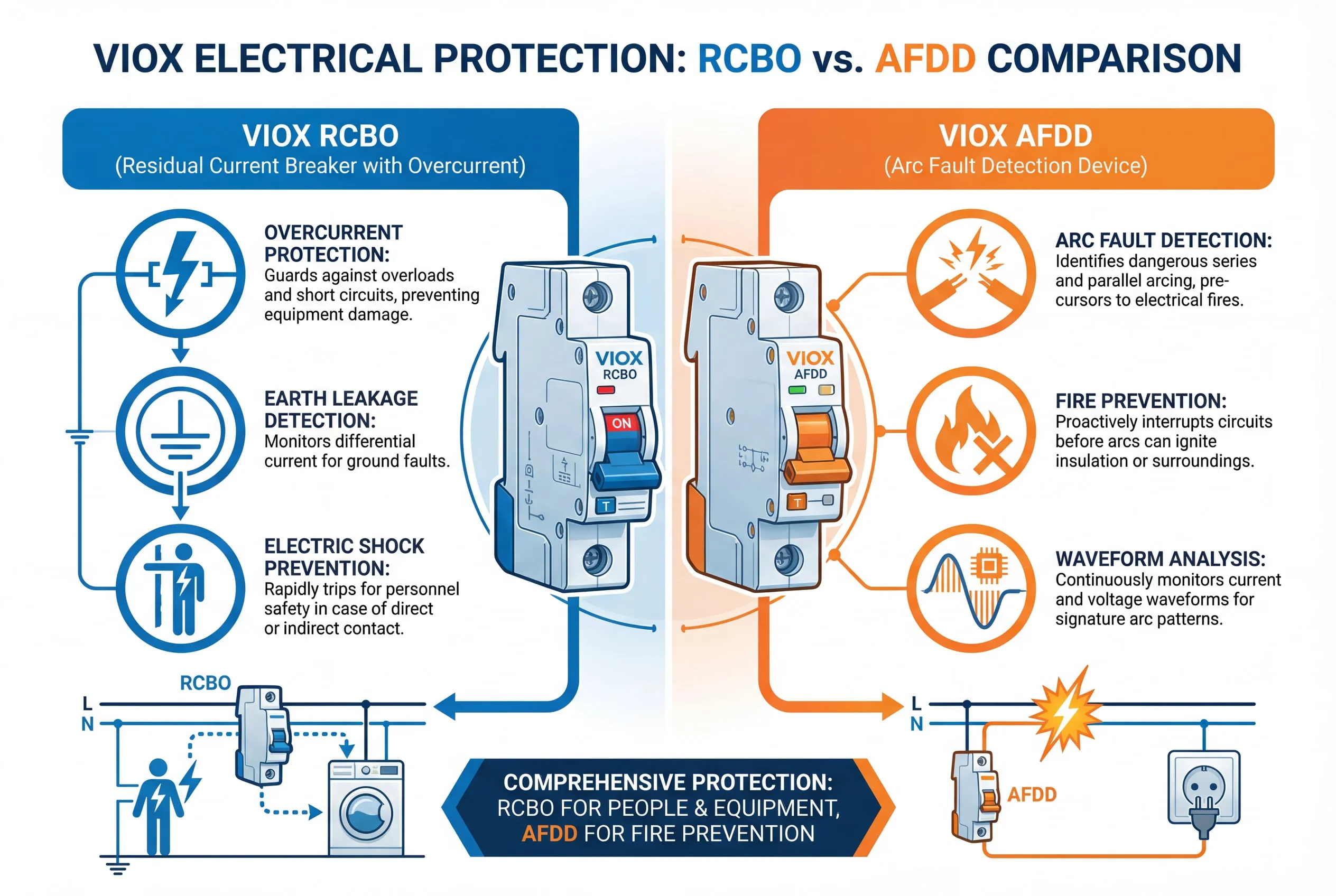

In modern electrical installations, safety is paramount. As electrical systems become increasingly complex and the demand for power grows, protecting against electrical hazards has never been more critical. Two essential devices—Residual Current Circuit Breakers with Overcurrent Protection (RCBO) and Arc Fault Detection Devices (AFDD)—play distinct yet complementary roles in safeguarding lives and property. For B2B electrical equipment professionals, understanding the difference between these devices is crucial for designing safe, compliant, and reliable electrical installations.

This comprehensive guide explores the fundamental differences between RCBO and AFDD, their specific applications, and how they work together to provide comprehensive electrical protection in residential, commercial, and industrial settings.

What is an RCBO (Residual Current Circuit Breaker with Overcurrent Protection)?

Definition and Core Function

An RCBO is a sophisticated electrical protection device that combines two critical safety functions in one compact unit. It merges the capabilities of a Miniature Circuit Breaker (MCB) and a Residual Current Device (RCD), delivering both overcurrent protection and earth leakage detection. This dual-protection mechanism makes RCBOs essential for modern electrical installations where space efficiency and comprehensive safety are priorities.

The primary function of an RCBO is to protect electrical circuits from three main hazards:

- Overload conditions: When the current exceeds the circuit’s rated capacity

- Short circuits: When live and neutral conductors come into direct contact

- Earth leakage currents: When current leaks to earth through damaged insulation or faulty equipment

How RCBOs Work

RCBOs operate using two distinct protection mechanisms working in parallel:

Overcurrent Protection: The MCB component uses thermal and magnetic trip mechanisms to detect and interrupt excessive current flow. The thermal element responds to sustained overload conditions, while the magnetic element provides instantaneous protection against short circuits.

Residual Current Detection: The RCD component continuously monitors the current balance between live and neutral conductors. Under normal conditions, these currents should be equal. When a fault occurs—such as current leaking through damaged insulation or a person touching a live conductor—the RCBO detects this imbalance and disconnects the circuit within milliseconds, typically 30mA or less for personal protection.

RCBO Types and Classifications

RCBOs are classified into several types based on their sensitivity to different waveforms:

- Type AC: Detects AC residual currents only

- Type A: Detects both AC and pulsating DC residual currents (essential for modern electronics)

- Type B: Detects AC, pulsating DC, and smooth DC residual currents (critical for EV charging and solar installations)

- Type F: Enhanced protection for applications with high-frequency disturbances

What is an AFDD (Arc Fault Detection Device)?

Definition and Core Function

An Arc Fault Detection Device (AFDD) is a specialized electrical safety device designed to detect and mitigate dangerous electrical arcs that can cause fires. Unlike traditional circuit breakers that respond to overcurrent or earth leakage, AFDDs use advanced microprocessor technology to identify the unique electrical signatures of hazardous arc faults before they can ignite surrounding materials.

Arc faults occur when electrical current jumps across gaps in damaged conductors, creating intense localized heat that can exceed 6,000°C—hot enough to ignite insulation, wood, and other flammable materials. These dangerous arcs can result from:

- Damaged or deteriorating wire insulation

- Loose or corroded connections

- Crushed or pierced cables

- Rodent damage to wiring

- DIY accidents (such as drilling through cables)

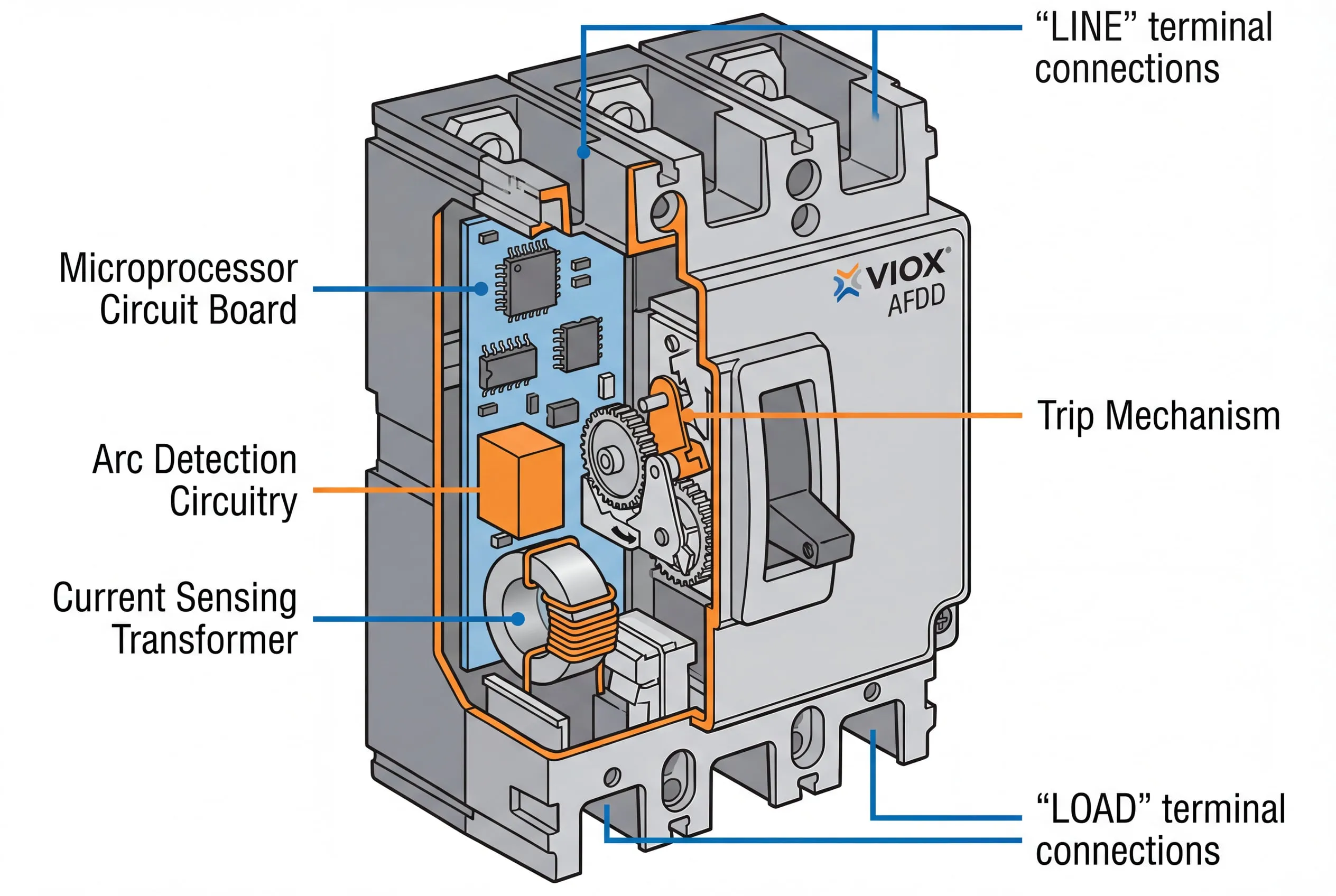

How AFDDs Work

AFDDs employ sophisticated electronic detection systems that continuously analyze electrical waveforms on protected circuits. The microprocessor technology distinguishes between:

Normal Arcing: Harmless arcs produced during routine switching operations, such as those from light switches, motor brushes, or appliance connections.

Dangerous Arcing: Hazardous arc patterns characteristic of series arcs (in broken conductors) and parallel arcs (between conductors), which indicate serious fault conditions.

When a dangerous arc fault is detected, the AFDD responds by:

- Analyzing the arc’s electrical signature and duration

- Verifying the arc exceeds safe threshold parameters

- Immediately disconnecting the circuit (typically within 120 milliseconds)

- Preventing the arc from reaching temperatures where fires can start

AFDD Standards and Compliance

AFDDs must comply with international standard IEC 62606, which defines:

- Safety requirements for arc fault detection devices

- Performance characteristics and testing procedures

- Response times and sensitivity thresholds

- Construction methods and operational criteria

Key Differences Between RCBO and AFDD

Understanding the fundamental differences between these devices is essential for proper electrical system design.

Protection Focus Comparison

| Aspect | RCBO | AFDD |

|---|---|---|

| Primary Protection | Overcurrent and earth leakage | Arc fault detection |

| Hazard Type | Electric shock, equipment damage | Electrical fires |

| Detection Method | Current magnitude and imbalance | Waveform analysis |

| Response Time | Milliseconds (30-300ms) | Rapid (typically <120ms) |

| Technology | Electromechanical/Electronic | Microprocessor-based |

Technical Specifications Comparison

| Feature | RCBO | AFDD |

|---|---|---|

| Standards | IEC 61009, IEC 62423 | IEC 62606 |

| Sensitivity | Current imbalance (typically 30mA) | Arc fault signatures |

| Installation | Standard consumer unit | Origin of protected circuit |

| Size | Compact (1-2 modules) | Variable (1-2 modules) |

| Cost | Moderate | Higher |

| False Trip Risk | Low with proper selection | Minimal with modern technology |

Detection Capabilities

RCBO Detection:

- Overload currents exceeding rated capacity

- Short circuit currents (instantaneous high current)

- Earth leakage currents (typically ≥30mA)

- Ground faults

AFDD Detection:

- Series arc faults (broken conductors)

- Parallel arc faults (conductor-to-conductor)

- High-frequency arc signatures

- Sustained dangerous arcing conditions

Applications and Use Cases

When to Use RCBO

RCBOs are essential for electrical installations requiring comprehensive overcurrent and shock protection:

Residential Applications:

- Socket outlet circuits

- Lighting circuits

- Kitchen and bathroom circuits

- Outdoor electrical installations

- Individual circuit protection in consumer units

Commercial Applications:

- Office electrical distribution

- Retail environments

- Small commercial premises

- Data center power distribution

- Healthcare facilities

Industrial Applications:

- Machine control circuits

- Lighting and power distribution

- Workshop socket outlets

- Process control installations

- Temporary power supplies

When to Use AFDD

AFDDs are specifically recommended or required for installations with elevated fire risk:

Mandatory Applications (per BS 7671:2018+A2:2022):

- Higher Risk Residential Buildings (HRRBs) – buildings over 18m tall or 6+ floors

- Houses in Multiple Occupation (HMOs)

- Purpose-built student accommodation

- Care homes and similar premises

Recommended Applications:

- Single-phase AC final circuits supplying socket outlets (≤32A)

- Timber-framed buildings

- Properties with concealed wiring

- Buildings with thatched roofs or combustible construction

- Sleeping accommodation

- Locations with difficult evacuation (e.g., high-rise buildings)

High-Value Applications:

- Museums and galleries

- Historic buildings

- Data centers and server rooms

- Properties with irreplaceable contents

Application Environment Comparison

| Environment | RCBO Required | AFDD Recommended |

|---|---|---|

| Standard residential | Yes | Recommended |

| High-rise residential (≥18m) | Yes | Mandatory |

| Commercial offices | Yes | Recommended |

| Industrial facilities | Yes | Case-by-case |

| Timber-frame construction | Yes | Strongly recommended |

| Thatched properties | Yes | Strongly recommended |

| Care homes/hospitals | Yes | Mandatory |

| Historic buildings | Yes | Strongly recommended |

Benefits of Each Device

RCBO Benefits

- Dual Protection: Combines overcurrent and earth leakage protection in one compact device

- Space Efficiency: Reduces consumer unit size requirements compared to separate MCB and RCD devices

- Selective Protection: Individual circuit protection prevents entire installation shutdown during faults

- Cost-Effective: More economical than installing separate protection devices

- Reduced Downtime: Fault isolation limited to affected circuit only

- Flexibility: Available in multiple types (A, AC, B) for various applications

- Proven Technology: Decades of reliable performance in the field

AFDD Benefits

- Fire Prevention: Detects arc faults that traditional breakers cannot identify

- Early Warning: Identifies deteriorating wiring before catastrophic failure

- Property Protection: Prevents fires that could cause extensive damage

- Life Safety: Protects occupants from fire-related injuries and fatalities

- Insurance Advantages: May reduce premiums for properties with AFDD protection

- Code Compliance: Meets latest electrical safety regulations

- Advanced Technology: Microprocessor-based detection provides sophisticated protection

Combined Protection: RCBO + AFDD

For maximum safety, modern electrical installations increasingly combine RCBO and AFDD protection. Several approaches are available:

Integration Options

Combined RCBO+AFDD Devices: Some manufacturers offer single units integrating both technologies, providing:

- Arc fault detection

- Overcurrent protection

- Earth leakage protection

- Space-saving installation

- Simplified wiring

Separate Device Installation: Using separate RCBO and AFDD devices on the same circuit:

- RCBO for overcurrent and shock protection

- AFDD for arc fault detection

- Modular flexibility

- Easier troubleshooting

Protection Layer Comparison

| Protection Layer | RCBO Only | AFDD Only | Combined RCBO+AFDD |

|---|---|---|---|

| Overload protection | ✓ | ✗ | ✓ |

| Short circuit protection | ✓ | ✗ | ✓ |

| Earth leakage protection | ✓ | ✗ | ✓ |

| Arc fault detection | ✗ | ✓ | ✓ |

| Fire prevention | Partial | ✓ | ✓ |

| Electric shock protection | ✓ | ✗ | ✓ |

| Overall Protection | Good | Limited | Comprehensive |

Selection Criteria for Electrical Professionals

RCBO Selection Factors

- Current Rating: Match to circuit load requirements (6A-63A typical)

- Type Selection: Choose AC, A, or B based on connected equipment

- Sensitivity: Select appropriate residual current threshold (30mA for personal protection)

- Breaking Capacity: Ensure adequate short circuit rating for installation

- Certification: Verify compliance with IEC 61009 or local standards

AFDD Selection Factors

- Compliance Requirements: Check mandatory requirements for building type

- Circuit Type: AFDDs typically protect socket outlet circuits ≤32A

- Integration: Decide between standalone or combined RCBO+AFDD devices

- Cost-Benefit: Evaluate fire risk against device cost

- Certification: Ensure compliance with IEC 62606

Standards and Regulatory Compliance

International Standards

| Device | Primary Standard | Additional Standards |

|---|---|---|

| RCBO | IEC 61009-1 | IEC 62423, BS EN 61009 |

| AFDD | IEC 62606 | BS EN 62606 |

| Combined Devices | IEC 61009-1 + IEC 62606 | Local regulations |

Regional Requirements

UK/Europe: BS 7671:2018+A2:2022 (18th Edition Wiring Regulations)

- RCBOs recommended for individual circuit protection

- AFDDs mandatory for HRRBs and HMOs

- AFDDs recommended for all socket outlet circuits

International: IEC 60364-4-42

- Recommends AFDDs for fire risk mitigation

- Specifies installation at circuit origin

- Defines application environments

Frequently Asked Questions (FAQ)

1. Can an RCBO detect arc faults?

No, standard RCBOs cannot detect arc faults. RCBOs are designed to protect against overcurrent conditions (overloads and short circuits) and earth leakage currents, but they lack the microprocessor technology needed to identify the specific electrical signatures of dangerous arc faults. For arc fault protection, you need a dedicated AFDD or a combined RCBO+AFDD device.

2. Do I need both RCBO and AFDD on the same circuit?

It depends on your specific installation requirements. For comprehensive protection, the ideal solution is either:

- Separate RCBO and AFDD devices installed together, or

- A combined RCBO+AFDD unit that integrates both functions

This combination provides complete protection against overcurrent, electric shock, and fire caused by arc faults. For high-risk residential buildings and HMOs, this combined protection is now mandatory in many jurisdictions.

3. Are AFDDs prone to nuisance tripping?

Modern AFDDs with advanced microprocessor technology are designed to distinguish between normal operational arcing (from switches, motor brushes, etc.) and dangerous arc faults. While early AFDD designs had some false tripping issues, current-generation devices from reputable manufacturers like VIOX Electric have significantly reduced nuisance tripping through sophisticated waveform analysis algorithms. Proper installation and device selection minimize false trips.

4. What is the typical cost difference between RCBO and AFDD?

AFDDs are typically 3-5 times more expensive than standard RCBOs due to their advanced microprocessor technology and sophisticated detection algorithms. However, costs have been decreasing as adoption increases. A typical RCBO costs £15-40, while an AFDD costs £80-150, and combined RCBO+AFDD devices range from £100-180. Despite higher initial costs, the fire prevention benefits and potential insurance savings often justify the investment.

5. Can I install AFDDs in existing electrical installations?

Yes, AFDDs can be retrofitted into existing installations during consumer unit upgrades or circuit modifications. However, considerations include:

- Available space in the consumer unit (AFDDs typically require 1-2 module widths)

- Compatibility with existing protective devices

- Circuit type suitability (typically for socket outlet circuits ≤32A)

- Cost-benefit analysis based on fire risk assessment

Consult a qualified electrician to evaluate your specific installation requirements.

6. How do I test RCBOs and AFDDs?

RCBO Testing:

- Press the integral test button monthly to verify mechanical operation

- The device should trip immediately when tested

- Professional testing should verify tripping times and sensitivity levels

- Annual inspection recommended for critical installations

AFDD Testing:

- Use the integral test button to verify device operation

- Professional testing requires specialized arc fault testing equipment

- Testing should confirm detection of both series and parallel arc faults

- Follow manufacturer recommendations for testing frequency

Never rely solely on test buttons—professional inspection and testing are essential for ensuring continued protection.

Conclusion

Understanding the difference between RCBO and AFDD is crucial for electrical professionals designing safe, compliant installations. While RCBOs provide essential protection against overcurrent and electric shock hazards, AFDDs offer specialized fire prevention through advanced arc fault detection. These devices serve complementary rather than competing functions.

For optimal electrical safety, modern installations increasingly adopt combined protection strategies, utilizing both RCBO and AFDD technologies. As regulations evolve and building safety standards become more stringent, this comprehensive approach to electrical protection will become standard practice.

VIOX Electric remains committed to manufacturing high-quality electrical protection devices that meet international standards and exceed industry expectations. Our range of RCBOs, AFDDs, and combined protection devices provides electrical professionals with reliable solutions for any installation requirement.

For technical specifications, product selection guidance, or application support, contact VIOX Electric’s technical team. We’re here to help you design safer electrical installations.