Introduction

Choosing the right MCB (Miniature Circuit Breaker) supplier can make or break your project’s safety, budget, and timeline. A single misjudgment—overlooking a critical certification, accepting substandard breaking capacity, or partnering with an unreliable manufacturer—can lead to equipment failures, costly downtime, and even safety hazards that put personnel at risk.

For B2B buyers, electrical wholesalers, and distributors, the stakes are higher than ever. With hundreds of MCB manufacturers claiming compliance with international standards, how do you separate genuine quality from clever marketing? The answer lies in a systematic evaluation process that goes beyond price and delivery promises.

This comprehensive buying checklist covers 10 essential factors every professional should verify before committing to an MCB supplier. Whether you’re sourcing circuit breakers for industrial machinery, commercial installations, or wholesale distribution, these criteria will help you make confident, informed decisions that protect your business and your customers.

Factor 1: Breaking Capacity (Icn/Ics Ratings)

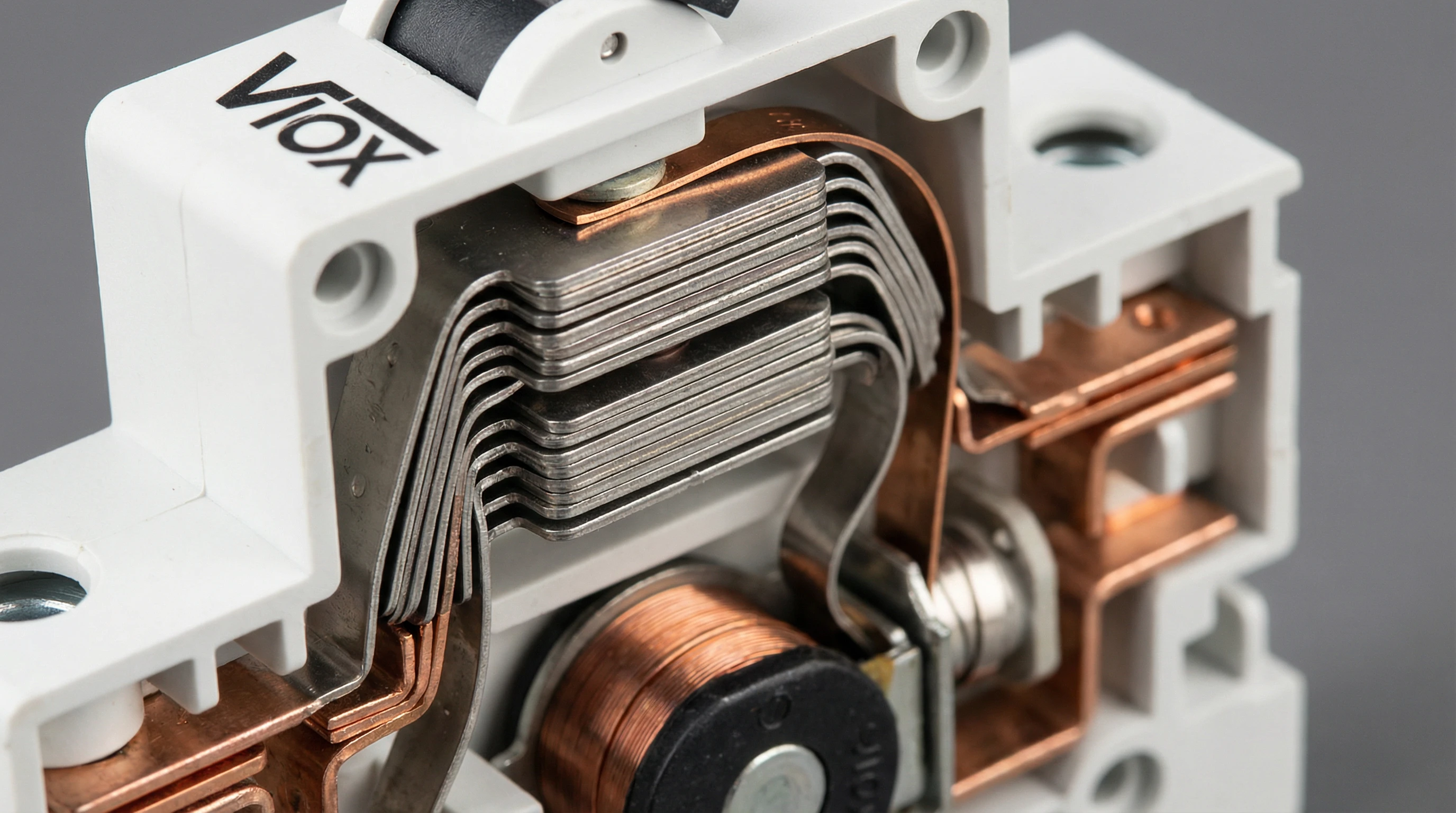

The breaking capacity represents the maximum short-circuit current an MCB can safely interrupt without catastrophic failure. This specification is non-negotiable for safety—an undersized breaking capacity can result in arc flash incidents, fire hazards, and equipment destruction.

Understanding the Ratings:

- Icn (Rated Short-Circuit Capacity): Defined by IEC 60898-1, this is the maximum fault current the MCB can interrupt. After operating at this level, the breaker may not be reusable.

- Ics (Service Breaking Capacity): Indicates the maximum fault current after which the MCB remains fully operational. Typically expressed as a percentage of Icn (50%, 75%, or 100%).

For industrial applications, prospective short-circuit currents can reach 15-25 kA or higher, especially near supply transformers. Residential and light commercial installations typically require 6-10 kA ratings.

What to Verify: Always ensure the MCB’s breaking capacity equals or exceeds the calculated Prospective Short Circuit Current (PSCC) at the installation point. For critical applications—hospitals, data centers, industrial processes—specify MCBs with Ics ratings of 75% or higher to ensure continued service after fault interruption.

Viox Electric manufactures MCBs with breaking capacities ranging from 6 kA to 25 kA, with Ics ratings up to 100% of Icn for maximum reliability in demanding environments.

Factor 2: Standards & Certifications (IEC/UL Compliance)

Certifications are not just bureaucratic checkboxes—they represent rigorous testing protocols that verify an MCB’s safety and performance under real-world fault conditions. For B2B buyers, proper certification verification is your first line of defense against counterfeit or substandard products.

Key Standards to Understand:

IEC 60898-1

The international standard for household and similar installations, widely adopted in Europe, Asia, and most global markets. Covers MCBs with rated voltage up to 440V, current up to 125A, and short-circuit capacity up to 25 kA. Testing includes temperature rise, endurance tests, tripping characteristics verification, and dielectric strength.

UL 489

The North American standard for molded-case circuit breakers, mandatory for installations under the National Electrical Code (NEC). More stringent than IEC standards, UL 489 includes comprehensive calibration tests, interrupting ability verification, and environmental resilience testing. Required for the U.S. and Canadian markets.

IEC 60947-2

Designed specifically for industrial circuit breakers, offering more robust performance requirements than IEC 60898. Essential for demanding industrial environments.

Verification Checklist:

- Request complete type test reports from ISO/IEC 17025 accredited laboratories

- Verify certification marks are physically present on the MCB housing, not just packaging

- Confirm the manufacturer holds ISO 9001 quality management certification

- Check for CE marking (Europe), CCC certification (China market), or region-specific requirements

Viox Electric maintains full IEC 60898-1, IEC 60947-2, and CE certifications across our MCB product lines, with all test reports available for buyer verification. Our manufacturing facilities are ISO 9001:2015 certified, ensuring consistent quality control.

Factor 3: Tripping Characteristics (B, C, D Curves)

Selecting the wrong tripping curve is one of the most common MCB procurement mistakes—it leads to either nuisance tripping that disrupts operations or insufficient protection that fails to prevent equipment damage. The tripping curve defines how quickly an MCB responds to overcurrent conditions.

Curve Types Explained:

Type B Curve (3-5x In): Designed for resistive loads with minimal inrush current. Ideal for residential lighting circuits, socket outlets, and applications with long cable runs where fault currents may be lower. Provides sensitive protection but will trip on moderate starting surges.

Type C Curve (5-10x In): The industrial workhorse. Suitable for circuits with moderate inductive loads—small motors, fans, pumps, fluorescent lighting, and mixed commercial loads. Balances protection with tolerance for normal equipment start-up currents.

Type D Curve (10-20x In): Engineered for high inrush applications. Essential for large motors, transformers, welding equipment, X-ray machines, and heavy industrial machinery. Allows equipment to ride through substantial starting currents while still protecting against genuine short circuits.

Selection Guidelines:

- Analyze load characteristics: resistive, inductive, or high-inrush

- For motor protection, Type C is standard for motors under 5 HP; Type D for larger motors

- Multiple small loads on one circuit typically need Type C

- Sensitive electronics may require specialized curves

Red Flag: A supplier who cannot explain which curve suits your application likely lacks technical depth. Viox Electric provides application-specific curve selection guidance and maintains stock in all standard curve types across our MCB range.

Factor 4: Rated Current & Voltage Specifications

Proper current and voltage ratings form the foundation of effective circuit protection. Mismatched ratings create either under-protection (allowing dangerous overloads) or over-protection (nuisance tripping that halts operations).

Rated Current (In): The maximum continuous current the MCB can carry without tripping. Must be calculated based on:

- Total circuit load (sum of all connected equipment)

- Cable ampacity (current-carrying capacity of wiring)

- Ambient temperature derating factors

- Future load expansion considerations

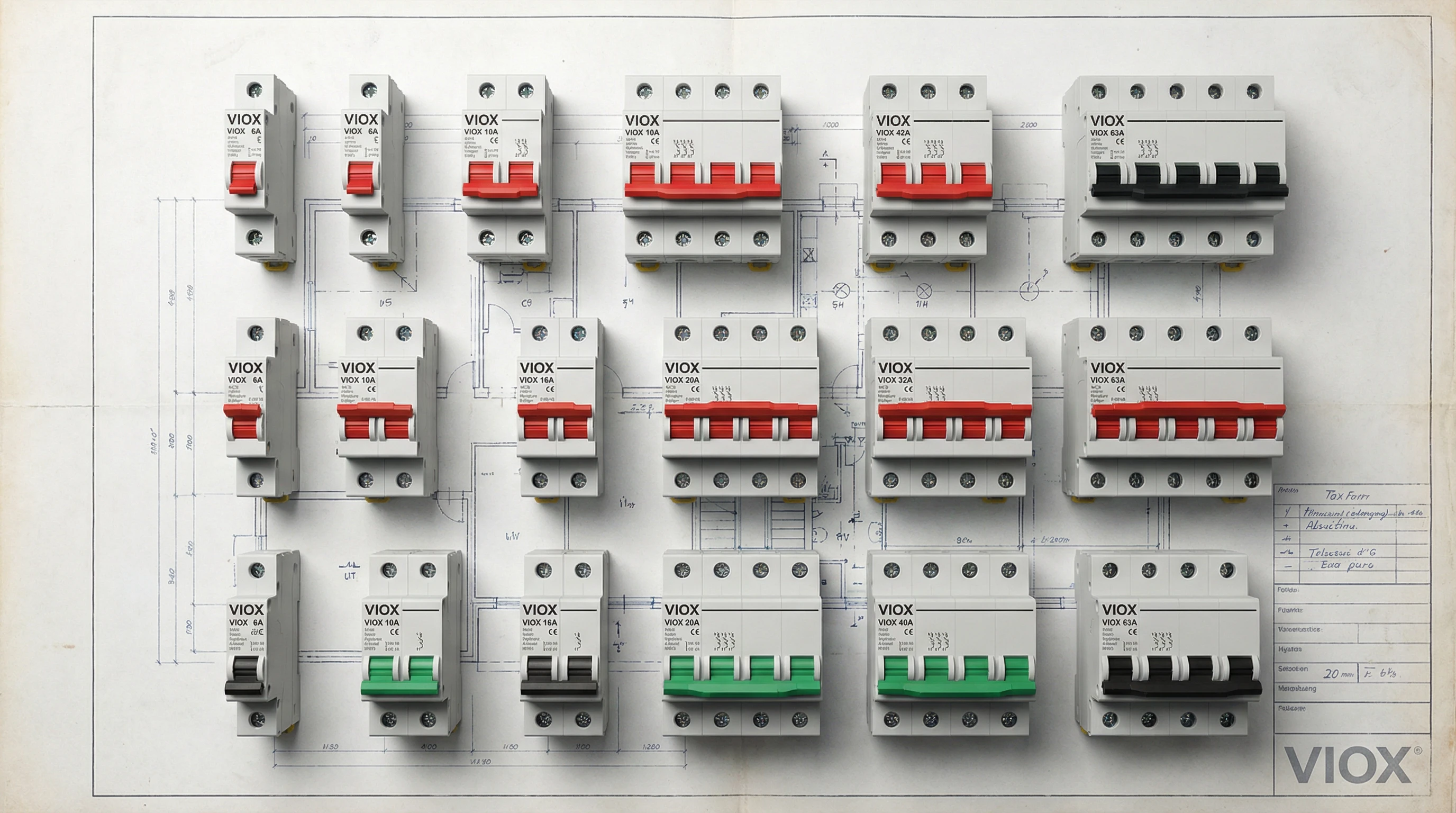

Common industrial MCB current ratings include 6A, 10A, 16A, 20A, 25A, 32A, 40A, 50A, and 63A. The selected rating should exceed normal operating current but remain below cable ampacity.

Rated Voltage (Ue): Must match or exceed your system voltage:

- Single-phase residential: 230V/240V

- Three-phase industrial: 400V/415V (line-to-line)

- North American systems: 120V/208V/240V/480V configurations

Pole Configuration: Match to your power system:

- 1-Pole (1P): Single-phase, phase conductor only

- 2-Pole (2P): Single-phase with neutral protection

- 3-Pole (3P): Three-phase systems (standard for industrial motors)

- 4-Pole (4P): Three-phase with neutral protection

Critical Check: Verify the MCB datasheet specifies voltage at both line-to-line and line-to-neutral values for three-phase applications. Viox Electric MCBs are available in all standard current ratings from 1A to 125A, with voltage ratings up to 440V AC and comprehensive pole configurations.

Factor 5: Quality Control & Testing Procedures

Certifications mean nothing without robust manufacturing quality control. The gap between certified design and actual production quality is where inferior MCBs slip through—leading to premature failures, inconsistent performance, and safety risks.

Essential QC Elements to Verify:

Incoming Material Inspection: Raw materials (copper contacts, silver alloy contacts, arc chutes, bimetallic strips) must meet specifications. Ask about material traceability and supplier qualification processes.

In-Process Testing: During manufacturing, verify:

- Contact resistance measurement on every unit

- Trip curve verification through automated testing

- Dimensional accuracy checks for DIN rail mounting

- Torque testing on terminals

Final Type Testing: Representative samples from each production batch should undergo:

- Temperature rise tests at rated current

- Endurance testing (mechanical and electrical)

- Dielectric strength verification

- Actual short-circuit interruption tests at rated Icn

Batch Tracking & Documentation: Each MCB should have traceable batch codes allowing recall of specific test data. This is critical for warranty claims and failure analysis.

Questions to Ask:

- What percentage of production undergoes automated testing?

- Can you provide batch-specific test reports?

- What is your defect rate per thousand units?

- Do you maintain a dedicated short-circuit testing laboratory?

Viox Electric operates a certified testing laboratory with automated testing on 100% of production units. Our short-circuit test facility can verify breaking capacity up to 25 kA, and we maintain complete batch traceability with test reports available on request.

Factor 6: Manufacturer Experience & Reputation

An MCB manufacturer’s track record speaks louder than any marketing brochure. Experience translates directly into reliable design, proven manufacturing processes, and the engineering depth to handle complex applications.

Experience Indicators:

- Years in MCB Production: Look for at least 10+ years of dedicated MCB manufacturing experience, not just general electrical equipment production

- Production Volume: Established manufacturers typically produce millions of units annually, indicating stable processes and economies of scale

- Export Markets: Manufacturers successfully exporting to Europe, North America, or other regulated markets have demonstrated compliance with stringent international standards

- Customer Portfolio: A mix of distributors, OEMs, and end-users across different industries shows versatility and reliability

Reputation Verification:

- Request reference customers you can contact directly

- Search for the manufacturer’s participation in international trade shows and industry associations

- Look for published technical papers or contributions to standards development

- Check online reviews and industry forums for real-world feedback

- Verify factory audit reports if available (particularly from major buyers)

Red Flags:

- Reluctance to provide customer references

- Inconsistent company history or frequent name changes

- Unable to demonstrate continuous production history

- No visible presence at major industry events

Viox Electric has been manufacturing MCBs since 2008, with annual production capacity exceeding 15 million units. We export to over 60 countries, maintain long-term partnerships with major distributors in Europe, Asia, and Africa, and regularly participate in international exhibitions including Intersolar, Middle East Electricity, and Canton Fair.

Factor 7: Product Range & Customization Options

For distributors and wholesalers, a comprehensive product range from a single manufacturer simplifies logistics, reduces inventory complexity, and ensures consistent quality across your catalog. For OEM buyers, customization capabilities enable product differentiation.

Essential Range Elements:

Current Ratings: Full spectrum from 1A to 125A in standard increments (1A, 2A, 3A, 6A, 10A, 16A, 20A, 25A, 32A, 40A, 50A, 63A, 80A, 100A, 125A)

Tripping Curves: Availability of B, C, and D curves across all major current ratings

Pole Configurations: Complete offering of 1P, 2P, 3P, and 4P versions

Breaking Capacities: Multiple options (6kA, 10kA, 15kA, 20kA, 25kA) to match different installation requirements

Accessory Compatibility: Availability of matching auxiliary contacts, shunt trips, under-voltage releases, and DIN rail accessories

Customization Capabilities:

- Custom branding and logo placement for OEM clients

- Modified terminal configurations

- Special packaging for private label programs

- Custom current ratings for specific applications (within design limits)

- Color coding or labeling systems for specific markets

MOQ & Flexibility: Understand minimum order quantities for:

- Standard products (usually lower MOQ)

- Custom branded products

- Non-standard specifications

Viox Electric maintains one of the industry’s most comprehensive MCB portfolios, with over 500 SKUs covering all standard ratings and configurations. We offer OEM customization with MOQs as low as 1,000 pieces for branded products and provide flexible mixed-container loading for distributors.

Factor 8: Supply Chain Reliability & Lead Times

Even the highest-quality MCBs are worthless if they can’t reach your customers on time. Supply chain reliability directly impacts your ability to fulfill orders, maintain inventory levels, and respond to market demands.

Critical Supply Chain Elements:

Production Capacity & Stability:

- Monthly production capacity (can they handle your volume plus growth?)

- Multiple production lines (reduces single-point-of-failure risk)

- Buffer inventory for fast-moving SKUs

- Ability to scale up for seasonal demand or large projects

Lead Time Transparency:

- Standard lead times for stock items (should be 2-4 weeks for established products)

- Custom order lead times (typically 4-8 weeks depending on customization)

- Communication protocols when delays occur

- Historical on-time delivery performance (request metrics)

Logistics Capabilities:

- Experience with international shipping and documentation

- Established relationships with freight forwarders

- Flexible shipping terms (FOB, CIF, DDU, DDP)

- Proper packaging to prevent shipping damage

- Ability to consolidate with other product lines if manufacturer offers multiple products

Inventory Management Support:

- VMI (Vendor Managed Inventory) programs for large distributors

- Consignment stock options

- Drop-shipping capabilities for e-commerce operations

Questions to Ask:

- What is your average lead time for a 20-foot container of standard MCBs?

- What was your on-time delivery rate last year?

- How do you communicate production delays?

- Can you handle urgent/expedited orders? At what cost premium?

Viox Electric maintains safety stock of top 200 SKUs, enabling 15-day lead times for standard orders. Our on-time delivery rate exceeds 95%, and we provide weekly production updates for all active orders. We work with established logistics partners and offer flexible shipping terms to accommodate various buyer requirements.

Factor 9: Technical Support & Documentation

Technical support isn’t just a nice-to-have—it’s essential for specification assistance, application troubleshooting, and resolving field issues that can damage your customer relationships.

Essential Documentation:

Product Datasheets: Must include complete technical specifications—rated current, voltage, breaking capacity, tripping curves, terminal torque, operating temperature range, mounting dimensions, and compliance standards. Vague or incomplete datasheets indicate either poor engineering or intentional obscuration.

Certificates & Test Reports:

- Type test reports from accredited laboratories

- Batch-specific test certificates

- CE Declaration of Conformity

- ISO 9001 certificate

- Material compliance certificates (RoHS, REACH)

Installation & Wiring Guides: Clear diagrams showing proper DIN rail mounting, terminal connections, and busbar integration.

Selection Tools: Technical guides or online calculators to help specify the correct MCB for different applications.

Technical Support Quality:

Pre-Sales Engineering: Can the manufacturer’s team help you:

- Select appropriate MCB specifications for your application?

- Provide load calculations and circuit protection coordination?

- Explain technical differences between product variants?

- Offer customization feasibility assessments?

After-Sales Support:

- Accessible technical support team (not just sales)

- Reasonable response times (24-48 hours for technical queries)

- English-language support capability (critical for international buyers)

- Willingness to conduct factory audits and facility tours

- Field failure analysis and root cause investigation

Training & Resources:

- Product training for distributor sales teams

- Technical webinars or workshops

- Updated online resources and product catalogs

Viox Electric provides comprehensive technical documentation in English for all products, with complete type test reports available on request. Our technical support team responds to inquiries within 24 hours and can provide application engineering assistance for complex projects. We regularly conduct distributor training programs and maintain an updated online technical resource center.

Factor 10: Warranty Terms & After-Sales Service

A manufacturer’s warranty terms reveal their confidence in product quality. Strong warranties backed by responsive service protect your investment and your reputation.

Warranty Essentials:

Standard Warranty Period: Industrial MCBs should carry minimum 2-year warranty from date of manufacture, with leading manufacturers offering 3-5 years. Be wary of warranties shorter than 18 months—they often signal quality concerns.

Warranty Coverage: Understand what’s covered:

- Manufacturing defects and material failures (should be fully covered)

- Premature wear under normal operating conditions

- Exclusions: misapplication, improper installation, operation beyond ratings, environmental damage

Warranty Claims Process:

- Simple, documented claim procedure

- Reasonable response timeframes (investigation within 2 weeks, resolution within 4-6 weeks)

- Clear replacement or credit policies

- Low bureaucratic burden (avoid manufacturers requiring extensive documentation that delays legitimate claims)

After-Sales Service Quality:

Responsiveness: How quickly does the manufacturer respond to quality complaints? Do they take ownership or deflect responsibility?

Failure Analysis: Will they conduct root cause analysis for failures? Do they share findings to prevent recurrence?

Spare Parts Availability: For customized or large-volume deployments, can the manufacturer maintain spare parts availability beyond the standard product lifecycle?

Batch Replacement: If a systemic defect is discovered, will the manufacturer proactively replace entire batches, or fight claims one by one?

Questions to Ask:

- What is your standard warranty period?

- What was your warranty claim rate last year?

- Can you share examples of how you’ve handled quality issues?

- Do you maintain spare parts inventory for discontinued models?

Viox Electric provides a standard 3-year warranty on all MCB products, covering manufacturing defects and premature failures under normal operating conditions. Our warranty claim rate is consistently below 0.3%, and we maintain a streamlined claims process with dedicated after-sales support. We stand behind our quality with proactive communication and rapid resolution when issues arise.

Conclusion: Make Confident MCB Procurement Decisions

Choosing the right MCB manufacturer is too important to leave to chance. The 10 factors outlined in this checklist provide a systematic framework for evaluating suppliers and ensuring you select circuit breakers that meet your safety, quality, and business requirements.

To recap the essentials:

- Verify breaking capacity meets or exceeds your installation’s PSCC

- Confirm proper IEC/UL certifications with documentation

- Select appropriate tripping curves for your load types

- Match current and voltage ratings to your specific applications

- Assess manufacturing quality control and testing procedures

- Evaluate manufacturer experience and market reputation

- Ensure comprehensive product range and customization options

- Confirm supply chain reliability and realistic lead times

- Verify technical support capabilities and complete documentation

- Review warranty terms and after-sales service commitment

Viox Electric meets and exceeds all 10 criteria in this checklist. With over 15 years of MCB manufacturing expertise, full international certifications, comprehensive product range, and unwavering commitment to quality, we’ve earned the trust of distributors and electrical professionals in over 60 countries.

Ready to Source Reliable MCBs for Your Projects?

Whether you’re a distributor seeking a dependable manufacturing partner, a wholesaler expanding your product catalog, or an electrical contractor specifying equipment for major installations, Viox Electric is ready to support your success.

Contact us today for:

- Bulk order quotes and competitive pricing

- Technical specification assistance

- Product samples for evaluation

- Custom branding and OEM solutions

- Factory audit arrangements

Viox Electric Company

Email: [email protected]

Phone: +86-18066396588

Website: www.viox.com

Secure your reliable MCB supply chain partner today and protect your projects with quality circuit protection you can trust.