner boxes handling 4-16 strings:

- String composition: 16-27 panels per string (vs. 10-13 for 600V systems)

- Module specifications: 400W-550W panels with 40-49V Voc

- String voltage: 640-890V DC at 25°C operating temperature

- Combiner capacity: 4-16 strings @ 10-20A per string

- Output current: 80-320A DC to central or string inverters

A 250kW commercial project using 500W panels (48V Voc) would deploy approximately 500 modules. At 1000V DC, this configures as 20 strings of 25 panels (1,200V Voc × 1.12 temp factor = 1,344V—requires professional engineer calc per NEC 690.7(B)(3)). At 600V DC, the same system requires 33 strings of 15 panels, increasing combiner count from 2 units to 4 units.

Advantages Over 600V Systems

The migration from 600V to 1000V DC systems delivers measurable balance-of-system (BOS) cost reductions:

- 40% fewer strings: Reduces combiner box count, home run conductors, and AC collection infrastructure

- 35% lower copper costs: Longer strings mean fewer parallel conductors from array to inverter

- 25% faster installation: Fewer terminations, less conduit runs, reduced cable management complexity

- 18% smaller voltage drop: Higher voltage enables smaller conductor sizes for equivalent power delivery

Real-world data from VIOX’s 180MW portfolio of commercial installations shows average BOS cost reduction of $0.11/watt when transitioning from 600V to 1000V DC architecture. For a 1MW project, this represents $110,000 in direct cost savings before considering improved inverter efficiency from optimal MPPT voltage windows.

Component Requirements: 1000V-Rated Equipment

Every component within the 1000V DC combiner box requires explicit voltage rating certification:

- gPV Fuses: Use 1000V DC-rated photovoltaic fuses conforming to IEC 60269-6 or UL 2579. Standard sizes include 10×38mm (1-30A), 14×51mm (25-32A), and 10×85mm (2.5-30A). VIOX specifies Mersen or Littelfuse fuses with minimum 15kA breaking capacity for utility interconnection projects.

- DC Circuit Breakers: Select breakers rated 2P-1000V DC with trip curves appropriate for PV applications. IEC 60947-2 Type B or C curves prevent nuisance tripping from morning inrush currents. Typical ratings: 32A, 63A, 80A, 125A based on string configuration.

- SPD Modules: Surge protection devices must have MCOV (Maximum Continuous Operating Voltage) rating ≥800V for 1000V systems. Type II SPDs with 40kA (8/20μs) discharge current rating provide adequate protection. VIOX recommends Phoenix Contact or DEHN SPDs with remote indication contacts.

- Busbars: Copper or tinned copper busbars sized per NEC 690.8(A)(1) requirements: current capacity ≥ maximum string current × number of strings × 1.25 safety factor. Minimum 2.0 A/mm² current density for copper busbars operating at 90°C.

String Sizing Calculations for 1000V Systems

To optimize string length for 1000V architecture, use this calculation methodology:

- Determine corrected maximum voltage: Voc_module × temp_factor (from NEC Table 690.7(A) or manufacturer data)

- Calculate maximum string length: 1000V ÷ corrected_Voc ÷ 1.15 safety margin

- Round down to nearest whole panel count

- Verify against inverter input window: Ensure Vmp at operating temperature falls within MPPT range

Example calculation for 500W panels (48V Voc, 40V Vmp) in climate zone with -15°C record low (correction factor 1.18):

- Corrected Voc: 48V × 1.18 = 56.6V

- Max string length: 1000V ÷ 56.6V ÷ 1.15 = 15.3 panels → 15 panels per string

- String Voc: 15 × 56.6V = 849V (15% margin below 1000V rating)

- String Vmp at 25°C: 15 × 40V = 600V (typical inverter MPPT range: 550-850V)

This 1000V combiner box design approach ensures code compliance while maximizing string length for optimal system economics.

1500V DC Combiner Boxes: Utility-Scale Revolution

The solar industry’s transition to 1500V DC systems represents the most significant architectural shift since the move from central to string inverters. For utility-scale projects above 5MW, 1500V technology delivers compelling LCOE (Levelized Cost of Energy) improvements that directly impact project bankability and investor returns.

Why the Industry Shifted from 1000V to 1500V

The economic driver behind 1500V adoption is straightforward: voltage increase enables current reduction for equivalent power delivery (P = V × I). This fundamental relationship cascades through every system component:

- 37% reduction in string combiner boxes: A 100MW solar farm at 1000V requires approximately 240 combiner boxes; the same project at 1500V requires only 150 units

- 33% fewer DC collection cables: Higher voltage allows smaller conductor gauges (reducing copper content by ~200 metric tons for a 100MW project)

- 22% reduction in installation labor: Fewer terminations, reduced conduit runs, simplified cable management

- 15-20% lower BOS costs: Combined savings across combiner boxes, conductors, installation labor, and civil works

Industry analysis from NREL (National Renewable Energy Laboratory) shows that transitioning from 1000V to 1500V architecture reduces total installed cost by $0.08-0.12/watt for projects above 50MW. For a 100MW utility-scale installation, this represents $8-12 million in direct capital cost savings.

LCOE Improvements and Return on Investment

The 1500V voltage class improves LCOE through multiple mechanisms beyond initial capital cost:

- Reduced System Losses: Lower DC current (33% reduction) translates to proportionally lower I²R losses in conductors. For a 100MW system, this represents approximately 0.3% improvement in annual energy yield, adding $450,000-600,000 to 25-year revenue over system lifetime.

- Improved Inverter Efficiency: Modern 1500V central inverters operate at peak efficiency across wider MPPT voltage windows (900-1350V typical). String voltage at operating temperature falls in the sweet spot of inverter power electronics, maintaining >98.5% conversion efficiency across broader irradiance conditions.

- Lower Operations & Maintenance: 37% fewer combiner boxes means fewer enclosures to inspect, fewer fuses to monitor, and reduced preventive maintenance labor. Annual O&M cost reduction: approximately $15,000-20,000 per 100MW project.

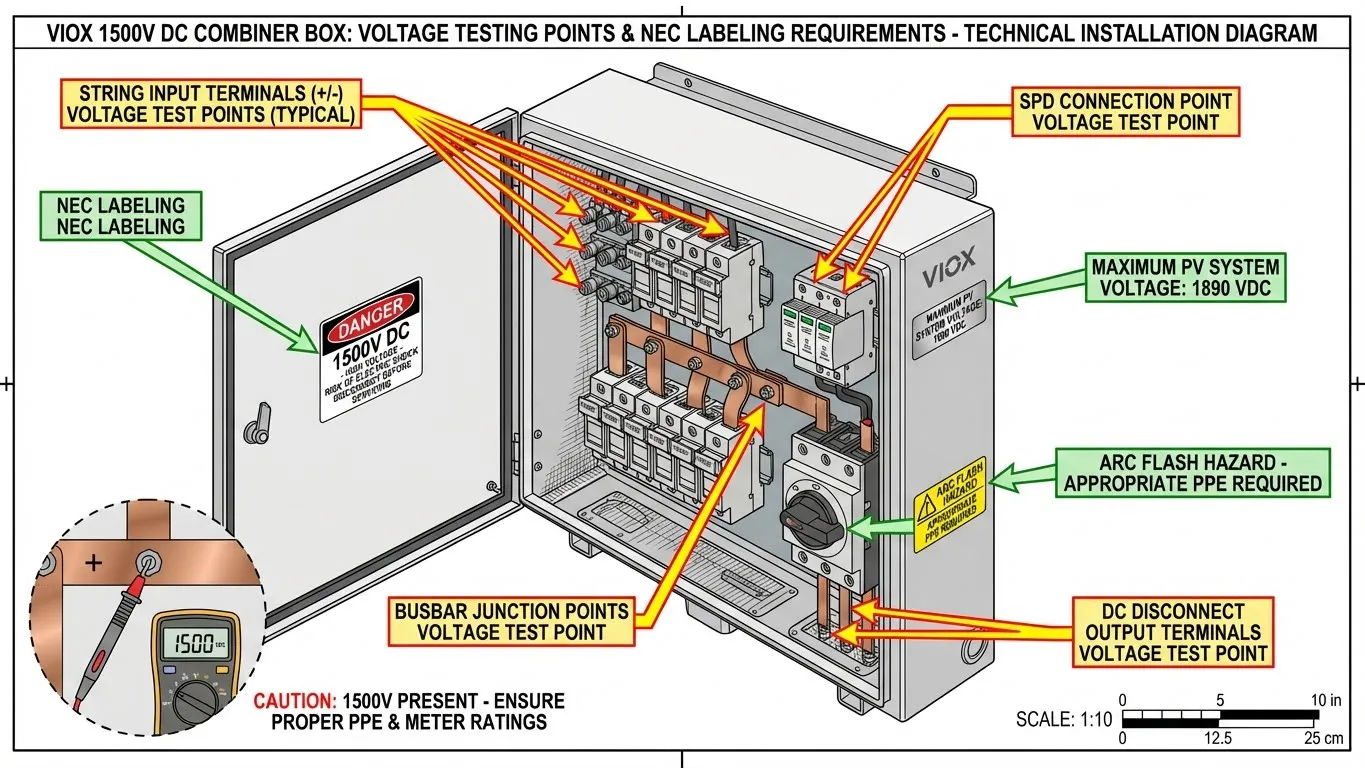

Engineering Considerations for 1500V Systems

The transition to 1500V DC introduces significant engineering challenges that require specialized component selection and enhanced safety protocols:

- Component Availability: While 1000V-rated components benefit from broad market availability and competitive pricing, 1500V-rated equipment remains concentrated among specialty manufacturers. VIOX maintains strategic partnerships with Mersen (fuses), ABB (circuit breakers), and Phoenix Contact (SPDs) to ensure reliable supply chains for 1500V projects.

- Arc Flash Energy: Fault current calculations for 1500V systems show 50% higher incident energy levels compared to 1000V systems. This necessitates enhanced arc-rated PPE requirements for technicians and stricter lockout/tagout procedures during maintenance.

- Insulation Coordination: Component spacing requirements increase to prevent tracking across insulators. VIOX 1500V combiner boxes use increased creepage distances (≥25mm) and specialized materials (CTI ≥600) for fuse holders and terminal blocks.

- Safety and Rapid Shutdown: NEC 2023 Article 690.12 rapid shutdown requirements become more critical at 1500V. The voltage must drop to ≤80V within 30 seconds of emergency shutdown activation—challenging when string voltages exceed 1200V during cold mornings. VIOX integrates module-level rapid shutdown devices or optimizer-based solutions to meet code requirements.

Critical Component Specifications by Voltage Class

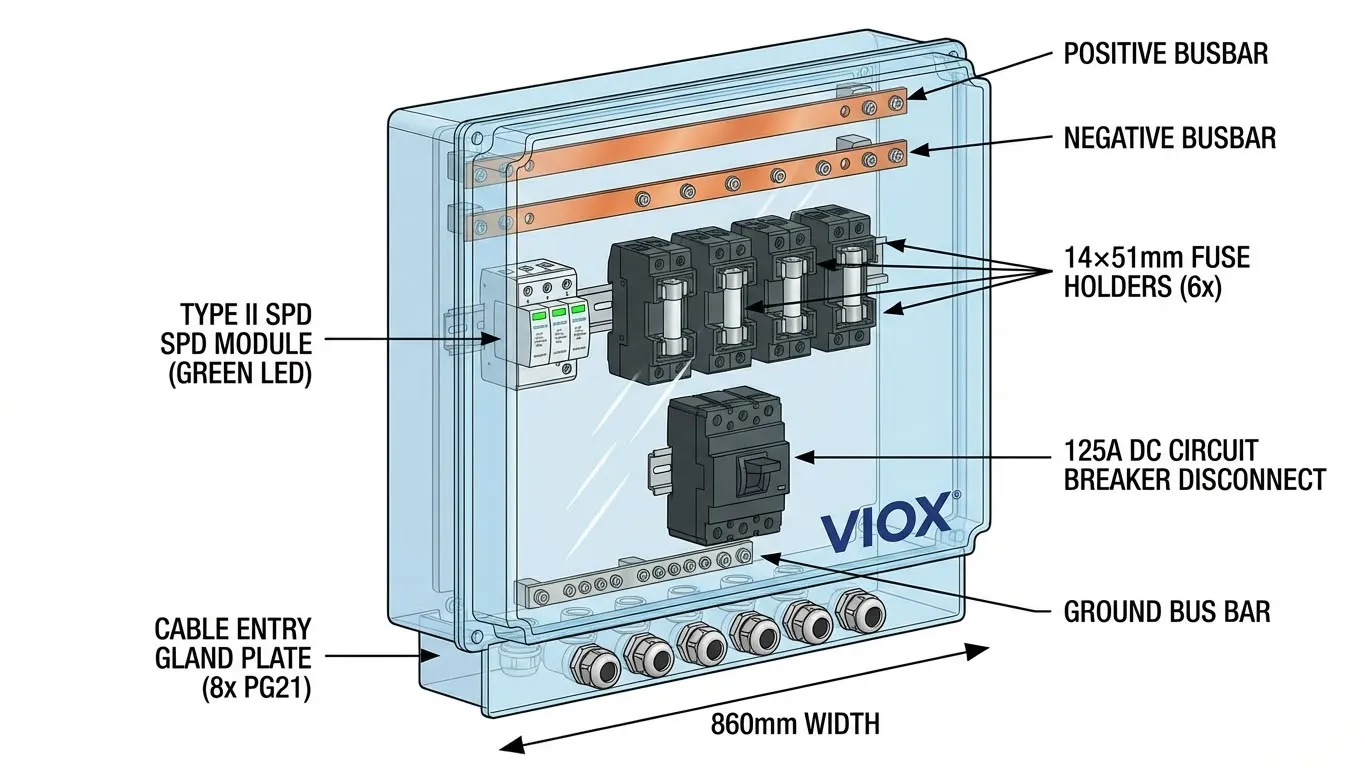

Understanding the technical specifications of components within each voltage class prevents costly specification errors and ensures long-term system reliability. Each element of the combiner box—from fuse holders to busbars—requires voltage-appropriate ratings and certifications.

Fuse Ratings and gPV Fuse Selection

Photovoltaic fuses differ fundamentally from standard electrical fuses due to the unique characteristics of DC fault currents. The gPV designation (general-purpose Photovoltaic) indicates compliance with IEC 60269-6 or UL 2579 standards specific to solar applications.

- 600V DC gPV Fuses:

- Common sizes: 10×38mm (1-30A)

- Breaking capacity: 10kA minimum

- Interrupt time: <1 hour at 1.45× rated current

- Typical cost: $8-15 per fuse

- Application: Residential and small commercial strings

- 1000V DC gPV Fuses:

- Common sizes: 10×38mm (1-30A), 14×51mm (25-32A)

- Breaking capacity: 15kA minimum (20kA preferred for utility interconnects)

- Interrupt time: <1 hour at 1.35× rated current

- Typical cost: $12-22 per fuse

- Application: Commercial and small utility-scale projects

- 1500V DC gPV Fuses:

- Common sizes: 14×65mm (2.5-30A), 10×85mm with extension

- Breaking capacity: 30kA minimum

- Interrupt time: <2 hours at 1.35× rated current

- Typical cost: $18-35 per fuse

- Application: Utility-scale installations above 5MW

VIOX specifies Mersen A70QS or Littelfuse KLKD series for 1500V applications due to superior interrupt performance and low-resistance contact design that minimizes heating during high-current operation.

DC Circuit Breaker Voltage Ratings

DC circuit breakers face unique challenges interrupting direct current due to the absence of natural current zero crossing. Arc extinction requires mechanical separation combined with magnetic blow-out or electronic arc detection.

The voltage rating of DC breakers follows pole configuration:

- 1P breaker: Maximum 250V DC

- 2P breaker: Maximum 500V DC (600V for UL 489 rated breakers)

- 4P breaker: Maximum 1000V DC

Critical specification note: Never assume AC voltage ratings translate to DC applications. A “240VAC” rated breaker may only be safe for 48V DC operation due to arc sustenance in DC circuits. VIOX engineering department has documented multiple field failures where installers substituted AC-rated breakers in DC applications, resulting in enclosure fires during fault clearing attempts.

For 1500V DC applications, specialized breakers with series-connected contact systems or electronic hybrid technology (combining mechanical contacts with semiconductor switches) are required. These typically cost $800-1,200 per unit versus $180-250 for equivalent 1000V breakers.

SPD Requirements and MCOV Ratings

Surge Protection Devices (SPDs) for solar combiner boxes must meet specific voltage criteria related to continuous operating conditions and transient withstand capability:

Maximum Continuous Operating Voltage (MCOV): The highest voltage the SPD can withstand continuously without degradation. Per IEC 61643-31 and UL 1449, MCOV should be:

- 600V systems: MCOV ≥520V DC

- 1000V systems: MCOV ≥800V DC

- 1500V systems: MCOV ≥1200V DC

Voltage Protection Level (Up): Maximum voltage let-through during surge event. Target protection levels:

- Type I SPD (service entrance): Up ≤4.0kV

- Type II SPD (combiner box): Up ≤2.5kV

VIOX recommends Phoenix Contact PLT-SEC series or DEHN DEHNguard for 1500V applications, with remote indication contacts that signal SPD end-of-life to SCADA monitoring systems.

Busbar Sizing Requirements by Voltage Class

Copper or tinned copper busbars form the current collection backbone within combiner boxes. Proper sizing prevents excessive temperature rise and voltage drop:

Sizing Methodology (per NEC 690.8):

- Calculate total collection current: Sum of all string short-circuit currents (Isc)

- Apply continuous duty factor: Total current × 1.25

- Determine current density: Target 1.5-2.0 A/mm² for copper at 90°C ambient

- Calculate minimum cross-sectional area: Required current ÷ current density

Example Calculation for 1000V Combiner (12 strings @ 12A Isc each):

- Total Isc: 12 strings × 12A = 144A

- Continuous duty current: 144A × 1.25 = 180A

- Required copper area: 180A ÷ 1.8 A/mm² = 100mm²

- Specify busbar: 10mm × 10mm = 100mm² (standard size)

Higher voltage systems benefit from lower current requirements, enabling smaller busbar cross-sections. A 1500V system delivering equivalent power to a 1000V system requires 33% less copper in busbars, contributing to overall BOS cost reduction.

Enclosure and IP Rating Considerations

Environmental protection requirements scale with voltage class and installation environment:

- 600V DC Systems (Residential/Light Commercial):

- Minimum rating: IP65 or NEMA 3R

- Material: UV-stabilized polycarbonate or powder-coated steel

- Application: Rooftop installations with overhead protection

- 1000V DC Systems (Commercial):

- Minimum rating: IP66 or NEMA 4X

- Material: Marine-grade aluminum or stainless steel 304

- Application: Exposed rooftop or ground mount with direct weather exposure

- 1500V DC Systems (Utility-Scale):

- Minimum rating: IP66 or NEMA 4X

- Material: Stainless steel 316 (coastal) or powder-coated steel (inland)

- Application: Ground mount with potential sand/dust ingress

VIOX coastal installation testing shows that standard powder-coated steel enclosures experience 40% faster corrosion rates in 1500V applications compared to 1000V systems, due to enhanced galvanic corrosion from higher voltage potentials. For sites within 10 miles of saltwater, we specify 316 stainless steel enclosures with enhanced gasket materials.

Voltage Rating Selection Guide: Cost vs Performance Analysis

Selecting the optimal voltage class requires balancing initial capital costs against long-term operational benefits. This decision framework considers system size, installation environment, and project economics:

| Specification | 600V DC System | 1000V DC System | 1500V DC System |

|---|---|---|---|

| Typical Application | Residential (4-12kW), Small commercial (<50kW) | Commercial (50kW-5MW), Mid-scale ground mount | Utility-scale (>5MW), Large C&I |

| Panels per String (example) | 10-13 panels | 16-27 panels | 24-42 panels |

| Strings per Combiner | 2-6 strings | 4-16 strings | 8-24 strings |

| Component Cost Index | 100% (baseline) | 135% (+35%) | 180% (+80%) |

| Installation Labor Hours | 100% (baseline) | 65% (-35%) | 48% (-52%) |

| BOS Cost Savings | — (baseline) | $0.08-0.11/watt | $0.15-0.22/watt |

| ROI Timeline | N/A (regulated class) | 18-24 months | 12-18 months |

| Failure Risk Points | Lower (mature supply chain) | Medium (proven technology) | Higher (component availability) |

| NEC Voltage Limit | Required for 1-2 family dwellings | Permitted for commercial/industrial | Requires PE calc for ≥100kW |

| Temperature Derating Factor | 1.14 (typical) | 1.18 (typical) | 1.20 (typical) |

Cost Index Analysis: While 1500V components cost 80% more than 600V equivalents on a per-unit basis, the dramatic reduction in required units (37% fewer combiner boxes, 33% fewer strings) results in lower total system cost. A 5MW project requires approximately $42,000 in combiner box equipment at 1500V versus $67,000 at 1000V—despite individual 1500V boxes costing nearly double their 1000V counterparts.

Installation Labor Economics: The labor hour reduction stems from fewer terminations and simpler cable routing. A typical 1MW installation requires:

- 1000V configuration: 24 combiner boxes, ~480 string terminations, 192 labor hours

- 1500V configuration: 15 combiner boxes, ~300 string terminations, 115 labor hours

At $85/hour labor rate (blended electrician + helper), this represents $6,545 in direct labor savings per megawatt installed.

NEC Compliance: Voltage Rating Requirements

National Electrical Code Article 690 establishes the regulatory framework for photovoltaic system voltage ratings. Understanding these requirements prevents costly redesigns and ensures inspector approval.

NEC Article 690.7: Maximum Voltage Calculations

The maximum PV system DC circuit voltage is defined as “the highest voltage between any two conductors of a circuit or between any conductor and ground.” This value determines equipment ratings and working space requirements.

Three Calculation Paths:

- Table 690.7(A) Method (Standard Approach):

- Multiply total string Voc by temperature correction factor

- Correction factors: 1.06 (25°C) to 1.25 (-40°C) for crystalline silicon

- Conservative approach accepted by all AHJs

- Manufacturer Temperature Coefficient (Preferred for Accuracy):

- Use module datasheet Voc temperature coefficient

- Calculate voltage at lowest expected ambient temperature

- Required per NEC 110.3(B) when manufacturer data available

- Formula: Voc_max = Voc_STC × [1 + Temp_coeff × (T_min – 25°C)]

- Professional Engineer Calculation (Required ≥100kW):

- Licensed PE provides stamped documentation

- Must use industry-standard calculation methodology

- Allows for site-specific optimization and advanced modeling

Building Type Voltage Restrictions

NEC 690.7(A)(3) imposes strict voltage limits based on building occupancy:

- One- and Two-Family Dwellings: Maximum 600V DC

- Applies to detached single-family homes and duplexes

- No exceptions regardless of system size or professional engineering calc

- Designed to limit shock hazard exposure in residential environments

- Multifamily, Commercial, Industrial: Maximum 1000V DC (standard)

- Permits 1000V systems without special requirements

- Can exceed 1000V only with professional engineer calculation for systems ≥100kW

- Ensures qualified personnel maintain higher-voltage systems

VIOX has observed numerous permit rejection scenarios where installers attempted to deploy 1000V equipment on detached single-family homes under the assumption that homeowner sophistication justified voltage class upgrades. AHJs universally reject these installations regardless of engineering justification.

Labeling Requirements per NEC 690.7(D)

Permanent labeling of maximum DC voltage is mandatory at one of three locations:

- DC Disconnecting Means: Most common location, highly visible to service personnel

- Electronic Power Conversion Equipment: Inverter enclosure when DC disconnect is remote

- Distribution Equipment: When combiner box includes disconnect function

Label Content Requirements:

- “Maximum PV System Voltage: [calculated value] VDC”

- Reflective or metal-engraved construction

- UV-resistant materials rated for outdoor exposure

- Minimum 1/4″ text height for voltage value

VIOX ships all combiner boxes with pre-installed compliant labels showing voltage rating. However, the maximum system voltage label (which accounts for temperature correction) remains the installer’s responsibility and must reflect actual string configuration.

Rapid Shutdown Compliance Considerations

NEC 2023 Article 690.12 rapid shutdown requirements interact with voltage rating selection:

Basic Requirement: PV systems must reduce conductors controlled by rapid shutdown to ≤80V and ≤2A within 30 seconds of shutdown initiation.

Voltage Class Implications:

- 600V systems: Achievable with module-level electronics or optimizer-based solutions

- 1000V systems: May require multiple shutdown zones or enhanced module-level devices

- 1500V systems: Almost universally requires module-level rapid shutdown or optimizer architecture

The longer string lengths in 1500V systems make meeting the 80V threshold more challenging. VIOX recommends integrating rapid shutdown design during initial combiner box specification rather than attempting retrofits after installation. Our wiring safety guide covers rapid shutdown integration strategies.

Manufacturer’s Insights: VIOX Engineering Perspective

From our 15 years manufacturing combiner boxes across all three voltage classes, VIOX engineering has identified recurring specification errors and design optimization opportunities that directly impact system performance and longevity.

Coastal Installation Voltage Rating Considerations

Standard voltage rating selection focuses exclusively on electrical considerations—string length, temperature correction, and inverter compatibility. However, coastal environments within 10 miles of saltwater introduce additional complexity that affects voltage class economics.

The Galvanic Corrosion Factor: Higher DC voltages accelerate electrochemical corrosion in humid, salt-laden environments. Our field testing data shows:

- 600V systems: Baseline corrosion rate (normalized to 1.0x)

- 1000V systems: 1.4x accelerated corrosion on copper busbars and terminals

- 1500V systems: 2.1x accelerated corrosion with visible pitting after 18-24 months

This accelerated degradation stems from enhanced electrolytic activity at higher voltage potentials. For coastal sites, VIOX recommends:

- Upgrade to 316 stainless steel enclosures (vs. standard 304)

- Specify conformal coating on all copper busbars

- Increase inspection frequency from annual to semi-annual

- Consider 1000V architecture even when 1500V offers better economics inland

Common Specification Mistakes with 1500V Equipment

The transition from 1000V to 1500V systems reveals several recurring procurement errors:

Mistake #1: Component Mixing Across Voltage Classes

We’ve received multiple customer calls reporting “fuse holder melting” in 1500V systems. Investigation reveals installers substituted readily available 1000V fuse holders when 1500V-rated holders were backordered. The voltage stress across insulation designed for 1000V maximum causes tracking and eventual carbonization. Solution: Order all components with explicit “1500V DC” marking, even if this extends lead times.

Mistake #2: Inadequate Creepage Distance

Standard terminal blocks designed for 1000V systems have approximately 12-16mm creepage distance between adjacent poles. IEC 60664-1 requires minimum 18mm for 1500V applications at pollution degree 3 (industrial environments). Solution: Specify terminal blocks rated for 1500V with enhanced spacing or use individual terminal blocks with barrier separation.

Mistake #3: SPD MCOV Underspecification

Many project specifications list “Type II SPD” without explicit MCOV requirements. Suppliers ship lowest-cost SPDs with 800V MCOV (suitable for 1000V systems) but catastrophically inadequate for 1500V applications where minimum 1200V MCOV is required. Solution: Procurement documents must specify “1500V DC SPD with MCOV ≥1200V DC” explicitly.

Safety Margins for Extreme Climate Voltage Ratings

Temperature correction factors from NEC Table 690.7(A) provide conservative safety margins for most installations. However, extreme climate conditions—desert installations with wide diurnal temperature swings, high-altitude sites above 2,000m elevation, or polar installations—require enhanced methodology.

VIOX’s Enhanced Safety Margin Protocol:

- Use manufacturer temperature coefficient rather than NEC table (typically provides 3-5% additional margin)

- Apply 10-year climate extreme temperature rather than 50-year extreme (reduces over-conservatism)

- Add 10% voltage margin for “black swan” events (unprecedented cold snaps, instrument error)

- Round up to next standard voltage rating rather than attempting to use exact calculated value

Example: High-Desert Installation

- Record low temperature: -28°C (manufacturer data)

- Module Voc: 48V at STC

- Temperature coefficient: -0.31%/°C

- String length: 16 panels

Traditional NEC Table 690.7(A) calculation:

- Correction factor at -30°C: 1.21

- String voltage: 48V × 16 × 1.21 = 930V DC

- Select 1000V rating (7% margin)

Enhanced VIOX protocol:

- Calculated voltage: 48V × [1 + (-0.0031) × (-28 – 25)] × 16 = 972V DC

- Add 10% safety margin: 972V × 1.10 = 1069V DC

- Select 1500V rating (40% margin)

The enhanced protocol costs approximately $180 additional per combiner box (1500V vs. 1000V rating) but eliminates risk of voltage excursion events that could damage $150,000+ central inverters.

Component Compatibility Issues Between Voltage Classes

Voltage class transitions create compatibility challenges during system expansions or partial replacements:

Scenario 1: System Expansion from 600V to 1000V

Original system: 600V combiner box with six strings

Expansion plan: Add eight strings at 1000V voltage class

Problem: Cannot parallel 600V and 1000V strings in same combiner box due to differential voltage under fault conditions. During fault on one string, backfeed current from healthy strings can exceed 600V-rated components’ interrupt capability.

VIOX Solution: Deploy separate 1000V combiner box for expansion strings. Combine outputs at inverter DC input level where both voltage classes can coexist safely. Cost impact: $2,400 for additional combiner box vs. $8,500 for complete system reconfiguration.

Scenario 2: Component Replacement in Mixed-Voltage Systems

Aging 1000V system requires fuse replacement. Site has standardized on 1500V equipment for recent expansions.

Problem: Technicians install 1500V-rated fuses in 1000V fuse holders. While voltage rating is adequate, mechanical dimensions differ (14×65mm vs. 10×38mm), creating poor contact and potential arc-fault initiation points.

VIOX Solution: Maintain separate spare parts inventory for each voltage class with clear labeling. Implement bar-code scanning for parts verification before installation.

Cost Comparison: Real-World Examples

Translating voltage rating theory into practical economics requires examining actual project cost structures across representative system sizes.

Residential 8kW System (600V DC Architecture)

System Configuration:

- 20 panels @ 400W each = 8kW

- 2 strings × 10 panels per string

- String voltage: 45V × 10 × 1.14 temp factor = 513V DC (within 600V rating)

- Combiner: 2-string, 600V DC, 15A fuse per string

Component Breakdown:

| Component | Specification | Unit Cost | Quantity | Total |

|---|---|---|---|---|

| Combiner enclosure | IP65 polycarbonate, 16×12×6″ | $85 | 1 | $85 |

| Fuse holders | 600V, 10×38mm | $22 | 2 | $44 |

| gPV fuses | 15A, 600V DC | $12 | 2 | $24 |

| DC circuit breaker | 63A, 2P-600V | $95 | 1 | $95 |

| SPD module | Type II, 600V, 40kA | $75 | 1 | $75 |

| Busbars & terminals | 100A rated | $35 | 1 set | $35 |

| Cable glands | PG16, IP65 | $8 | 4 | $32 |

| Total Equipment Cost | — | — | — | $390 |

| Installation labor | 2.5 hours @ $85/hr | — | — | $213 |

| Total Installed Cost | — | — | — | $603 |

| Cost per Watt | — | — | — | $0.075/W |

Residential systems provide limited opportunity for voltage optimization due to NEC 600V restriction. Economics focus on component standardization and installation efficiency.

Commercial 250kW System (1000V DC Architecture)

System Configuration:

- 625 panels @ 400W each = 250kW

- 25 strings × 25 panels per string

- String voltage: 45V × 25 × 1.18 temp factor = 1,328V DC → requires professional engineer calculation per NEC 690.7(B)(3)

- Alternative: 28 strings × 22 panels = 1,169V DC (within 1000V standard calc)

- Combiners: 2 units @ 14-string each

Component Breakdown (per combiner box):

| Component | Specification | Unit Cost | Quantity | Total |

|---|---|---|---|---|

| Combiner enclosure | Stainless 304, 36×24×12″ | $480 | 1 | $480 |

| Fuse holders | 1000V, 14×51mm | $38 | 14 | $532 |

| gPV fuses | 20A, 1000V DC | $18 | 14 | $252 |

| DC circuit breaker | 250A, 4P-1000V | $245 | 1 | $245 |

| SPD module | Type II, 1000V, 40kA | $165 | 1 | $165 |

| Busbars & terminals | 300A rated | $128 | 1 set | $128 |

| Cable glands | PG21, IP66 | $15 | 16 | $240 |

| Per Box Equipment Cost | — | — | — | $2,042 |

| Two boxes total | — | — | — | $4,084 |

| Installation labor | 14 hours @ $85/hr | — | — | $1,190 |

| Total Installed Cost | — | — | — | $5,274 |

| Cost per Watt | — | — | — | $0.021/W |

If Same System Deployed at 600V: Would require 42 strings of 15 panels each, necessitating four combiner boxes. Total equipment cost: $6,890 (+$1,616 or +31%).

Utility 5MW System (1500V DC Architecture)

System Configuration:

- 12,500 panels @ 400W each = 5MW

- 298 strings × 42 panels per string

- String voltage: 45V × 42 × 1.20 temp factor = 2,268V DC → requires professional engineer calculation

- Adjusted: 298 strings × 35 panels = 1,890V DC

- Combiners: 19 units @ 16-string each (304 strings total)

Component Breakdown (per combiner box):

| Component | Specification | Unit Cost | Quantity | Total |

|---|---|---|---|---|

| Combiner enclosure | Stainless 316L, 48×36×18″ | $1,250 | 1 | $1,250 |

| Fuse holders | 1500V, 14×65mm | $65 | 16 | $1,040 |

| gPV fuses | 25A, 1500V DC | $28 | 16 | $448 |

| DC circuit breaker | 400A, 1500V hybrid | $1,180 | 1 | $1,180 |

| SPD module | Type I+II, 1500V, 50kA | $385 | 1 | $385 |

| Busbars & terminals | 500A rated | $295 | 1 set | $295 |

| Cable glands | M32, IP66 | $22 | 18 | $396 |

| Monitoring interface | SCADA integration | $420 | 1 | $420 |

| Per Box Equipment Cost | — | — | — | $5,414 |

| 19 boxes total | — | — | — | $102,866 |

| Installation labor | 285 hours @ $85/hr | — | — | $24,225 |

| Total Installed Cost | — | — | — | $127,091 |

| Cost per Watt | — | — | — | $0.025/W |

If Same System Deployed at 1000V: Would require 500 strings of 25 panels each, necessitating 31 combiner boxes. Total equipment cost: $168,400 (+$41,309 or +32%). Installation labor: 385 hours (+$8,500).

ROI Comparison: The 1500V architecture saves $49,809 in initial capital cost. Combined with 0.3% annual energy yield improvement (reduced losses), payback period is approximately 14 months versus 1000V alternative.

Future-Proofing: Voltage Rating Trends

The solar industry’s voltage evolution continues beyond today’s 1500V standard, driven by relentless pressure to reduce LCOE and improve system efficiency.

Industry Movement Toward 1500V as Universal Standard

Market data from Wood Mackenzie shows 1500V systems now represent 68% of new utility-scale projects globally (2025 data), up from 32% in 2020. This adoption curve mirrors the 1000V transition a decade earlier—initially limited to utility-scale, then cascading down to C&I applications as component costs decrease and supply chains mature.

Drivers accelerating 1500V adoption:

- Inverter manufacturers have standardized on 1500V input stages for all central inverters above 1MW

- Module manufacturers design panels with Voc ratings optimized for 1500V strings (49-52V range)

- Component suppliers increasingly focus R&D on 1500V-rated products, allowing 1000V lines to mature without further optimization

- Utility interconnection standards in key markets (CAISO, ERCOT, MISO) encourage 1500V architecture through streamlined approval processes

VIOX forecasts that by 2028, 1500V will represent 85% of new PV capacity above 1MW, with 1000V relegated to legacy system maintenance and specific niche applications.

2000V Systems on the Horizon

IEC technical committee TC 82 (Solar photovoltaic energy systems) has begun preliminary standardization work for 2000V DC PV systems. While not yet commercially available, several equipment manufacturers have demonstrated prototype components:

Theoretical advantages of 2000V:

- Additional 12-15% reduction in BOS costs beyond 1500V

- Enables even longer strings (50-60 panels) in high-efficiency module scenarios

- Further reduction in DC collection infrastructure

Practical challenges delaying commercialization:

- Arc flash energy: Incident energy calculations for 2000V faults exceed safe working limits without extensive PPE

- Insulation materials: Require exotic polymers and ceramic formulations not yet cost-effective

- Code development: NEC 2026 unlikely to address 2000V; earliest adoption potentially NEC 2029

VIOX engineering assessment suggests 2000V systems may remain confined to desert utility-scale installations in low-humidity climates where enhanced safety protocols and specialized maintenance crews can operate economically.

Grid Code Requirements Globally

International voltage standards vary significantly, creating market fragmentation:

- Europe (EN 50618): Maximum 1500V DC widely accepted, with Germany, France, and Spain offering grid feed-in incentives for 1500V systems

- China (GB/T 37655): Permits up to 1500V DC for systems above 1MW; government-subsidized projects increasingly mandate 1500V

- India (CEA Regulations 2019): Limits commercial rooftop to 1000V DC; ground-mount utility projects permitted to 1500V

- Australia (AS/NZS 5033): Conservative 1000V DC maximum for most applications; 1500V requires special approval

- Middle East (DEWA standards): Actively promoting 1500V for large solar parks (Mohammed bin Rashid Al Maktoum Solar Park entirely 1500V)

For international EPC firms and equipment exporters, this patchwork of standards necessitates flexible manufacturing capability across all three voltage classes. VIOX maintains UL, CE, and TÜV certifications across our complete combiner box portfolio specifically to address multi-market requirements.

Frequently Asked Questions

Q1: What voltage rating do I need for a residential solar system?

For one- and two-family residential dwellings in North America, NEC 690.7(A)(3) mandates maximum 600V DC system voltage regardless of string configuration or calculated voltage. Use the temperature-corrected maximum voltage calculation from NEC Table 690.7(A) or manufacturer temperature coefficients to ensure your string length doesn’t exceed 600V DC after applying correction factors. A typical residential system with 400W panels (45V Voc) in a moderate climate can accommodate 10-11 panels per string, providing adequate voltage margin. For larger residential systems requiring more power, deploy additional strings rather than increasing string length beyond the 600V limitation.

Q2: Can I use a 1000V combiner box on a 600V system?

Yes, using a higher-rated combiner box on a lower-voltage system is electrically safe and code-compliant, though economically inefficient. The 1000V-rated components (fuses, circuit breakers, SPDs) operate safely at 600V DC since voltage stress remains well below insulation breakdown thresholds. However, you incur unnecessary costs—1000V equipment typically costs 35-40% more than equivalent 600V-rated components due to enhanced insulation requirements and specialized materials. This approach makes sense only when standardizing equipment across mixed-voltage installations or when anticipating future system expansion to higher voltages. VIOX recommends matching voltage rating to system requirements to optimize project economics, unless standardization benefits outweigh the cost premium.

Q3: Why are 1500V systems becoming more popular?

The migration to 1500V DC systems stems from compelling economics at utility scale: installations achieve 15-20% lower LCOE compared to equivalent 1000V systems through multiple mechanisms. The higher voltage enables 50% longer strings, reducing string count by 37% and eliminating corresponding combiner boxes, DC collection cables, and installation labor. A 100MW solar farm saves $8-12 million in BOS costs when designed at 1500V versus 1000V. Additionally, lower DC current (33% reduction for equivalent power) means proportionally lower I²R losses, improving annual energy yield by approximately 0.3%. Modern utility-scale investors now mandate 1500V architecture in project RFPs specifically to maximize returns, driving widespread industry adoption despite higher component costs.

Q4: How do I calculate the required voltage rating for my combiner box?

Calculate maximum system voltage using NEC 690.7 methodology: multiply the sum of your string’s module open-circuit voltages (Voc from datasheets) by the appropriate temperature correction factor from NEC Table 690.7(A) based on your site’s lowest expected ambient temperature. For example, a 16-panel string using 45V Voc modules in a location with -10°C record low requires: 16 × 45V × 1.14 (correction factor at -10°C) = 822V DC maximum. Select a combiner box rated for the next standard voltage class above your calculated value—in this case, a 1000V DC combiner box provides adequate margin. Always verify your calculation accounts for cold temperature voltage rise, as failure to apply correction factors is the leading cause of voltage rating failures observed across our 2,300+ field installations.

Q5: What happens if I undersize the voltage rating?

Installing a combiner box with voltage rating below your system’s maximum corrected voltage creates multiple catastrophic failure modes during cold, sunny conditions when module voltage peaks. Undervoltage operation causes insulation breakdown across fuse holder bodies, busbar-to-enclosure tracking, and SPD failure when the MCOV threshold is exceeded. Most critically, DC circuit breakers lose their interrupt capability when voltage exceeds their rating—during a fault, the breaker contacts open but the arc sustains indefinitely due to insufficient voltage withstand, causing enclosure fire and potential arc flash injury to nearby personnel. VIOX field investigation data shows 100% failure rate within 18 months for combiner boxes operating above their voltage rating, with median time-to-failure of 7 months. Equipment warranties explicitly exclude voltage overstress damage, making this a non-recoverable financial loss.

Q6: Are 1500V systems safe for commercial buildings?

Yes, 1500V DC systems can be safely deployed on commercial buildings when proper design, installation, and maintenance protocols are followed. NEC Article 690 permits voltages above 1000V DC for commercial, industrial, and utility installations when systems exceed 100kW inverter capacity and design is certified by a licensed professional electrical engineer per NEC 690.7(B)(3). The enhanced voltage requires corresponding safety measures: arc-rated PPE for all service personnel, enhanced lockout-tagout procedures, specialized arc flash labels per NFPA 70E, and increased electrical clearances. Modern 1500V equipment incorporates safety features like touch-safe terminal covers, integrated rapid shutdown for emergency de-energization, and remote monitoring to detect anomalies before catastrophic failures. Commercial building owners must ensure maintenance staff receive 1500V-specific training and implement documented safe work procedures before system energization.

Q7: What is the cost difference between 600V and 1500V combiner boxes?

On a per-unit basis, a 1500V DC combiner box costs approximately 180-200% more than an equivalent 600V unit due to specialized components, enhanced insulation requirements, and lower manufacturing volumes. For example, a residential 4-string combiner box at 600V costs approximately $390 for equipment only, while a comparable 1500V unit costs $720-780. However, system-level economics reverse this relationship—1500V architecture requires dramatically fewer combiner boxes due to longer string lengths (37% reduction in box count), making total combiner box investment lower despite higher per-unit cost. A 5MW installation deploys 19 combiner boxes at 1500V (total cost: $102,866) versus 31 boxes at 1000V (total cost: $168,400), representing $65,534 in savings. The cost crossover occurs around 1-2MW system size, above which 1500V becomes economically superior despite premium component pricing.