The Legacy Infrastructure Dilemma

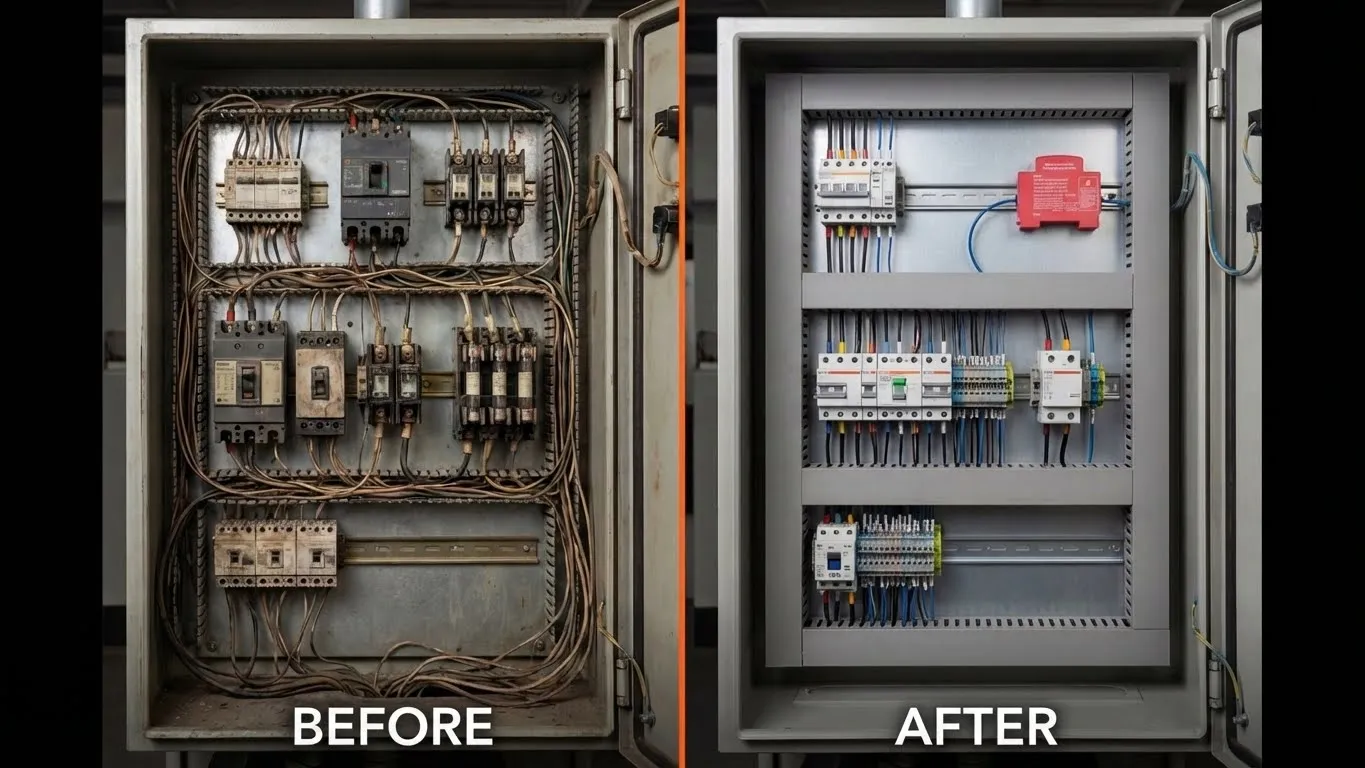

Across manufacturing facilities, commercial buildings, and industrial plants, thousands of control panels installed 20 to 40 years ago continue operating—often without adequate fire protection. These legacy systems represent a silent vulnerability: they were designed in an era before modern fire safety standards, built with materials that degrade over time, and lack the automated protection that today’s codes increasingly demand.

The challenge facing facility managers is stark: electrical fires in control panels cause an estimated $1.36 billion in annual property damage in the United States alone, yet upgrading fire protection in older panels has traditionally required expensive, invasive modifications. Complete panel replacements can cost $5,000 to $50,000 per unit, creating a financial barrier that leaves critical infrastructure unprotected.

This is where DIN Rail Mount Extinguishers revolutionize the retrofit equation. By leveraging the standard 35mm DIN rail mounting system already present in most control panels—even those decades old—these compact fire suppression devices enable non-invasive fire protection upgrades that require minimal downtime, no structural modifications, and a fraction of traditional retrofit costs.

For maintenance engineers and facility managers responsible for aging electrical infrastructure, DIN Rail Mount Extinguishers offer the easiest, most cost-effective pathway to compliance and safety without the operational disruption of complete system replacement.

The Retrofit Challenge: Why Old Control Panels Need Fire Protection Upgrades

The Aging Infrastructure Reality

According to industry research, the average age of electrical control infrastructure is increasing as organizations delay replacements. Many facilities operate panels installed in the 1980s and 1990s, when fire protection requirements were less stringent and aerosol suppression technology didn’t exist. These legacy systems face multiple fire risk factors:

- Material Degradation: Insulation becomes brittle after 20-30 years, increasing short circuit risks. Circuit boards develop microscopic cracks. Terminal connections loosen from decades of thermal cycling. Each degradation mechanism elevates fire probability.

- Outdated Design Standards: Older panels often lack modern safety features like arc-fault detection, proper ventilation systems, and thermal monitoring. They were designed for lower electrical loads than today’s demands create.

- Obsolete Components: Finding replacement parts for discontinued equipment creates maintenance challenges. Jury-rigged repairs and incompatible substitutions introduce additional fire hazards.

- Compliance Gaps: Fire codes evolve continuously. Panels that met 1990s requirements may violate current NFPA 70 (National Electrical Code) or NFPA 2010 (Condensed Aerosol Fire-Extinguishing Systems) standards, creating insurance and regulatory liabilities.

Common Retrofit Obstacles

| Challenge | Description | Impact on Traditional Retrofit | DIN Rail Mount Solution |

|---|---|---|---|

| Space Constraints | Legacy panels have zero spare room for fire suppression equipment | Requires external mounting or panel enlargement ($2,000-8,000) | Mounts on existing DIN rail using 1-pole breaker space |

| Downtime Requirements | Traditional retrofits need 4-12 hours of electrical shutdown | Production losses of $5,000-50,000+ per hour | Installation in <30 minutes during scheduled maintenance |

| Structural Modifications | Piping, cylinders, and external devices require drilling/welding | Creates contamination risks, insurance complications | No panel modifications—snap-on installation |

| Obsolete Mounting Points | Old panel designs lack modern attachment provisions | Custom fabrication required ($500-2,000) | Universal 35mm DIN rail compatibility (99% of panels) |

| Budget Limitations | Clean agent systems cost $3,000-8,000 per panel | Prevents protection of all at-risk equipment | Unit cost $250-600 enables complete facility coverage |

| Certification Documentation | Modifications may require re-certification of entire panel | Engineering costs $1,000-5,000 per panel | UL2775/NFPA 2010 certified—no panel re-certification needed |

| Unknown Panel Condition | Hidden deterioration discovered during retrofit | Project cost overruns of 30-100% | Non-invasive installation doesn’t expose hidden issues |

Research from facility modernization studies indicates that the primary barrier to retrofitting fire protection in aging control panels is not the recognition of risk, but the perceived complexity and cost of implementation. Traditional solutions reinforce this barrier. DIN Rail Mount Extinguishers eliminate it.

Why Traditional Fire Suppression Methods Don’t Work for Retrofits

The Water System Problem

Retrofitting sprinkler systems into electrical rooms requires extensive piping work, structural penetrations, and water supply modifications. Beyond the $2-7 per square foot installation cost, water-based systems introduce catastrophic failure modes:

- Electrical Incompatibility: Water conducts electricity, creating shock hazards and equipment damage during suppression

- Corrosion Risk: Even without activation, humidity from sprinkler piping accelerates component aging

- False Activation Consequences: Accidental discharge destroys the panel and connected systems

- Code Prohibitions: Most jurisdictions prohibit water-based suppression in energized electrical equipment rooms

The Gas System Retrofit Challenge

Clean agent gas systems (FM-200, Novec 1230, CO₂) provide electronics-safe suppression but create significant retrofit obstacles:

Infrastructure Requirements: External cylinders (150-300 lbs) need dedicated floor space or wall reinforcement. Distribution piping must route through walls and ceilings. Discharge nozzles require precise positioning calculations.

Installation Complexity: Typical gas system retrofit requires:

- 8-16 hours of electrical shutdown

- Coordination with HVAC contractors (pressure relief dampers)

- Building permit applications and inspections

- Commissioning testing with certified technicians

Ongoing Maintenance Burden: Annual cylinder weighing, pressure monitoring, five-year hydrostatic testing, and agent replacement create recurring costs of $300-800 per panel annually.

Economic Barriers: Total installed cost of $3,400-6,200 per panel makes comprehensive facility protection prohibitively expensive for organizations with 10-50+ control panels.

The Manual Extinguisher Gap

Portable fire extinguishers represent the lowest-cost option but provide inadequate protection for enclosed control panels:

- Detection Delay: Fires inside closed panels aren’t visible until advanced stages

- Access Restrictions: Energized equipment prevents safe manual approach

- Response Time: Manual intervention requires 2-5 minutes versus automatic systems’ <10 seconds

- Unmanned Periods: Night shifts, weekends, and holidays leave equipment unprotected

The DIN Rail Mount Extinguisher Advantage for Legacy Systems

Universal Compatibility with Existing Infrastructure

The genius of DIN Rail Mount Extinguishers lies in leveraging infrastructure that already exists in virtually every control panel manufactured since the 1970s. The 35mm DIN rail became the global standard for mounting electrical components, ensuring that retrofit compatibility isn’t a question—it’s guaranteed.

Form Factor Integration: Measuring 84.5mm × 18mm × 60mm, the VIOX QRR0.01G/S occupies the same footprint as a single-pole circuit breaker. This means:

- No panel modifications required

- No space negotiations with existing equipment

- Installation without removing or relocating components

- Visual consistency with the panel’s original design

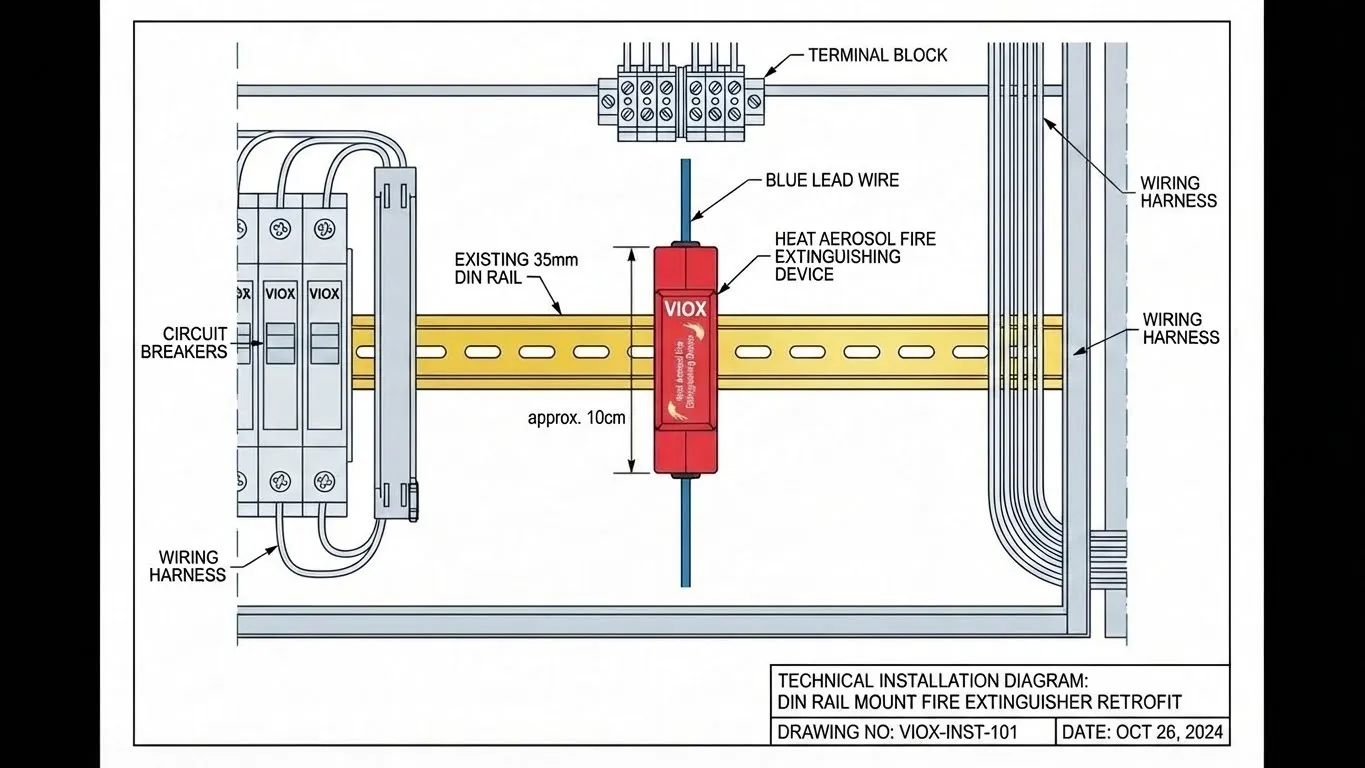

Plug-and-Play Deployment: Unlike piped suppression systems requiring weeks of planning and coordination, DIN rail units install in minutes:

- Identify mounting location on existing DIN rail

- Snap unit onto rail using integrated mounting clip

- Route thermal detection cord through high-risk areas

- System is operational—no power connection required for basic operation

This simplicity enables rapid deployment across entire facilities. A maintenance team can retrofit fire protection to 10-20 panels in a single day—an impossible timeline with traditional systems.

Autonomous Operation—No Panel Integration Required

One of the greatest retrofit challenges with gas suppression systems is integrating detection and control with legacy panels. Many older panels lack communication protocols, spare inputs/outputs, or even sufficient electrical capacity for modern fire systems.

DIN Rail Mount Extinguishers solve this through autonomous operation:

Thermal Activation Cord: A heat-sensitive detection line snakes through the panel interior. When cabinet temperature reaches 170°C (indicative of fire conditions), the cord activates mechanically—no electrical power required. This ensures:

- Protection during electrical failures (which often cause fires)

- Independence from panel control systems

- Zero integration with obsolete control architectures

- Immunity to programming errors or software bugs

Optional Smart Features: For panels with modern BMS integration, advanced models offer:

- RS485 Modbus communication

- Remote activation capability

- Fire feedback signaling

- Status monitoring via 4G connectivity

But critically, these features are optional enhancements, not requirements. The basic system protects completely independently.

Technical Specifications: VIOX QRR0.01G/S for Retrofit Applications

| Specification | Value | Retrofit Advantage |

|---|---|---|

| Physical Dimensions | 84.5 × 18 × 60mm | Fits in 1-pole breaker space—no panel enlargement |

| Agent Dosage | 10g (Red), 20g (Blue) | Scalable protection for various cabinet sizes |

| Protected Volume | ≤0.4m³ (10g model) | Ideal for typical control panel interiors (0.3-0.4m³) |

| Activation Temperature | 170°C ±5°C | Thermal cord triggers at fire temperature threshold |

| Discharge Time | ≤6 seconds | Suppresses fire before spread to adjacent equipment |

| Operating Temperature | -40°C to +85°C | Functions in unheated/outdoor legacy installations |

| Service Life | 10 years | Maintenance-free operation—no annual inspections needed |

| Mounting Standard | 35mm DIN Rail | Universal compatibility with panels back to 1970s |

| Certifications | UL2775, CE, ROHS | Meets modern fire protection standards |

| Electrical Requirements | None (thermal activation) | Operates without panel power supply |

This specification profile makes the VIOX QRR0.01G/S specifically optimized for retrofit scenarios where space, power, and integration complexity present barriers to traditional solutions.

Step-by-Step Retrofit Installation Process

The installation simplicity of DIN Rail Mount Extinguishers enables maintenance personnel to complete retrofits without specialized fire system technicians—a significant cost advantage over gas suppression systems requiring certified installers.

Pre-Installation Assessment (15 minutes)

Step 1: Panel Inventory

- Identify panels requiring retrofit based on age, criticality, and fire risk factors

- Measure internal cabinet volume to confirm unit sizing (most control panels: 0.3-0.5m³)

- Verify 35mm DIN rail presence and available mounting positions

- Document panel electrical load and operating environment

Step 2: Mounting Location Selection

- Position unit in upper cabinet section where heat naturally accumulates

- Ensure 0.3m clearance from protected equipment (per NFPA 2010)

- Verify discharge nozzle has unobstructed coverage throughout cabinet interior

- Confirm 1.5m safety distance from personnel access points

Step 3: Thermal Cord Routing Plan

- Identify high-risk components (transformers, high-current terminals, power supplies)

- Plan cord path to maximize coverage of fire initiation points

- Verify sufficient cord length (typically 30-50cm included)

Installation Execution (20 minutes per panel)

Step 4: Physical Mounting

- Snap DIN rail mounting clip onto rail—requires zero tools

- Position unit securely; audible click confirms engagement

- Verify unit stability; mounting clip withstands 50N force

Step 5: Thermal Cord Deployment

- Route detection cord through cabinet following planned path

- Maintain minimum 50mm spacing from energized conductors

- Secure cord with cable ties or existing wire management clips

- Avoid sharp bends (minimum radius: 25mm)

- Ensure cord doesn’t obstruct panel door closure or interfere with existing equipment

Step 6: System Verification

- Confirm discharge nozzle direction covers entire cabinet volume

- Check thermal cord for damage or excessive tension

- Verify label information (activation temperature, coverage volume)

- Document installation date and unit serial number

Step 7: Optional Electrical Integration (Smart models only)

- Connect fire feedback terminals to BMS if monitoring desired

- Link RS485 communication for remote status access

- Configure activation inputs for enhanced detection (smoke sensors)

Post-Installation Testing & Documentation

Step 8: Functional Confirmation

- Visual inspection of all connections and clearances

- Thermal cord continuity check (if electrical model)

- Documentation photography for maintenance records

- Update facility fire protection drawings

Step 9: Personnel Training (5 minutes)

- Inform maintenance staff of new protection

- Explain thermal activation mechanism

- Clarify no routine maintenance requirements

- Provide emergency contact information

The entire retrofit process—from initial assessment through final documentation—completes in under 30 minutes per panel. A facility with 20 aging control panels can achieve complete fire protection in a single shift, with minimal disruption to operations.

Cost Comparison: Retrofit vs. Complete Panel Replacement

The True Cost of Fire Protection Retrofit Options

| Solution Type | Equipment Cost | Installation Labor | Ancillary Components | Downtime Cost (4 hrs @ $10k/hr) | Total Cost per Panel | Maintenance (Annual) |

|---|---|---|---|---|---|---|

| Complete Panel Replacement | $5,000-25,000 | $2,000-8,000 | New wiring, recertification ($1,000-3,000) | $40,000 | $48,000-76,000 | $200-500 |

| Gas Suppression Retrofit | $2,000-4,000 | $800-1,500 | Piping, cylinders, detectors ($600-1,200) | $40,000 | $43,400-46,700 | $300-800 |

| Water Sprinkler Retrofit | $800-2,000 | $1,500-3,000 | Piping, pressure ($1,000-2,000) | $40,000 | $43,300-47,000 | $150-300 |

| Manual Extinguisher | $50-150 | $0-50 | Wall mount, signage ($20-50) | $0 | $70-250 | $50-100 |

| DIN Rail Mount Extinguisher | $250-400 | $100-200 | Thermal cord (included) | $0 (no shutdown required) | $350-600 | $0 (maintenance-free) |

The cost advantage of DIN Rail Mount Extinguishers for retrofit applications becomes overwhelming when analyzing total lifecycle costs:

Initial Investment Savings: $42,800-75,400 per panel versus gas suppression or replacement options

10-Year Lifecycle Advantage: With zero annual maintenance costs, DIN rail solutions save $1,500-8,000 per panel over a decade compared to gas systems requiring inspections, pressure testing, and agent replacement

Facility-Wide Protection Economics: For a facility with 25 aging control panels:

- Gas suppression retrofit: $1,085,000-1,167,500

- DIN rail retrofit: $8,750-15,000

- Net savings: $1,070,000-1,159,250

This economic reality enables organizations to protect their entire electrical infrastructure rather than selectively protecting only the highest-value equipment—a critical safety advantage.

The Hidden Costs of Doing Nothing

Deferring fire protection retrofits creates quantifiable risks:

Equipment Replacement: A single panel fire destroys $10,000-100,000 in electrical infrastructure

Business Interruption: Manufacturing downtime averages $22,000 per minute in automotive sectors

Insurance Implications: Underwriters increasingly require documented fire protection for aging electrical equipment

Regulatory Penalties: OSHA citations for inadequate electrical safety range from $7,000-70,000 per violation

Liability Exposure: Fires causing injury or death trigger wrongful death claims and negligent maintenance lawsuits

The $350-600 investment in retrofit fire protection represents insurance with a return measured in prevented catastrophes.

Real-World Retrofit Scenarios and Applications

Manufacturing Facility Modernization

Challenge: A mid-sized automotive parts manufacturer operating 30 control panels installed in 1985-1995. Insurance survey identified lack of automated fire suppression as “high risk” finding.

Traditional Solution: Gas suppression retrofit quoted at $3,800 per panel ($114,000 total), requiring three weeks of phased installation and multiple production shutdowns.

DIN Rail Mount Solution: VIOX QRR0.01G/S units installed across all 30 panels in two days during scheduled weekend maintenance. Total investment: $12,000. Insurance premium reduction: $8,500 annually.

ROI: 1.4 years payback from insurance savings alone, before considering risk mitigation value.

Data Center Legacy Infrastructure

Challenge: University data center with 1990s-era electrical distribution system lacked fire protection. Full replacement estimated at $180,000 but budget unavailable.

DIN Rail Mount Solution: 15 panels retrofitted with aerosol extinguishers during overnight maintenance windows. Zero disruption to server operations. Total cost: $7,500.

Result: Achieved compliance with insurance requirements, prevented premium increase of $12,000/year, protected $4M in server infrastructure.

Industrial Plant Compliance Retrofit

Challenge: Chemical processing facility failed fire marshal inspection due to unprotected electrical rooms. 60-day compliance deadline.

Traditional Solution: Clean agent system design, permitting, and installation timeline: 90+ days (missed deadline).

DIN Rail Mount Solution: 40 control panels retrofitted in six days using existing maintenance staff. Passed re-inspection with 20 days to spare.

Compliance Value: Avoided facility shutdown order that would have cost $500,000+ per week.

Aging Building Infrastructure Upgrade

Challenge: 1970s commercial building with original electrical panels lacking modern fire protection. Building sale contingent on fire safety upgrades.

DIN Rail Mount Solution: 25 panels across five floors retrofitted in three days without tenant disruption. Building sale proceeded on schedule.

Transaction Value: $150,000 price reduction avoided by completing fire safety requirements before closing.

Frequently Asked Questions

Q: Can DIN Rail Mount Extinguishers protect panels installed before DIN rail mounting became standard?

A: While 35mm DIN rail standardization occurred in the 1970s, earlier panels used various mounting methods. For panels without DIN rails (primarily pre-1970 installations), VIOX offers magnetic mount and screw-fix alternatives using the same aerosol technology. A site survey determines the optimal mounting method. In practice, 99% of control panels requiring retrofit have standard DIN rails.

Q: Will installing fire suppression in an old panel void remaining equipment warranties?

A: DIN Rail Mount Extinguishers install non-invasively without modifying panel components or wiring, preserving manufacturer warranties. Unlike gas suppression retrofits requiring pressure relief modifications or sprinkler systems involving structural alterations, DIN rail units simply occupy an available mounting position. Document installation with photos showing no panel modifications for warranty protection.

Q: How do I determine if my aging panel’s DIN rail can support additional devices?

A: Standard 35mm DIN rails are rated for 50N (11.2 lbs) force per mounting point. The VIOX QRR0.01G/S weighs <100g, well within capacity even on aging rails. However, visually inspect rails for corrosion, physical damage, or looseness before installation. If rails show degradation, replacement rail sections cost $2-10 per meter and install without electrical shutdown—still far cheaper than alternative retrofit methods.

Q: Can multiple DIN Rail Mount Extinguishers protect larger panels or electrical rooms?

A: Yes. Each 10g unit protects ≤0.4m³. For larger panels (0.6-1.2m³), install multiple units with overlapping coverage zones. For electrical rooms exceeding 3m³, VIOX offers indirect aerosol systems with distributed nozzles connected to larger generators. The modular nature of DIN rail units enables scalable protection matching panel size evolution—a critical advantage when panels expand over time.

Q: What happens to the aerosol residue after discharge, and how does cleanup work in an old panel?

A: Modern aerosol formulations produce micron-sized, non-corrosive particles. After discharge, visible residue settles within 20 minutes. Cleanup involves compressed air or vacuum—no liquid cleaning that could damage aging components. The aerosol is electrically non-conductive and won’t cause shorts in equipment with existing insulation deterioration. For panels with sensitive electronics, post-discharge inspection verifies no operational impact before re-energization.

Q: Do local fire codes require permits or inspections when retrofitting fire suppression to existing panels?

A: Requirements vary by jurisdiction. Generally, non-invasive retrofits (like DIN rail units that don’t modify panel structure) don’t trigger permit requirements. However, always verify with your local AHJ (Authority Having Jurisdiction). The NFPA 2010 certification of VIOX units often satisfies code requirements without additional engineering documentation. Many jurisdictions view DIN rail retrofits as equivalent to adding circuit breakers—permitted work that doesn’t require inspection.

Making the Retrofit Decision

Aging control panels represent accumulated operational wisdom—they work, operators understand them, and replacement seems financially unjustifiable. But this logic overlooks the compounding fire risks that decades of service create. Electrical insulation degrades. Connections loosen. Dust accumulates. Component obsolescence forces jury-rigged repairs. Each factor elevates ignition probability.

Traditional fire protection retrofit methods—gas suppression systems, sprinkler modifications, complete panel replacements—impose costs and complexity that perpetuate the “do nothing” status quo. Organizations recognize the risk but defer action because implementation seems overwhelming.

DIN Rail Mount Extinguishers fundamentally change this calculation. By leveraging existing infrastructure, eliminating electrical shutdown requirements, and reducing costs by 90-95% versus traditional retrofits, they remove the barriers that prevent action.

The decision becomes straightforward: invest $350-600 per panel to deploy automatic fire suppression that protects 24/7 for a decade without maintenance, or continue operating unprotected equipment knowing that a single electrical fire will cost orders of magnitude more than comprehensive protection.

For facility managers and maintenance engineers responsible for aging electrical infrastructure, the question isn’t whether to retrofit fire protection—it’s why you haven’t already. The technology exists. The economics overwhelmingly favor action. The installation requires minimal effort. Every day of delay compounds the risk.

Implementation Pathway:

- Conduct Facility Survey: Inventory control panels by age, criticality, and current protection status

- Prioritize Retrofit Sequence: Address highest-risk equipment first (aged panels protecting critical processes)

- Calculate Coverage Requirements: Measure panel interior volumes to determine unit quantities needed

- Request Specifications: Contact VIOX Electric for technical documentation and retrofit guidance

- Schedule Installation: Plan retrofits during routine maintenance windows to minimize operational impact

- Document Compliance: Photograph installations, update fire protection plans, notify insurance carriers

The VIOX QRR0.01G/S represents the intersection of fire suppression technology and practical retrofit engineering—purpose-built to solve the specific challenge of protecting legacy electrical infrastructure without the cost, complexity, and disruption of traditional methods.